Rolling control device and rolling control method

A technology of control device and control method, applied in contour control, temperature control, length measuring device, etc., can solve problems such as poor shape, and achieve the effect of improving quality and shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

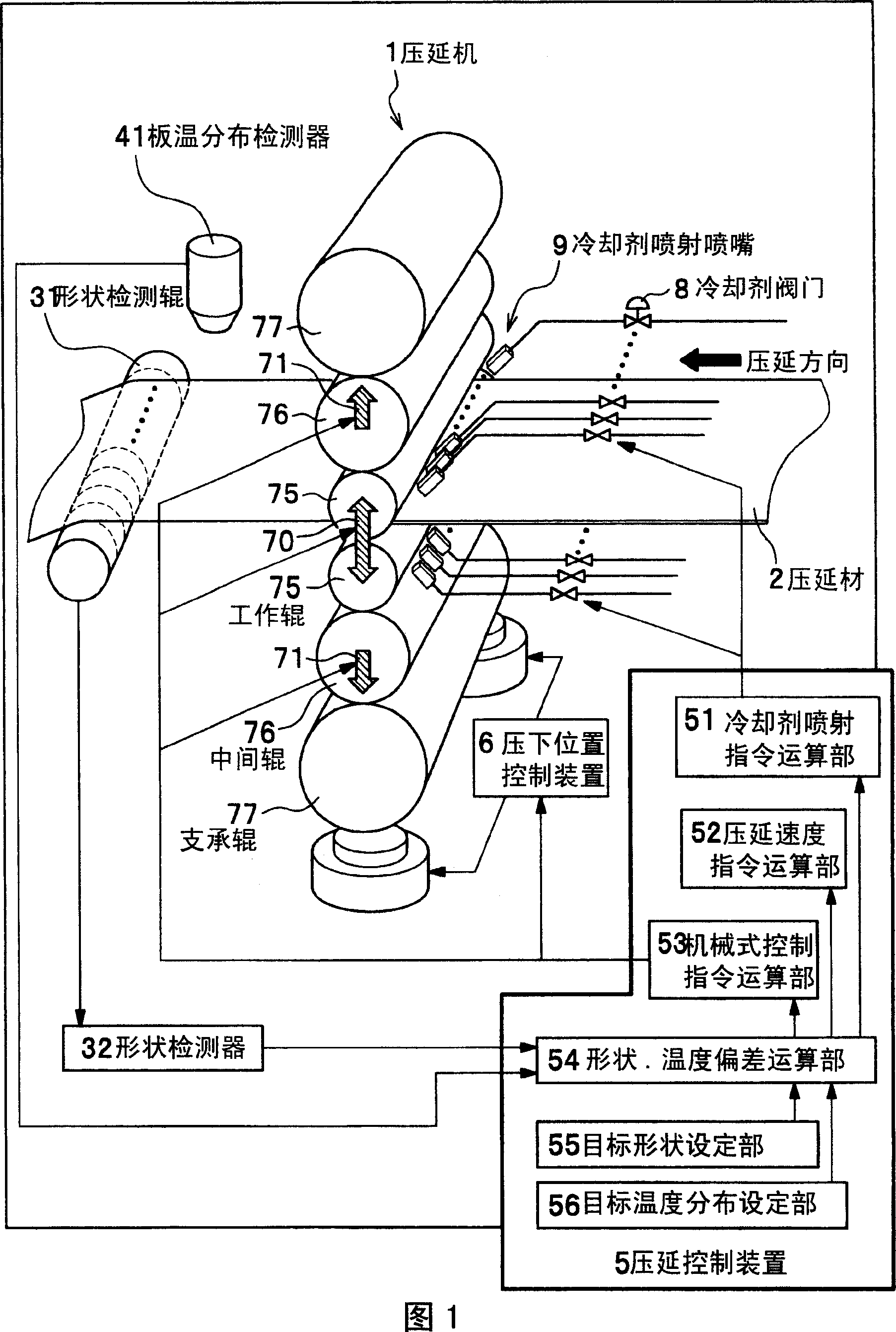

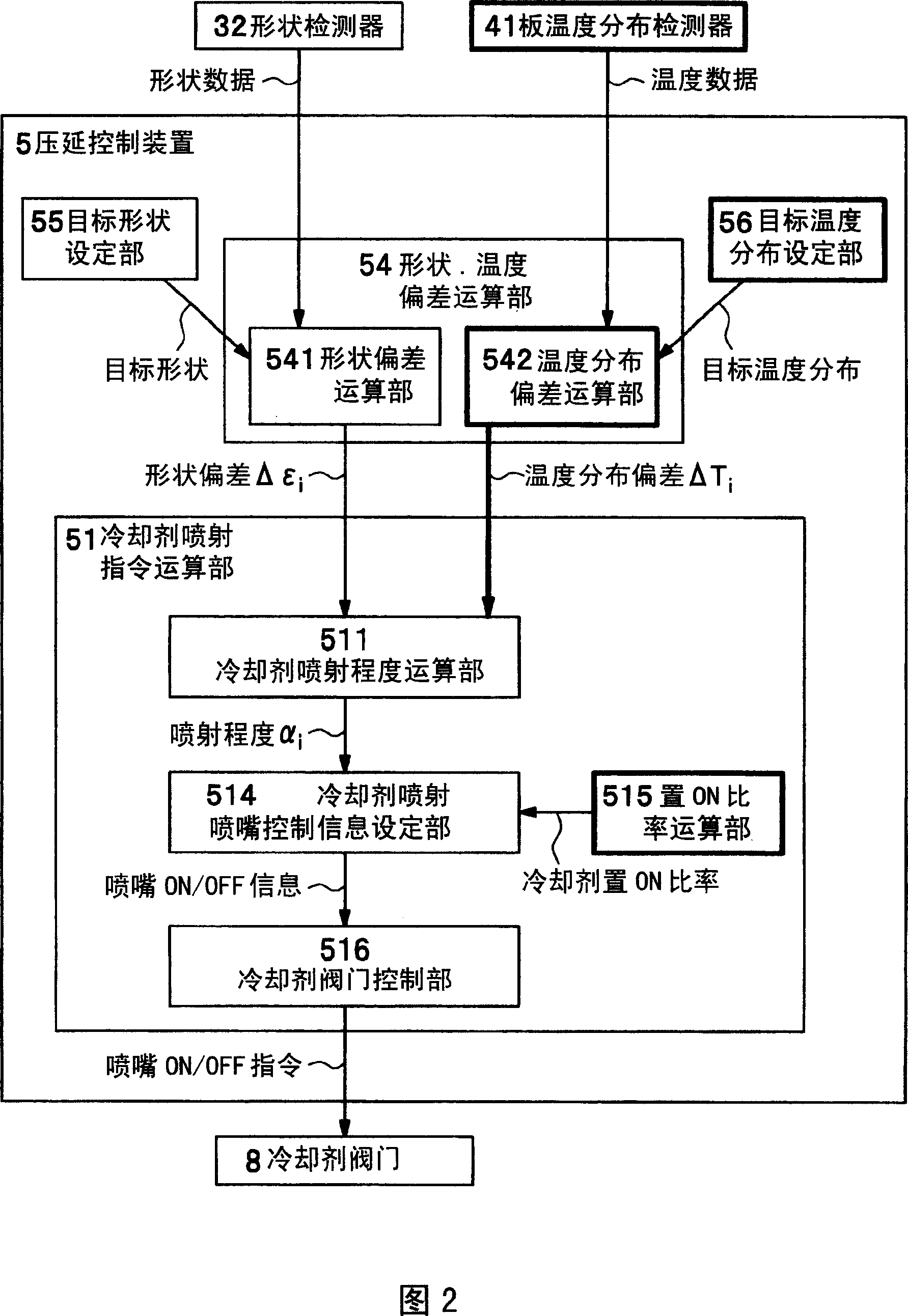

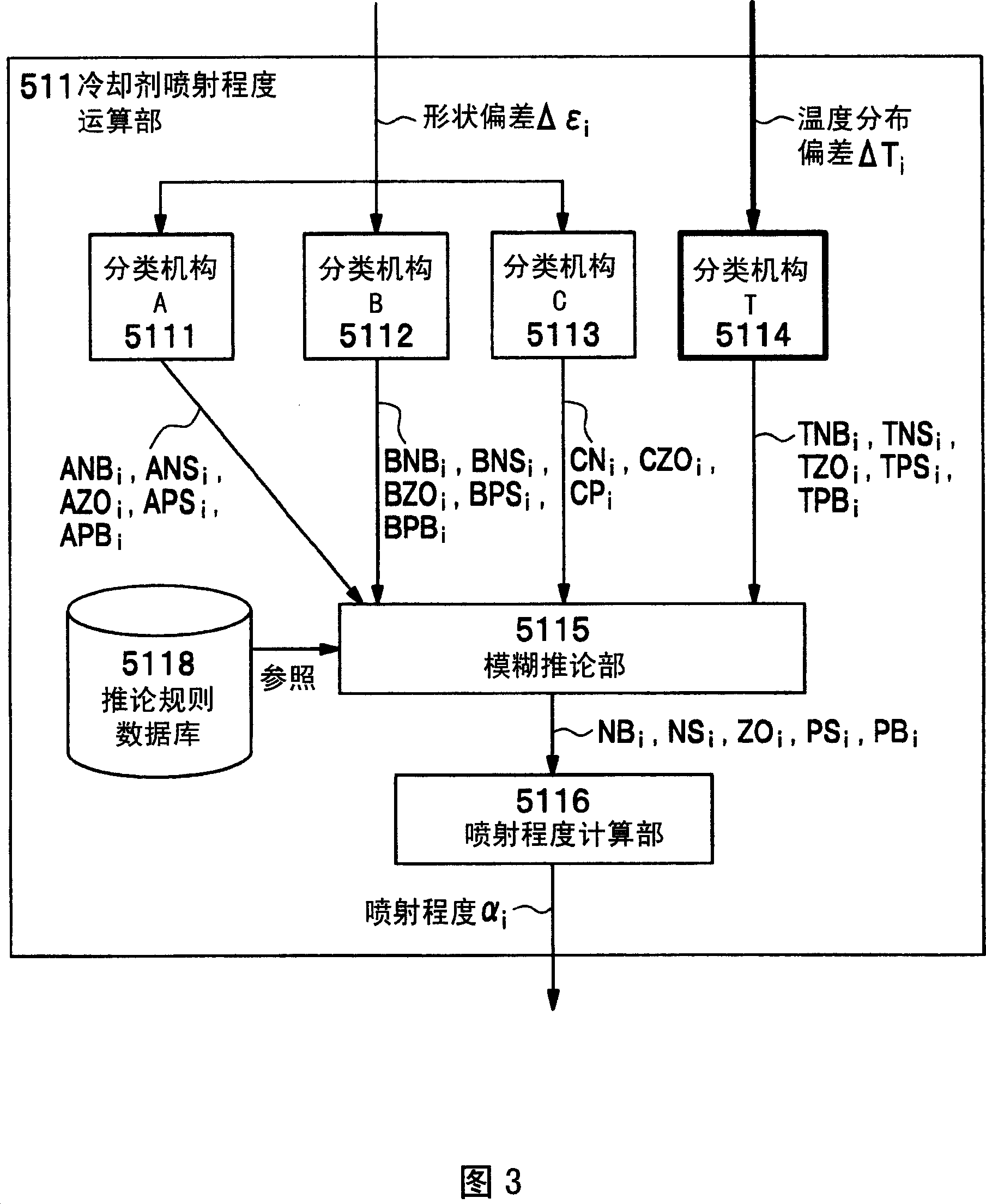

[0028] Hereinafter, a first embodiment of the present invention will be described in appropriate detail with reference to FIGS. 1 to 5 . Fig. 1 shows a schematic configuration example of a rolling machine to which the rolling control device of the present invention is applied. As shown in FIG. 1 , the calender rolls of the calender 1 are 6-stage calender rolls composed of work rolls 75 , intermediate rolls 76 and backup rolls 77 .

[0029] On the inlet side of the calender 1, a plurality of coolant injection nozzles 9 for injecting coolant to the work rolls 75 and the rolled material 2 are provided along the work rolls 75 in the sheet width direction. These coolant injection nozzles 9 have a structure that can individually control ON / OFF of coolant injection by controlling the opening and closing of the coolant valve 8 , or control the injection amount of the injected coolant.

[0030]In addition, on the exit side of the calender 1, a shape detecting roll 31 and a shape detec...

no. 2 Embodiment approach

[0087]Next, a second embodiment of the present invention will be described with reference to FIGS. 6 to 9 . Fig. 6 is a schematic diagram showing a configuration example of functional blocks of a rolling control device in a second embodiment.

[0088] As shown in FIG. 6, the rolling control device 5a in the second embodiment is constituted by a computer equipped with a CPU and a memory on the hardware side, and has a target shape setting unit 55 and a target temperature division setting unit 56 in terms of functions. , the shape and temperature deviation calculation unit 54, the coolant injection command calculation unit 51a and other functional blocks constituted. The only difference from the first embodiment is the coolant injection command calculation unit 51a. Moreover, the structure (refer FIG. 1) of the rolling machine 1 using the rolling control apparatus 5a is also the same as that of 1st Embodiment. Hereinafter, the same components as those in the first embodiment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com