Rolling method for overcoming compound wave shape

A composite wave and plate shape technology, applied in contour control and other directions, can solve problems such as long response time and slow heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

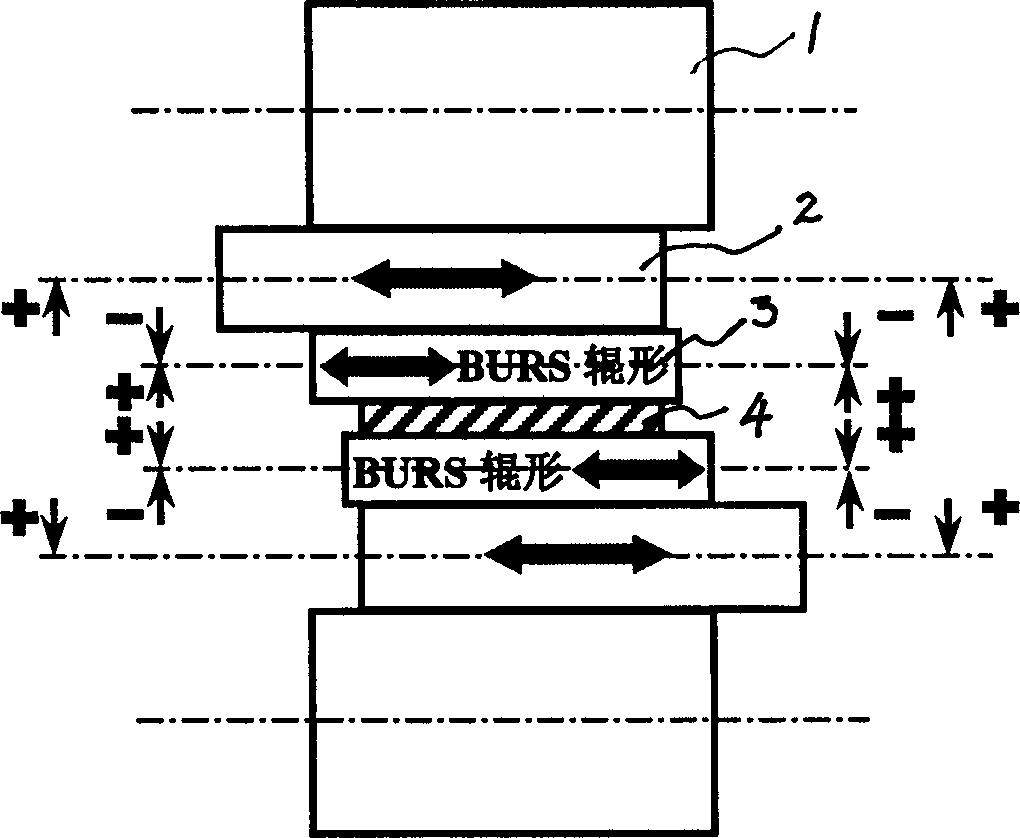

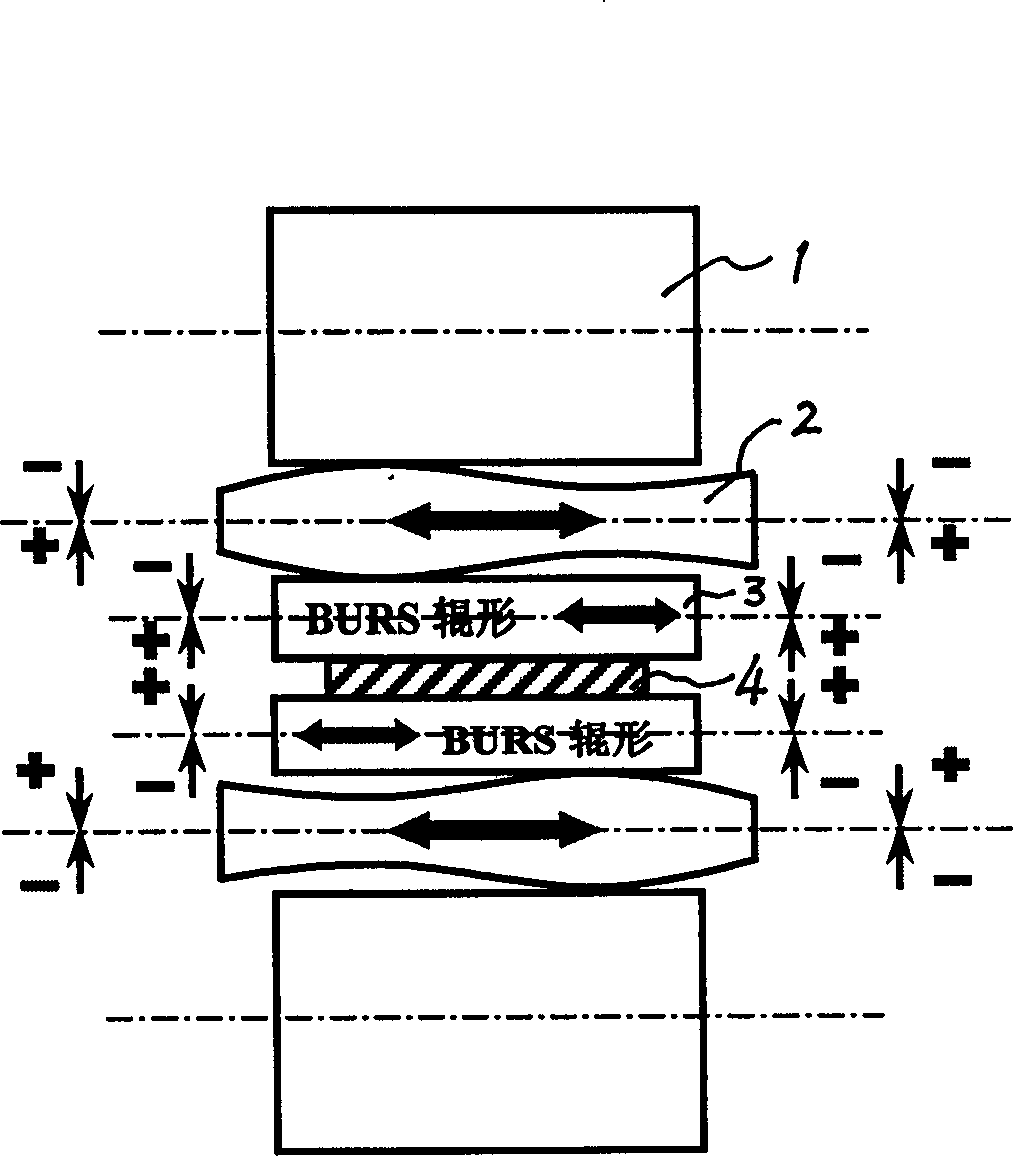

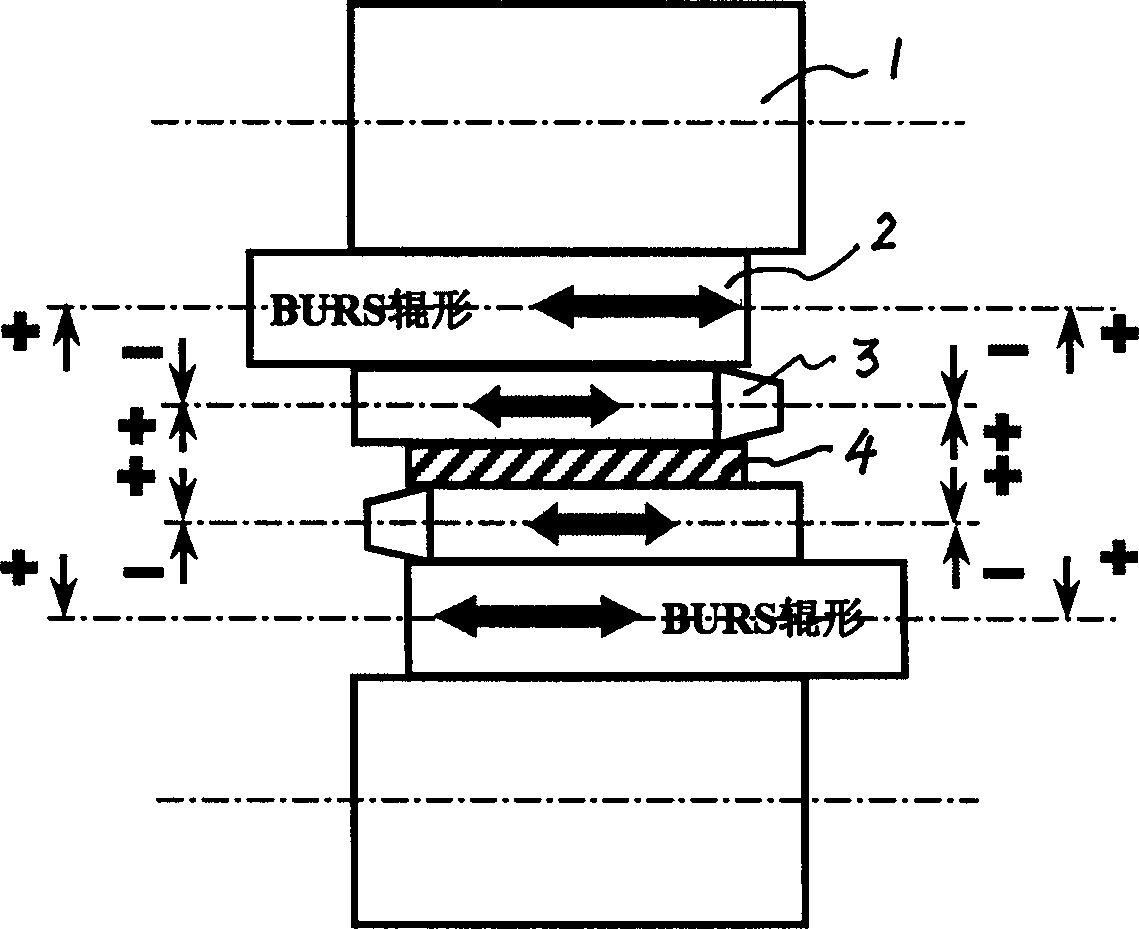

[0120] Assume that for a 4-high rolling mill, the diameter of the work roll is 500mm, the length of the roll surface is 2000mm, and the width of the strip steel is 1800mm-1000mm, high-order defects are prone to occur at the symmetrical 1 / 4 position on both sides, see Figure 5 :

[0121] For this purpose, the design roll gap is as follows:

[0122] Secondary convexity of the whole roll surface: 200μm;

[0123] High order convexity: 30μm;

[0124] Determine the roll shape according to the shape of the roll gap as follows:

[0125] y=c 0 +c 1 ·x+c 2 x 2 +c 3 x 3 +c 4 x 4 +c 5 x 5 +c 6 x 6 +c 7 x 7 +c 8 x 8 +c 9 x 9

[0126] c 0 =500

[0127] c 1 =0.00027586887550113

[0128] c 2 =8.799468063602584×10 -8

[0129] c 3 =-4.704429994380516×10 -9

[0130] c 4 =2.2971381877533835×10 -11

[0131] c 5 =-4.525431832112869×10 -14

[0132] c 6 =4.499916884881123×10 -17

[0133] c 7 =-2.404927260411608×10 -20

[0134] c 8 =6.607807466785785×10 -2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com