Cold-rolled plate shape control method based on optimization algorithm

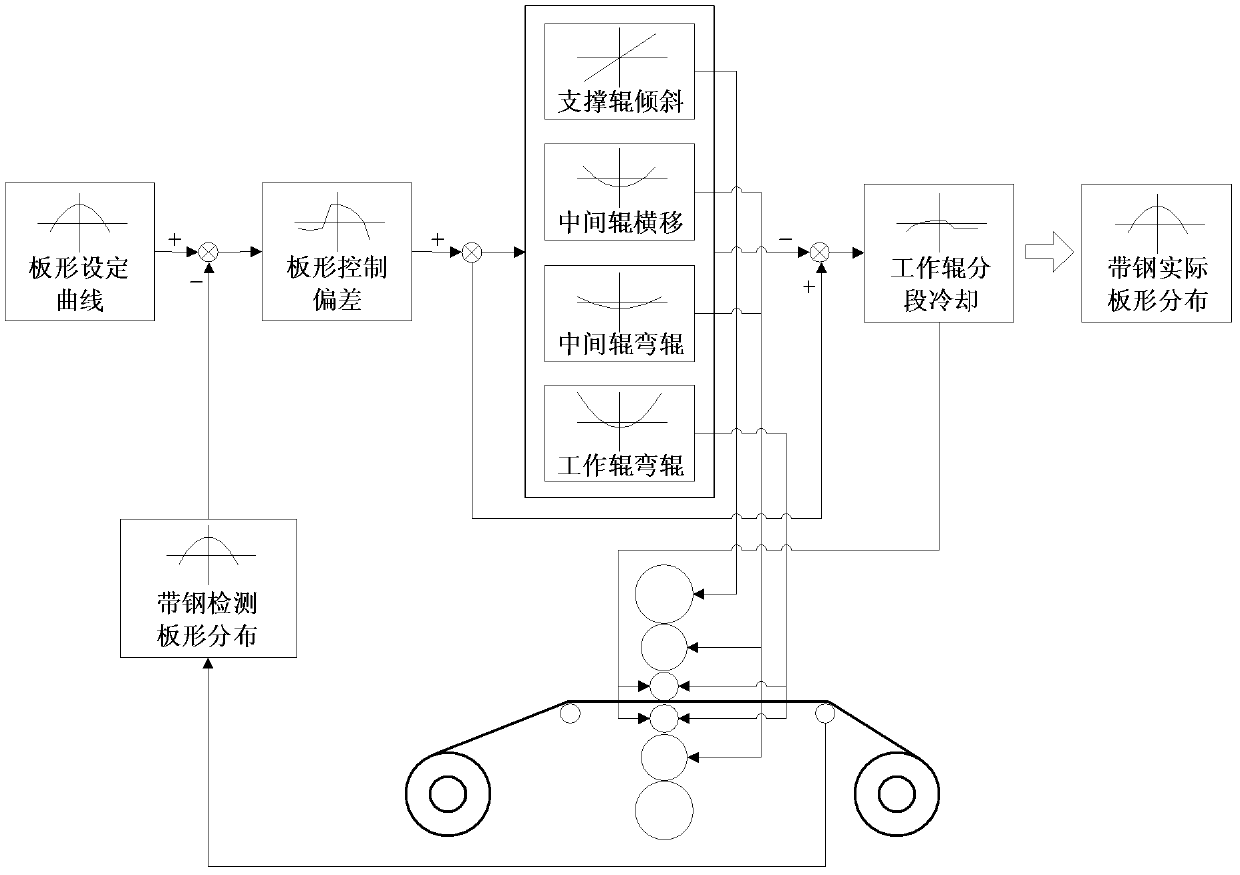

A control method and technology of cold-rolled sheet, applied in the direction of contour control, etc., can solve the problem that the L1 level CPU shape control program is not suitable for real-time calculation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

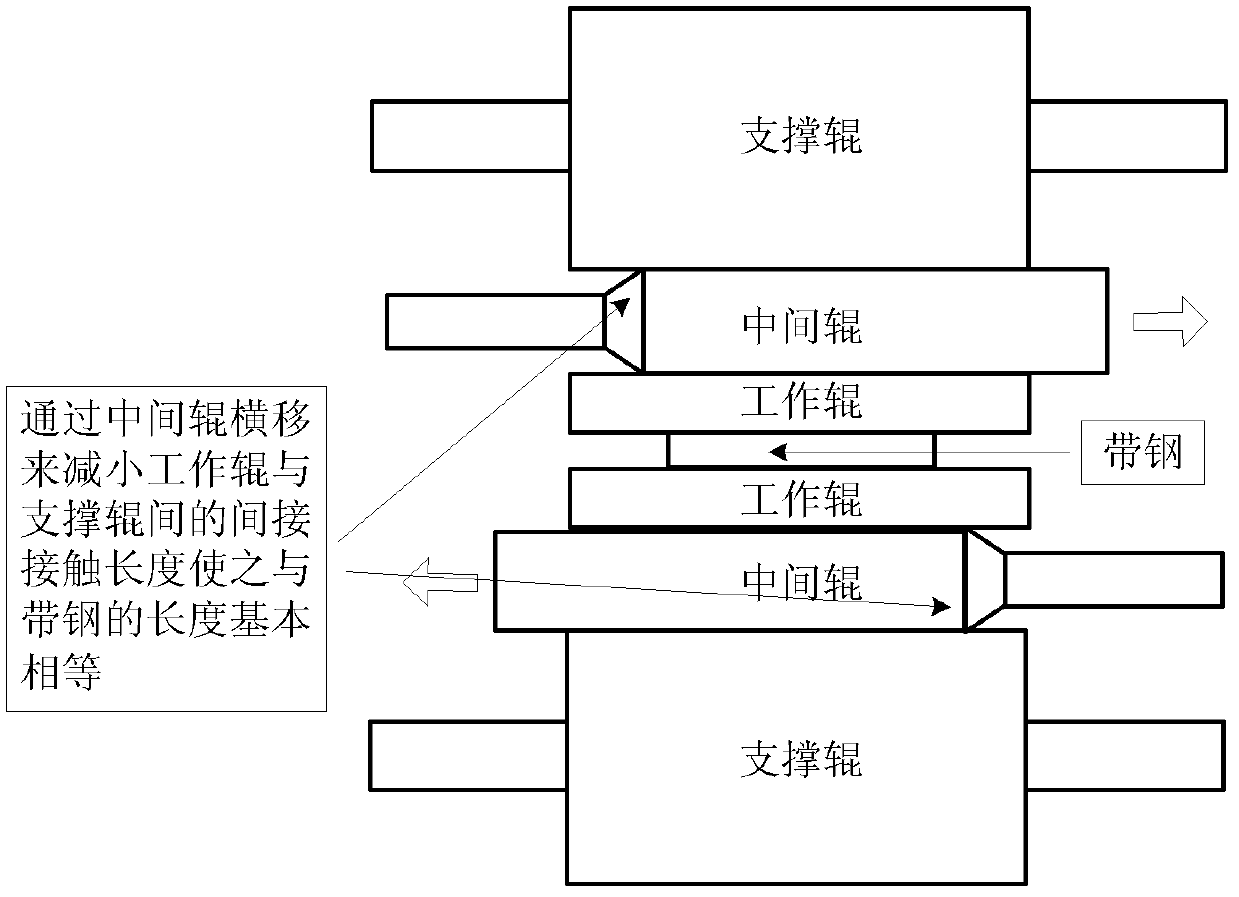

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the online detection method of plate shape

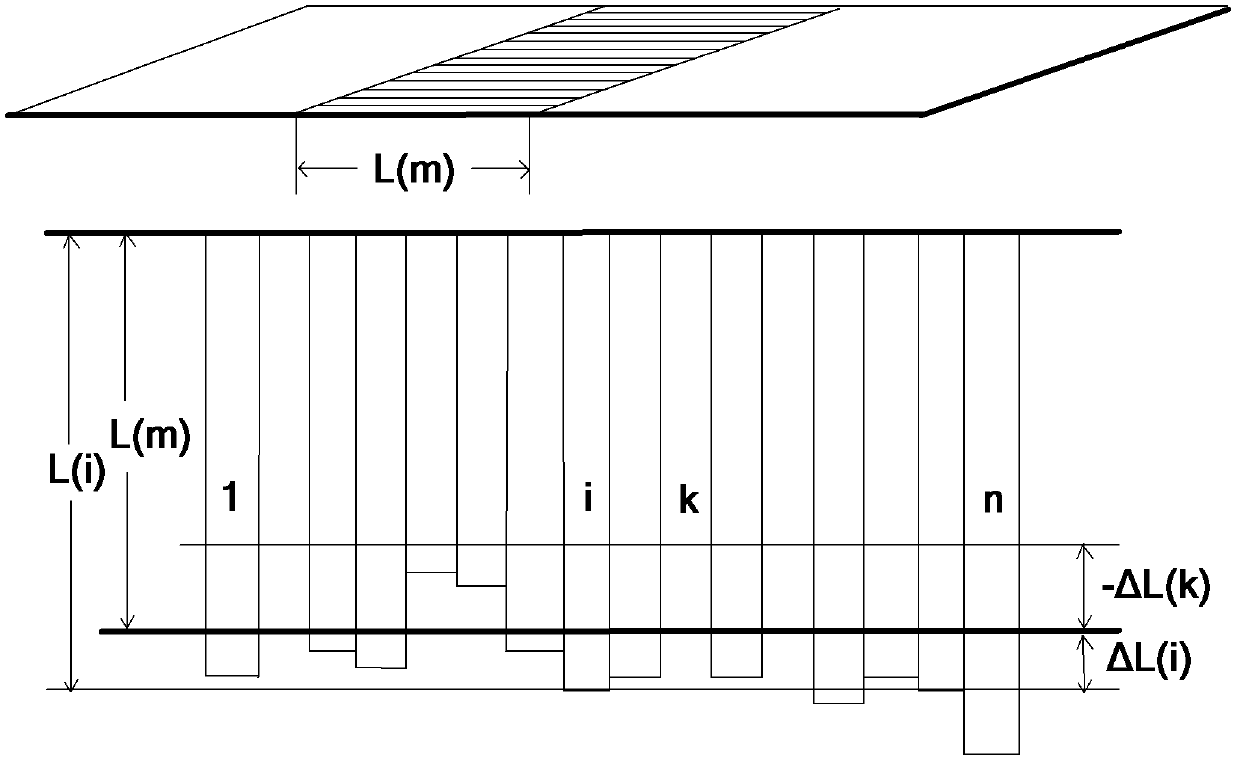

[0050] The plate shape refers to the degree of warping of the plate, and its essence refers to the distribution of residual stress inside the strip. In cold rolling production, the meaning of the shape of the strip refers to the flatness of the strip, that is, the tensile stress difference of the strip along the width direction. In fact, the meaning of the plate shape also includes the transverse thickness difference of the strip. Generally, the plate shape mentioned only represents the flatness of the plate shape, without considering the transverse thickness difference. Commonly used plate shape representation methods are: "relative length difference representation", "tensile stress difference representation", "strip section shape representation", "waveform representation" and so on.

[0051] The relative length difference representation of straightness: such as image 3 As shown, if a length of untensioned s...

Embodiment 2

[0083] Embodiment 2: Determination method of edge plate shape measurement area and its coverage

[0084] like Figure 5 As shown, if starting from the OS side (operating side) and ending at the DS side (transmission side), each measuring area of the flat measuring roll is numbered from z_1 to z_n, then there will be two Measurement zones z_os and z_ds.

[0085] The purpose of determining the edge measurement area is to determine the effective flatness detection and control area.

[0086] like Image 6 As shown, the length of the uncovered area on the OS side and the DS side is calculated by the following formula:

[0087] l_free_os=(w_zone_sum-w_strip)*0.5-strip_shift+d_axial (Formula 2-1)

[0088] l_free_ds=(w_zone_sum-w_strip)-l_free_os (Formula 2-2)

[0089]In the formula: l_free_ds is the length of the uncovered zone on the DS side, l_free_os is the length of the uncovered zone on the OS side, w_zone_sum is the sum of the width of the measurement zone of the shape r...

Embodiment 3

[0102] Embodiment 3: The setting method of target plate shape

[0103] In cold rolling production, most of the rolled cold plates need to be further processed in subsequent processes, such as hot-dip galvanizing, annealing units and other processes. The plate shape will affect the operation stability of these units, and in the subsequent processes, the plate Therefore, when setting the flatness target curve of the rolling mill, the requirements of the subsequent units must be considered, and the target flatness curve is usually set as a micro-medium wave or a micro-edge wave.

[0104] In this embodiment, the shape setting curve adopts such as Image 6 As shown in the segmented curve, the curve divides the strip width corresponding to the effective flatness detection and control area into two parts, the middle part and the edge part. The expression of the curve is shown in the following formula:

[0105] f s ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com