Optimal control method of cold-rolling mill process cooling system

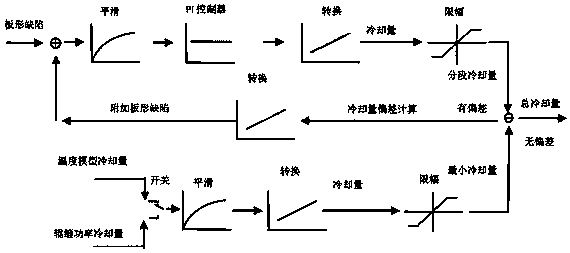

A technology for process cooling and optimal control, applied in the direction of temperature control, etc., can solve the problem of not mentioning the combination optimal control method, etc., and achieve the effect of realizing combination optimal control and satisfying good control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in more detail through the embodiments below in conjunction with the accompanying drawings.

[0042] The optimized control method of the process cooling system of the cold rolling mill, the combined optimal control of process cooling and segmental cooling is applied to the emulsion cooling control system of the fifth stand of a 1450 continuous cold rolling production line with five stands, and the process parameters are shown in Table 1:

[0043]

[0044] Table 1 rolling process parameters

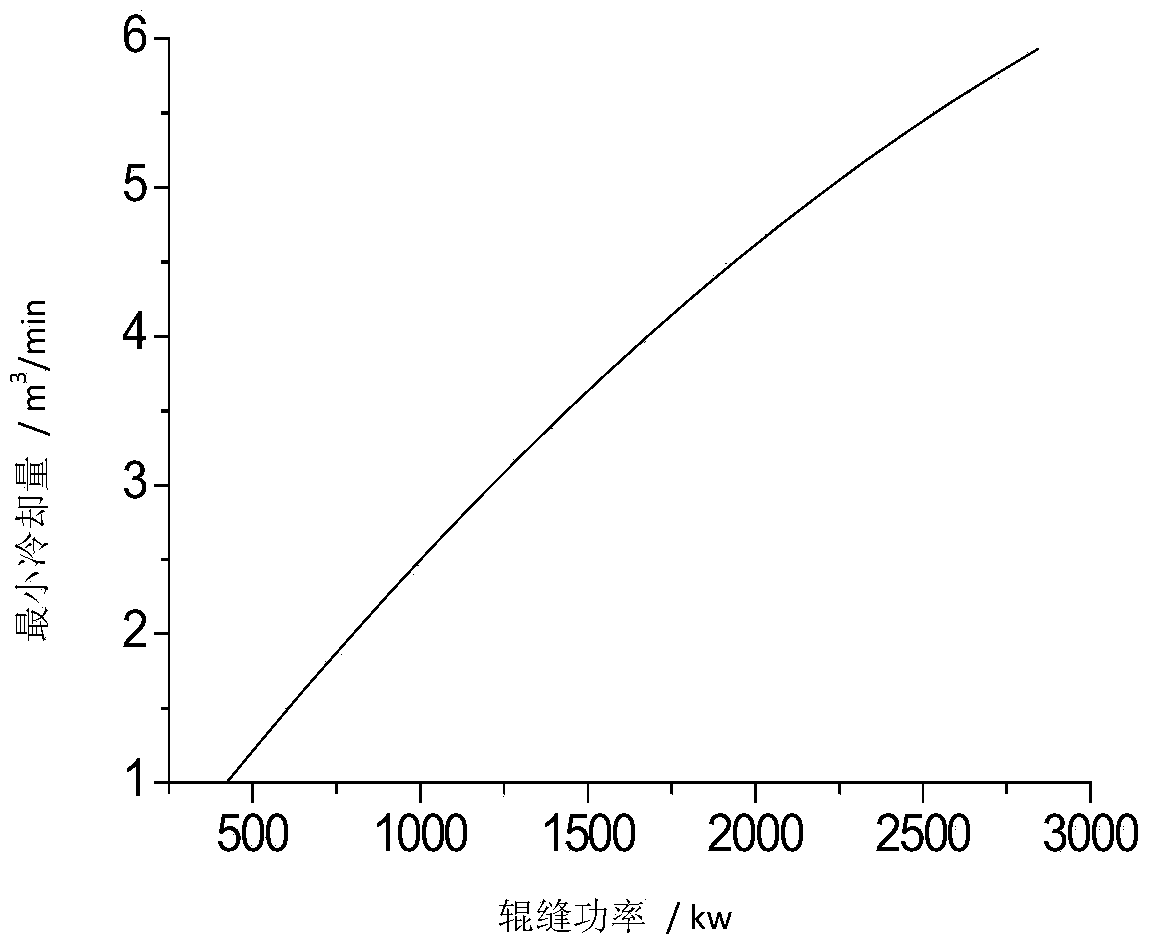

[0045] The thickness of the strip steel at the entrance of the rolling mill is 0.43mm, the target thickness of the strip steel at the exit is 0.35mm, and the steel grade of the strip steel is SPCC. Substitute the above process and equipment parameters into the formula Finally, the calculated roll gap rate is 1814KW, and the relationship between the roll gap power and the minimum cooling capacity is passed figure 1 , the minimum amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com