Checking device of shape deviation of large-diameter seal head

An inspection device and large-diameter technology, applied in the field of pressure vessels, can solve the problems of difficulty in use and storage, wrong head connection height, and inaccurate placement of mixing equipment inside the equipment, etc., to achieve convenient use and simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

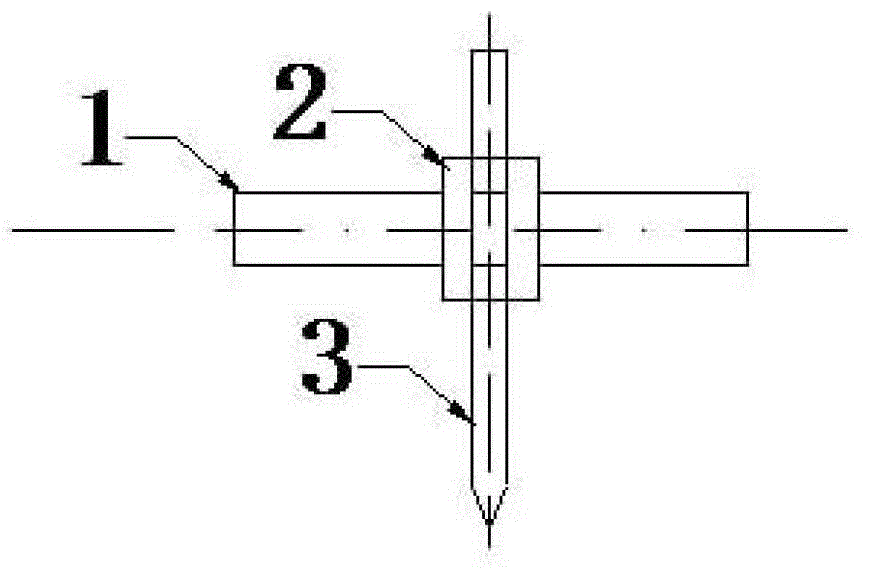

[0017] Such as figure 1 As shown, a large-diameter head shape deviation inspection device includes a frame 1, a slider 2, and a scale 3. The center of the frame 1 is "0" point, and the two sides are respectively marked with the gauge distance. The scale 3 starts from the bottom to mark the gauge distance. The bottom end of the ruler 3 is preferably tapered to reduce the contact area; the slider 2 is installed on the frame 1 and is connected with the frame 1 by sliding fit; the ruler 3 is installed on the slider 2 and is movably connected with the slider 2; the ruler 3 and frame 1 form a cross.

Embodiment 2

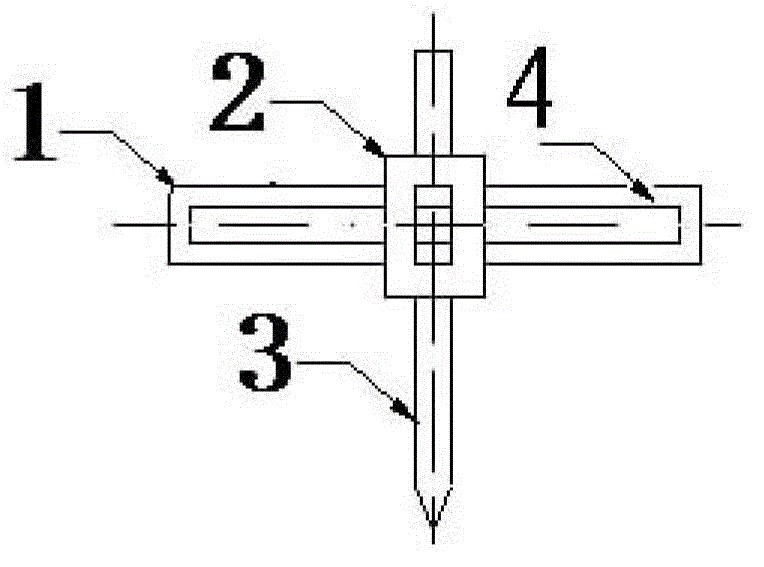

[0019] Such as figure 2 As shown, except that a supporting point 4 is added in the middle of the frame 1 to increase the rigidity of the frame 1, the others are the same as in the embodiment 1.

[0020] The processing material of the present invention is preferably aluminum alloy, and the reasons are as follows: 1. The hardness can be guaranteed, and the deflection is relatively small when measuring large-diameter heads; Large curvature for easy handling.

[0021] Working process of the present invention is as follows:

[0022] 1. Measure the diameter of the head and mark it;

[0023] 2. Place the frame 1 on the end face of the head so that the diameter marks are just distributed on the center line of the frame 1;

[0024] 3. Adjust the frame 1 in the diameter direction, so that the readings on both sides of the contact position between the frame 1 and the head are the same (make the "0" point of the frame 1 coincide with the highest point of the head);

[0025] 4. Adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com