Strip shape control method based on target strip shape settings of cold-rolled strip steel

A technology for shape control and cold-rolled strip steel, which is applied in the field of steel rolling, can solve the problems of not being suitable for thin material target shape, poor quality of thin material shape control, and inability to realize setting and control, etc., achieving good application effect, Improve the quality of plate shape control, the yield of finished products and the effect of improving the operating efficiency of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

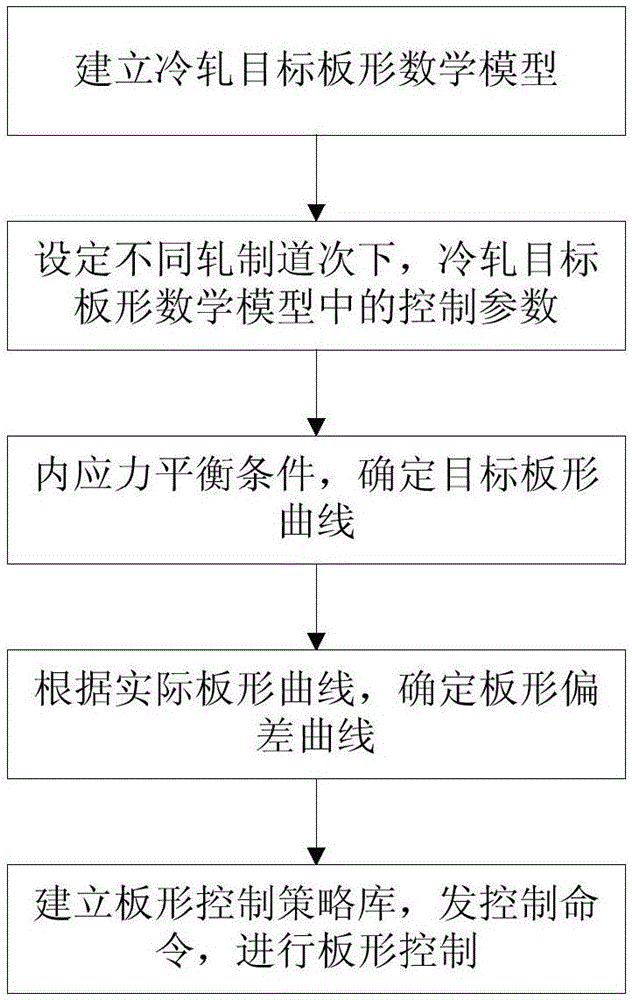

[0059] The shape control method of this embodiment is suitable for cold rolling mills such as single stand, 4 stands, 5 stands, 6 stands, etc., and can roll thin strip steel with a thickness less than 0.3mm, such as figure 1 As shown, the specific process of shape control in this embodiment is as follows:

[0060] (1) According to the characteristics of cold-rolled strip steel, the structure and working principle of the flatness control actuator of single-stand rolling mill or continuous rolling mill, determine the cold-rolled target flatness mathematical model describing the flatness control of cold-rolled strip steel, described The mathematical model of cold rolling target shape is:

[0061] F(x)=g*[a 1 +a 2 *x+a 3 *x 2 +a 4 *x 3 +a 5 *x 4 +a 6 *x 5 +a 7 *x 6 ]

[0062] Wherein, x is the abscissa of the normalized width direction, -1≤x≤1, x=Y / B, Y is the abscissa of the strip width direction, and B is the strip width;

[0063] a 1 ~a 7 is the coefficient in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com