Sectional feeding honing head device with shape deviation compensation function

A honing head and deviation technology, which is applied in the field of segmented feed honing head devices, can solve problems such as waste, increased honing processing time, and processing size deviation, so as to simplify the motion and control system, increase production efficiency, and reduce manufacturing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

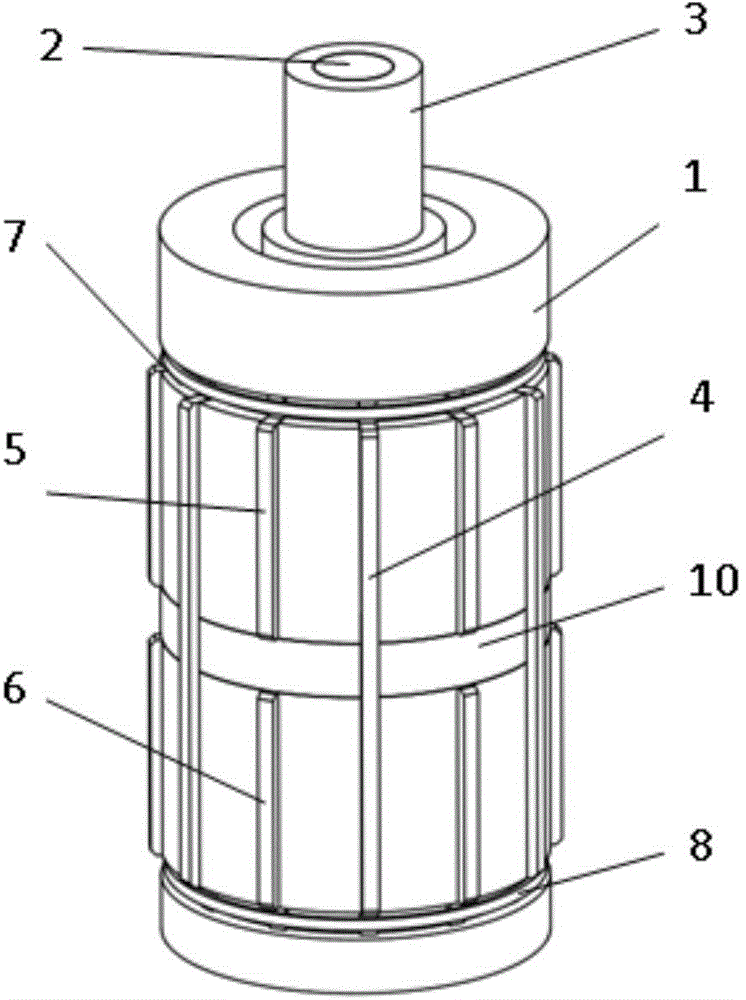

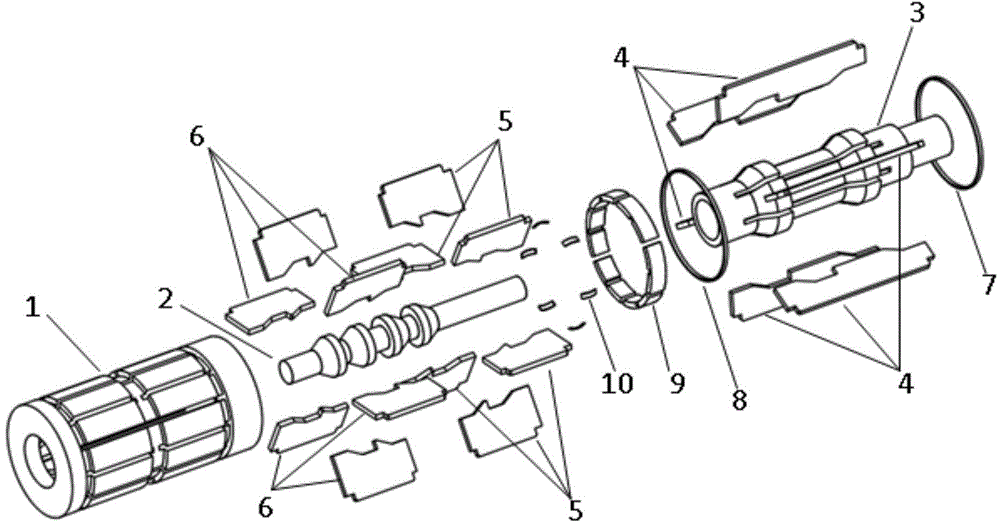

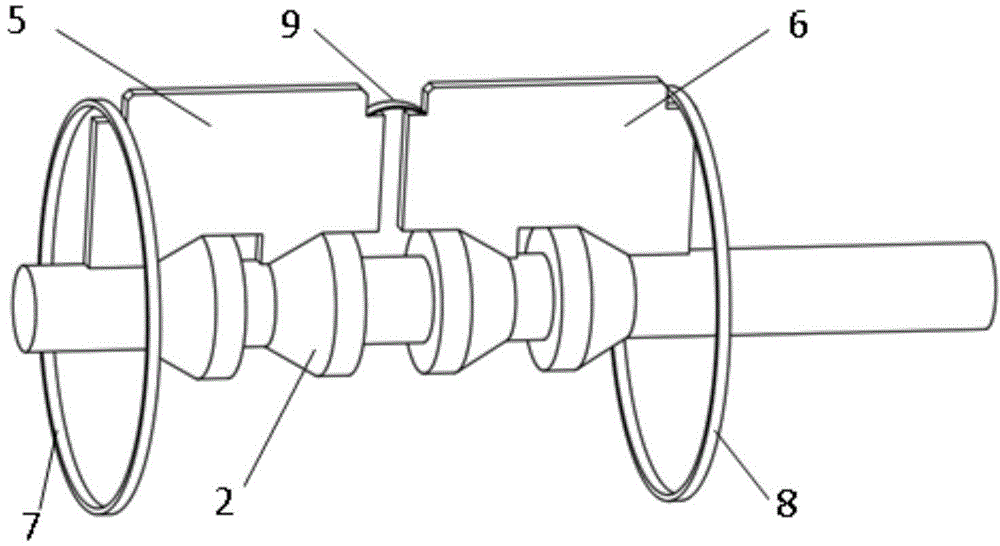

[0037] A segmented feed honing head device with shape deviation compensation function, its structure is as follows Figure 1-2 As shown, the device is mainly composed of a main body 1, an inner mandrel 2, an outer mandrel 3, a main oil stone seat 4, an upper compensation oil stone seat 5, a lower compensation oil stone seat 6, a knife retraction coil 7, a knife retraction coil 8, a retractor Knife spring sheet 9, compensating oilstone fixed block 10 form. Among them: the inner mandrel 2 is installed in the hole of the outer mandrel 3, and the outer mandrel 3 is installed in the center hole of the main body 1; the main oil stone seat 4 is installed in the main oil stone groove of the main body 1, and the main oil stone groove is uniform along the circumferential direction distribution; an upper compensating oil stone seat 5 and a lower compensating oil stone seat 6 form a compensating oil stone seat group. In one compensation oilstone groove, the compensation oilstone grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com