Assembly of prefabricated elements to form a prefabricated building with at least two floors and related building and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

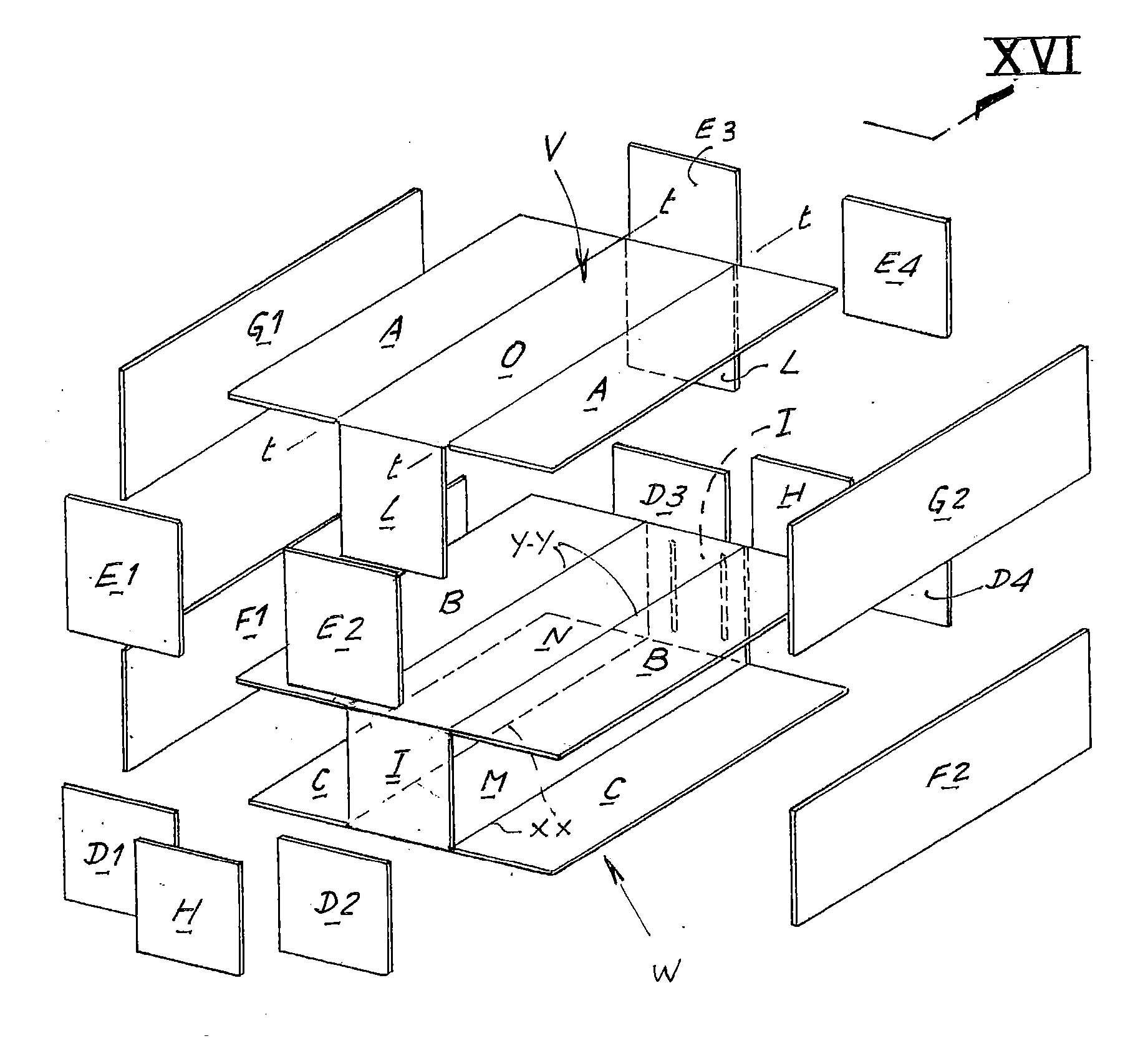

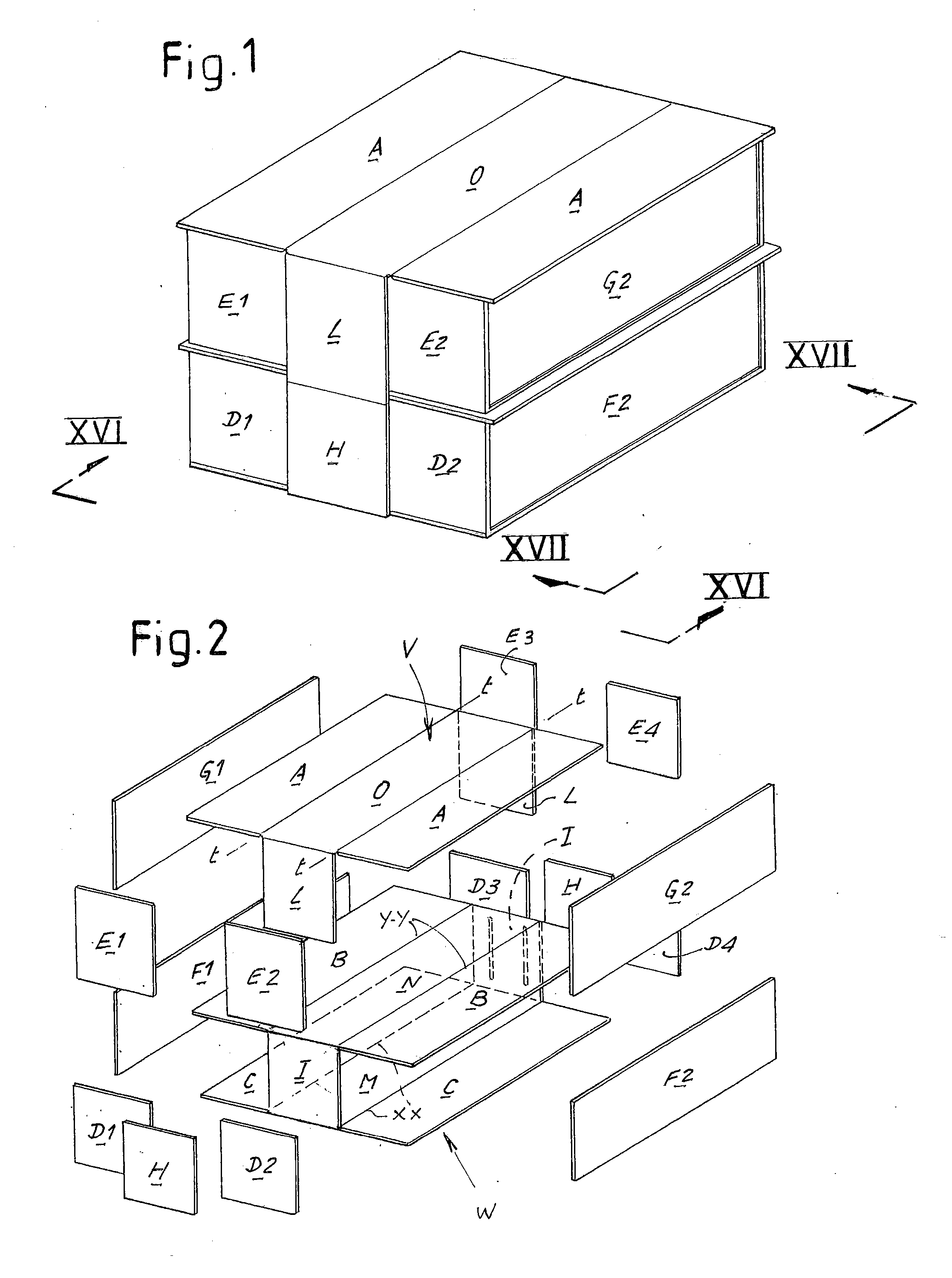

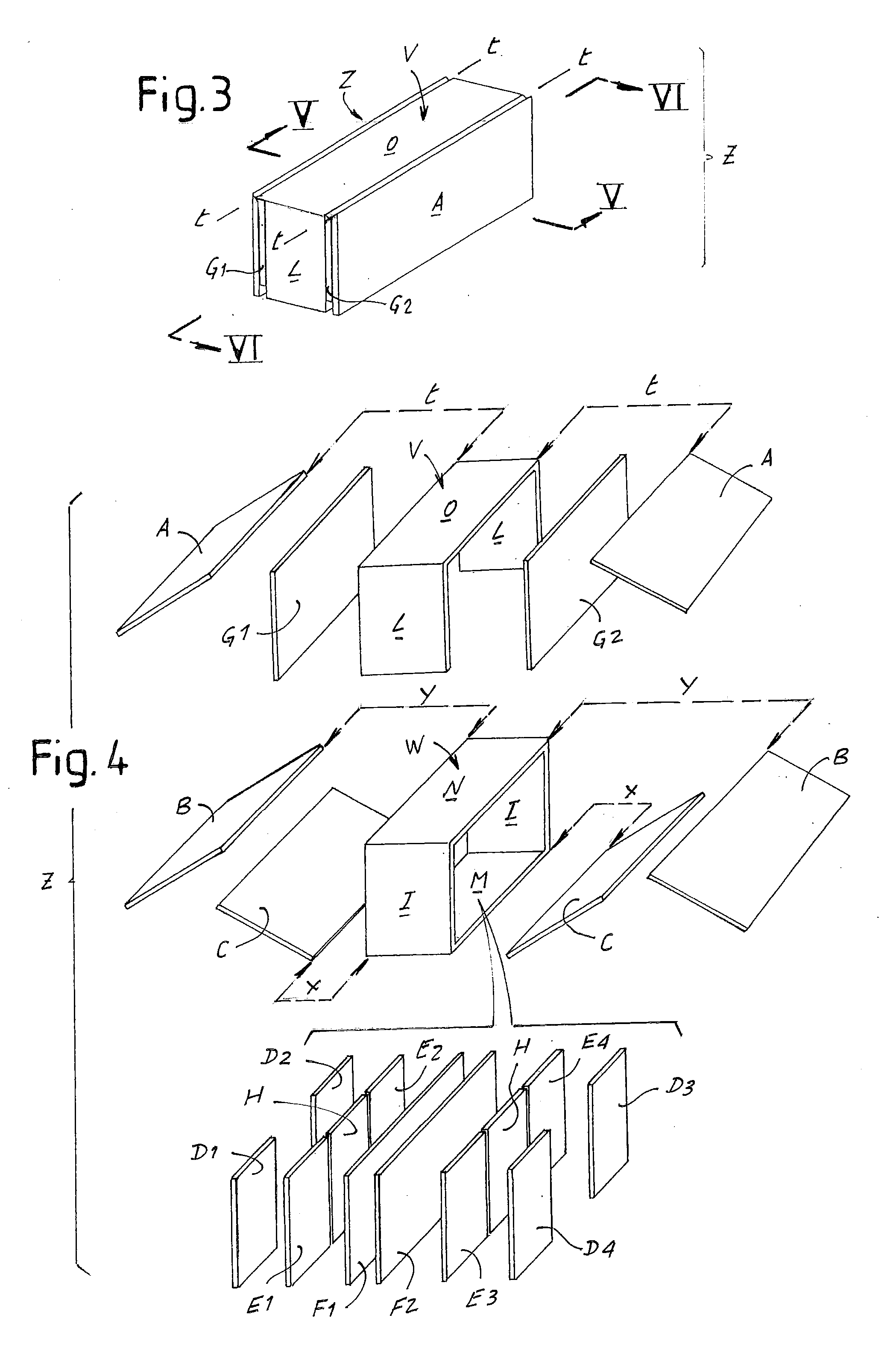

[0228]FIGS. 43, 44 and 53 show a The letters identifying the components of the grouping assembly are the same as the examples described above, varying only the arrangement of these components in the grouping Z and the mode of carrying out assembly.

[0229]In this embodiment, the structural casing of the assembly and therefore of the building is formed by a “reticular” or “punctiform” structure (FIG. 53). In practice the frame of the primary structure is formed by sections or beams made of metal (or another material, such as wood) which form the nine flat parts or frames with rectangular shape (the portions of floor M, C, N, B, O, A) which, after reaching the final position, form the walk floors of the ground story M-C, of the intermediate or second story N-B and the roof floors O-A. The secondary framework of the flat frames is for example composed of cold press-formed C sections.

[0230]For vertical support, the structural casing is provided with columns MG1 fixed permanently at the e...

fourth embodiment

[0253]FIGS. 66 and 67 show a The letters identifying the components of the grouping assembly are the same as the examples described above, varying only the arrangement of these components in the grouping Z and the mode of carrying out assembly.

[0254]In grouping configuration Z, the assembly consists of the following longitudinal arrangement of components (starting from the longitudinal vertical centerline plane of the grouping, outward; as the grouping is symmetrical, only the components referring to one side of the grouping will be indicated, indicating only the reference letter and not the number, which indicates the corresponding side):[0255]a pair of first transverse lateral end walls D-D relating to the first lateral portions of floor C,[0256]the first longitudinal wall F of the ground story,[0257]a pair of second transverse lateral end walls E-E relating to the second lateral portions of floor B,[0258]the first lateral portion C of the walk floor of the ground story,[0259]the...

fifth embodiment

[0263]FIGS. 68 and 69 show a The letters identifying the components of the grouping assembly are the same as the examples described above, varying only the arrangement of these components in the grouping Z and the mode of carrying out assembly.

[0264]In grouping configuration Z, the assembly consists of the following longitudinal arrangement of components (starting from the longitudinal vertical centerline plane of the grouping, outward; as the grouping is symmetrical, only the components referring to one side of the grouping will be indicated, indicating only the reference letter and not the number, which indicates the corresponding side):[0265]a pair of first transverse lateral end walls D-D relating to the first lateral portions of floor C,[0266]the first longitudinal wall F of the ground story,[0267]a pair of second transverse lateral end walls E-E relating to the second lateral portions of floor B,[0268]the second longitudinal wall G of the second story,[0269]the first lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com