Patents

Literature

32results about How to "Ensure the flow path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

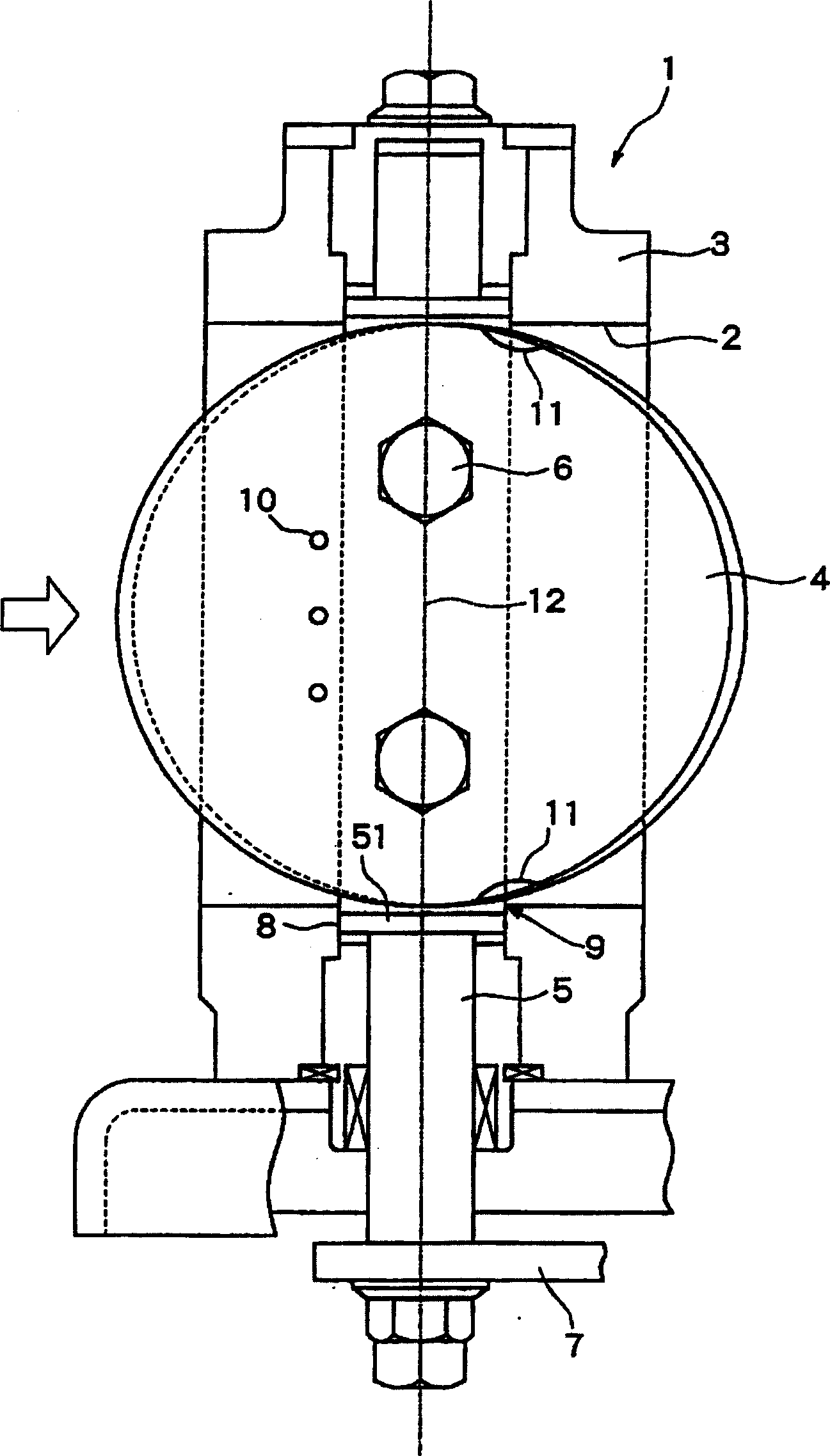

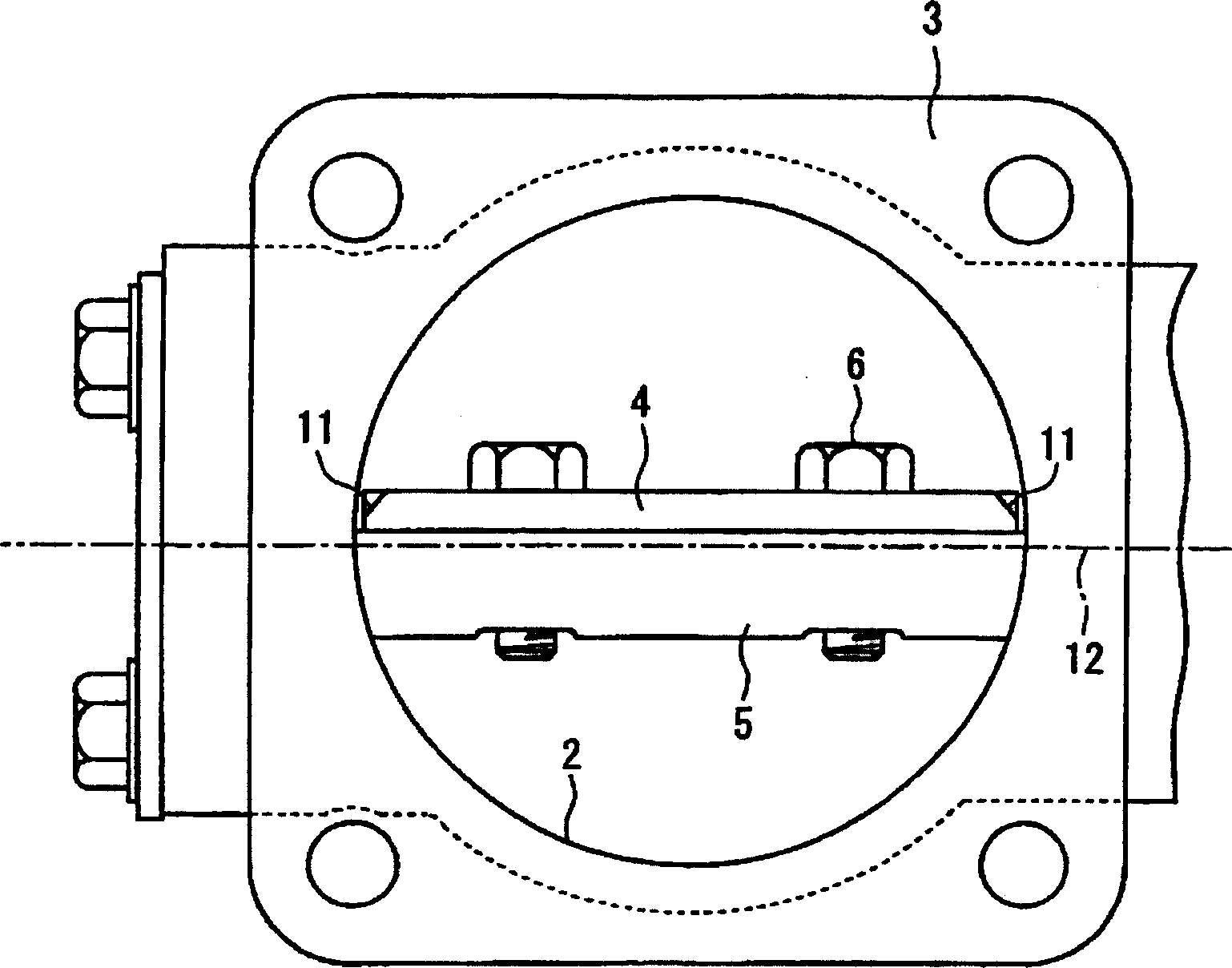

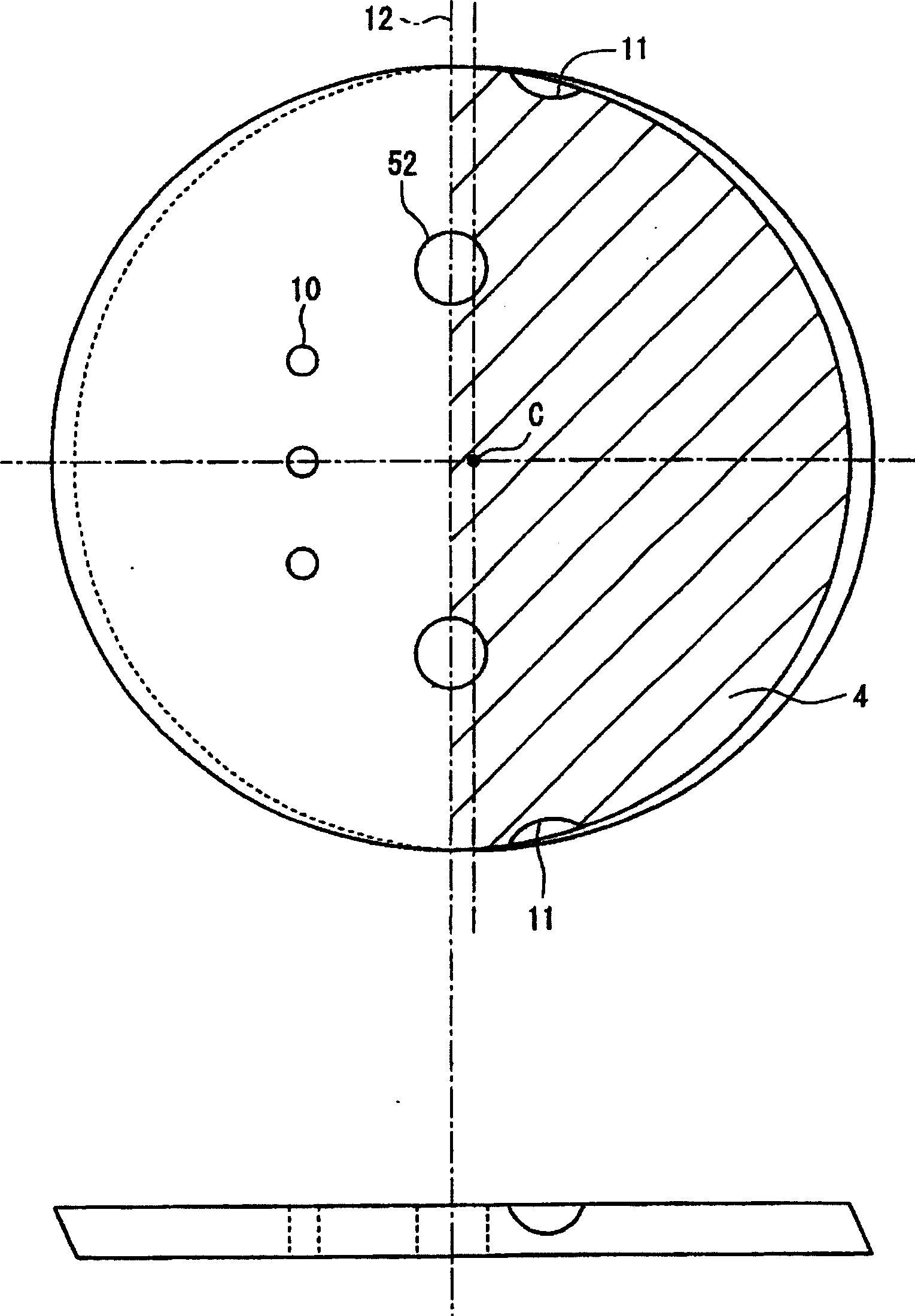

Exhaust gas throttle valve for engines

InactiveCN1680702AReduce gapEnsure the flow pathInternal combustion piston enginesDispersed particle filtrationThermal expansionThrottle

An exhaust gas throttle valve disposed in the exhaust system of an engine, wherein the center axis of rotation of a valve shaft (5) is set at a position deviated from the center axis of the exhaust gas passage, and two recessed portions (11) are symmetrically formed in the circumferential portion of a valve body (4) by cutting the surface thereof. The positions where the recessed portions (11) are formed are on the side of the center axis of the exhaust gas passage beyond the center axis (12) of rotation, and at where the peripheral portion of the valve body (4) faces the edge portions (9) where insertion holes (8) for the valve shaft (5) are opened in the exhaust gas passage. At these positions, the distance is a minimum between the peripheral portion of the valve body (4) and the edge portions (9). Therecessedportions (11) work to increase the gap relative to the edge portions (9) at that positions. It is therefore made possible to approximate the peripheral portion of the valve body (4) to the tubular wall of the exhaust gas passage (2) when the exhaust gas throttle valve is closed preventing the valve body (4) and the edge portions (9) from coming in contact together despite of the thermal expansion.

Owner:ISUZU MOTORS LTD

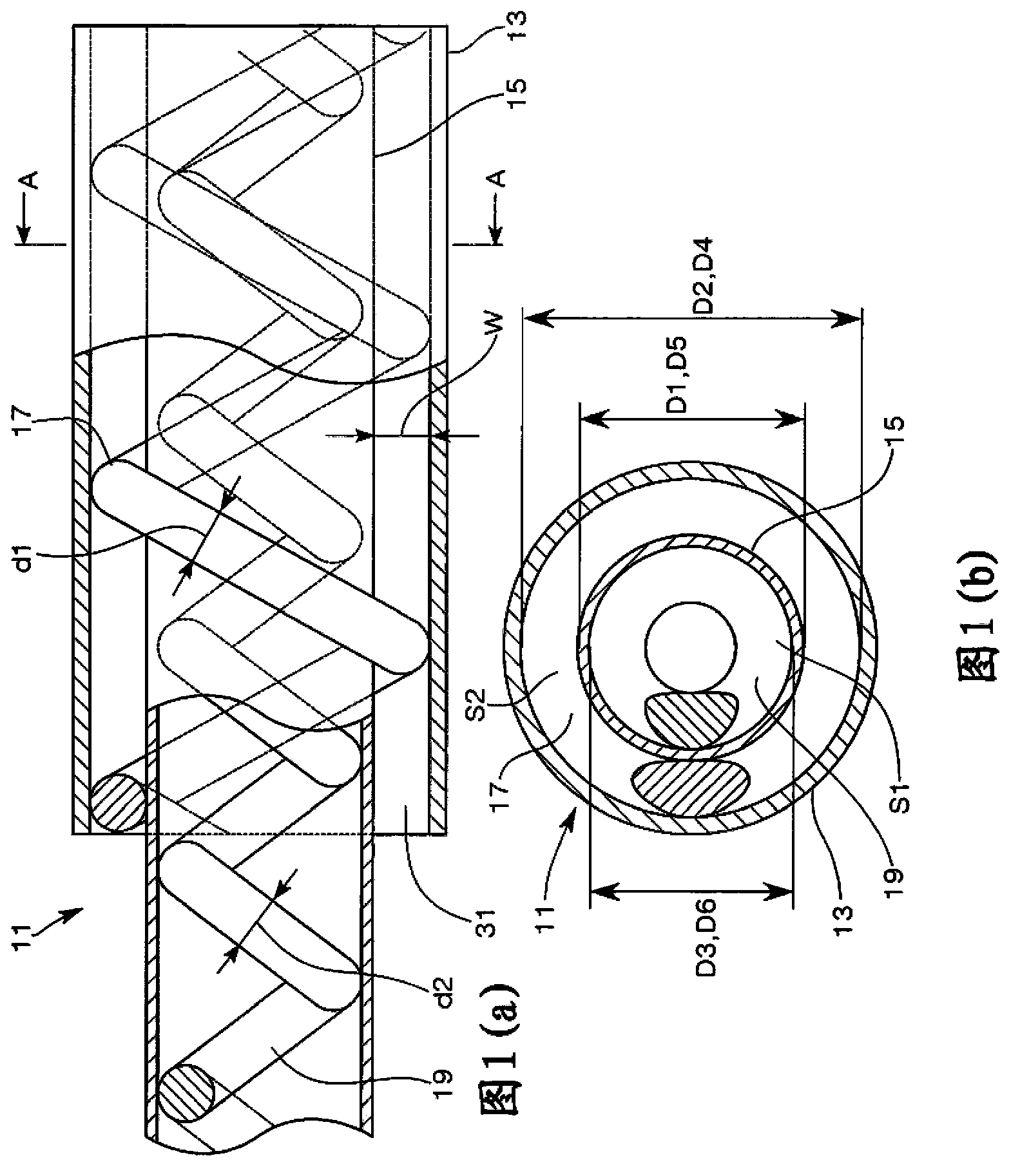

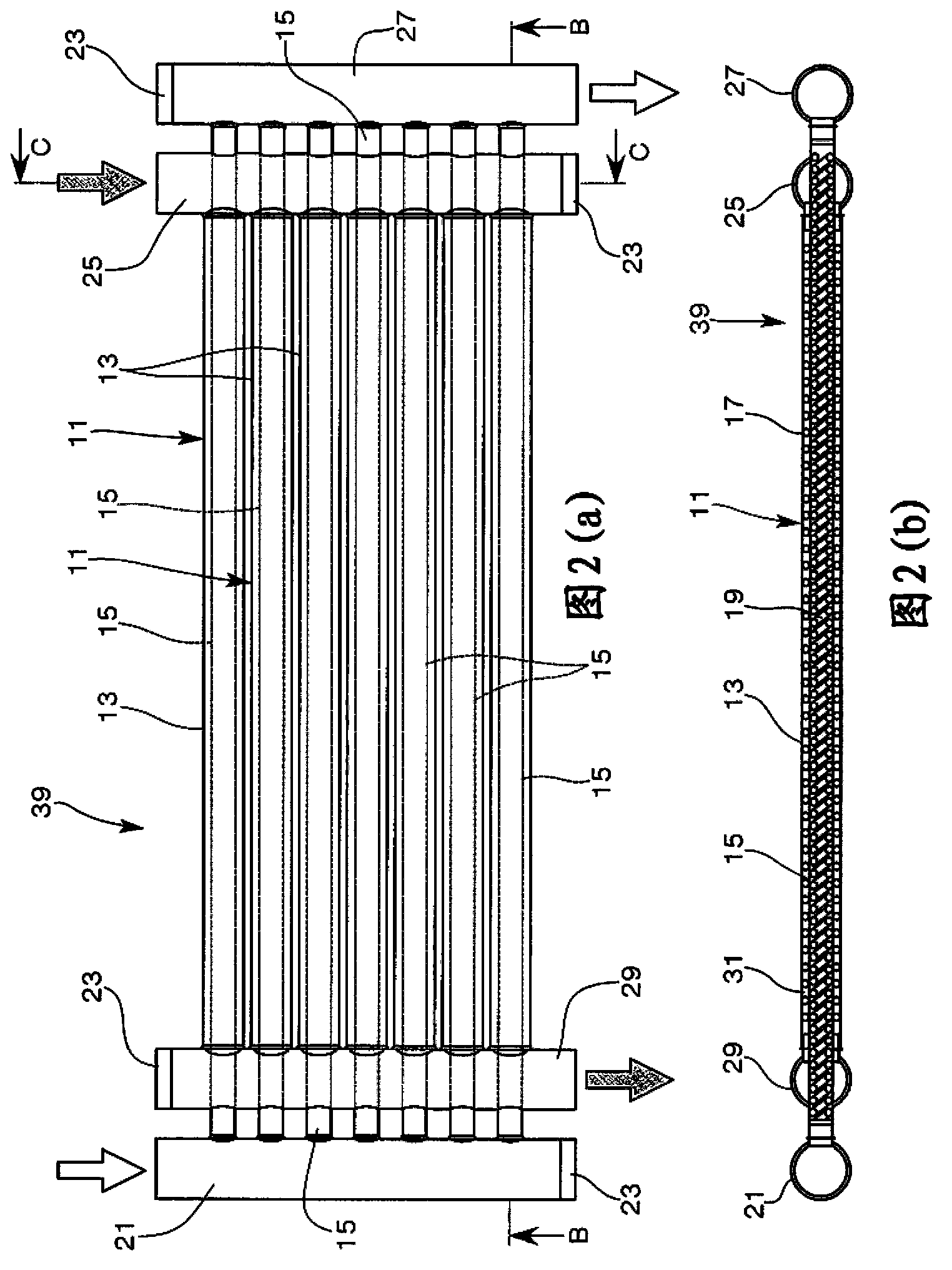

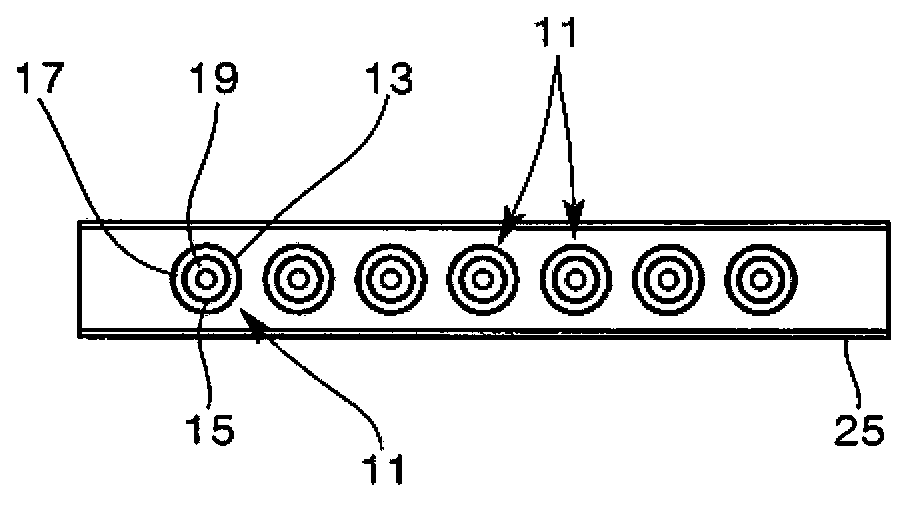

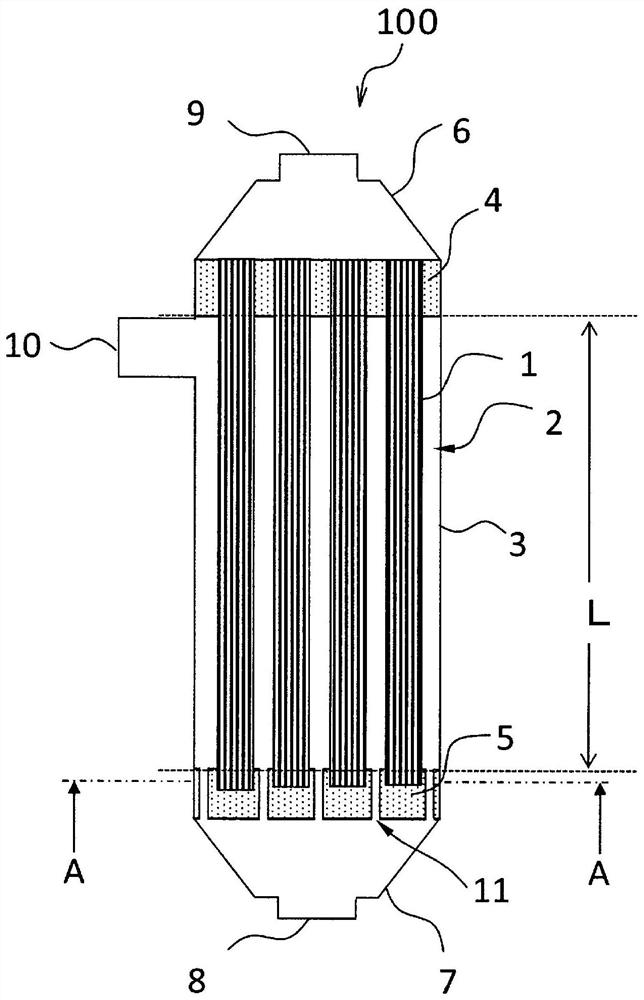

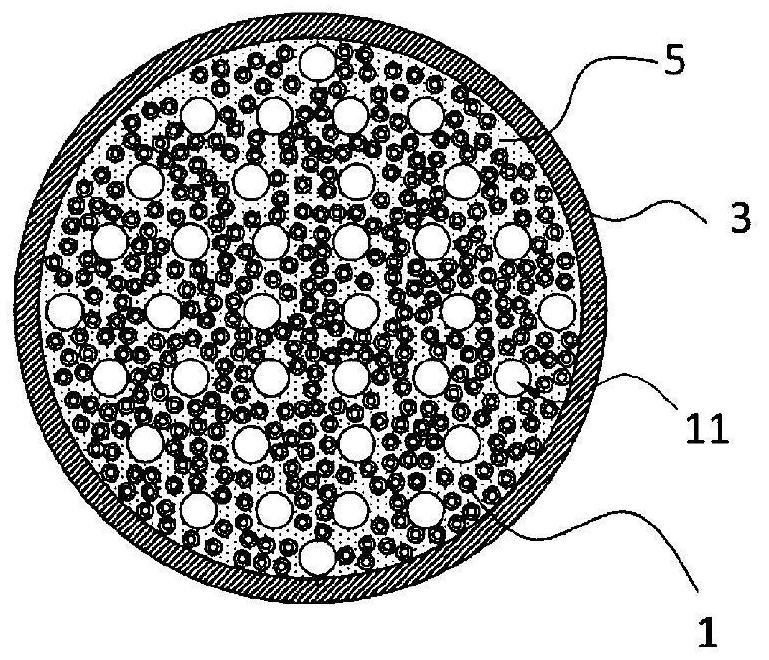

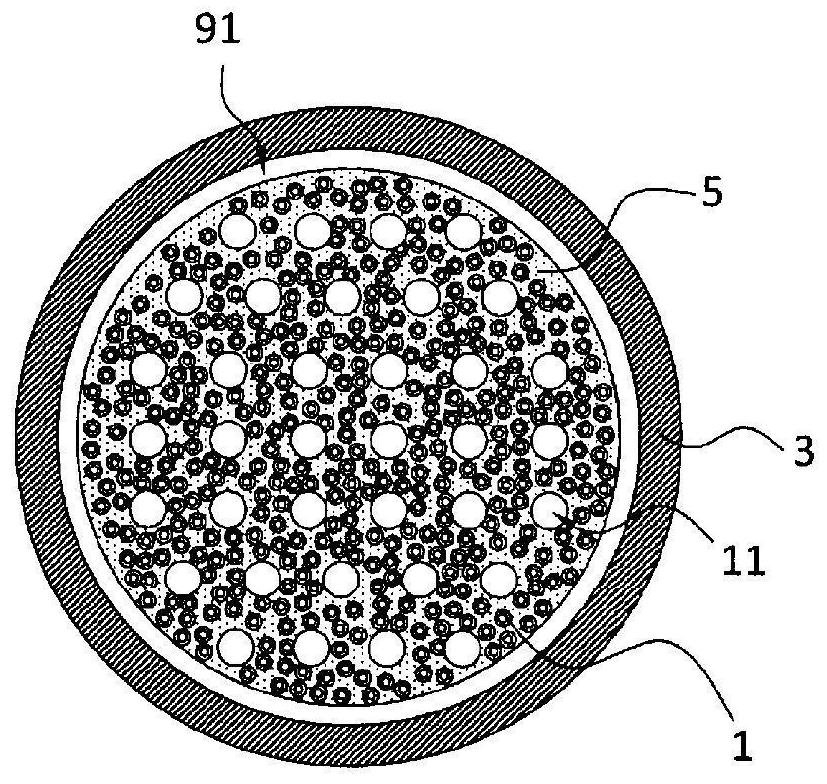

Heat transfer tubes and a heat exchanger using the same

InactiveCN103363820AAchieve compactionSpeed up the flowStationary conduit assembliesHeat exchanger casingsEngineeringHeat transfer efficiency

Provided is heat transfer tubes and a heat exchanger using the same. In the compact heat exchanger, outer tubes and inner tubes can be assembled in an accurate manner without causing reduction in heat transfer efficiency. The heat transfer tubes comprise: a plurality of parallel outer tubes (13); inner tubes (15) inserted into the outer tubes (13) and disposed so that both ends of the inner tubes (15) extend beyond the outer tubes (13); a gap support member (17) disposed in the gap between the inner circumferential surface of the outer tube (13) and the outer circumferential surface of the inner tube (15), the gap support member (17) being made of a wire material arranged so as to be in contact with the inner circumferential surface and the outer circumferential surface in a spiral shape along substantially the entire length of the outer tube (13); and a support member (19) made of a wire material arranged so as to be in contact with the inner circumferential surface of the inner tube (15) in a spiral shape along the entire length of the inner tube (15). The area ratio of a primary flow path in the inner tubes (15) and a secondary flow path in the outer tubes (13) is 1:1-1:1.6.

Owner:CI KASEI COMPANY +1

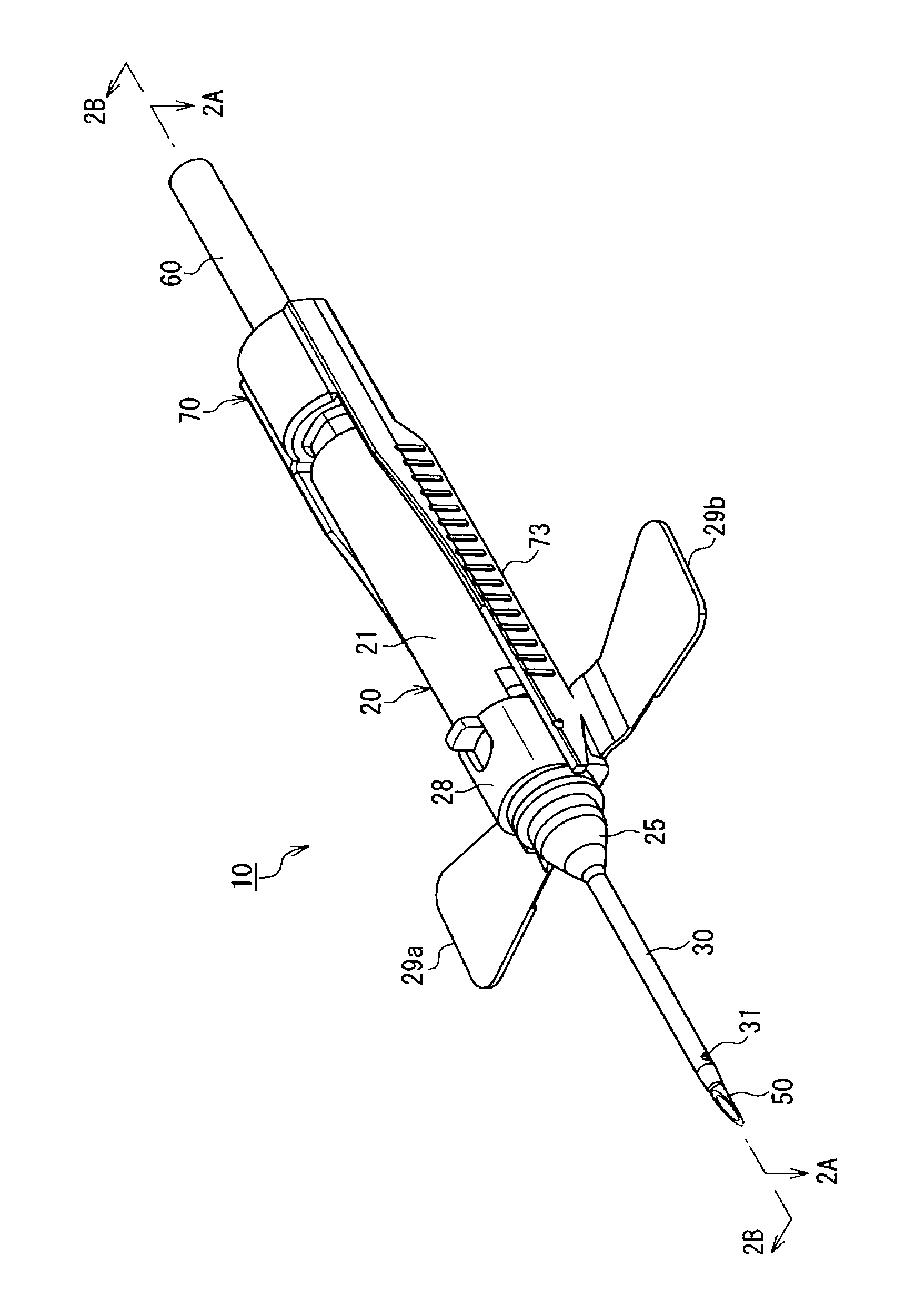

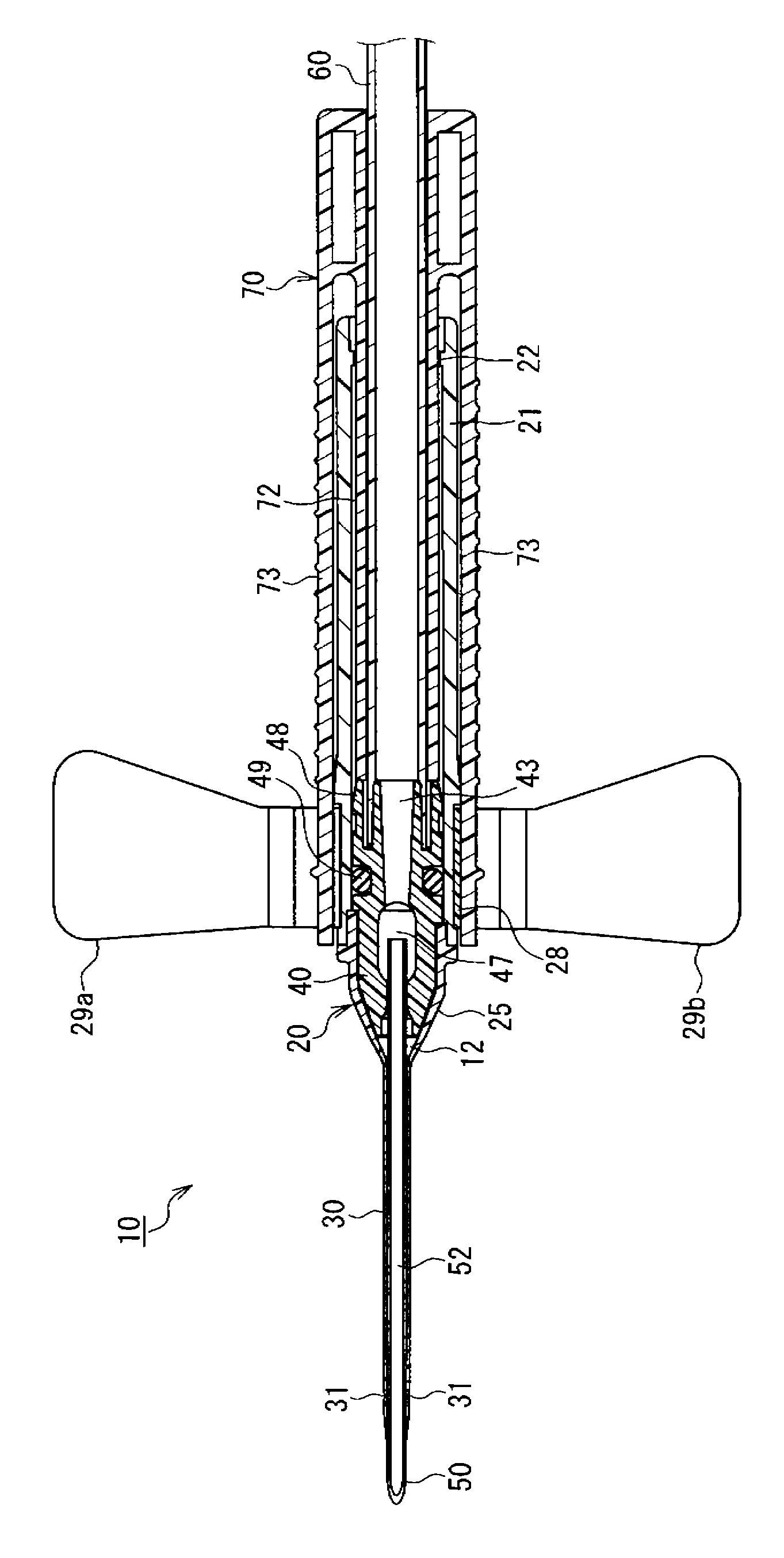

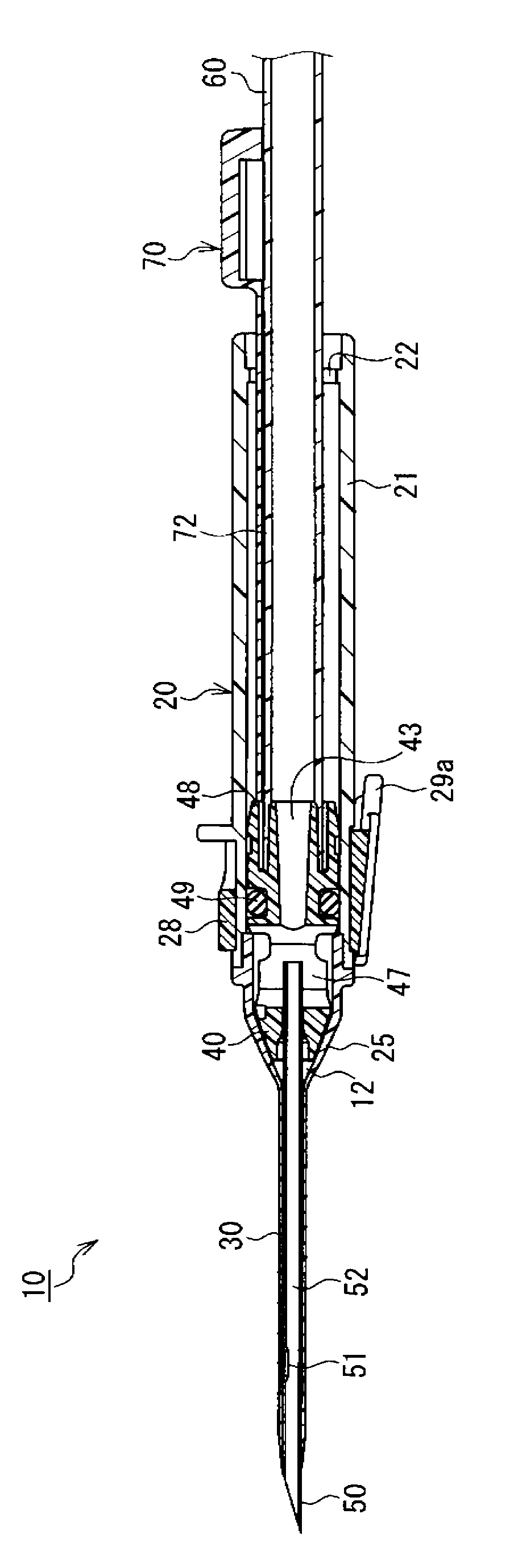

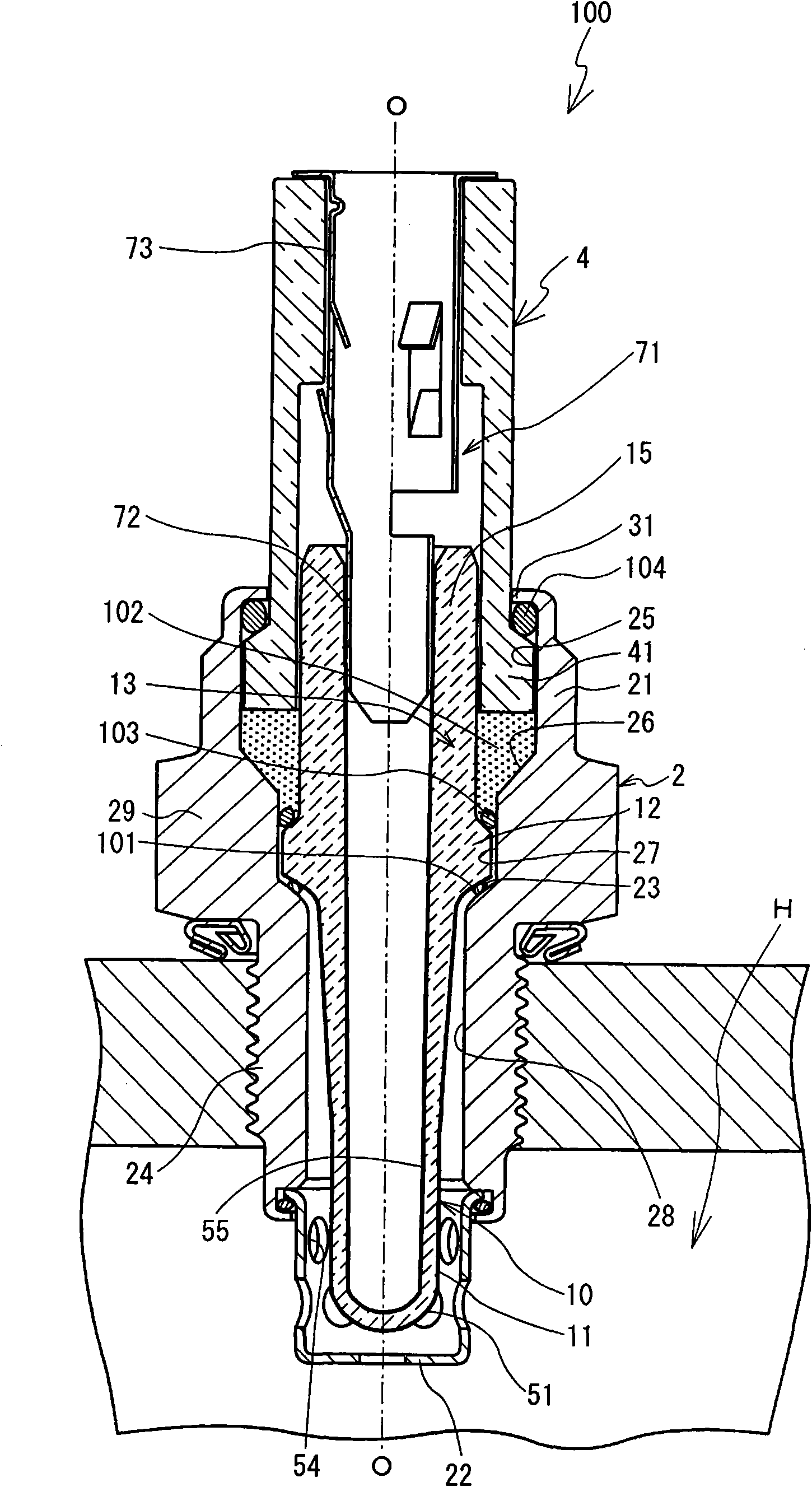

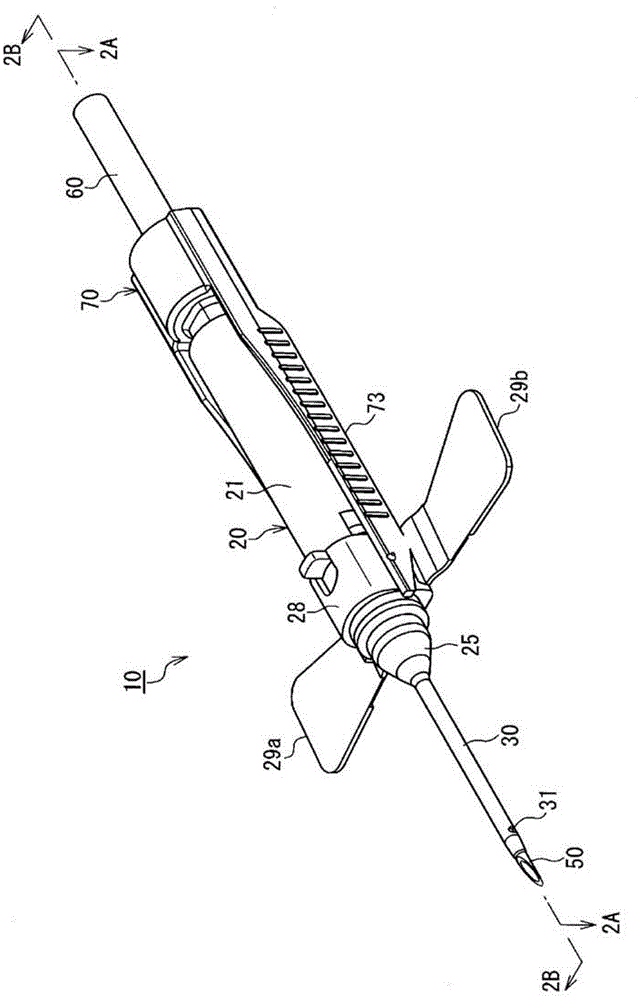

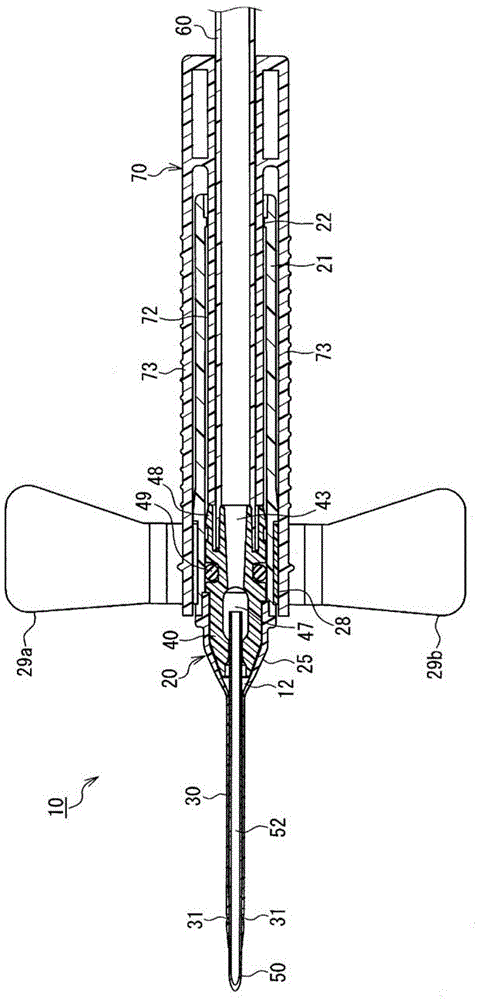

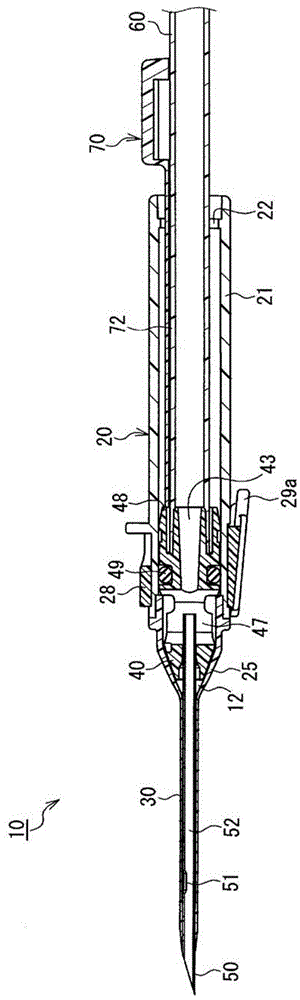

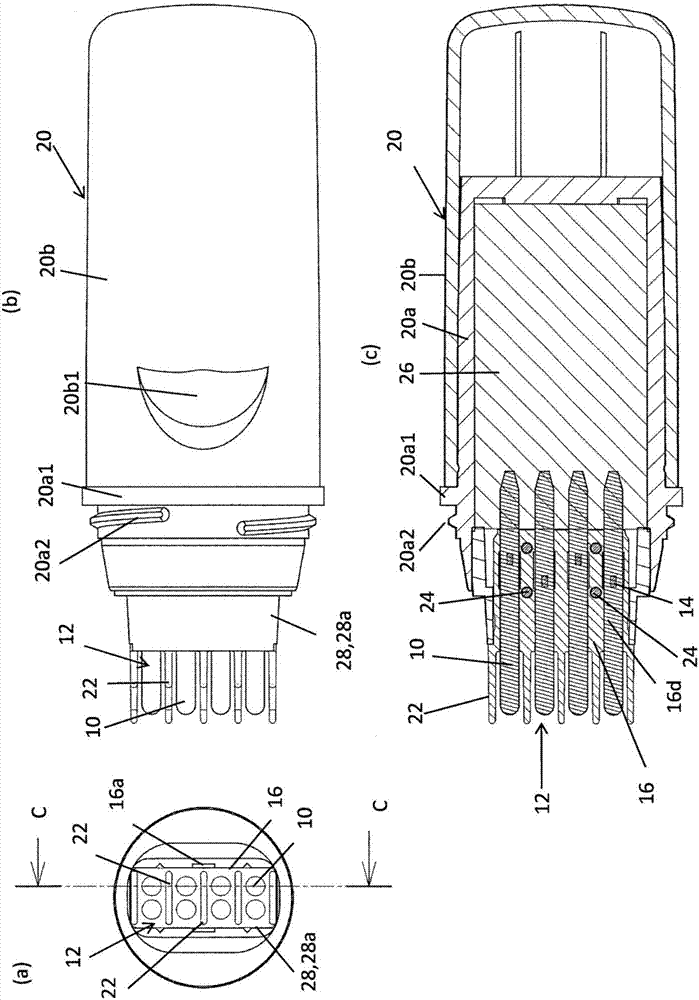

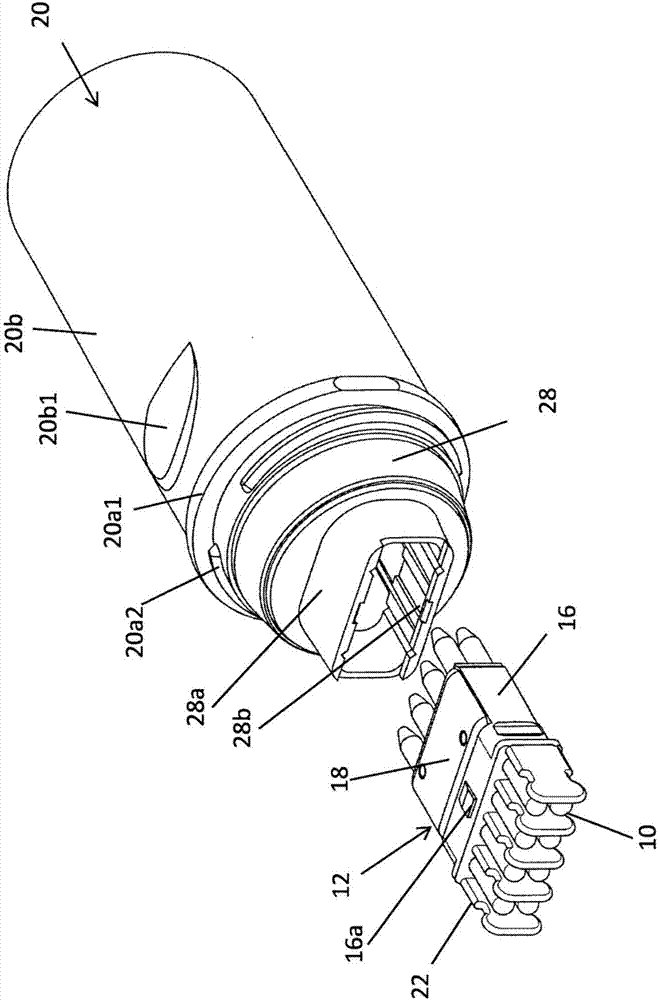

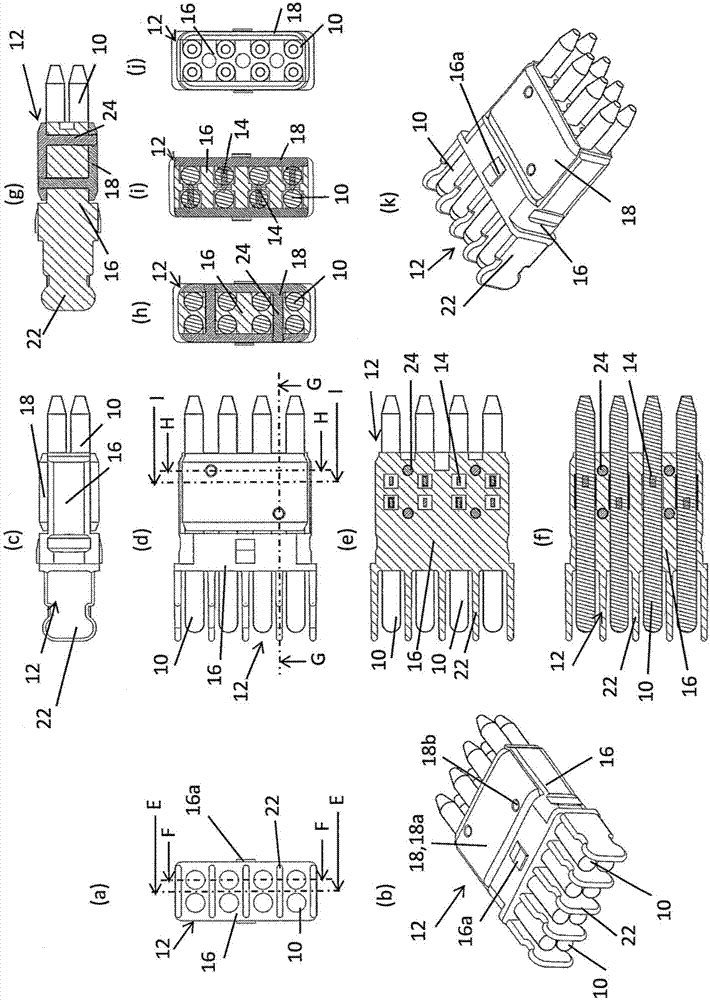

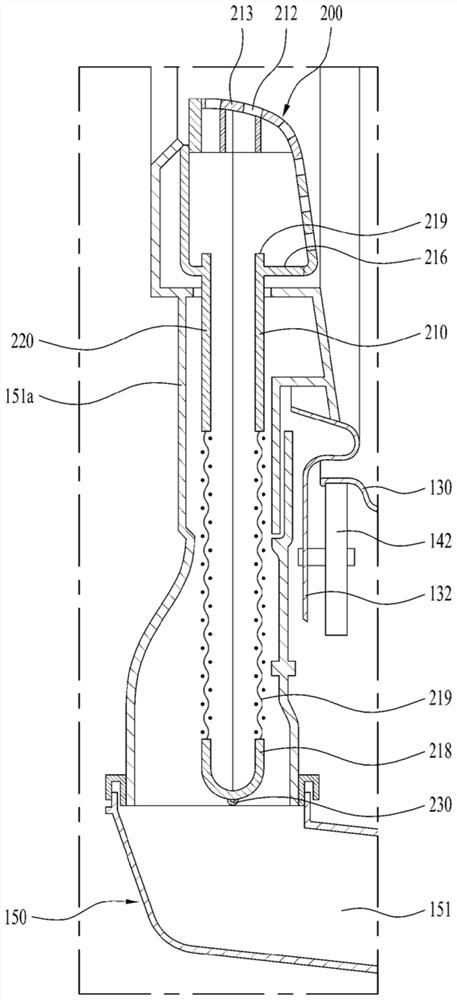

Indwelling needle device

InactiveCN102933242AEnsure the flow pathEasy pre-charge operationCatheterInfusion needlesEngineeringClose contact

When a hub (40) is in an initial position at which it is located on the front end side of an inner cavity of a shield (20), an inner needle (50) penetrates an outer needle (30) and protrudes from a leading end of the outer needle to the outside, and when the hub is in a retracted position at which it is located on the rear end side of the inner cavity of the shield, the inner needle is housed within the inner cavity of the shield. A first side hole (31) is formed in an outer circumferential face of the outer needle, and a second side hole (51) is formed in an outer circumferential face of the inner needle. When the hub is in the initial position, an inner circumferential face of a region (33) of the outer needle that contains the first side hole is in close contact with the outer circumferential face of the inner needle, and the second side hole is located closer to the hub than the region where the inner circumferential face of the outer needle is in close contact with the outer circumferential face of the inner needle. Thus, a priming operation for filling a gap between the inner needle and the outer needle with blood can be easily performed, and leakage of blood through the side hole of the outer needle during puncture does not occur.

Owner:JMS CO LTD

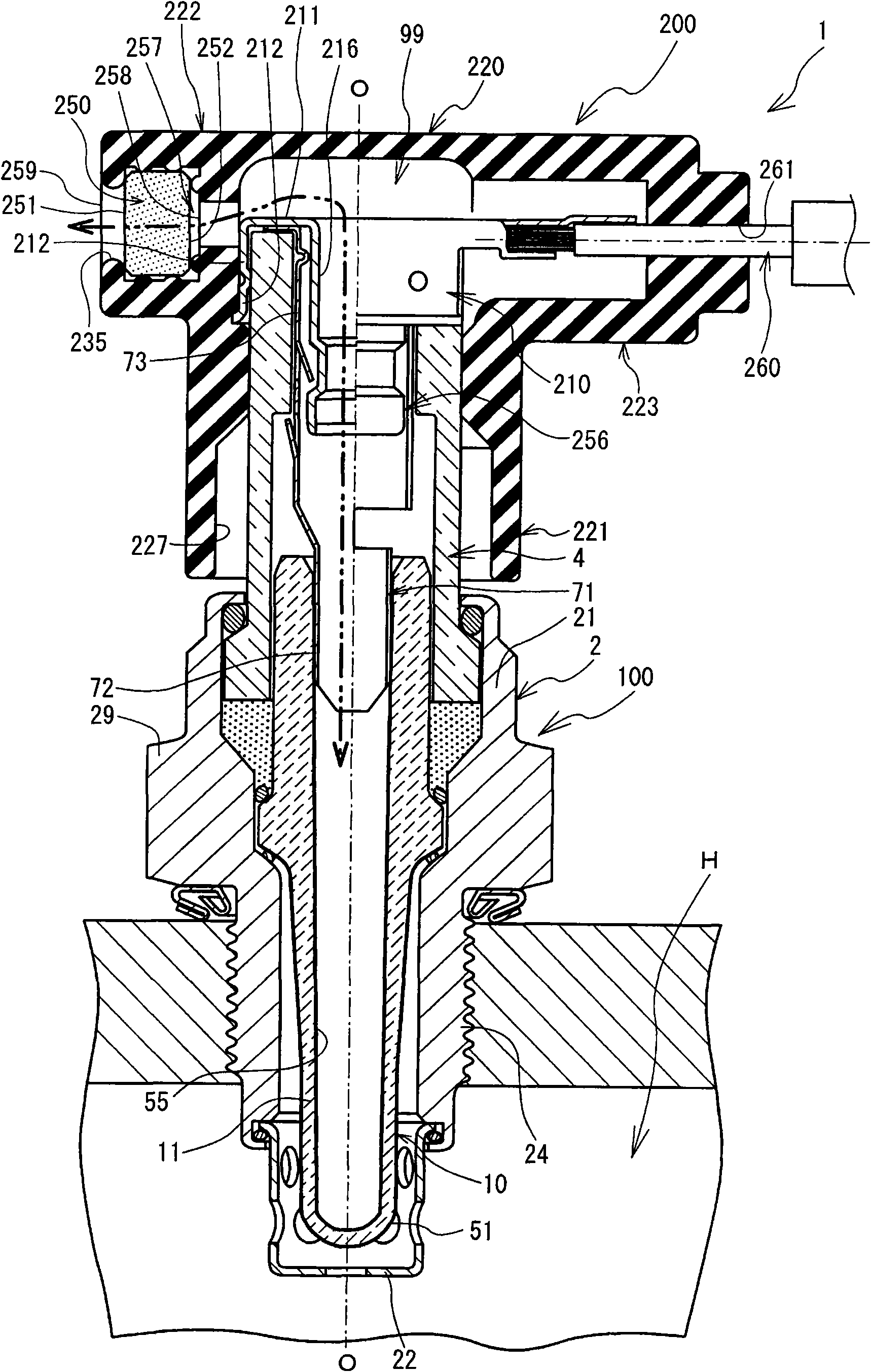

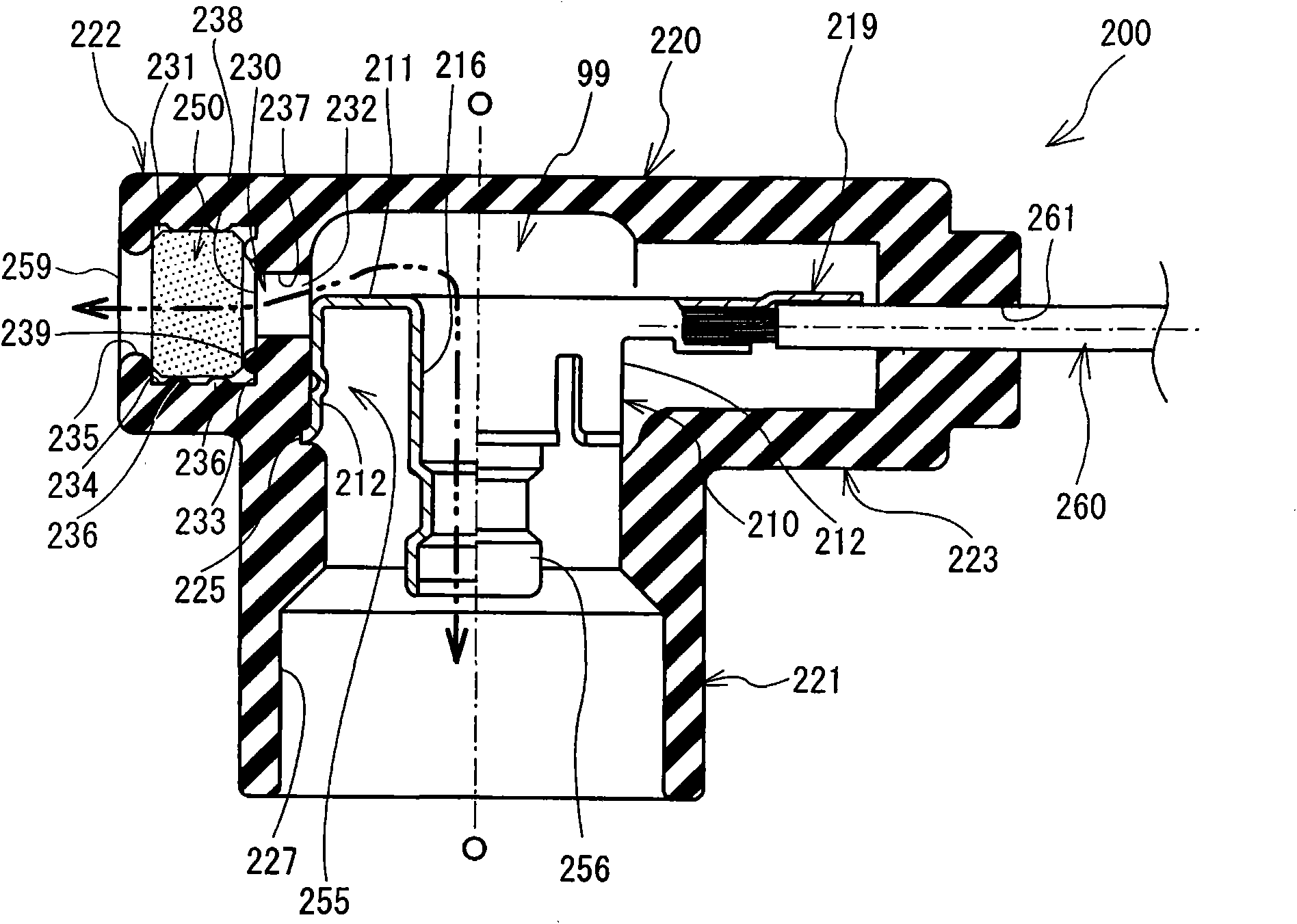

Gas sensor unit

InactiveCN101887044ASuppresses the case of skewed configurationsEnsure ventilation areaMaterial analysis by electric/magnetic meansVentilation volumeEngineering

The present invention provides gas sensor unit capable of ensuring the ventilation volume. A first protruding part (239) is arranged on the connection surface (233) in the filter configuration hole (231). The inner surface (252) of the filter member (250) configured in the filter configuration hole (231) is only contacted to the front end part of the protruding part (239). A gap (257) is formed between the inner surface (252) and the connection surface (233), so as to prevent the close contact of the inner surface (252) and the connection surface (233). At this point, parts on the inner surface (252) except the part contacted with the filter configuration hole (231) totally face to the gap (257). Therefore, compared with the prior instance that the inner surface (252) and the connection surface (233) are in close contact, the ventilating area in the inner surface (252) can be increased, thereby increasing the ventilation volume in the filter member (250).

Owner:NGK SPARK PLUG CO LTD

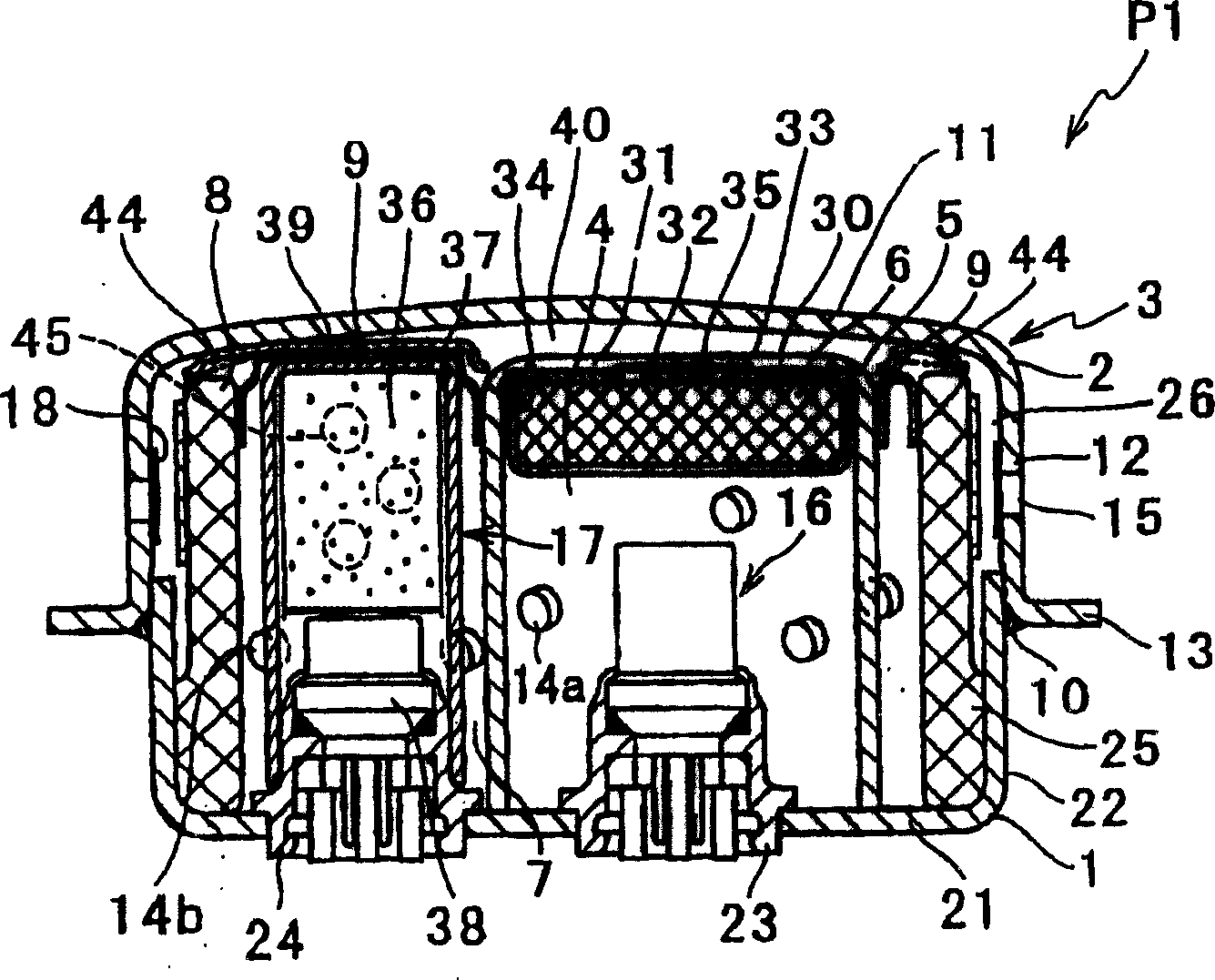

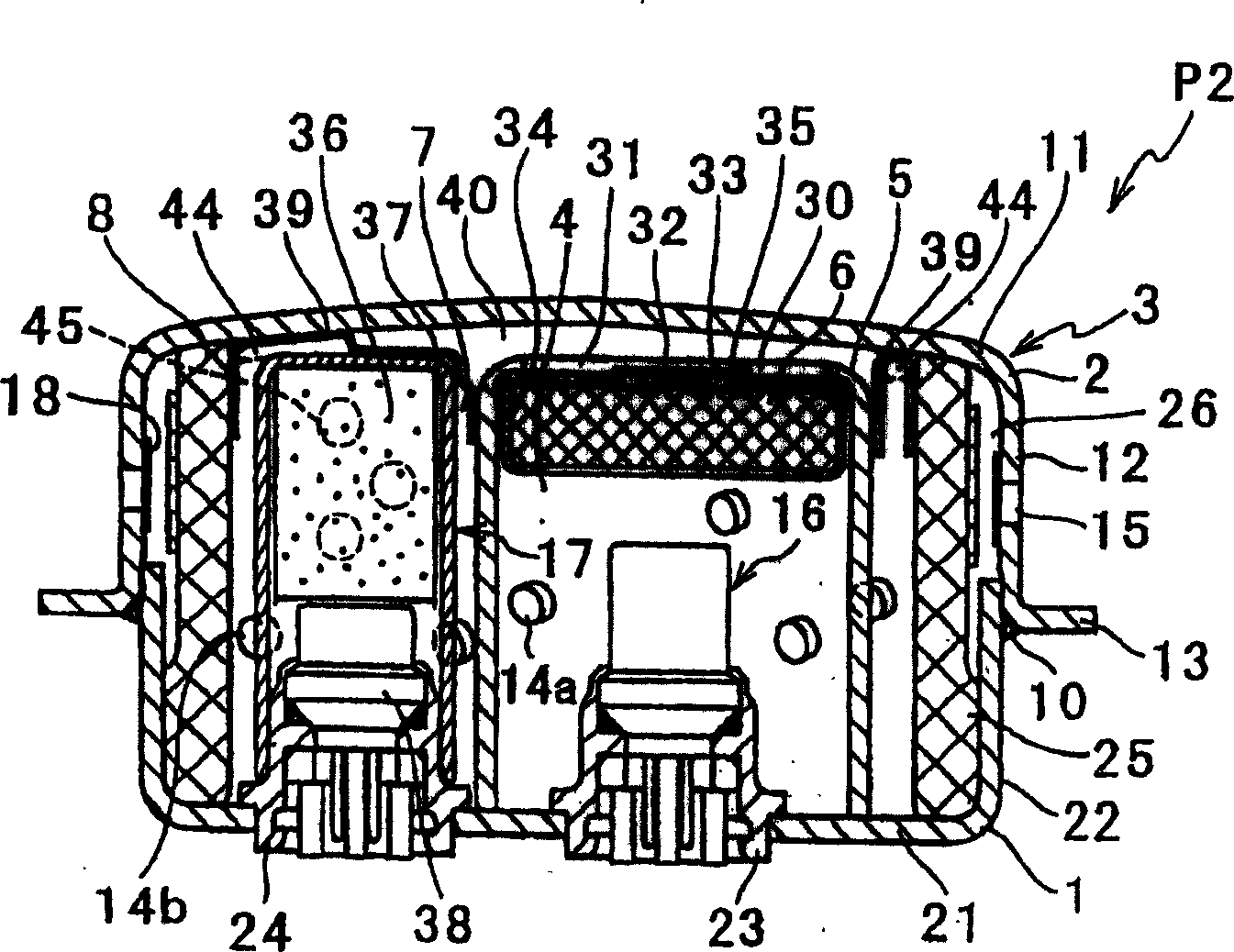

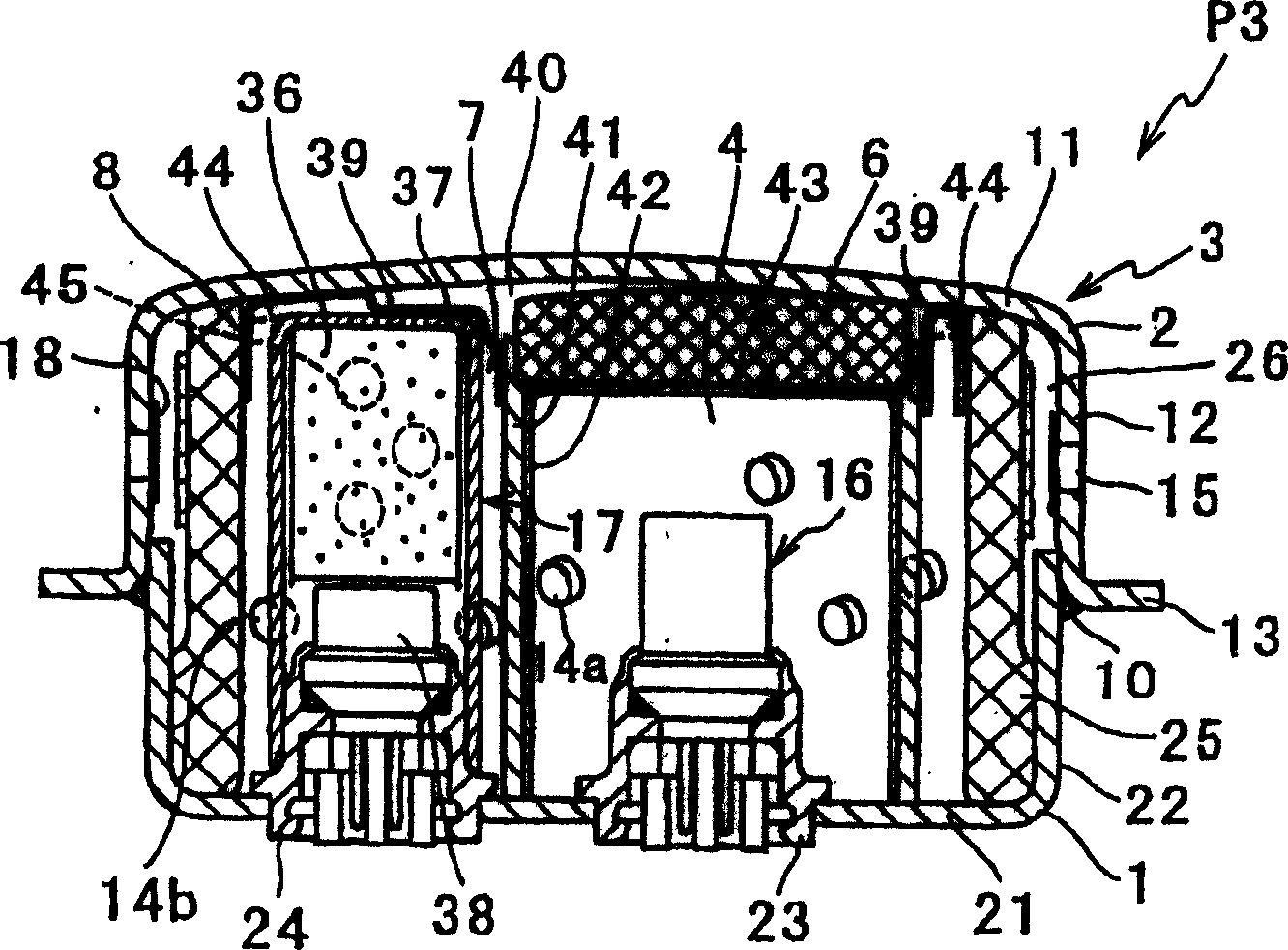

Gas generator

InactiveCN1635963AEnsure the flow pathAvoid deformationPedestrian/occupant safety arrangementCombustion chamberEngineering

A gas generator comprising the following parts: a cylindrical cover (3) composed of an initiation shell (1) and a closing shell (2) with a plurality of ignition devices (16, 17); formed on the cover ( 3) and a combustion chamber filled with gas generating agents (14a, 14b); a cylindrical member that divides the above combustion chamber into two or more combustion chambers (4, 7); The filter device (6, 8) in each combustion chamber (4, 7) above the chamber is characterized in that at least one of the above-mentioned filter devices (6, 8) is disc-shaped, and each of the above-mentioned combustion chambers (4, 7 ) are independent of each other.

Owner:NIPPON KAYAKU CO LTD

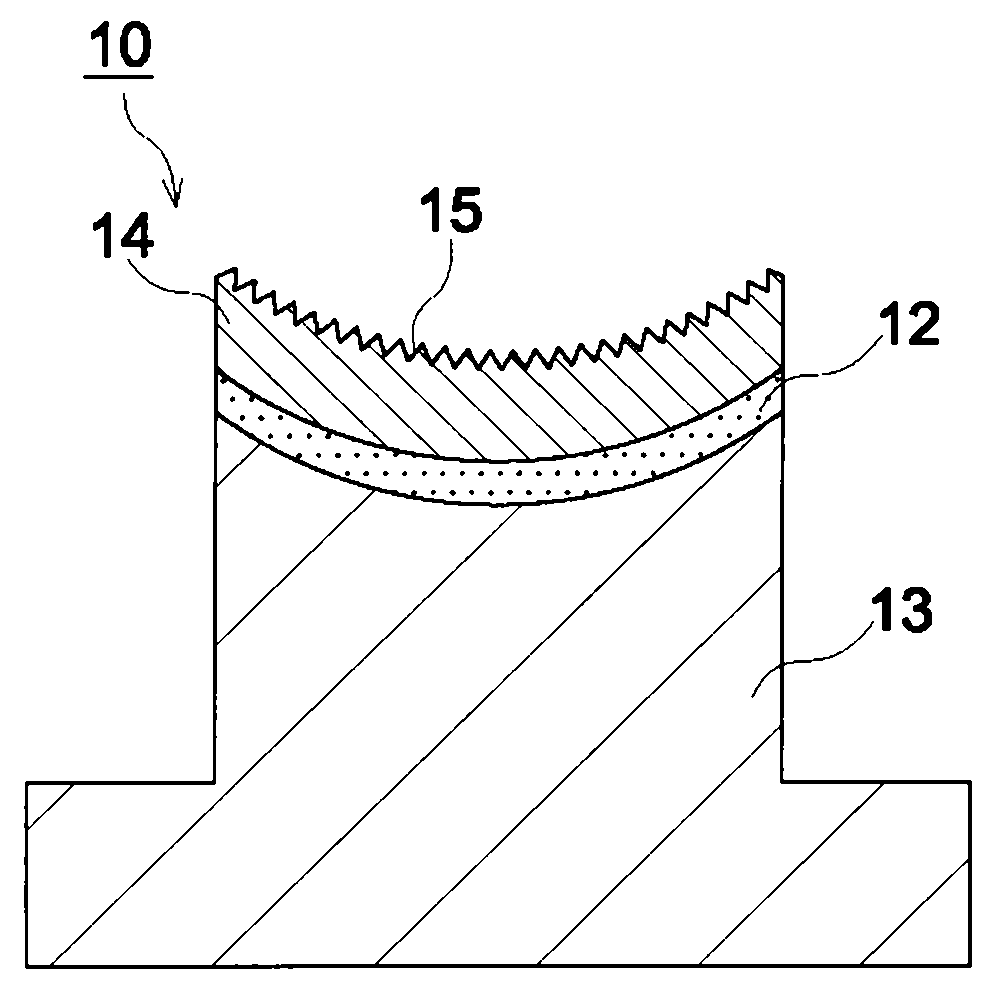

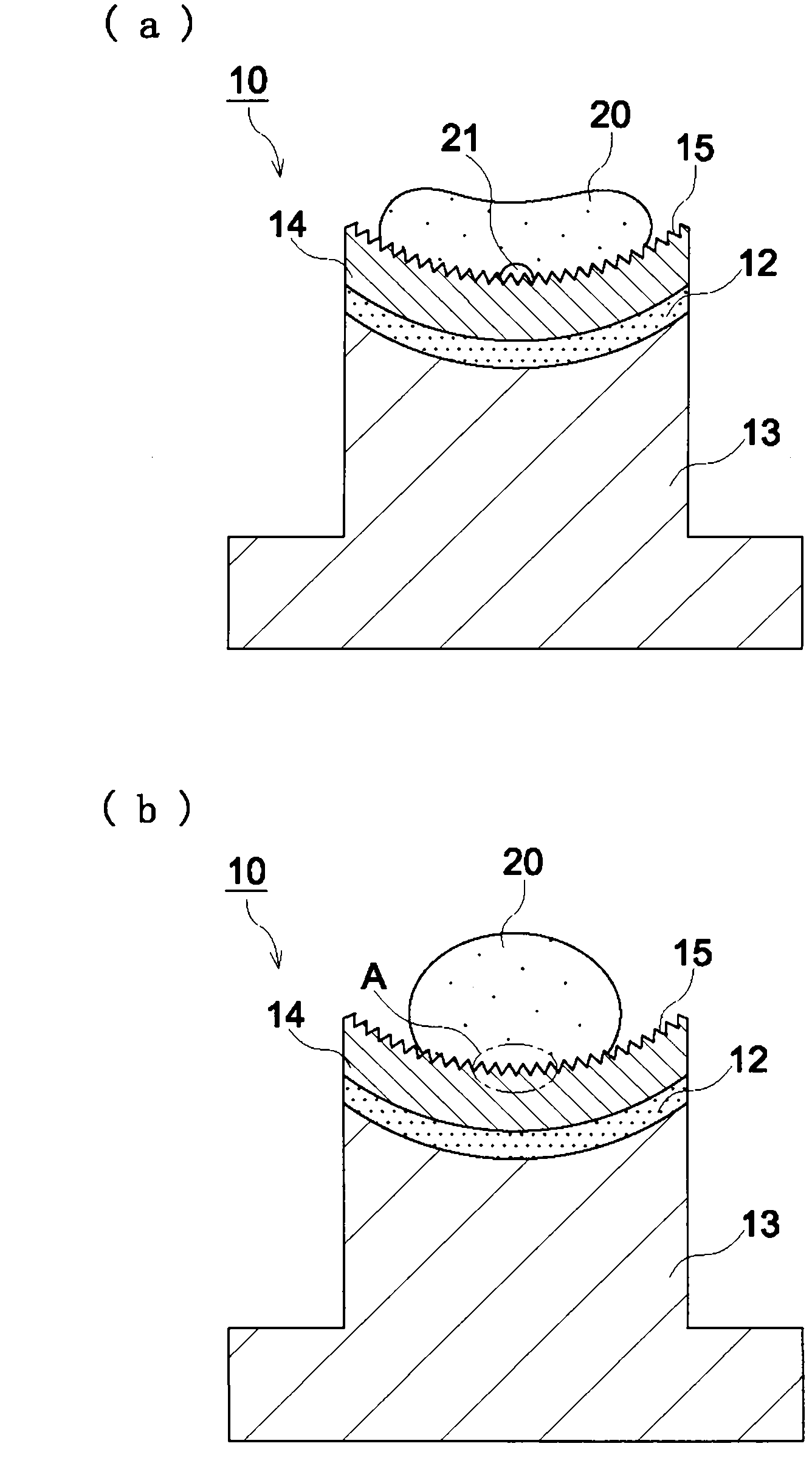

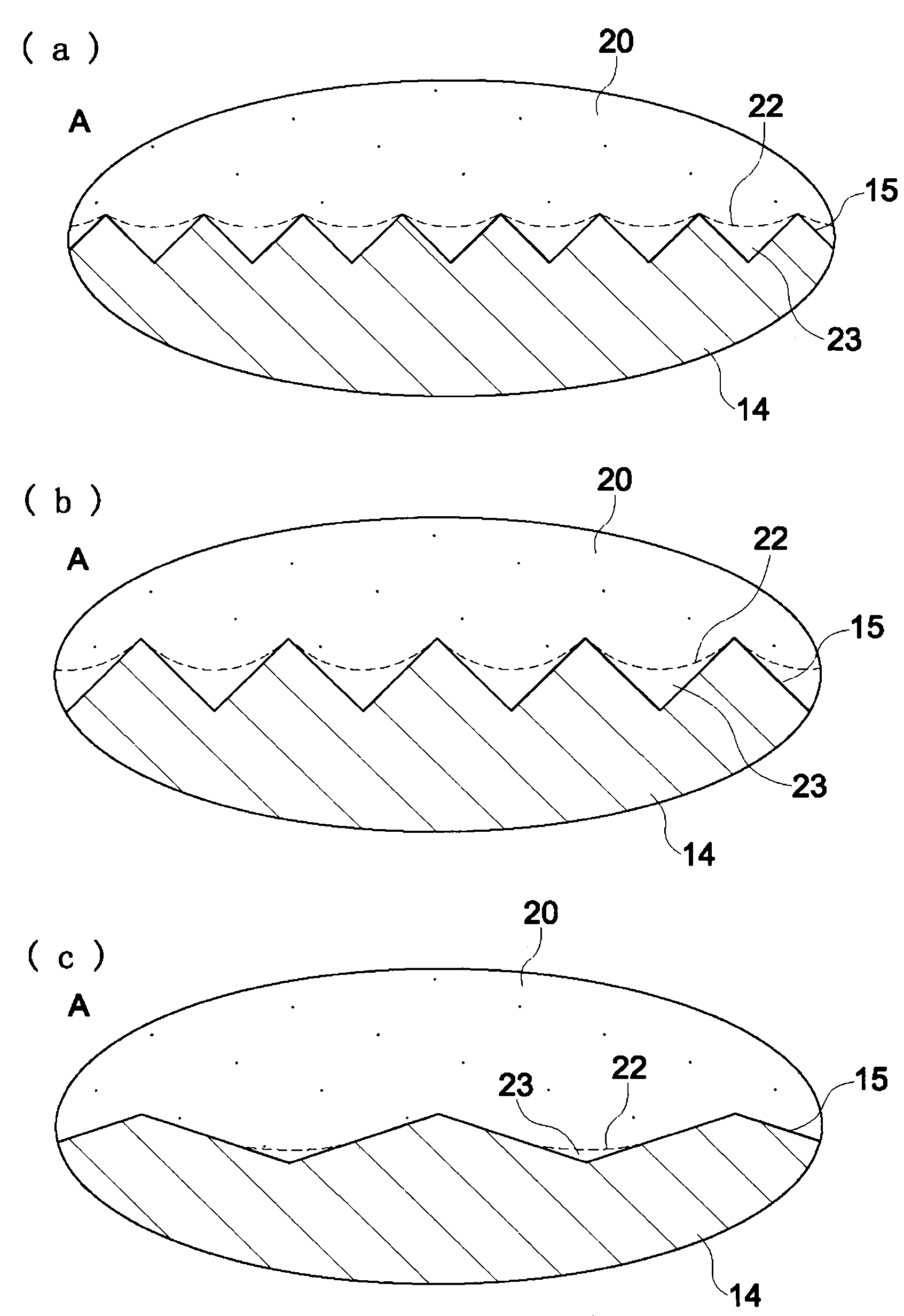

Lower die, production method of lower die, method for producing glass gob, and method for producing glass molded body

ActiveCN101980979AAvoid stockpilingInhibit deteriorationGlass pressing apparatusGlass press-moulding apparatusSurface rougheningMolten glass

Disclosed is a lower die for receiving molten glass drops which were dripped. A coating layer is formed on a base material through an intermediate layer, and surface roughening is performed on the surface of the coating layer in order to increase arithmetic average roughness (Ra). The surface of the coating layer subjected to the surface roughening has an arithmetic average roughness (Ra) of 0.01 [mu]m or more, and an average length (RSm) of a roughness curve element of 0.5[mu]m or less.

Owner:KONICA MINOLTA OPTO

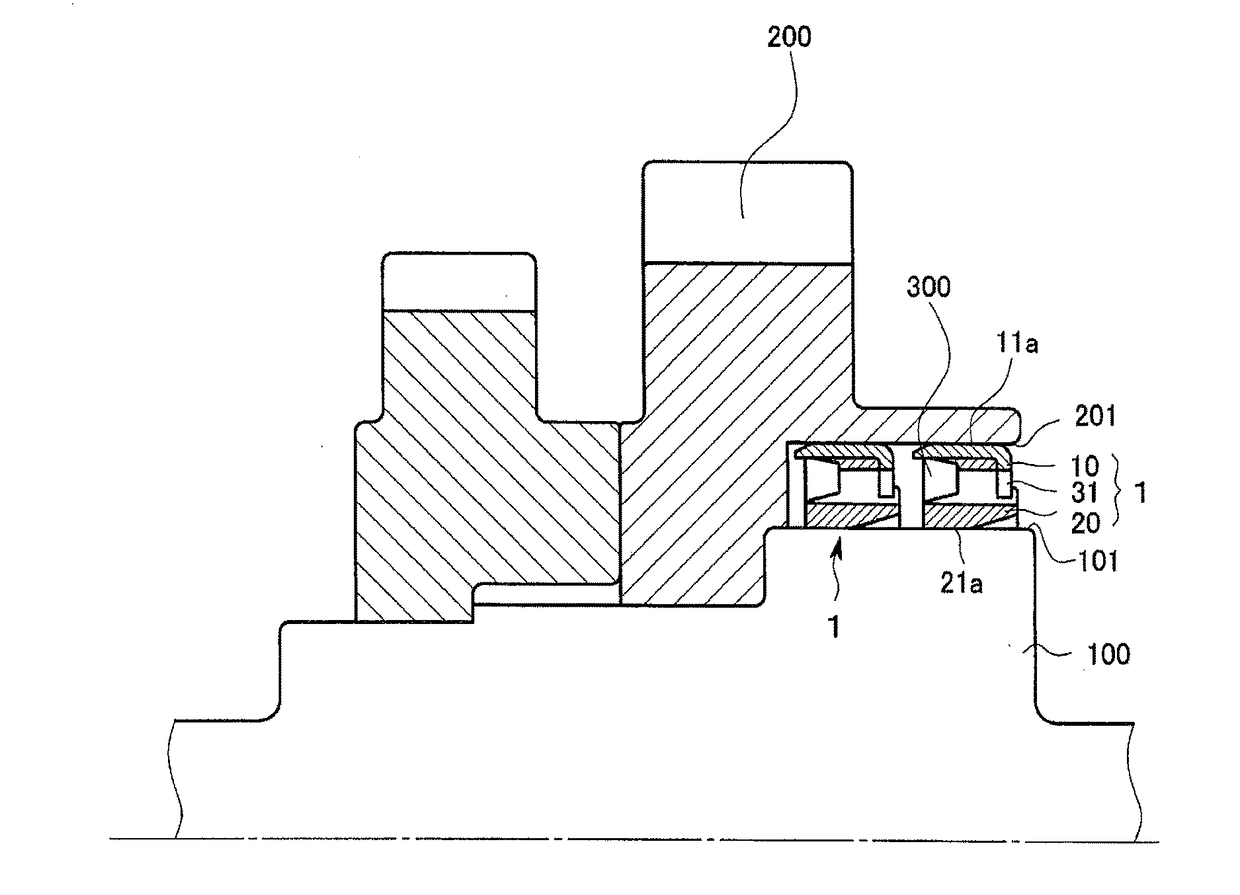

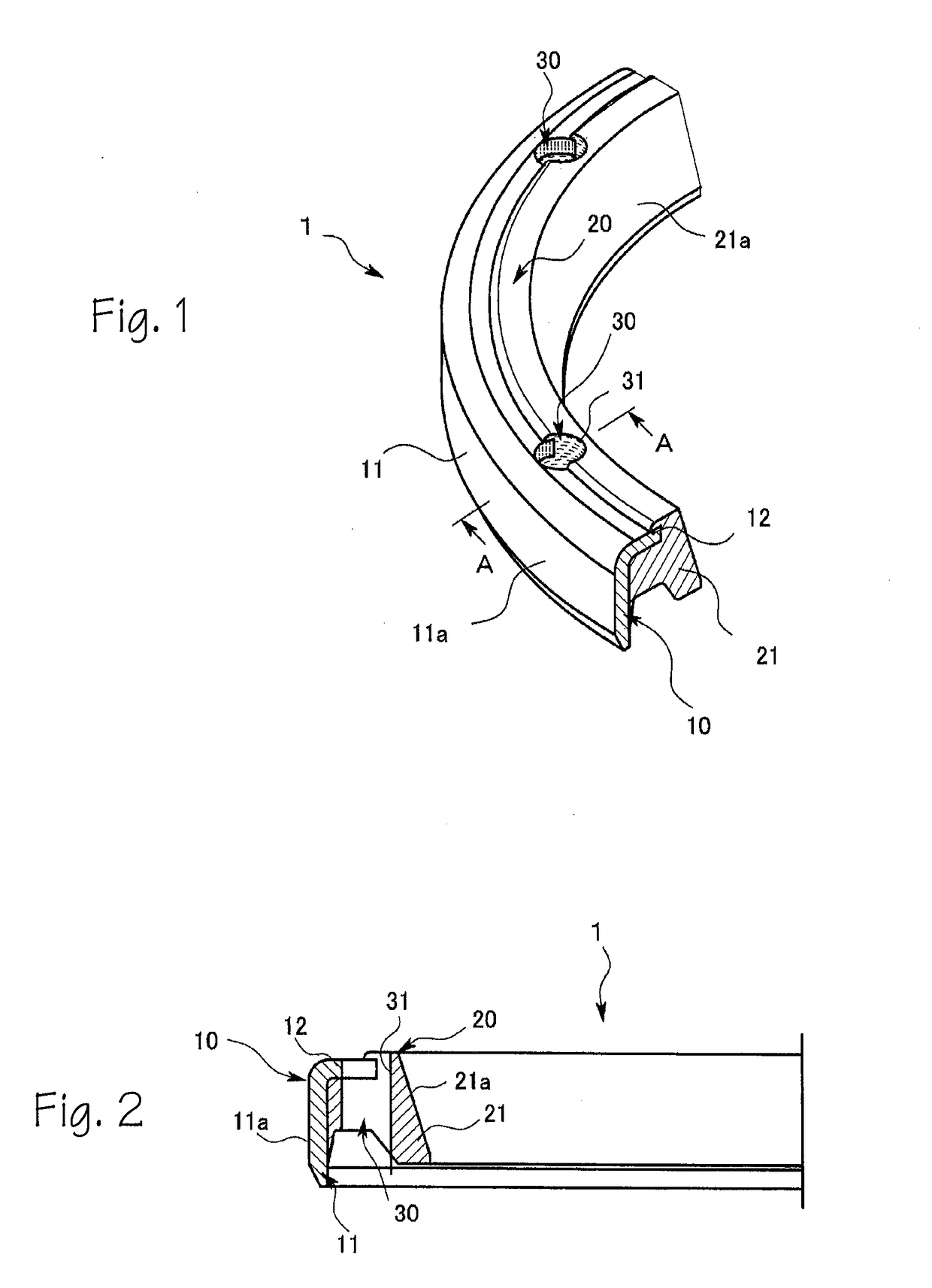

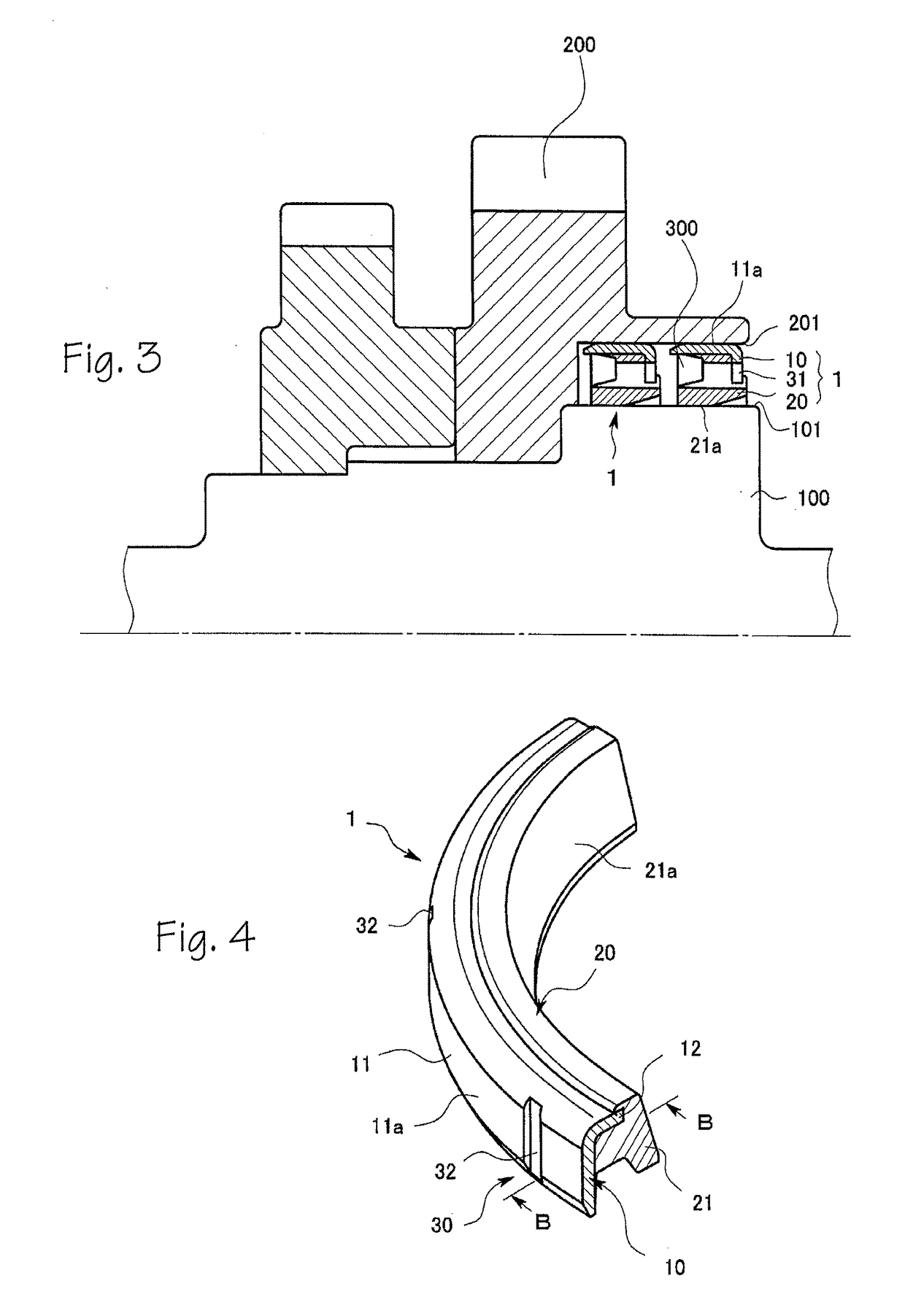

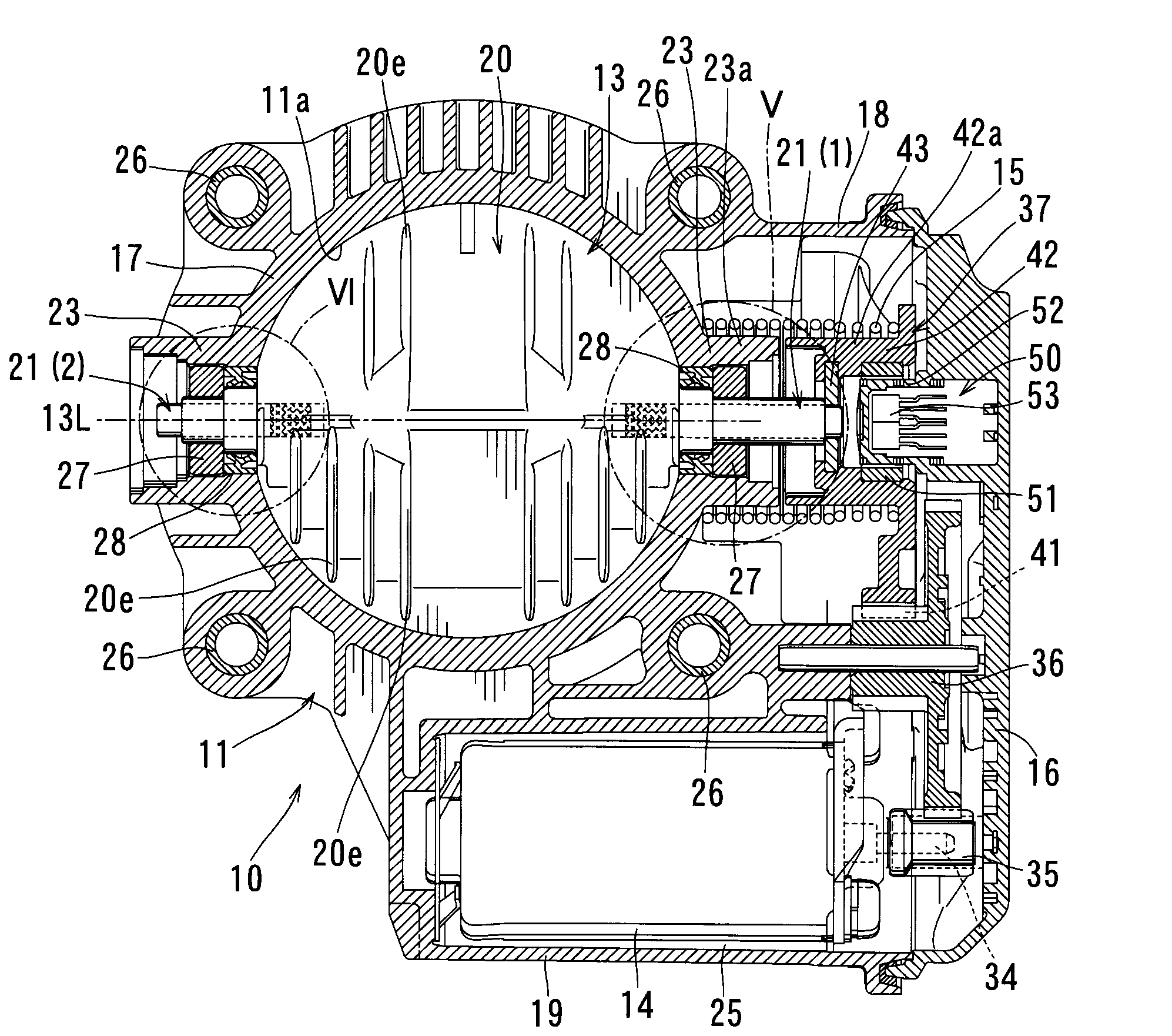

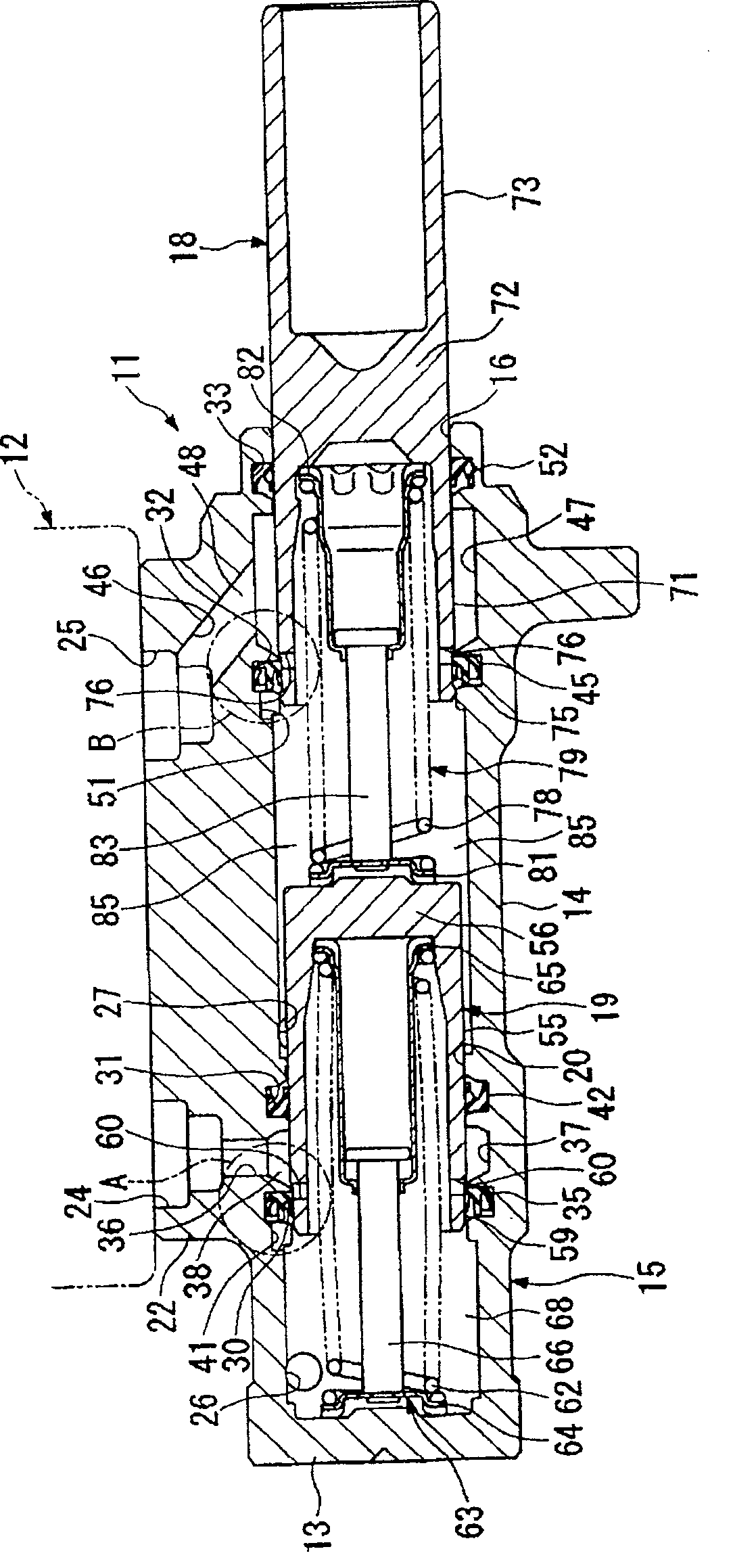

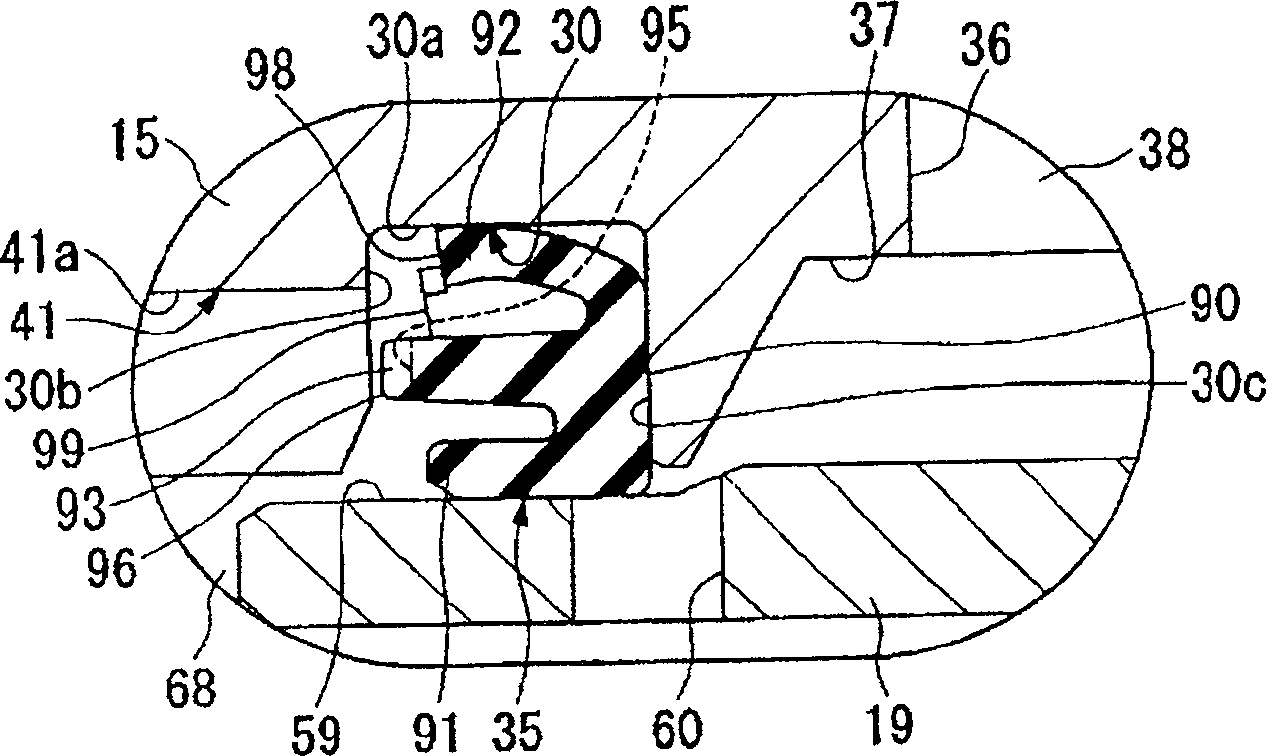

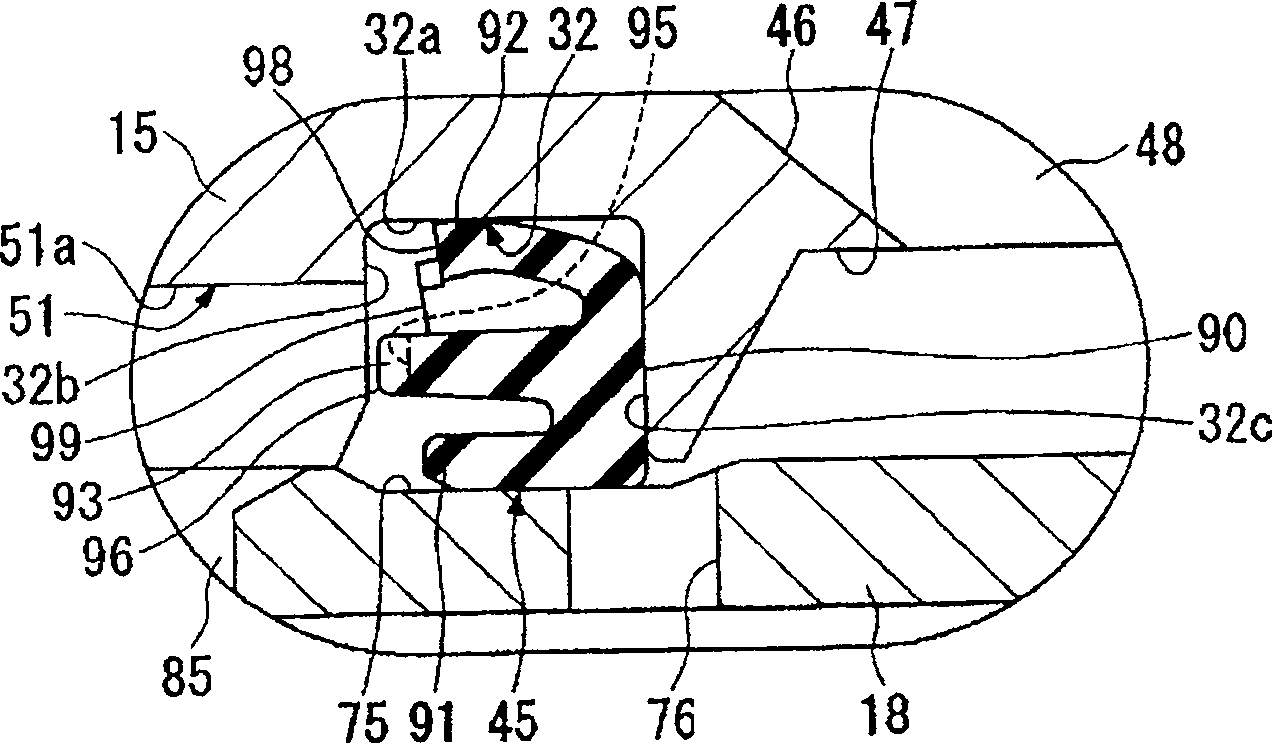

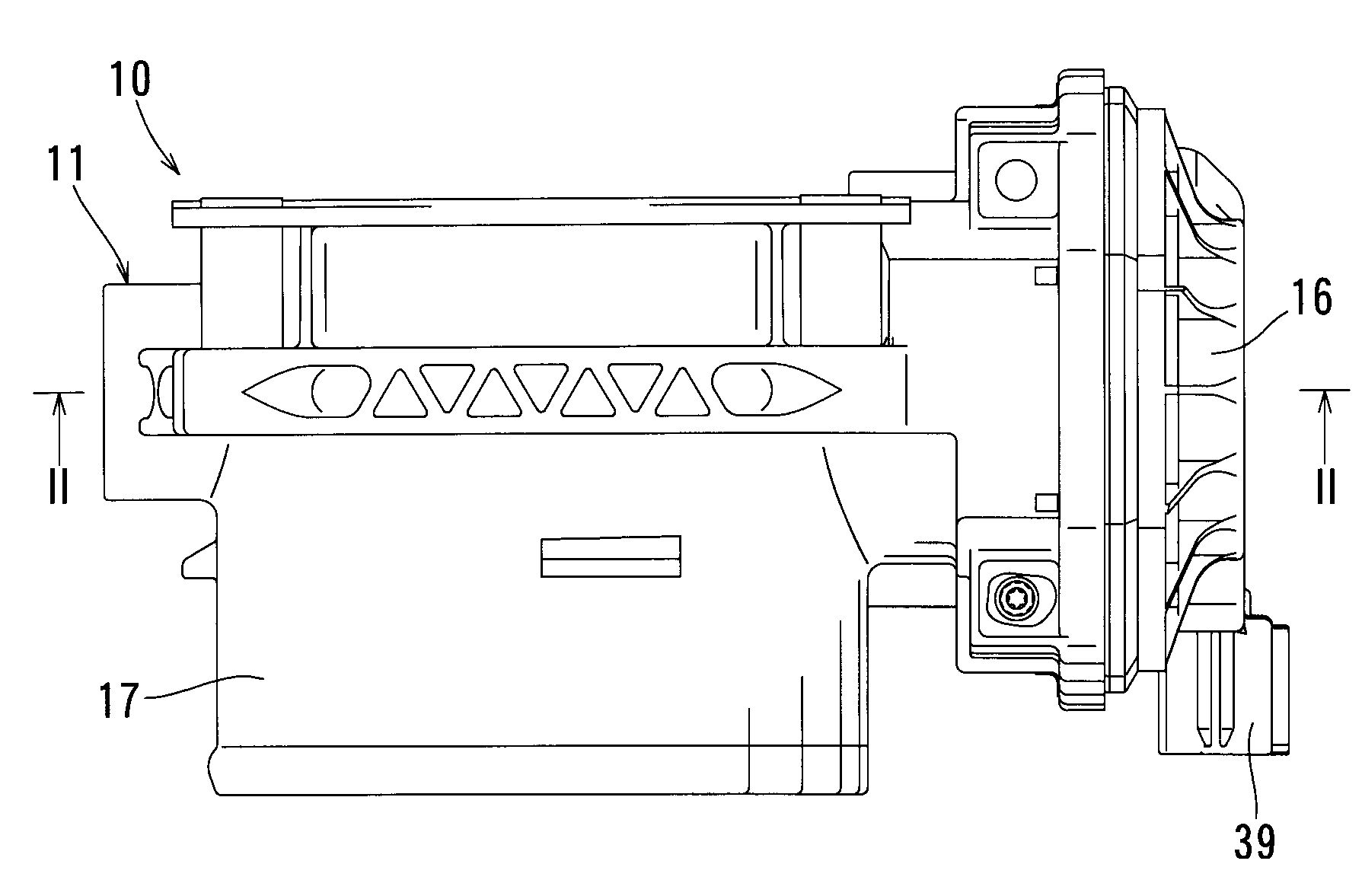

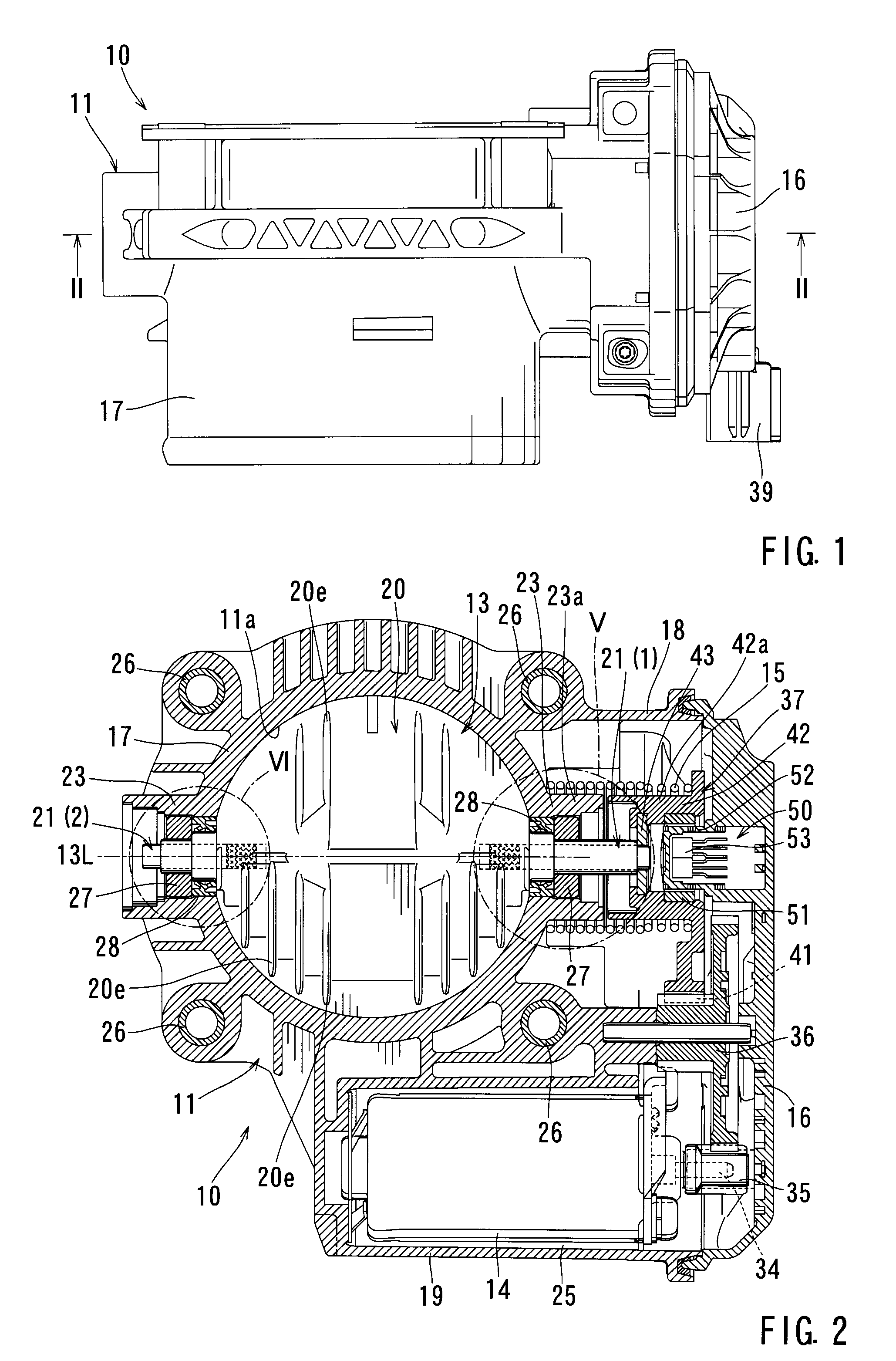

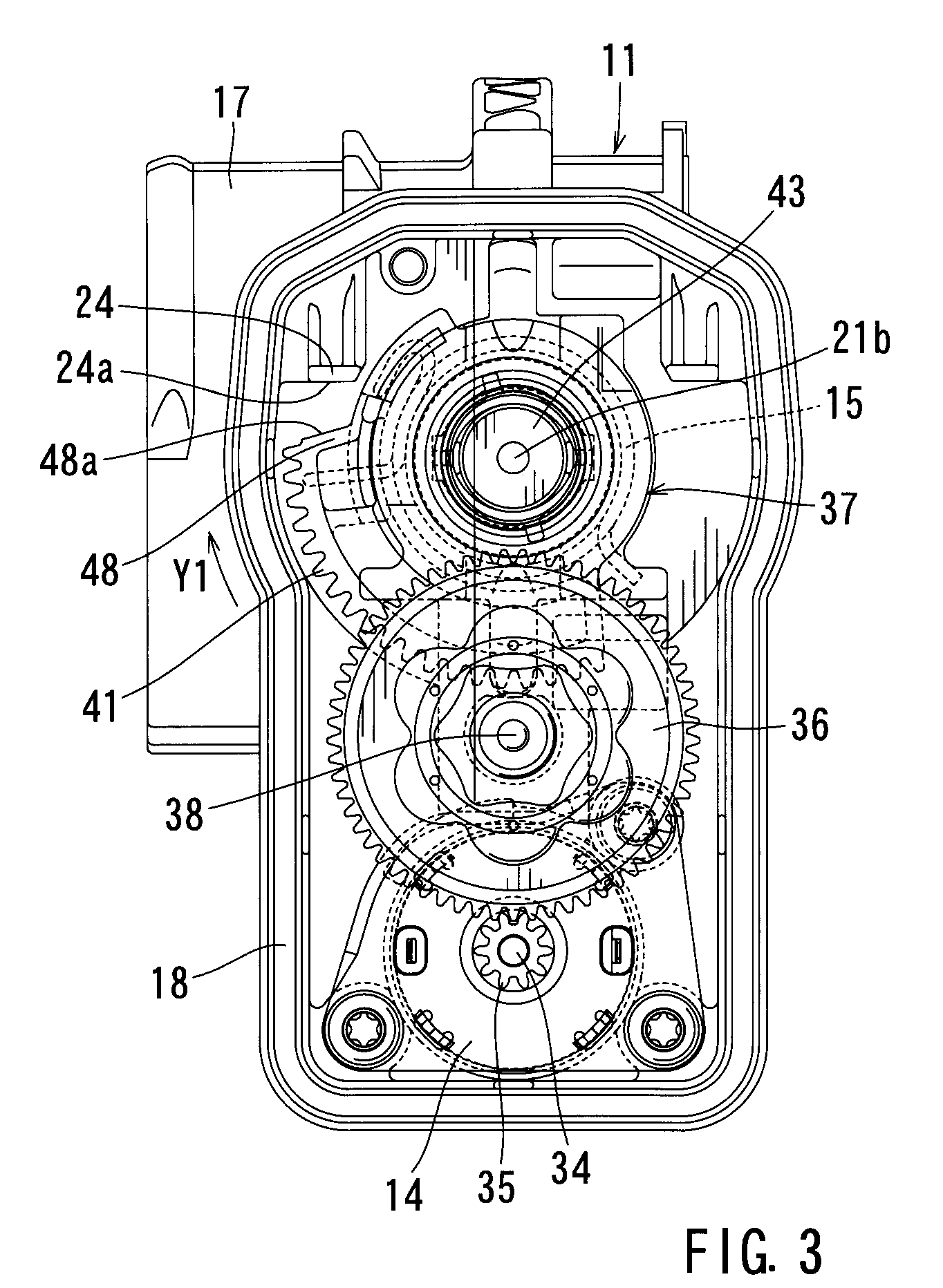

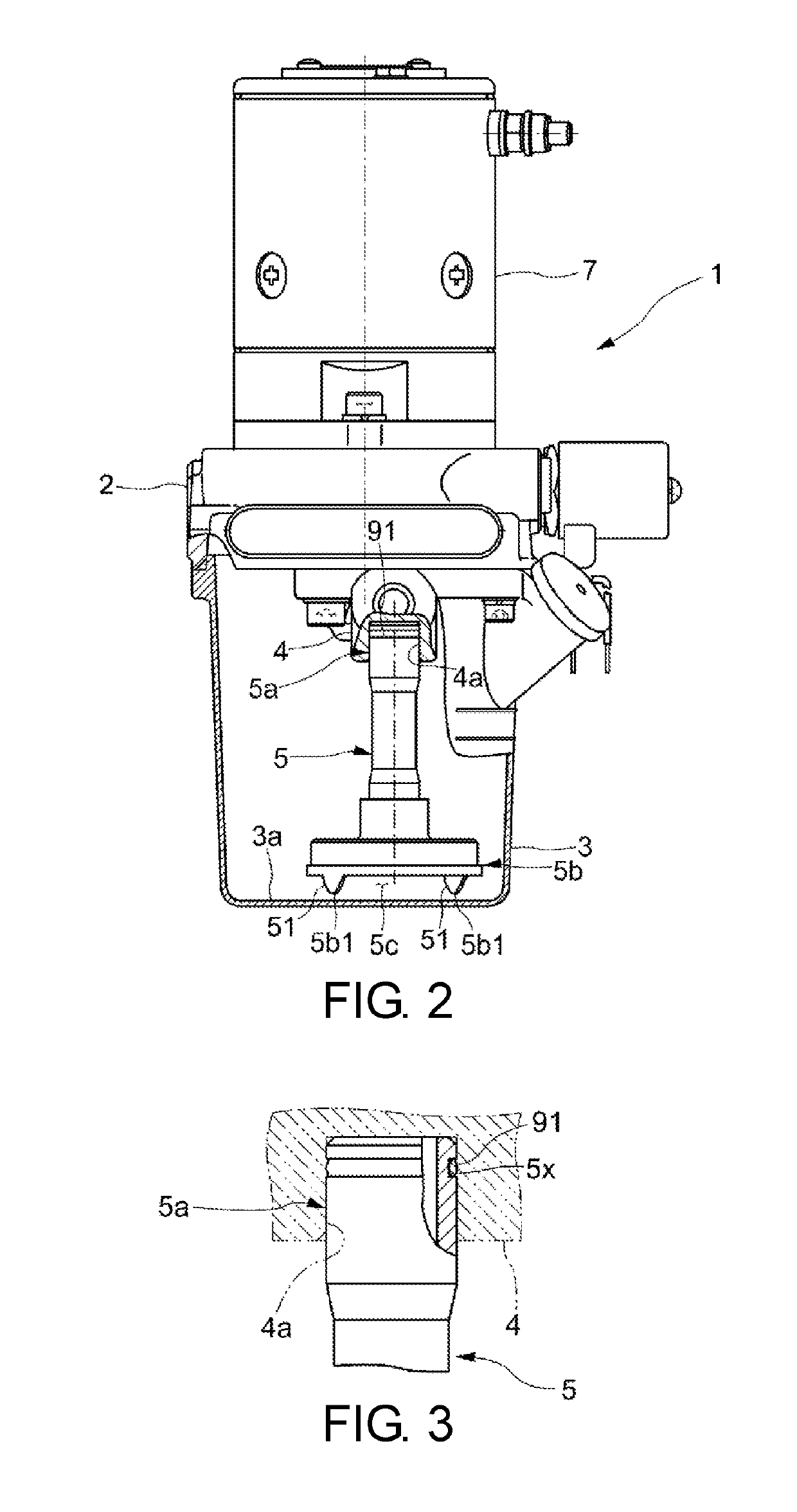

Balance shaft friction damper

InactiveUS20170292585A1Preventing reduction of sliding surfaceStably circulate the lubricantSpringsSprings/dampers design characteristicsEngineeringLubricant

The present invention has an object to provide a balance shaft friction damper (1) capable of preventing a torque reduction of a lip sliding surface while ensuring an axial flow path for a lubricant to stably circulate the lubricant. The object is achieved by a balance shaft friction damper (1) including: a metal mounting ring (10) that is mounted in an annular gap (300) between a shaft portion (100) of a balance shaft of an engine and a gear portion (200) provided on an outer periphery of the shaft portion (100), and has a fitting surface (11a) fitted and secured to one of an outer peripheral surface (101) of the shaft portion (100) and an inner peripheral surface (201) of the gear portion (200); and an annular elastic ring member (20) made of a rubber-like elastic material and provided on the mounting ring (10), and has a lip sliding surface (21a) brought into close contact with the other of the outer peripheral surface (101) of the shaft portion (100) and the inner peripheral surface (201) of the gear portion (200), wherein an oil flow path portion (30) that allows axial circulation of a lubricant is formed in a position across the mounting ring (10) and the elastic ring member (20) and apart from the lip sliding surface (21a), and / or an oil flow path portion (30) that allows axial circulation of a lubricant is formed in a position in the mounting ring (10) and apart from the lip sliding surface (21a).

Owner:NOK CORP

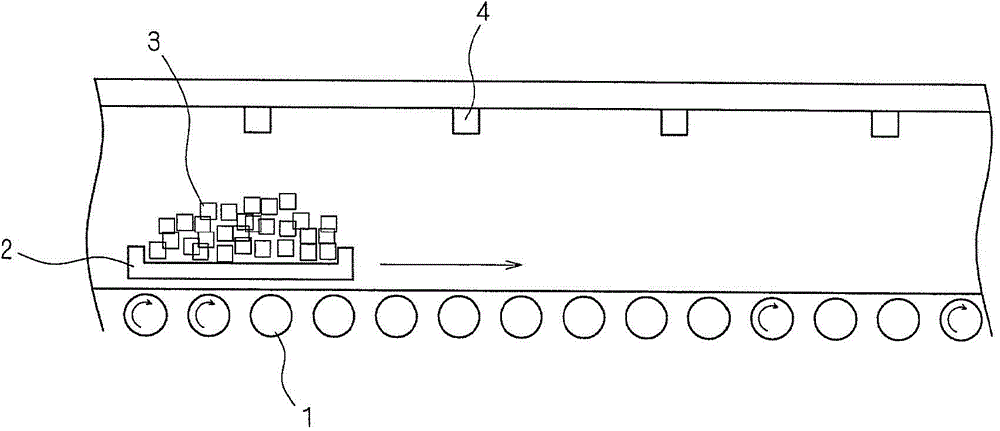

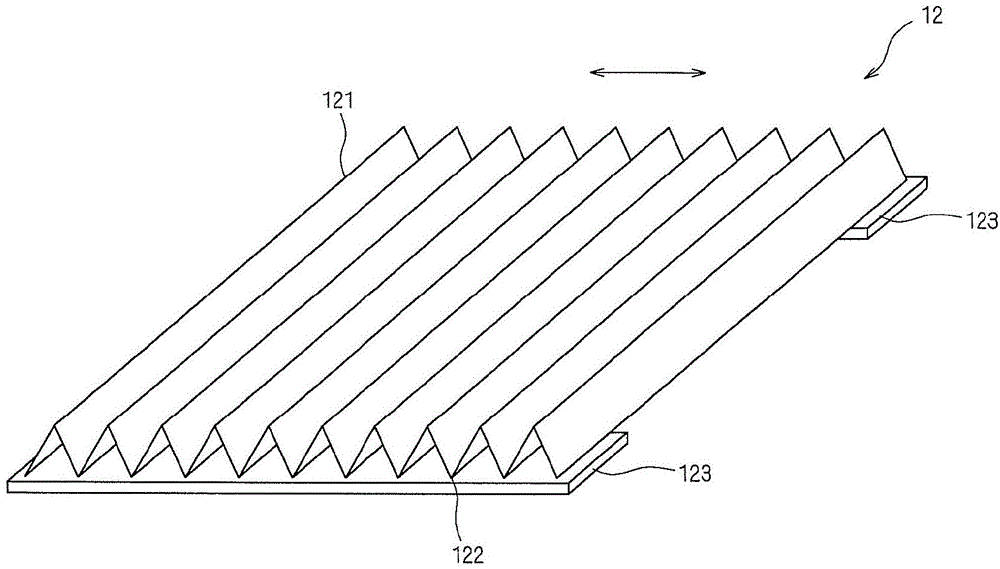

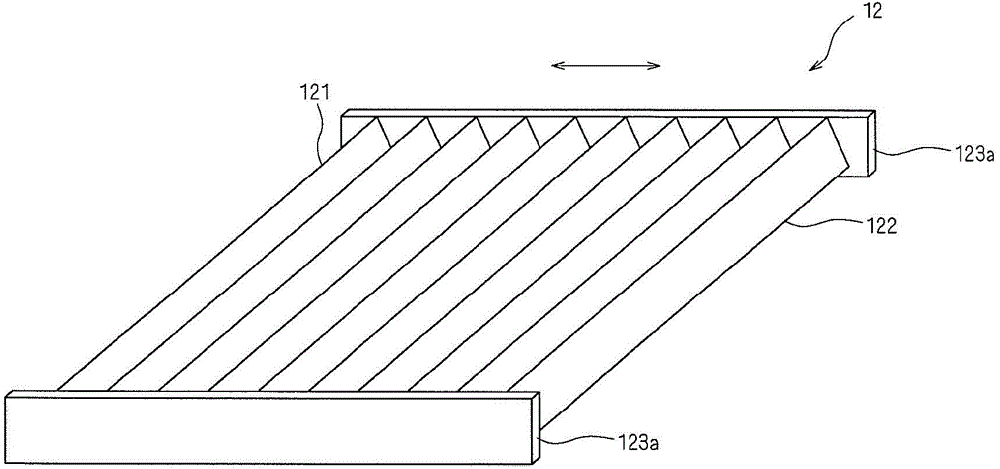

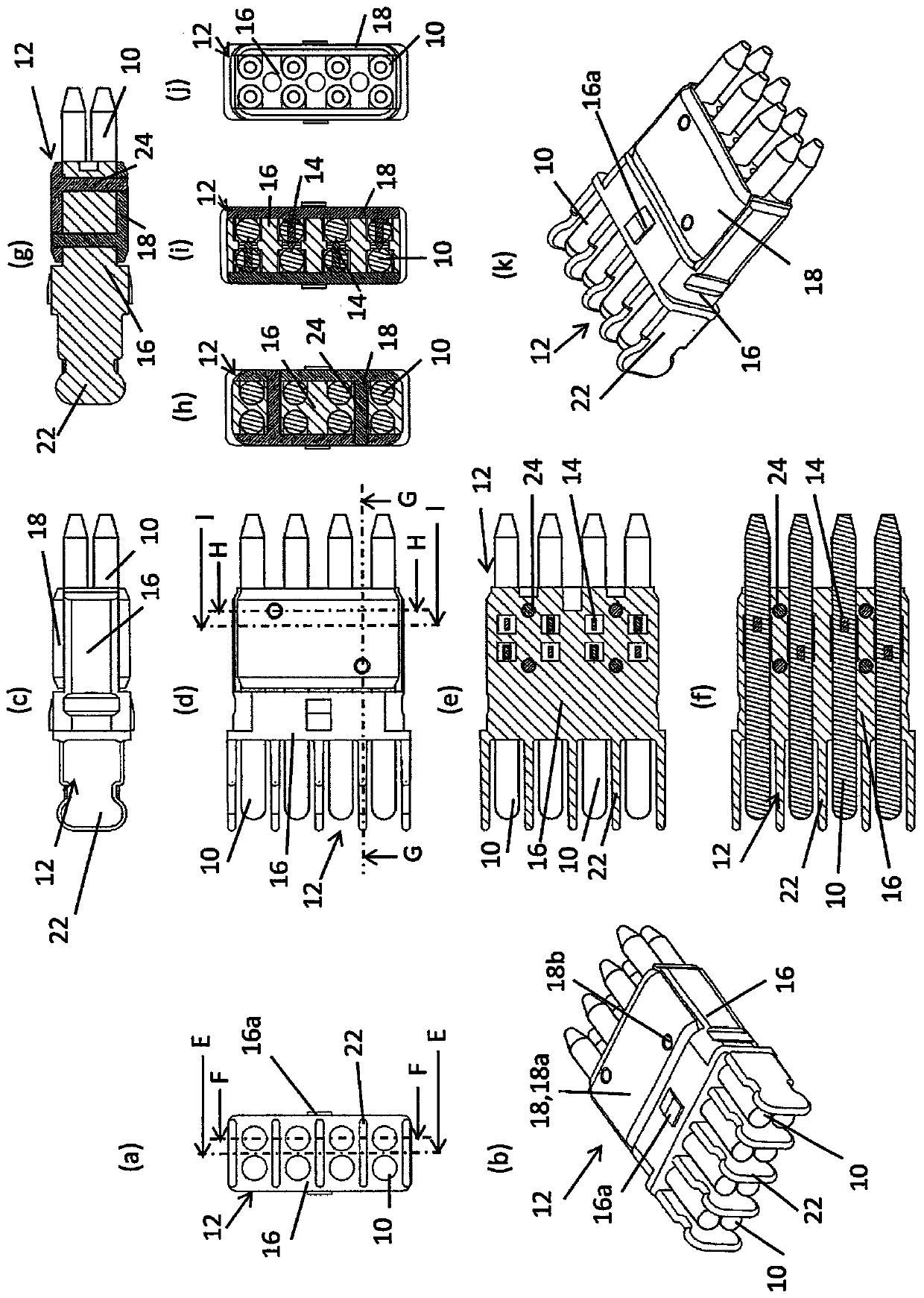

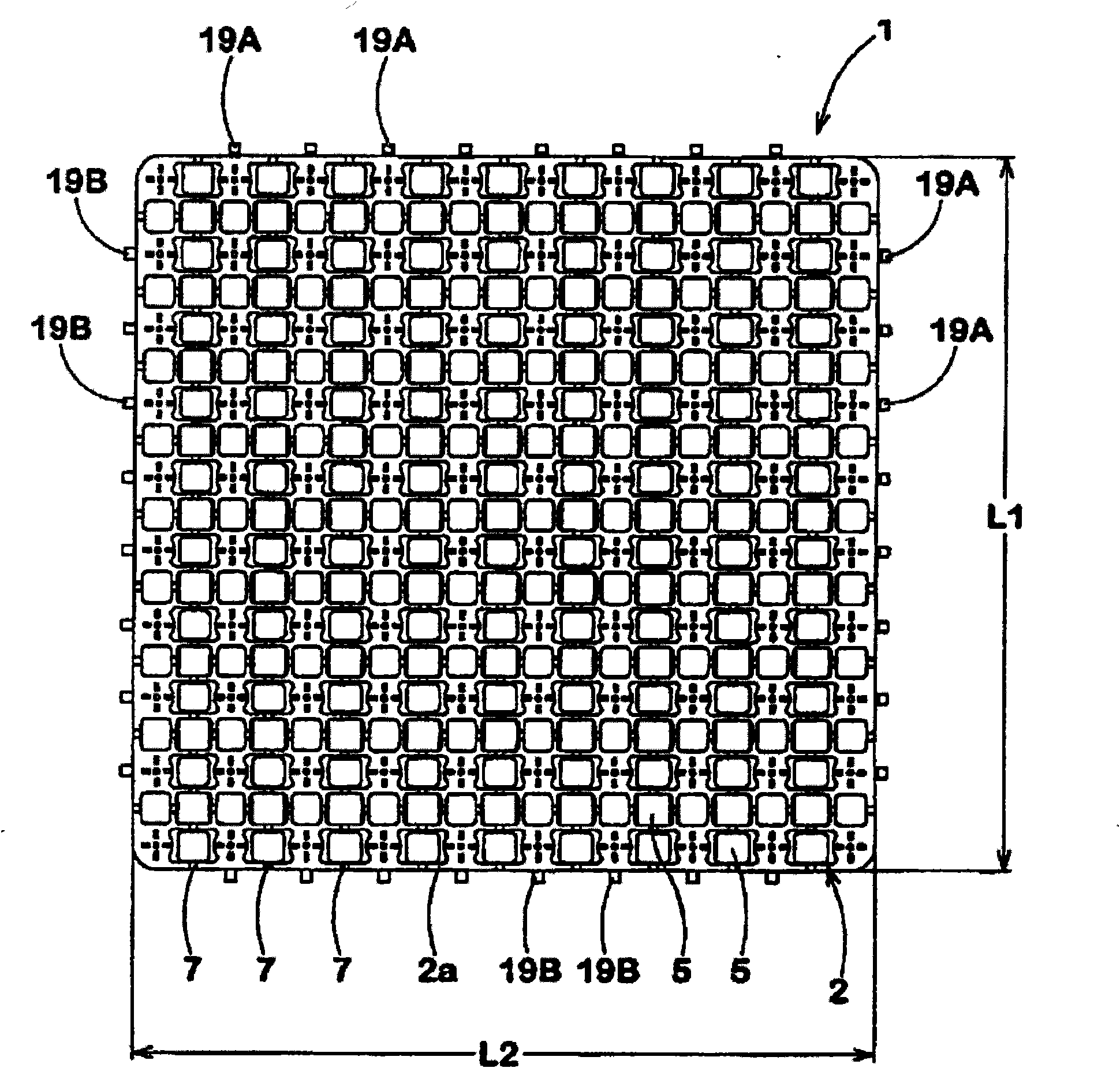

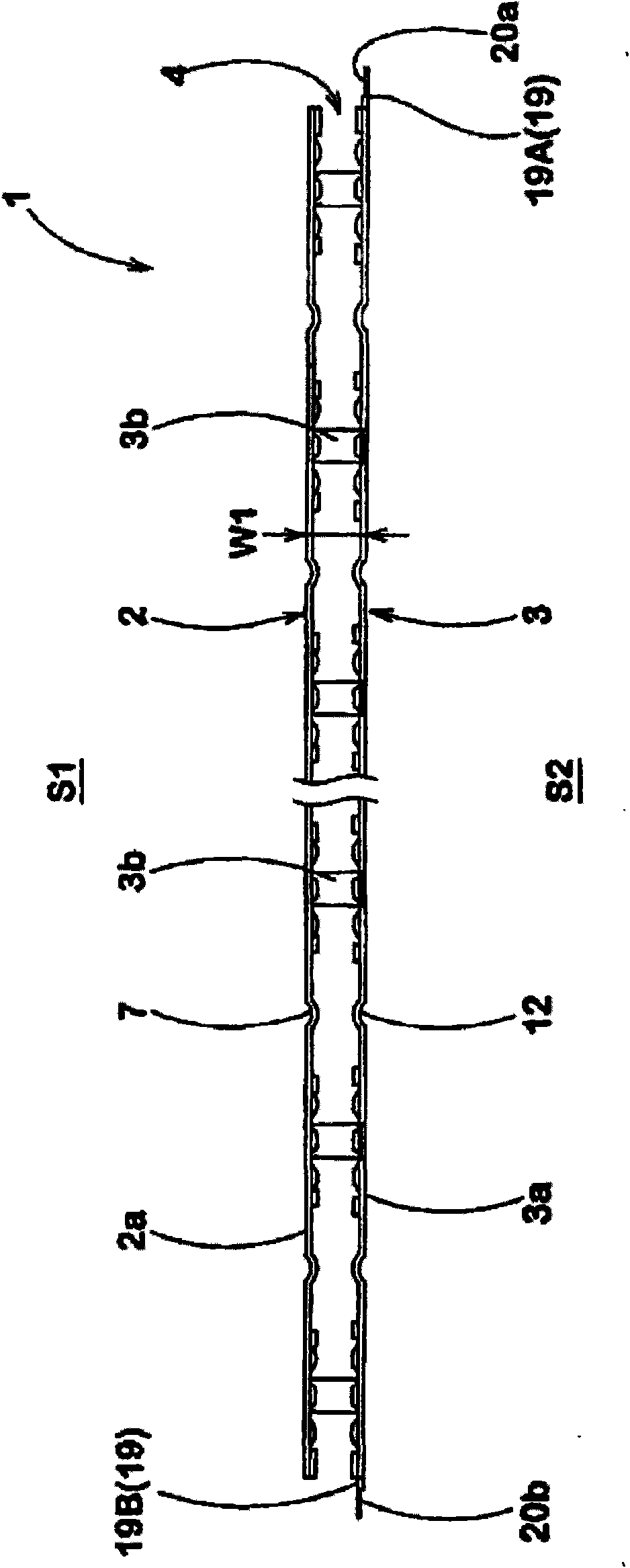

Hot processing clamp

A hot processing clamp (12) is used for hot processing chip electronic parts, and comprises a carrier part; the carrier part is repeatedly folded into peaks and valleys, thus forming a waveform used for carrying the electronic parts; the carrier part has a plurality of through holes bigger than the electronic parts; the clamp also comprises a pair of reinforcement plates (123) for a first reinforcement part; a waveform forward direction is a first direction, a horizontal direction orthogonal to the first direction is a second direction, the reinforcement plate (123) is not arranged on two ends of the first direction of the carrier part, but arranged on a bottom or side portion of two ends of the second direction of the carrier part.

Owner:MURATA MFG CO LTD +1

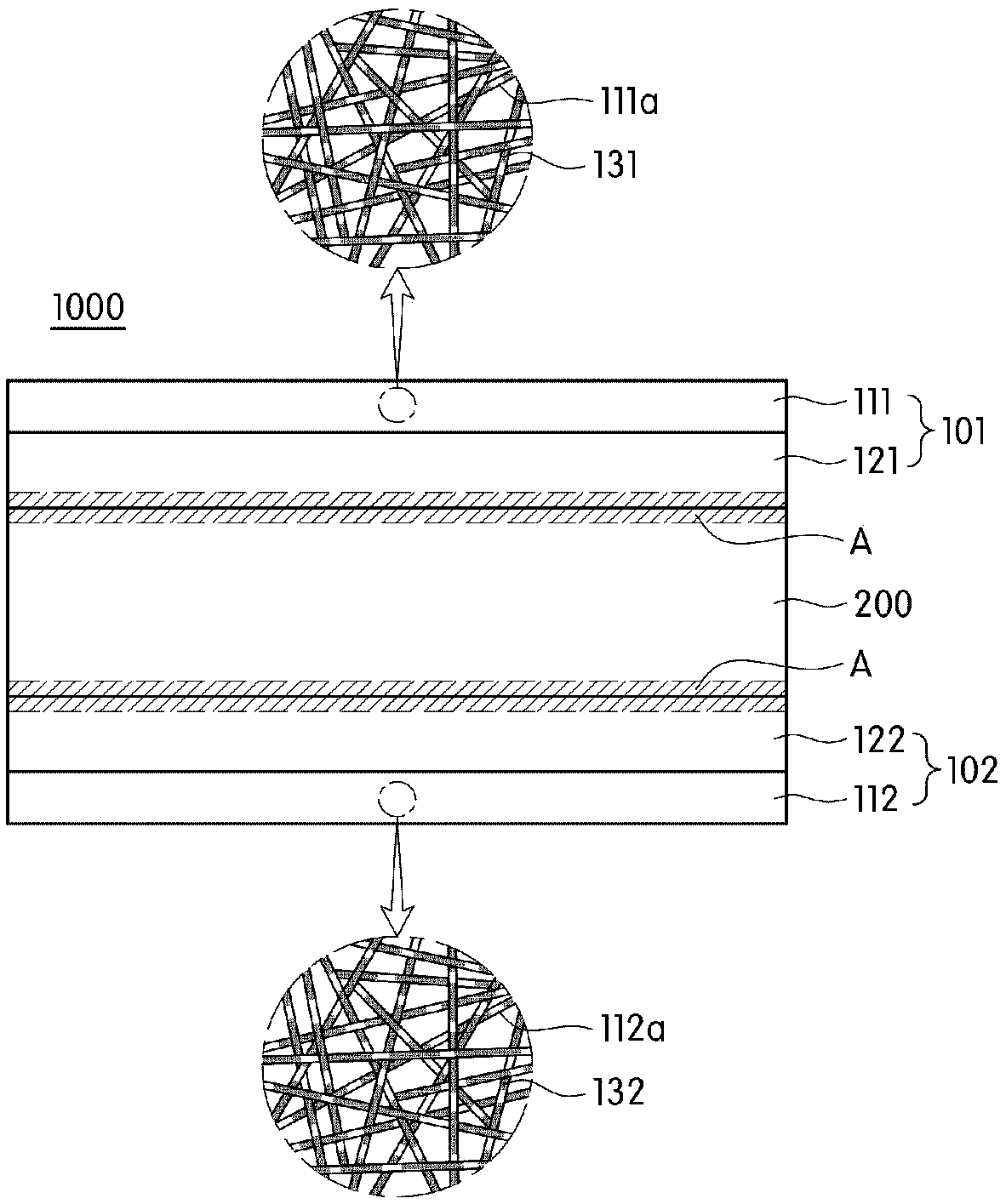

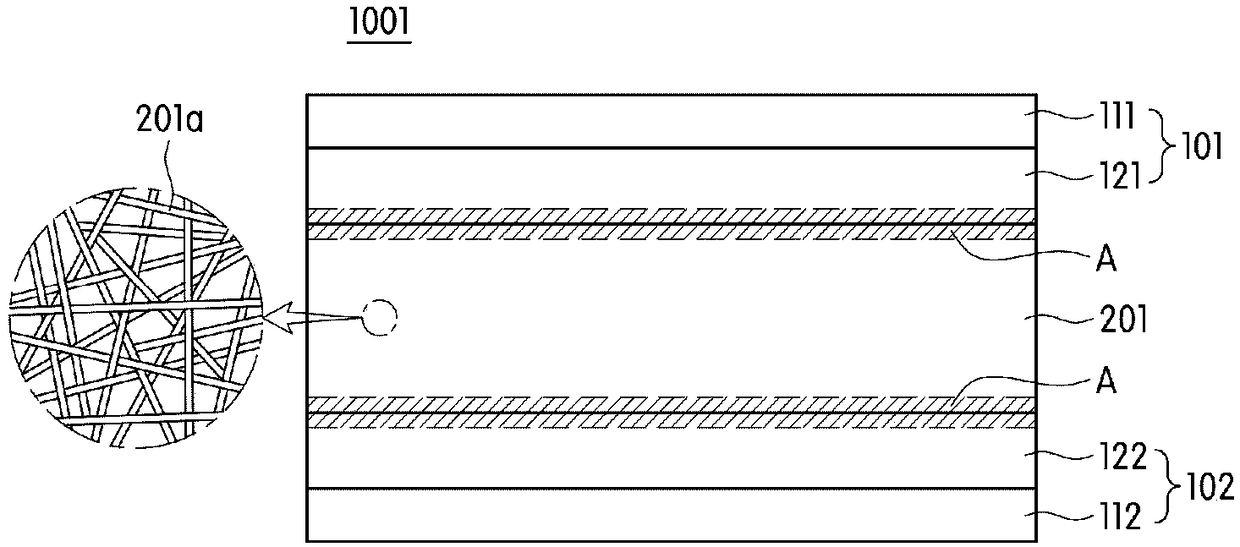

Filter assembly, method for manufacturing same, and filter module comprising same

ActiveCN109219475AFull physical performanceGuaranteed physical propertiesSemi-permeable membranesMembranesFiberHydrophilic coating

A filter assembly is provided. A filter assembly according to an embodiment of the present invention is implemented so as to comprise: a filtration medium comprising a nanofiber, having a three-dimensional network structure, and having a fiber web layer comprising a hydrophilic coating layer that covers at least a part of the outer surface of the nanofiber; and a first support body that supports the filtration medium, which is provided on both surfaces thereof, and has a channel formed therein. Accordingly, the filtration medium has excellent chemical resistance and improved hydrophilicity such that the flow rate can increase substantially. In addition, the improved hydrophilicity is maintained for a long period of time such that the utilization period can be extended substantially. Furthermore, any change in the pore structure of the filtration medium during the hydrophilicity endowing process is minimized such that the initially designed physical characteristics of the filtration medium can be fully exhibited. Moreover, the channel is efficiently formed in spite of a high pressure applied during filtration and / or backwashing such that any reduction in the flow rate is prevented,any damage to the membrane is minimized, and the resulting filter assembly having chemical resistance, excellent water permeability, and durability can be variously applied in the water treatment field.

Owner:AMOGREENTECH CO LTD

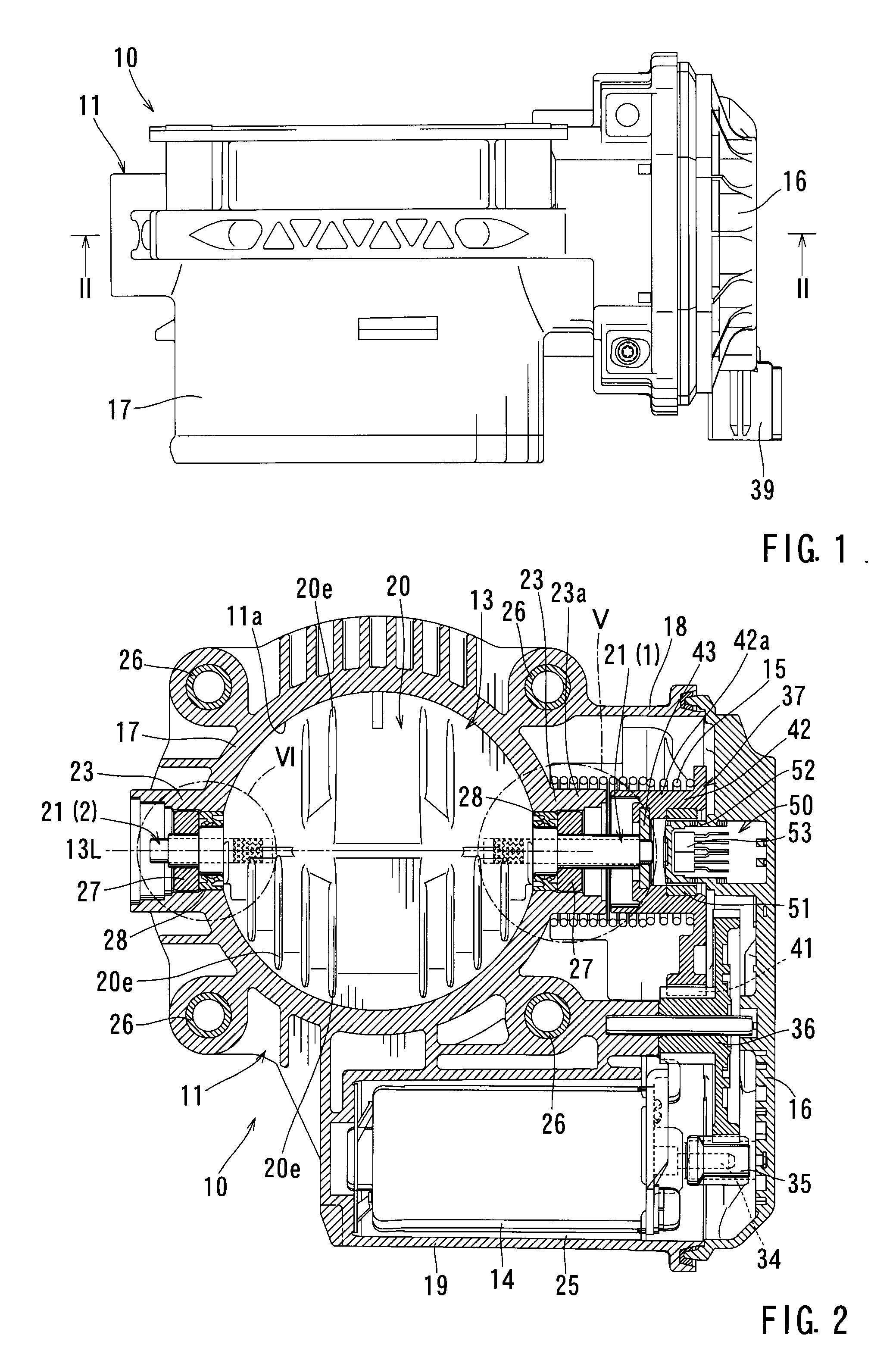

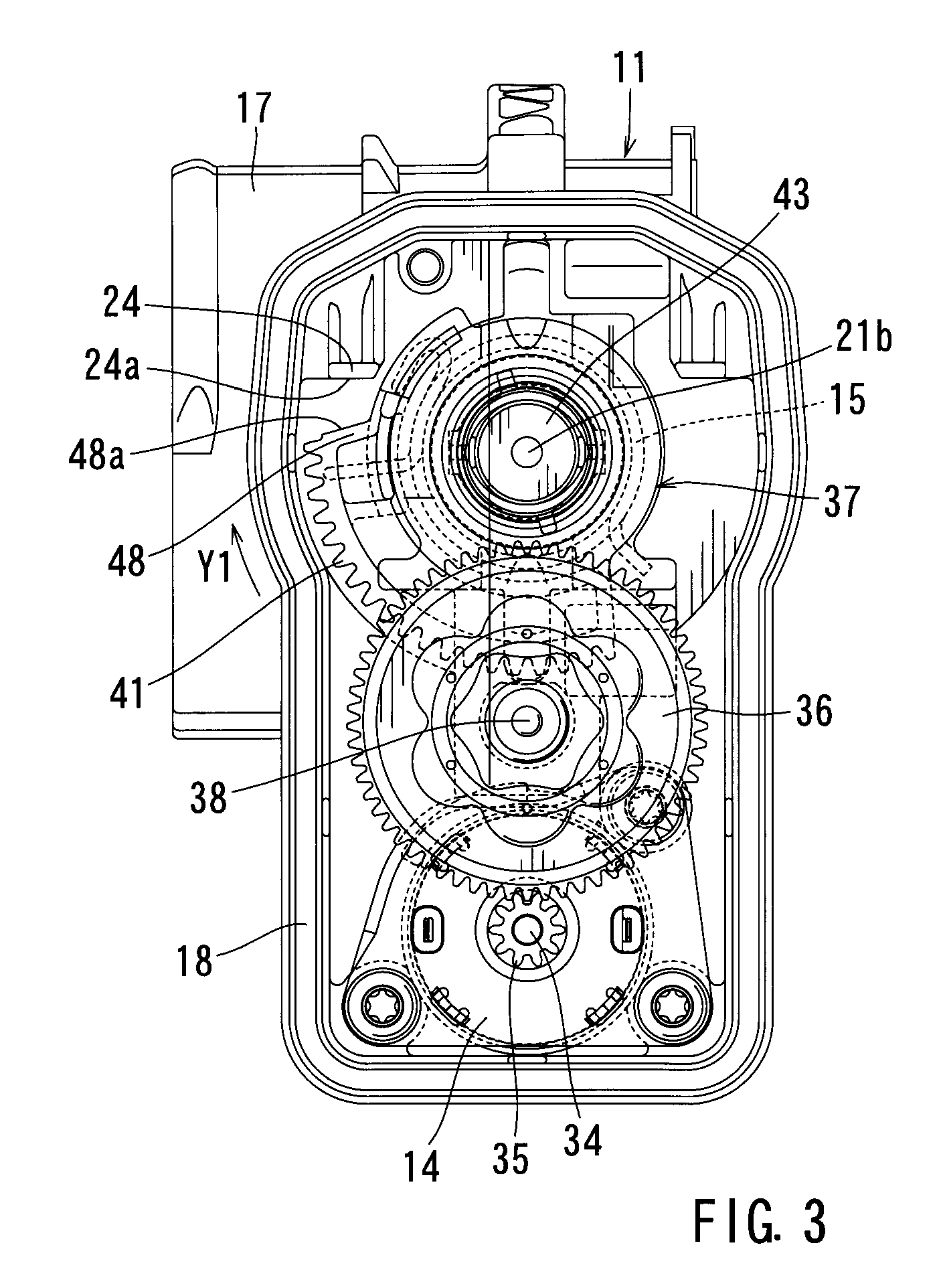

Butterfly valves and intake air control devices for internal combustion engines

The present invention includes a butterfly valve that has a resin valve body and a shaft. The shaft includes a first shaft member and a second shaft member. The first and second shaft members are integrated with the valve body. The first and second shaft members are spaced from each other in an axial direction by a predetermined distance.

Owner:AISAN IND CO LTD +1

Master cylinder

ActiveCN100526130CAvoid stickingEnsure the flow pathFluid braking transmissionMaster cylinderEngineering

Owner:HITACHI LTD

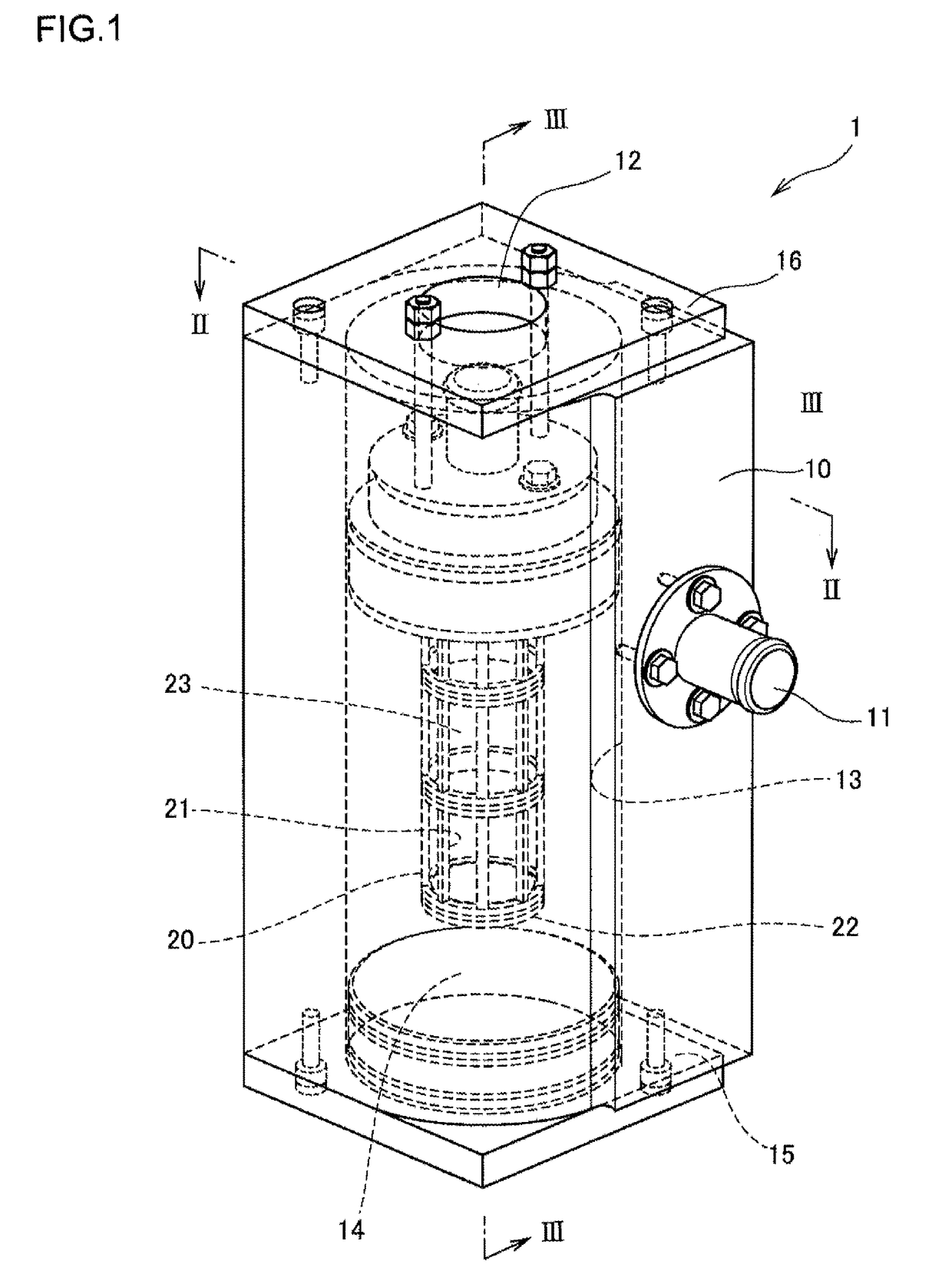

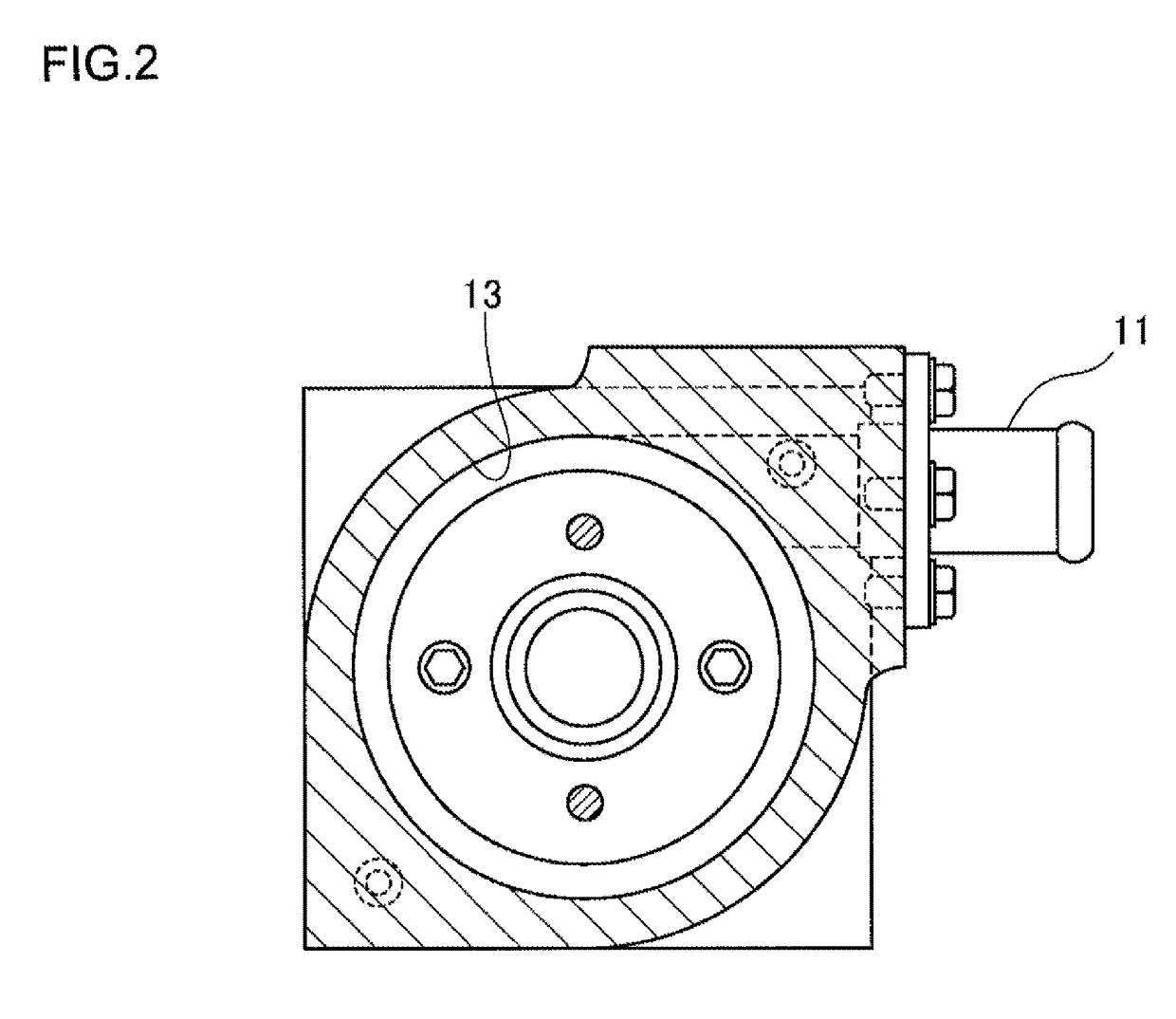

Ion-exchange equipment

ActiveUS20150171440A1Suppress pressure lossReduce pressure lossIon-exchange process apparatusSpecific water treatment objectivesIon exchangeIon

An ion-exchange equipment includes a tank unit formed with a cooling liquid flow-in port and a cooling liquid flow-out port and provided therein with an ion-exchange chamber, and an ion-exchange resin in form of particles filling the ion-exchange chamber of the tank unit. The ion-exchange chamber is provided so as to extend along an axial direction of the tank unit and the ion-exchange chamber has a circular cross section taken perpendicularly to the axial direction of the tank unit, and the cooling liquid flow-in port is formed so as to extend in a tangential direction of the ion-exchange chamber.

Owner:ROKI CO LTD

Butterfly valves and intake air control devices for internal combustion engines

The present invention includes a butterfly valve that has a resin valve body and a shaft. The shaft includes a first shaft member and a second shaft member. The first and second shaft members are integrated with the valve body. The first and second shaft members are spaced from each other in an axial direction by a predetermined distance.

Owner:AISAN IND CO LTD +1

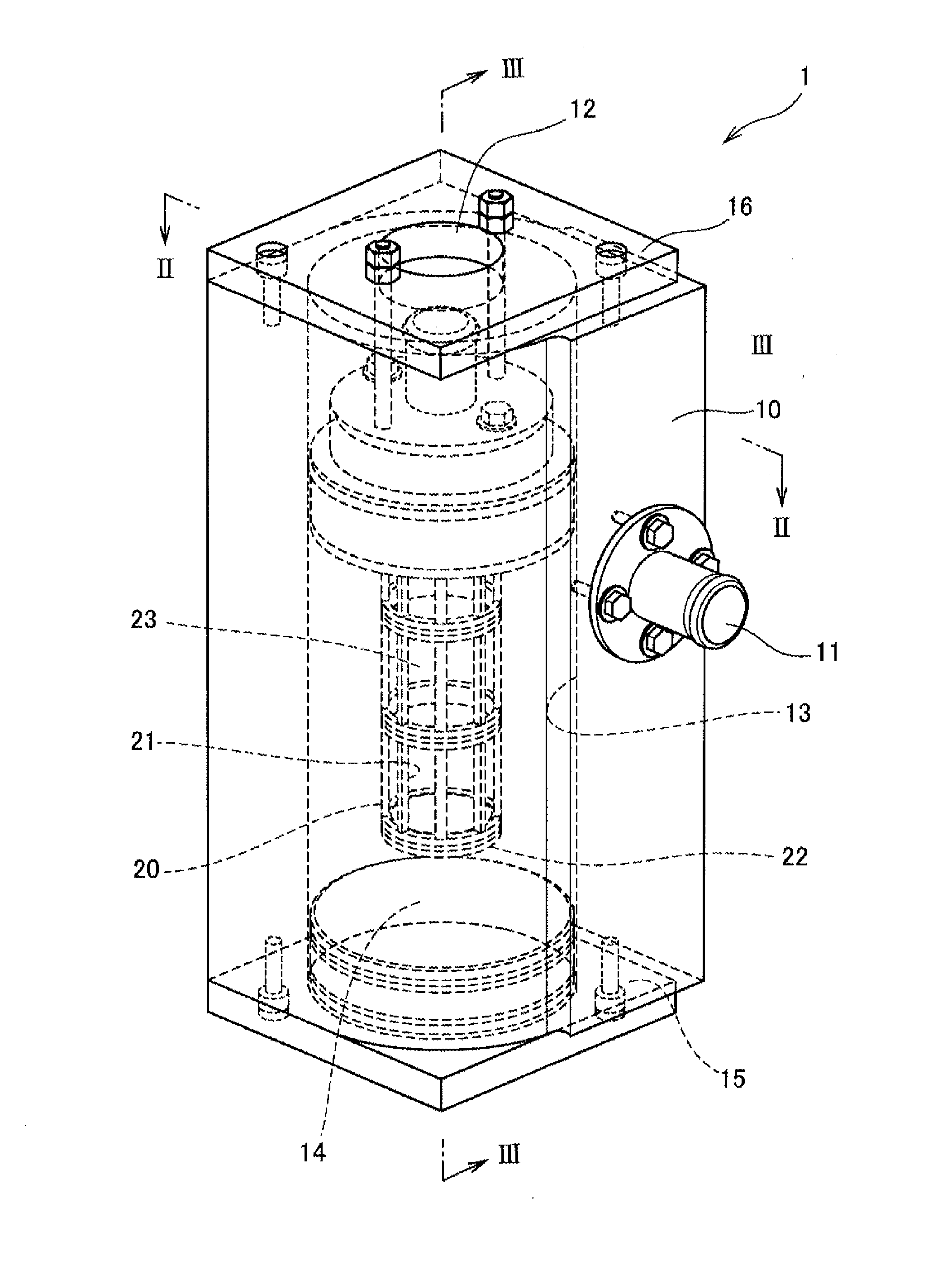

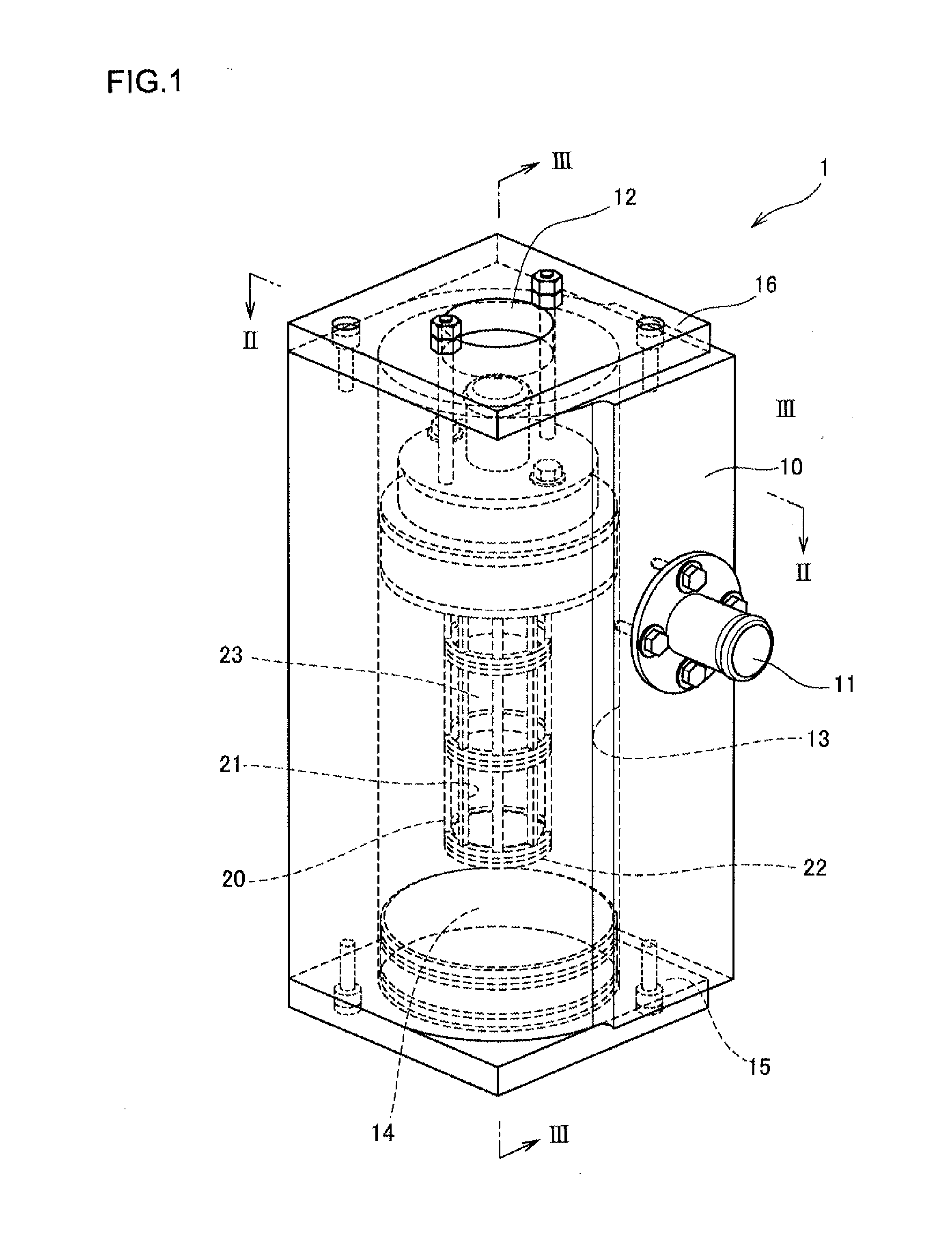

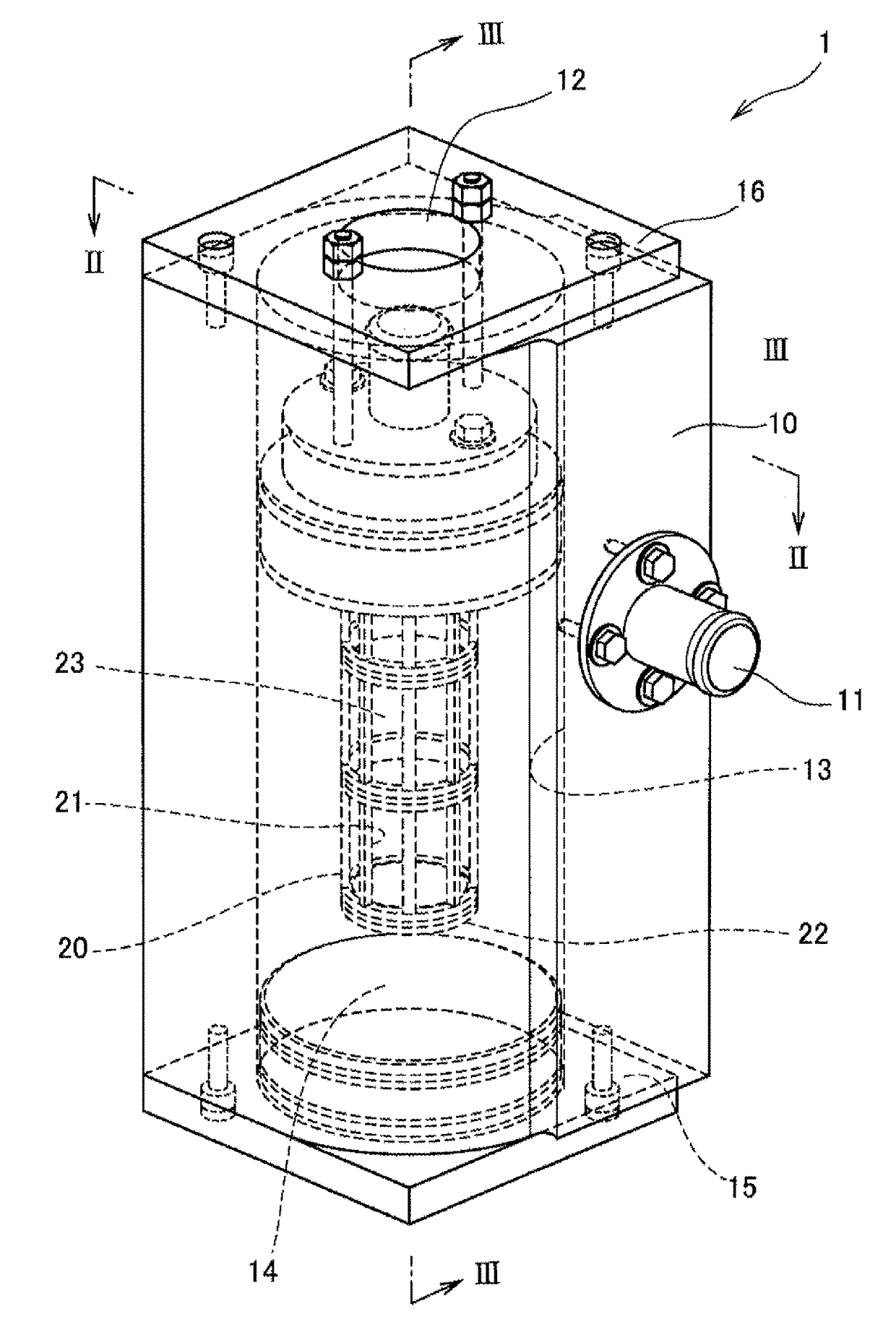

Ion-exchange equipment

ActiveUS9614234B2Suppress pressure lossEfficient removalIon-exchange process apparatusSpecific water treatment objectivesIon exchangeEngineering

An ion-exchange equipment includes a tank unit formed with a cooling liquid flow-in port and a cooling liquid flow-out port and provided therein with an ion-exchange chamber, and an ion-exchange resin in form of particles filling the ion-exchange chamber of the tank unit. The ion-exchange chamber is provided so as to extend along an axial direction of the tank unit and the ion-exchange chamber has a circular cross section taken perpendicularly to the axial direction of the tank unit, and the cooling liquid flow-in port is formed so as to extend in a tangential direction of the ion-exchange chamber.

Owner:ROKI CO LTD

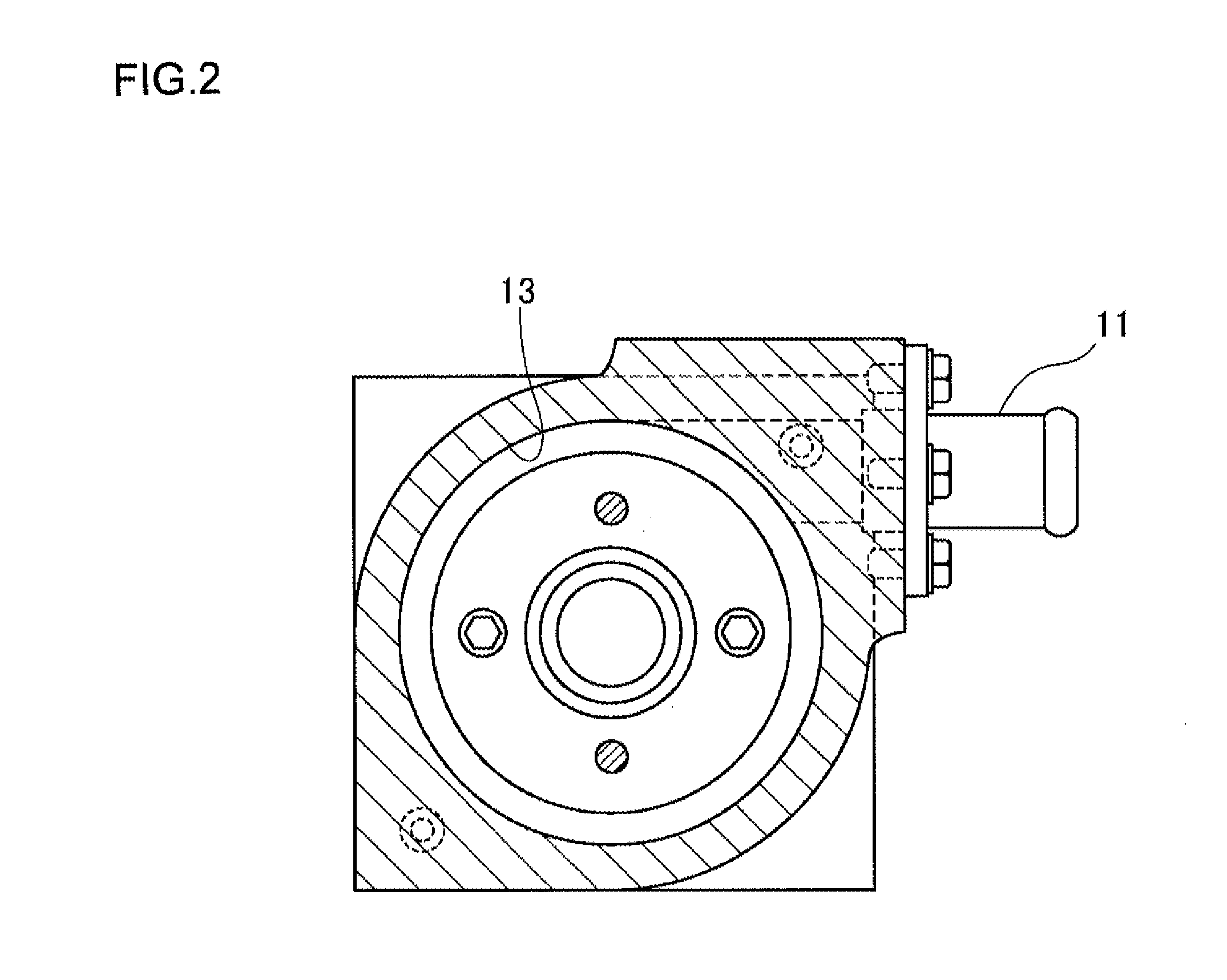

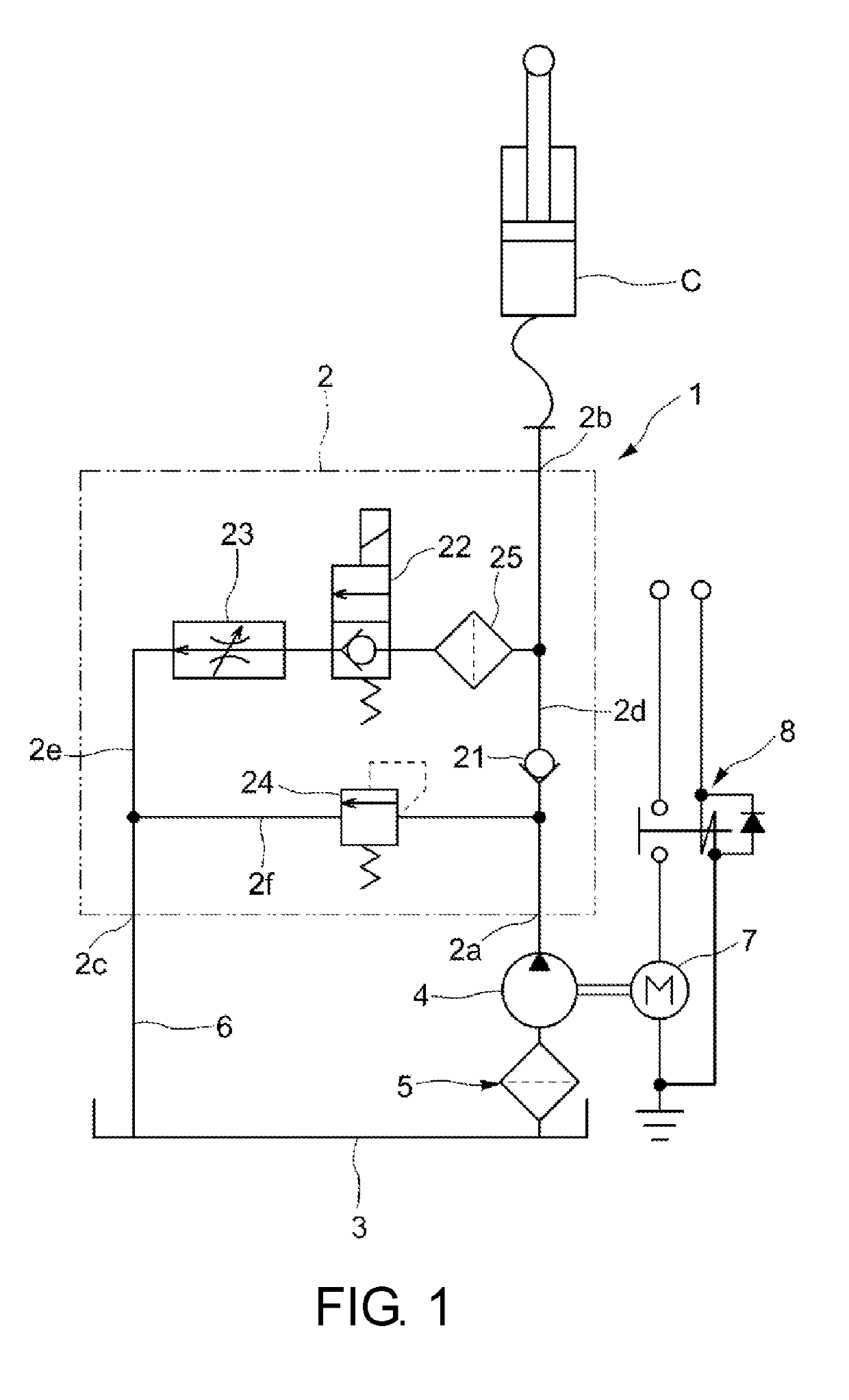

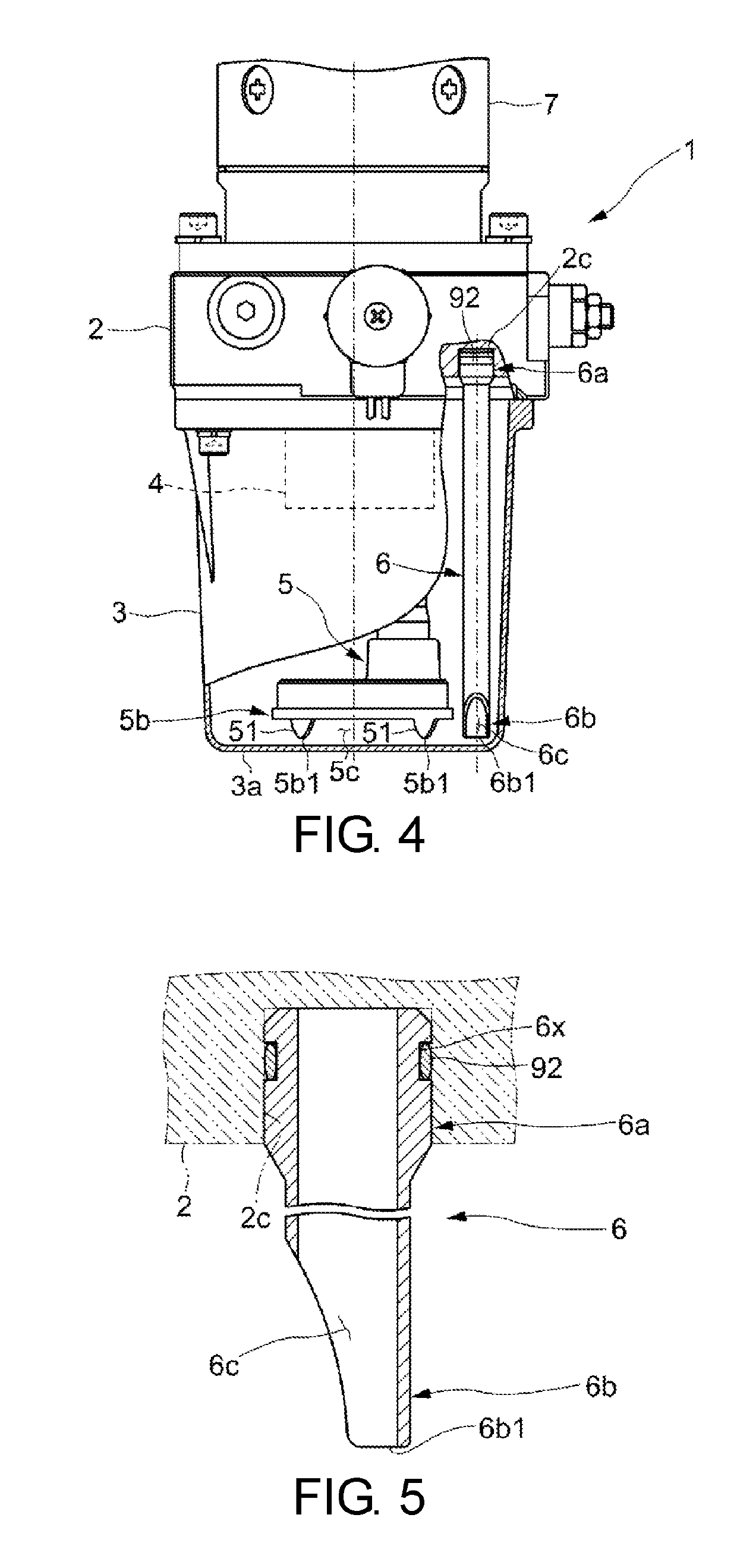

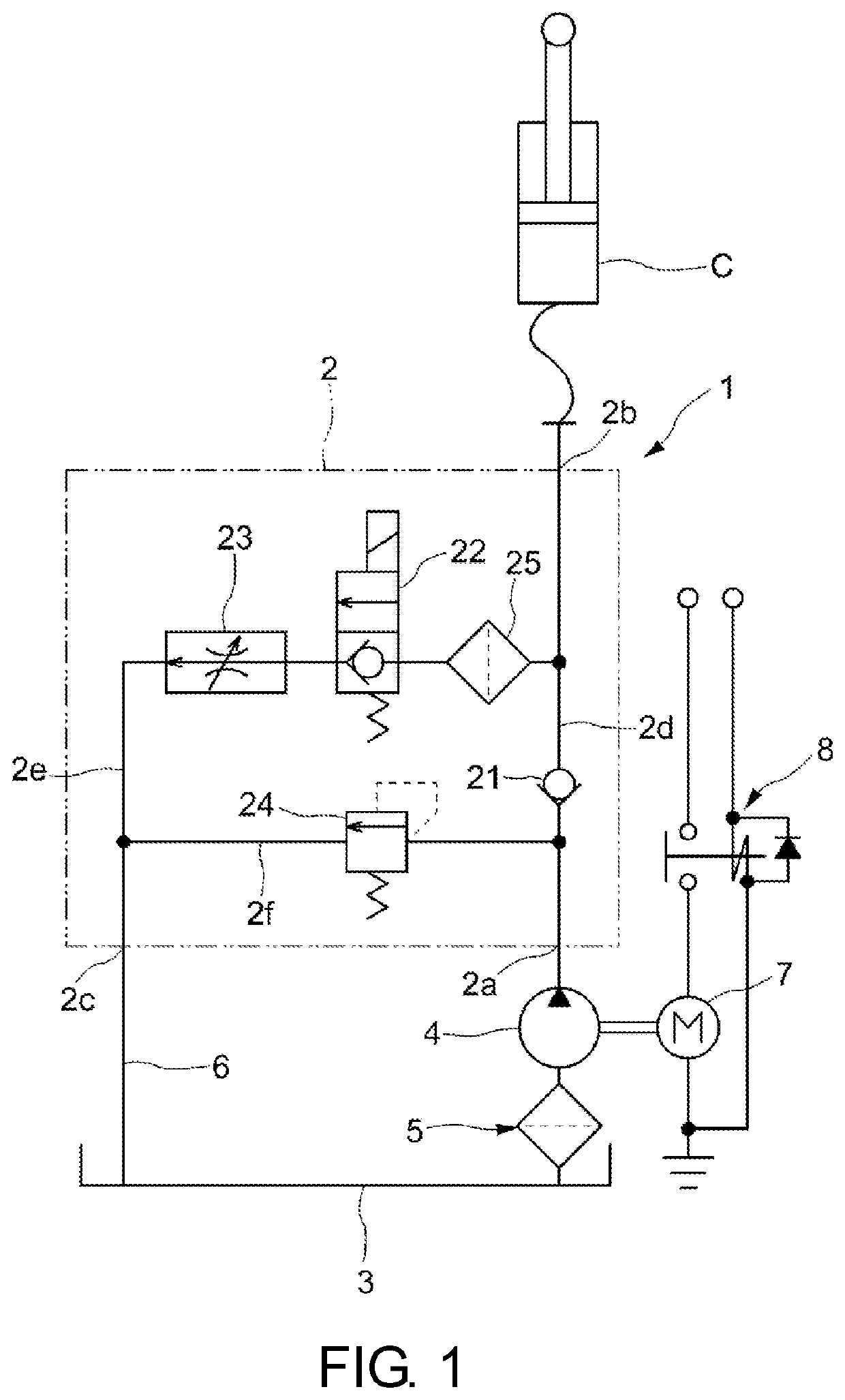

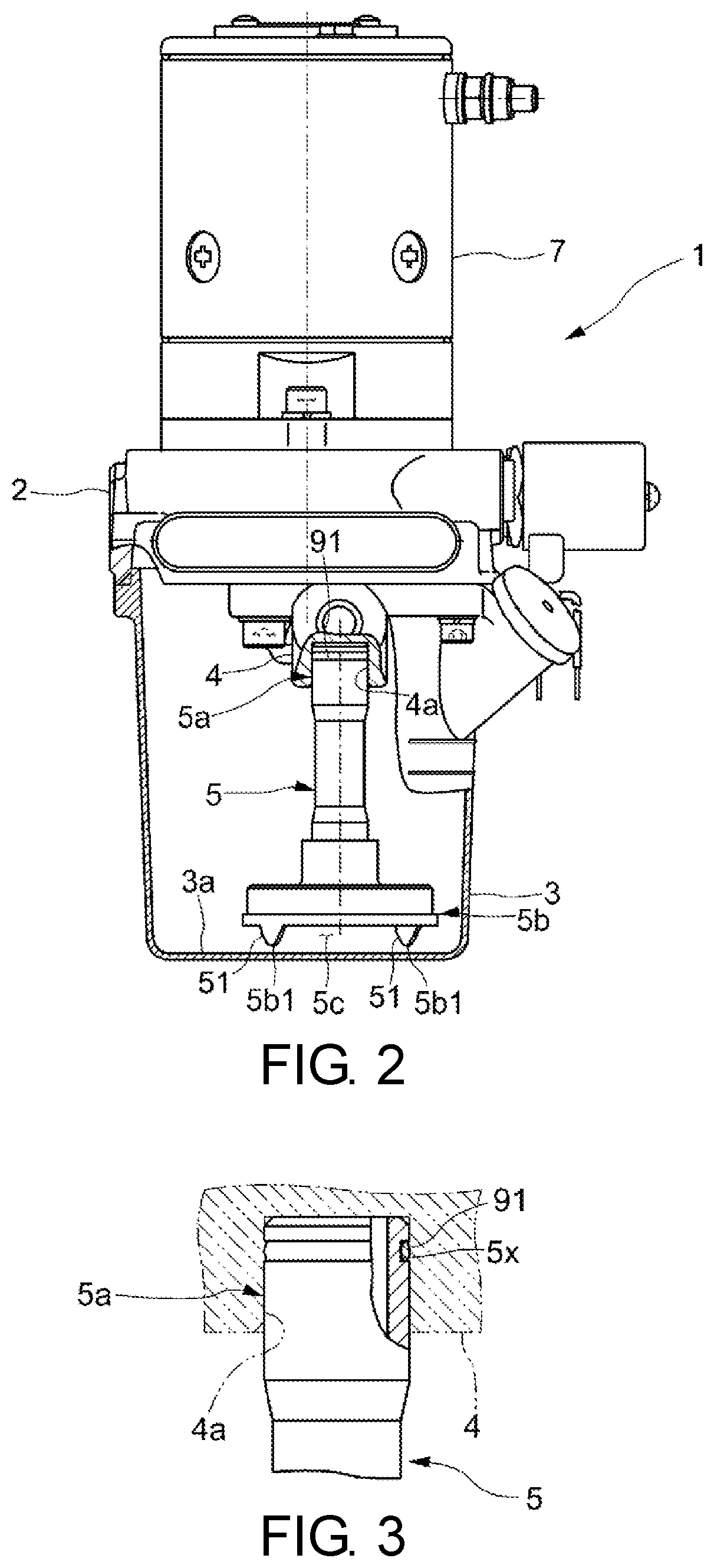

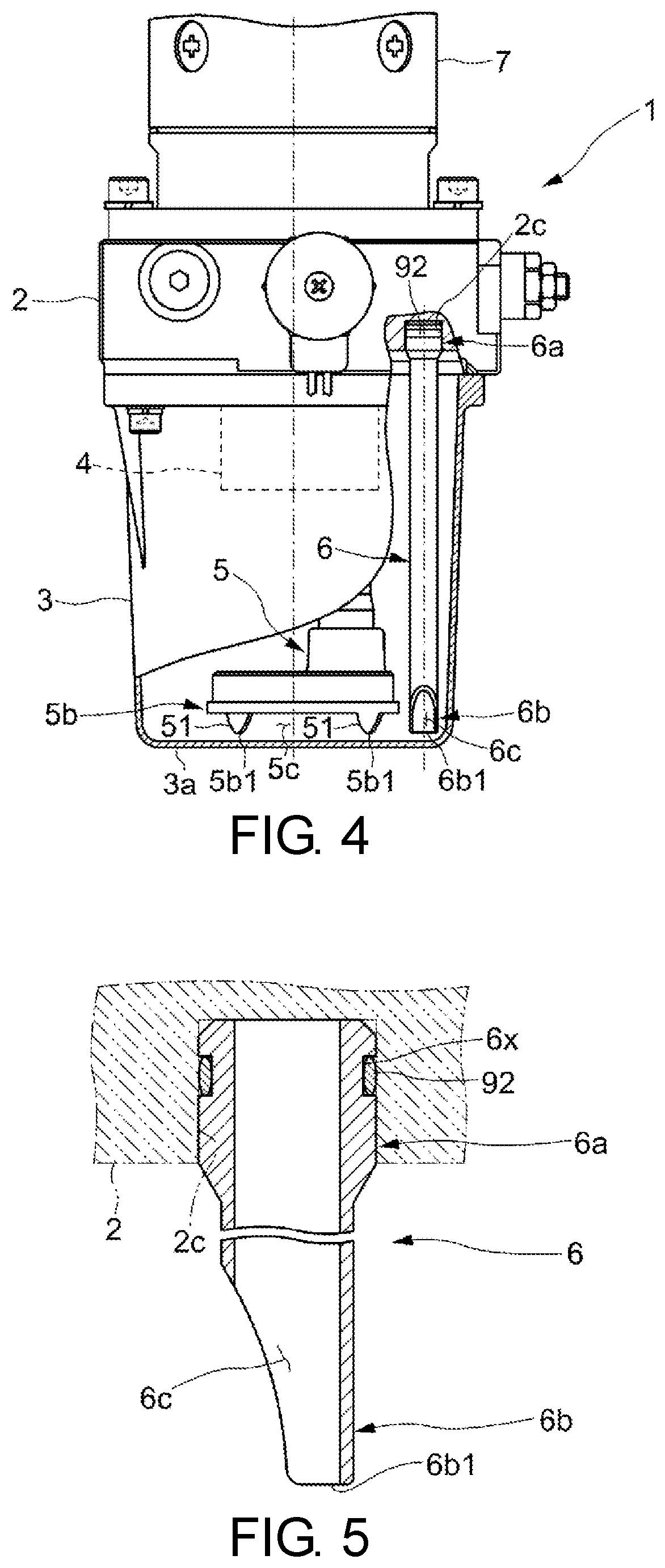

Hydraulic unit

ActiveUS20190202675A1Ensure the flow pathPositive displacement pump componentsServomotorsHydraulic pumpHydraulic circuit

A hydraulic unit is provided with: a manifold which forms a hydraulic circuit; a tank which is joined to the manifold; and a hydraulic pump which suctions hydraulic fluid in the tank and supplies the hydraulic fluid to the manifold, wherein the base end portion of a suction strainer is fitted into the hydraulic pump, and the suction strainer has such a shape that the base end portion of the suction strainer is not separated from the hydraulic pump in a state where the leading end portion of the suction strainer is in contact with the tank and an opening through which the hydraulic fluid is introduced from the tank is provided at the leading end portion.

Owner:SHIMADZU CORP

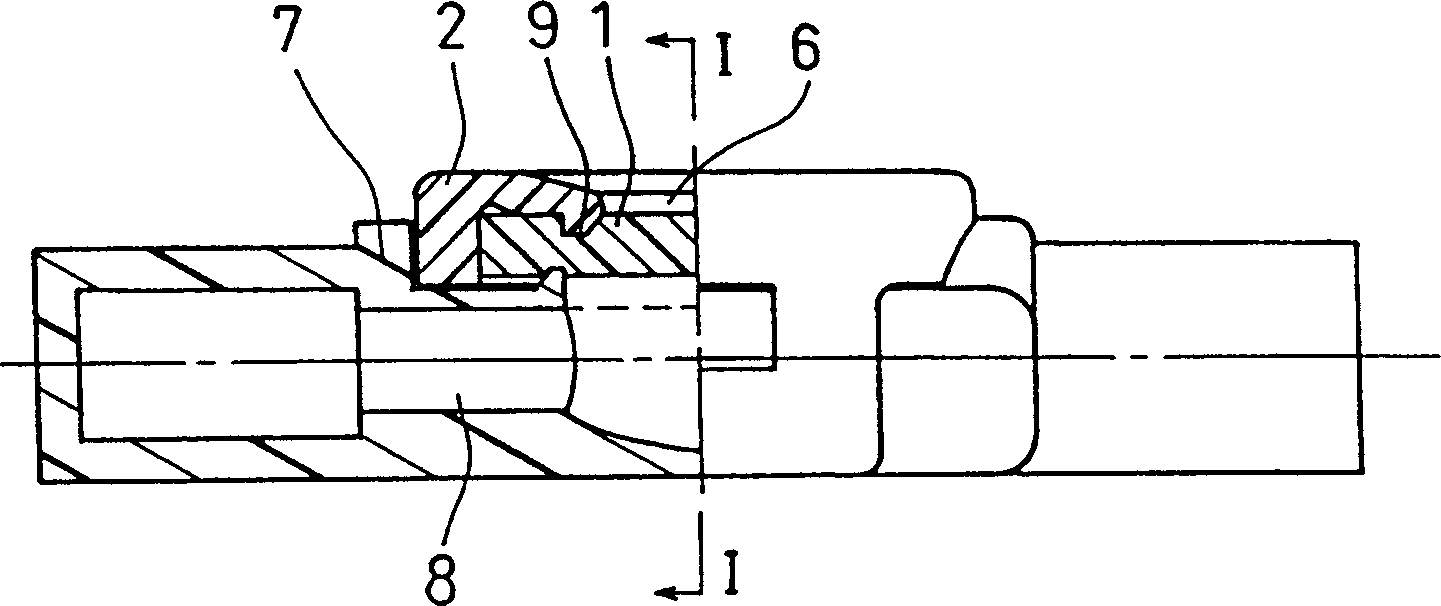

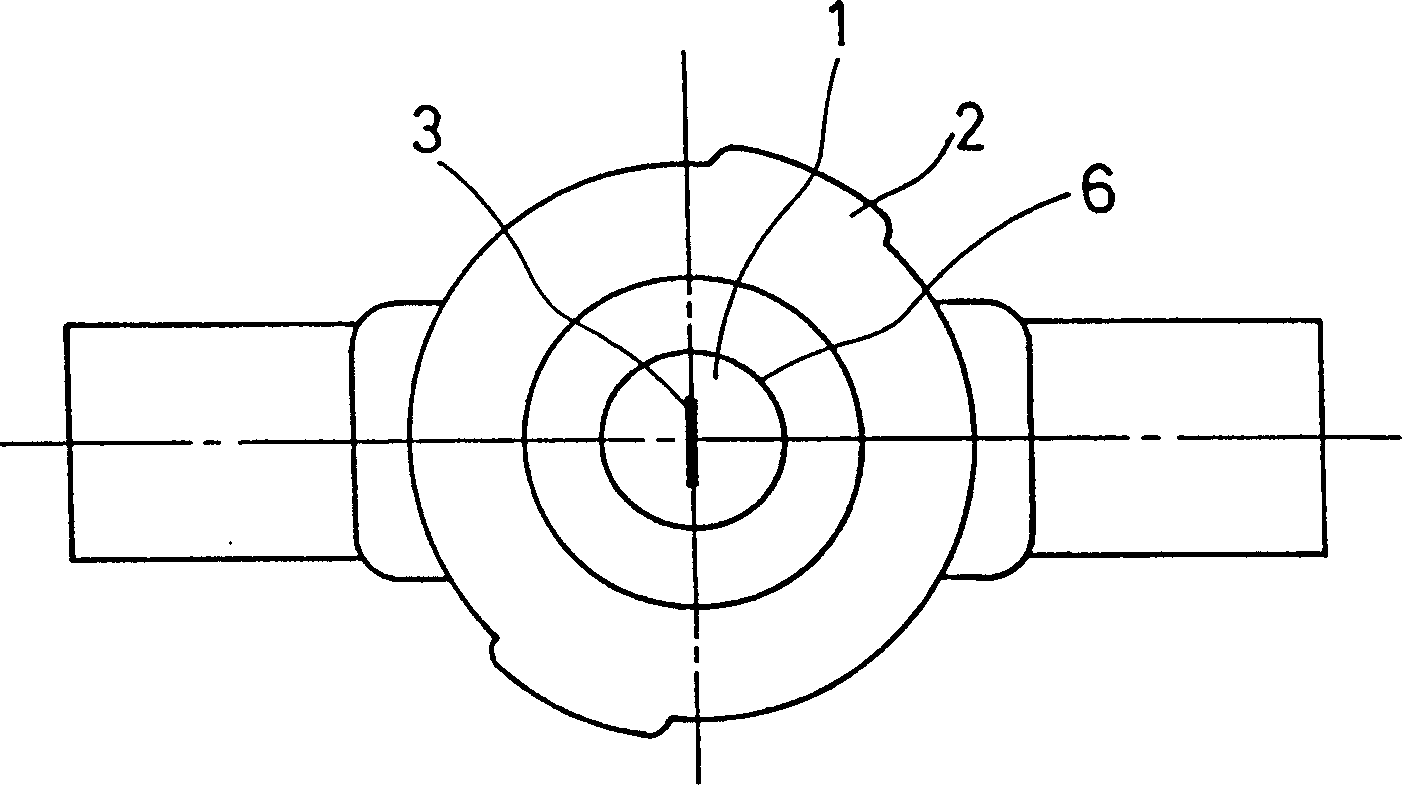

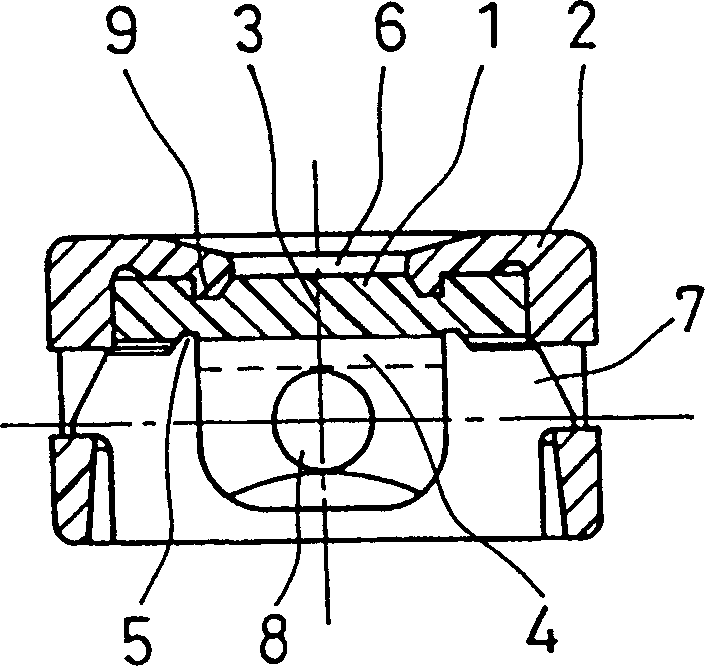

Mixing/charging port for medical treatment

InactiveCN1173752CMake sure to keepGuaranteed fixed effectOther medical devicesBiomedical engineeringMedical treatment

A mixing / charging port for medical treatment capable of reliably mixing / charging solutions or collecting the solutions in a medical instrument equipped with a solution feed passage, comprising a disc-like valve (1) having an insertion hole at the center, a cover (2) for restraining the valve (1) by covering at least the upper part of the periphery of the valve (1) with the center on the front surface side of the valve (1) left uncovered, and a round fitting hole (6) formed at the center of the cover (2) as anchor means for anchoring an insertion member to a mixing / charging port, the fitting hole (6) and the insertion member being so fitted to each other as to be capable of anchoring.

Owner:JMS CO LTD

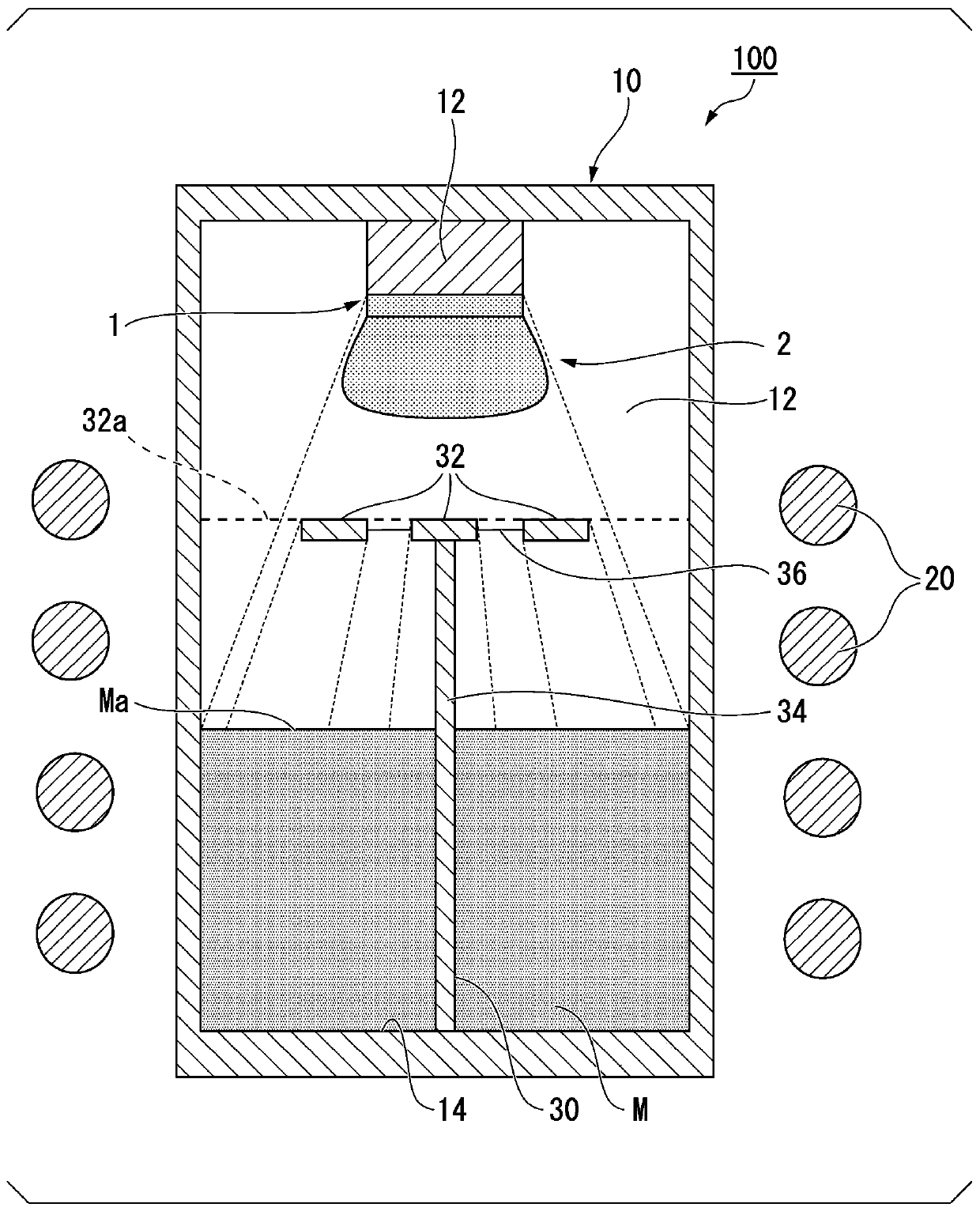

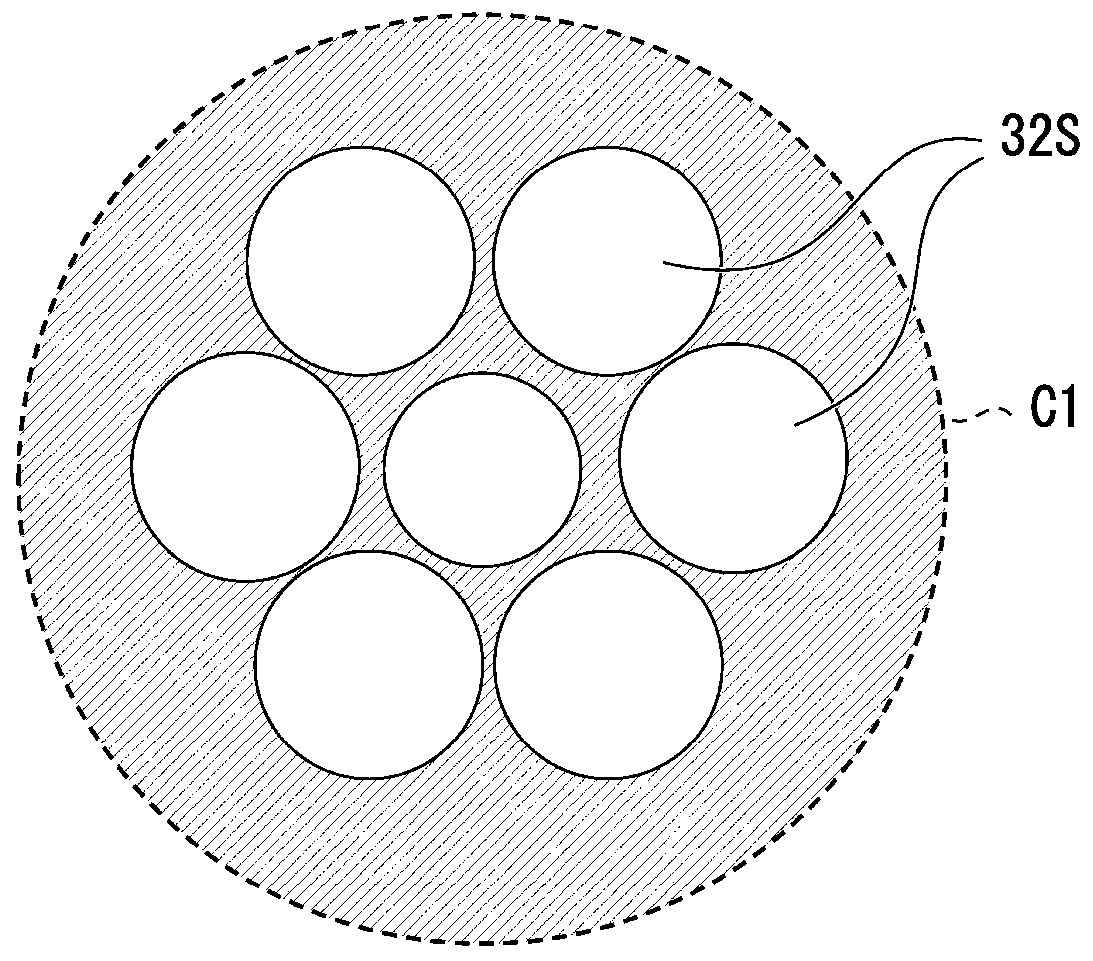

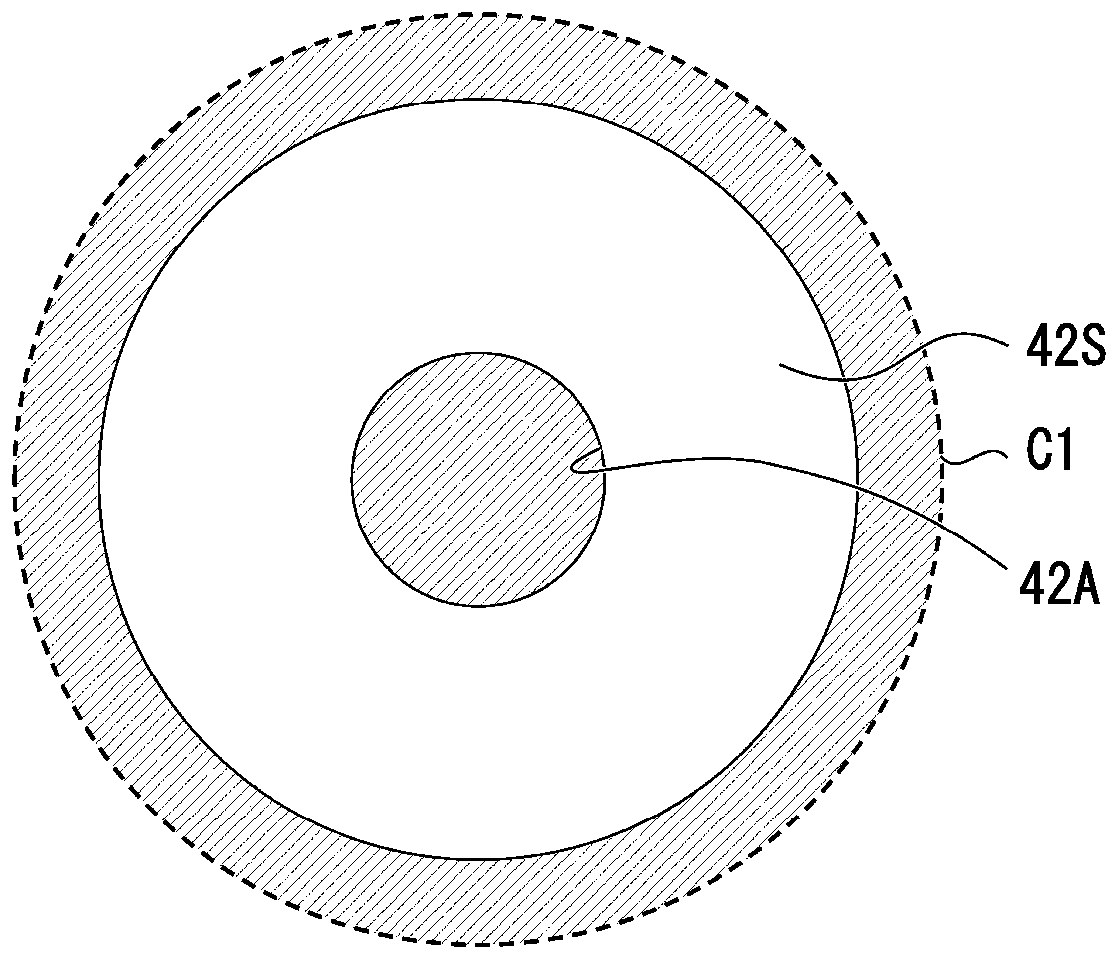

Shielding member and apparatus for single crystal growth

ActiveCN110820042AEnsure the flow pathRadiation suppressionAfter-treatment apparatusPolycrystalline material growthPhysical chemistrySingle crystal

The invention relates to a shielding member and an apparatus for single crystal growth. The shielding member is placed in an apparatus for single crystal growth, wherein the apparatus includes a crystal growth container including a raw material accommodating portion which accommodates a raw material in an inner bottom portion, and a crystal installation portion facing the raw material accommodating portion, and a heating unit that is configured to heat the crystal growth container, the apparatus for single crystal growth grows a single crystal of the raw material on a crystal installed on thecrystal installation portion by sublimating the the raw material from the raw material accommodating portion; the shielding member is placed between the raw material accommodating portion and the crystal installation portion, and includes a plurality of shielding plates, wherein each area of the plurality of shielding plates is 40% or less of a base area of the crystal growth container, and wherein, in a case where the raw material accommodating portion is filled with a raw material, a shielding ratio provided by a projection surface of the plurality of shielding plates, which is projected onan internal circle of the raw material accommodating portion at a raw material surface, is 0.5 or more.

Owner:RESONAC CORP

Indwelling needle device

InactiveCN102933242BEnsure the flow pathEasy pre-charge operationCatheterInfusion needlesEngineeringClose contact

When a hub (40) is in an initial position at which it is located on the front end side of an inner cavity of a shield (20), an inner needle (50) penetrates an outer needle (30) and protrudes from a leading end of the outer needle to the outside, and when the hub is in a retracted position at which it is located on the rear end side of the inner cavity of the shield, the inner needle is housed within the inner cavity of the shield. A first side hole (31) is formed in an outer circumferential face of the outer needle, and a second side hole (51) is formed in an outer circumferential face of the inner needle. When the hub is in the initial position, an inner circumferential face of a region (33) of the outer needle that contains the first side hole is in close contact with the outer circumferential face of the inner needle, and the second side hole is located closer to the hub than the region where the inner circumferential face of the outer needle is in close contact with the outer circumferential face of the inner needle. Thus, a priming operation for filling a gap between the inner needle and the outer needle with blood can be easily performed, and leakage of blood through the side hole of the outer needle during puncture does not occur.

Owner:JMS CO LTD

Applicator

Owner:MITSUBISHI PENCIL CO LTD

Hydraulic unit

ActiveUS10807850B2Ensure the flow pathPositive displacement pump componentsServomotorsHydraulic pumpHydraulic circuit

Owner:SHIMADZU CORP

Hollow fiber membrane module and its operation method

ActiveCN108430610BEnsure the flow pathImprove washing effectMembranesSemi-permeable membranesStructural engineeringHollow fiber membrane

Owner:TORAY IND INC

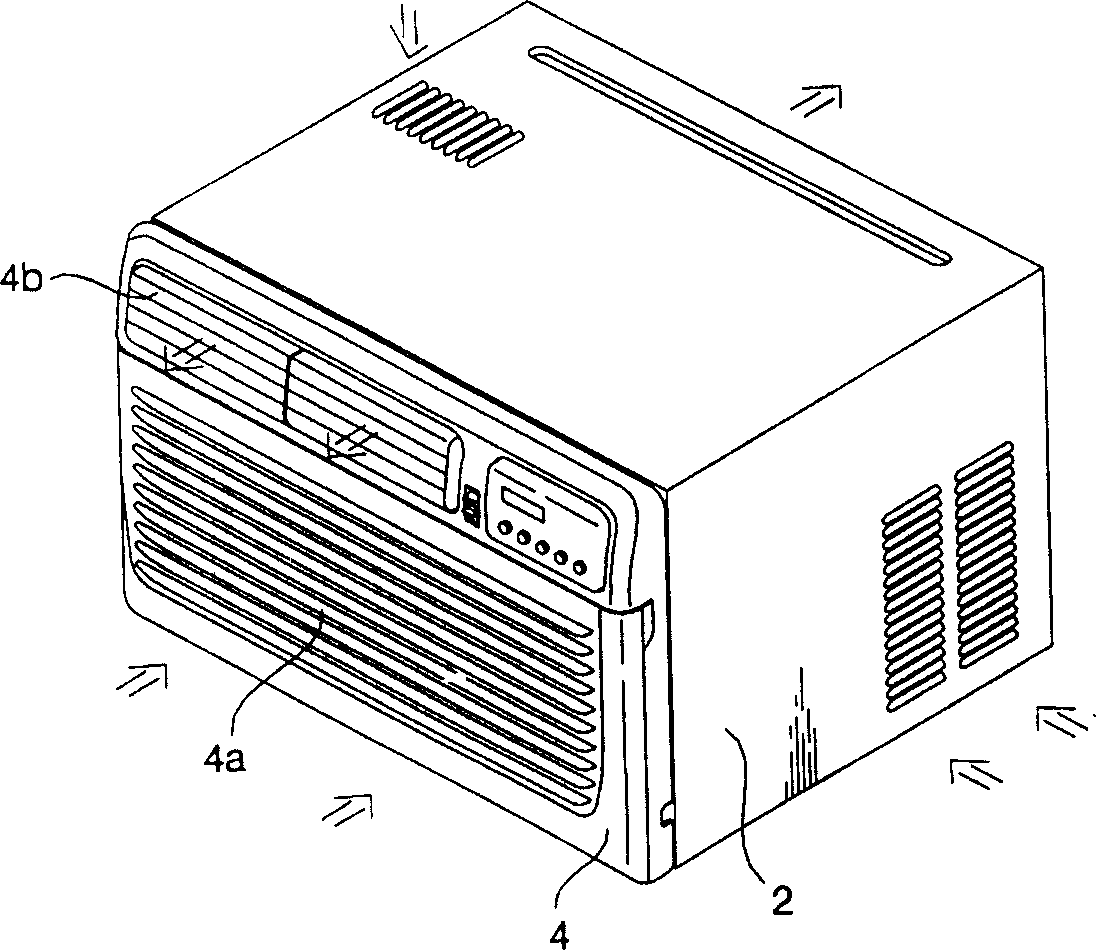

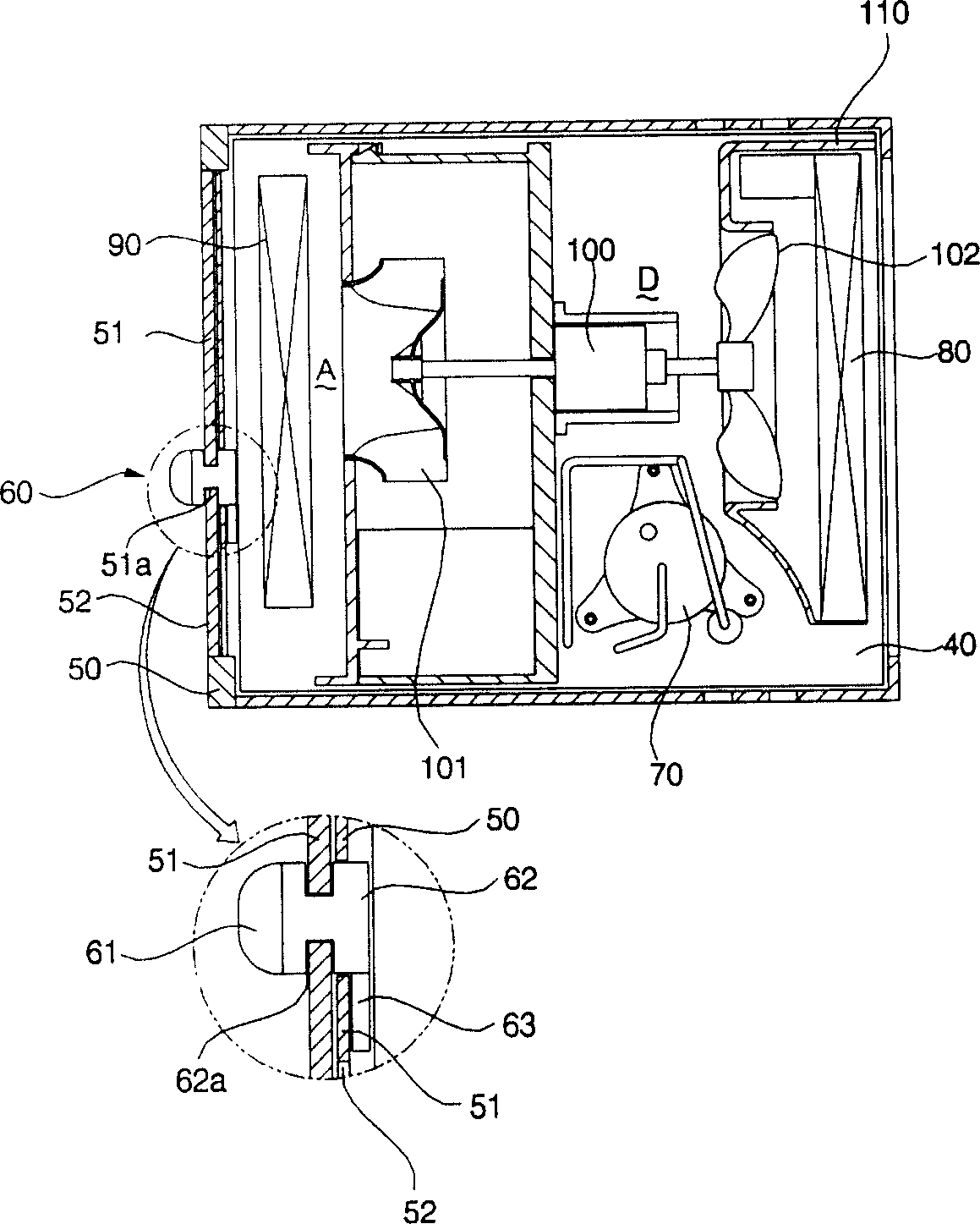

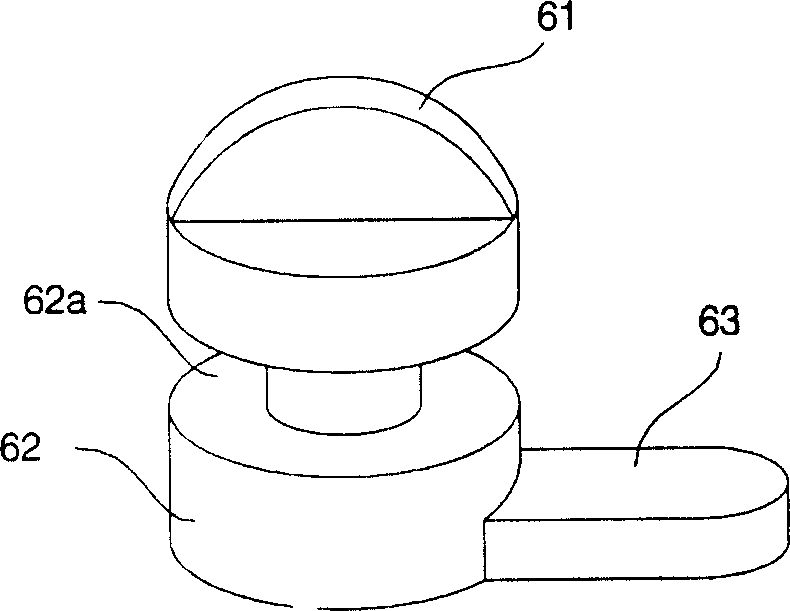

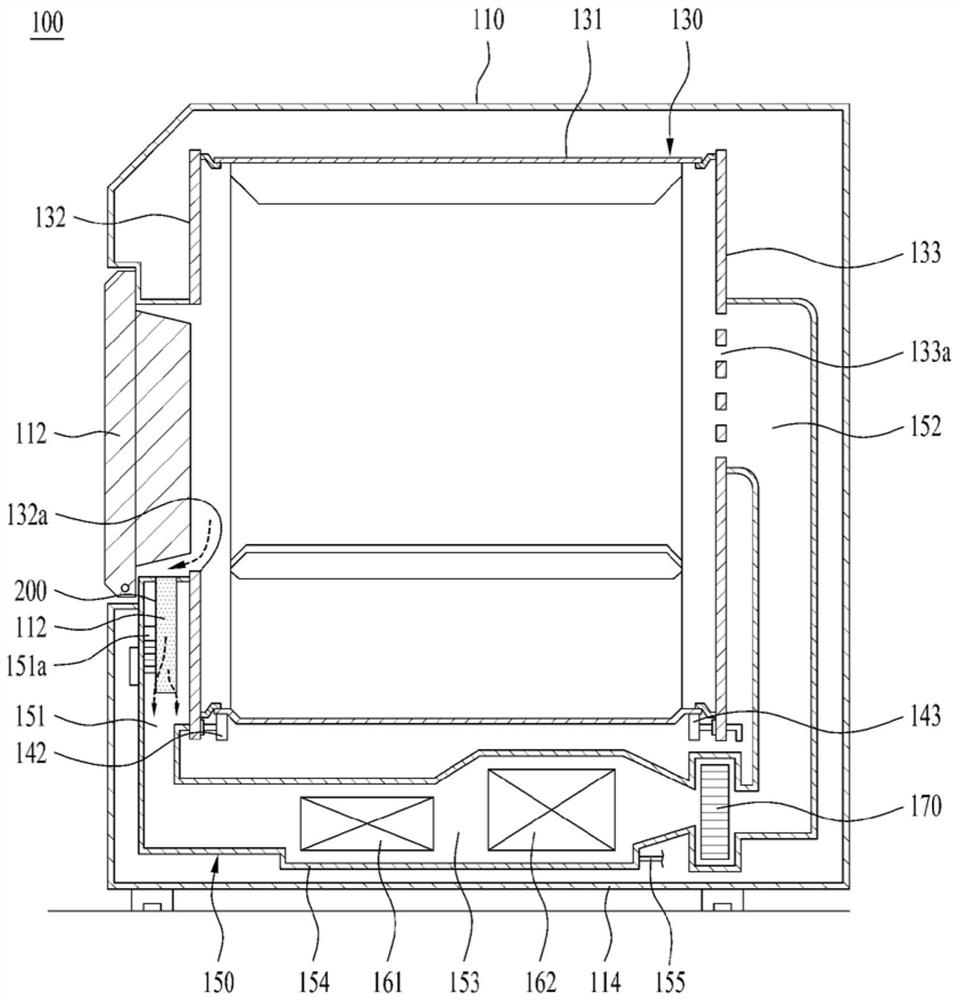

Integrated air conditioner

InactiveCN1892121AGood lookingEnsure the flow pathLighting and heating apparatusAir conditioning systemsFront panelAir flow control

The invention discloses an integrated air-conditioner, belonging to an air flow control component for an air-conditioner, and comprises: a front panel forming appearance of the air-conditioner; suction grill able to be assembled on and unassembled from the front panel; and suction grill fixer, preventing the front panel separating from the suction grill. Thus, it can improve the appearance of an air-conditioner and assure normal air suction and exhaust flow paths.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

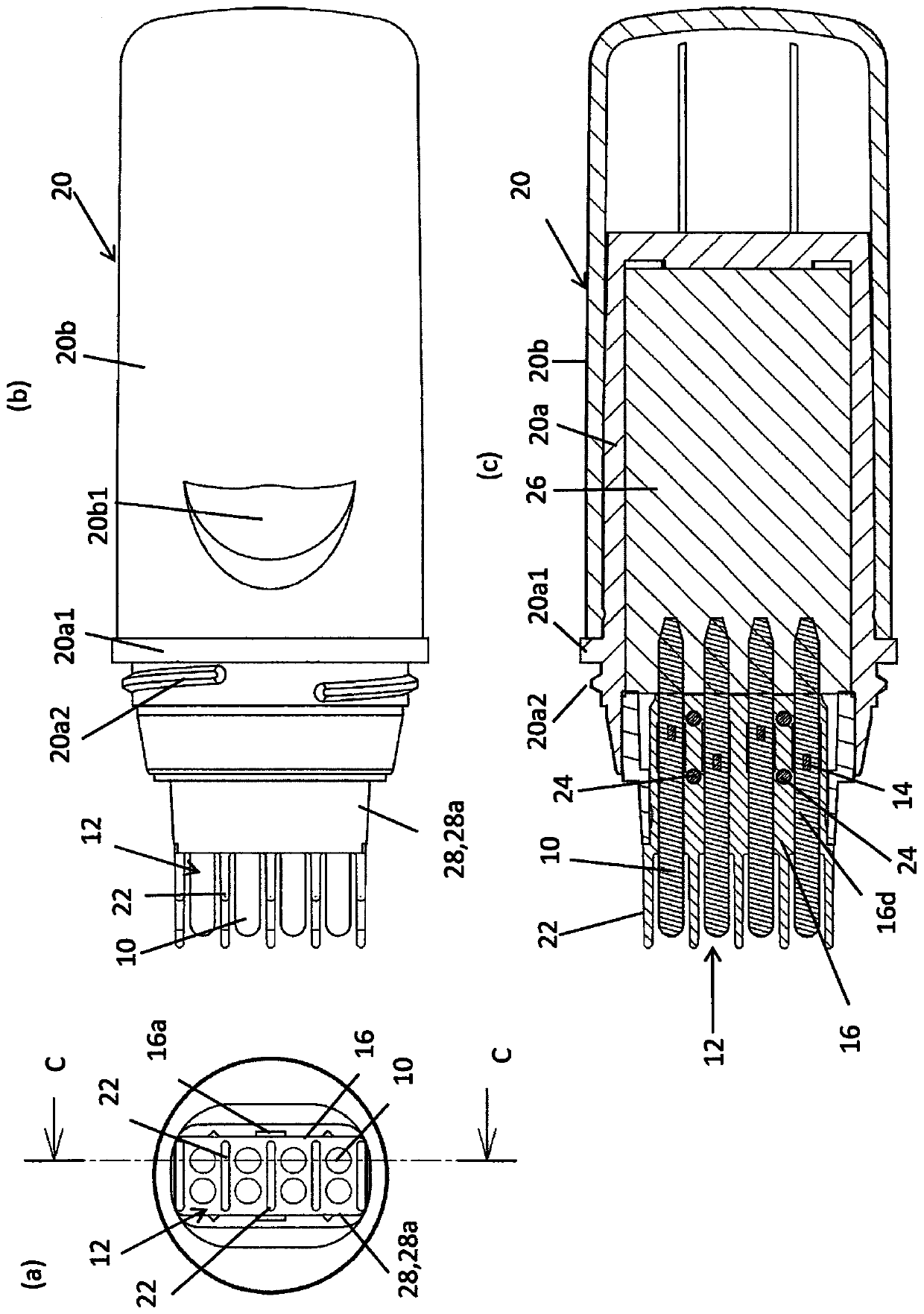

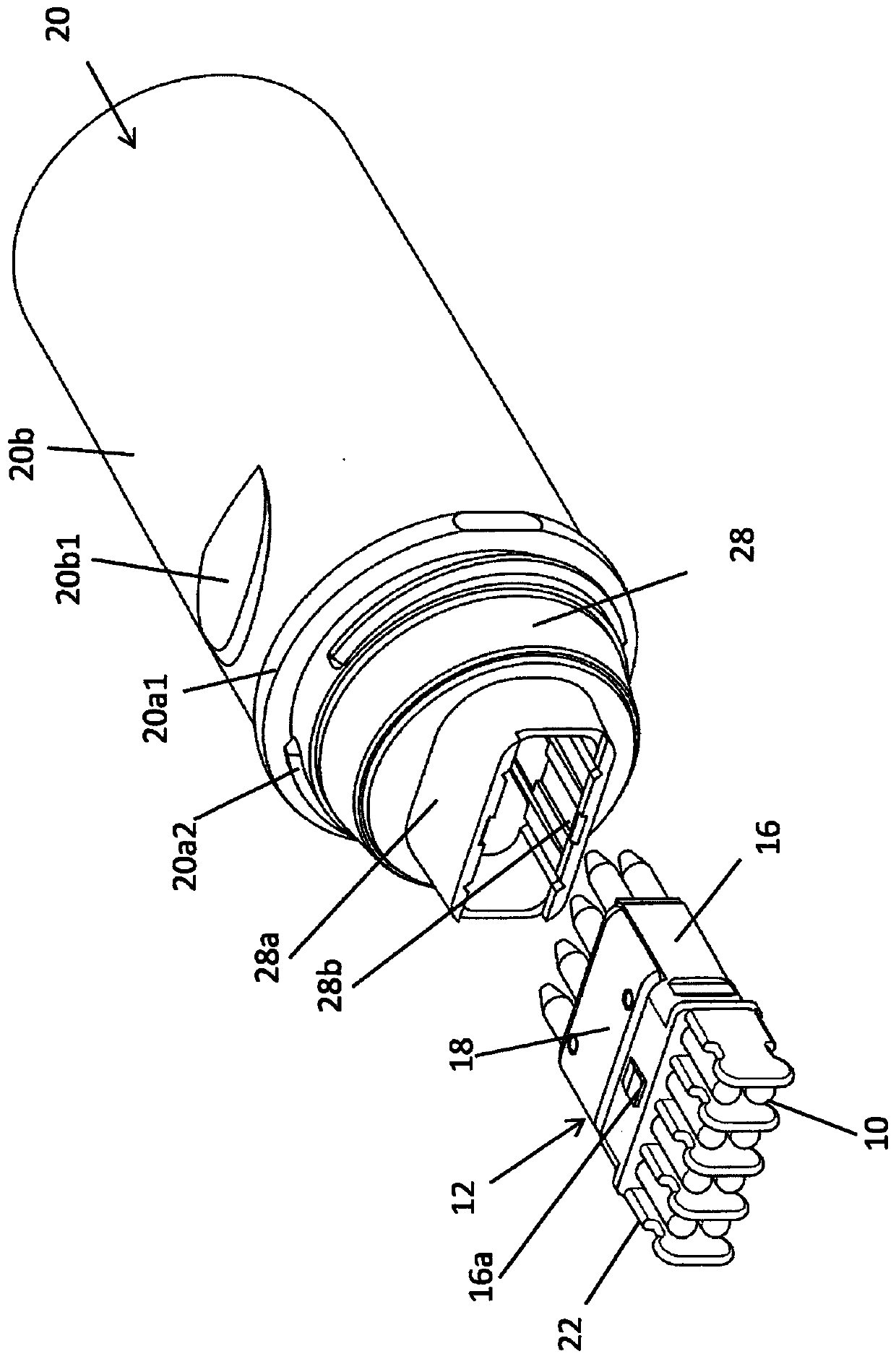

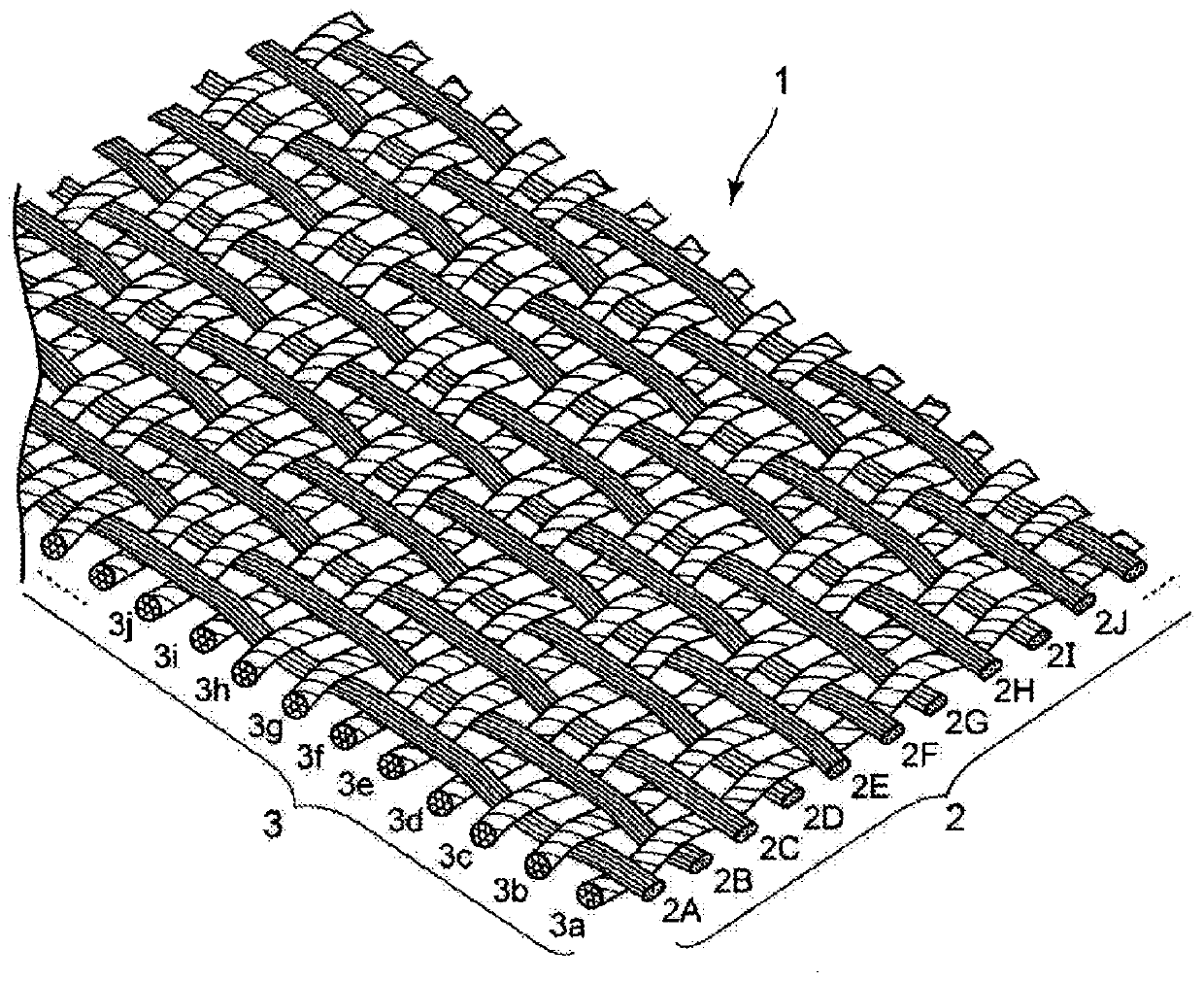

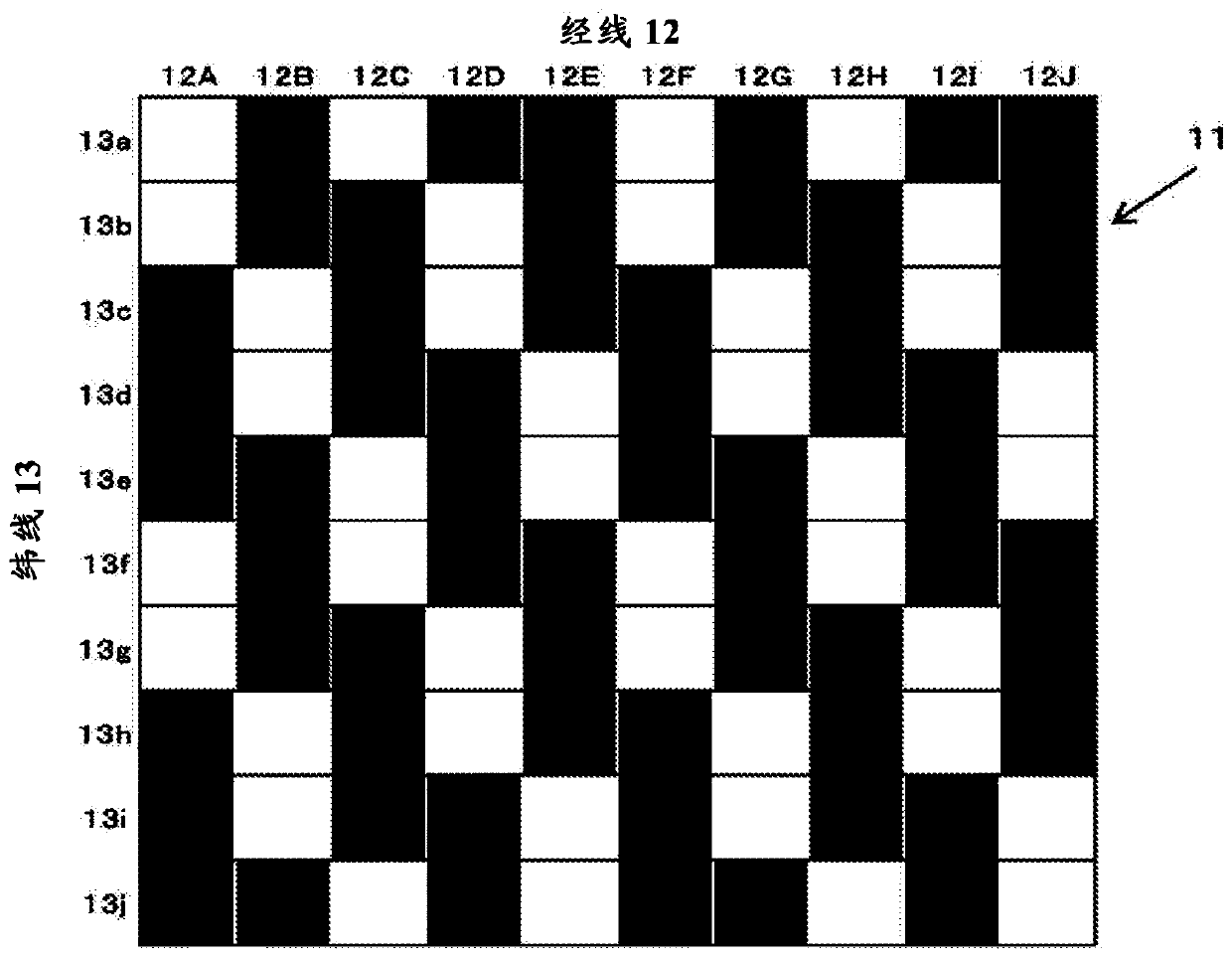

fuel cell unit

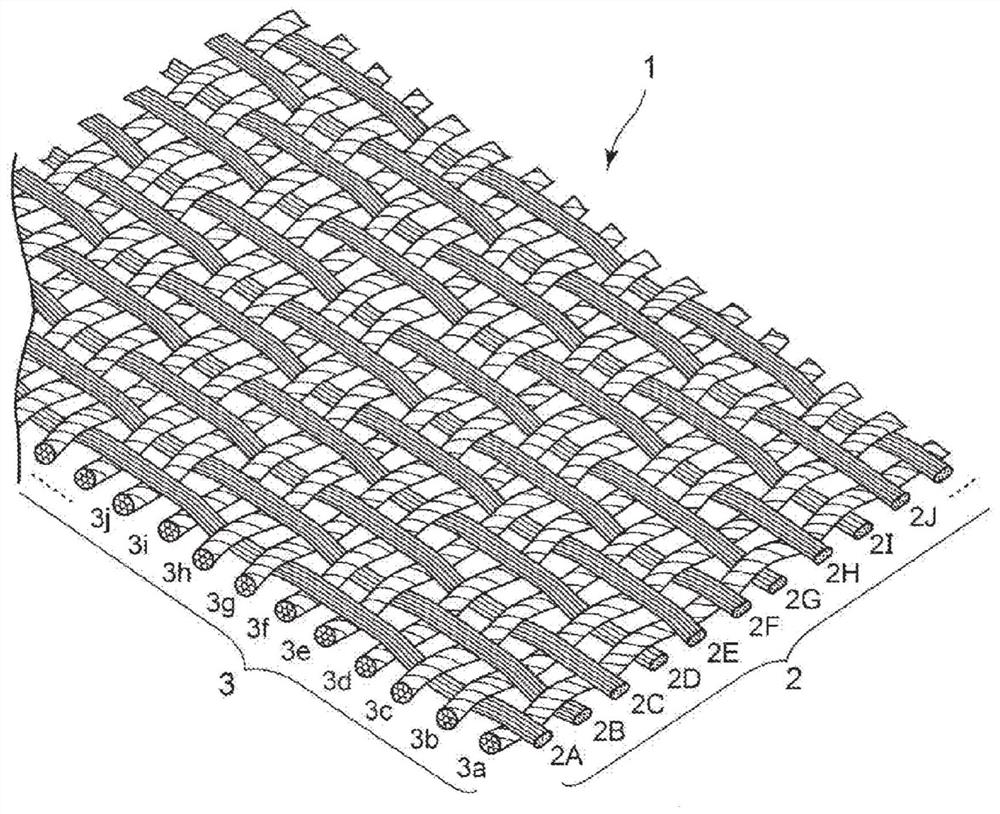

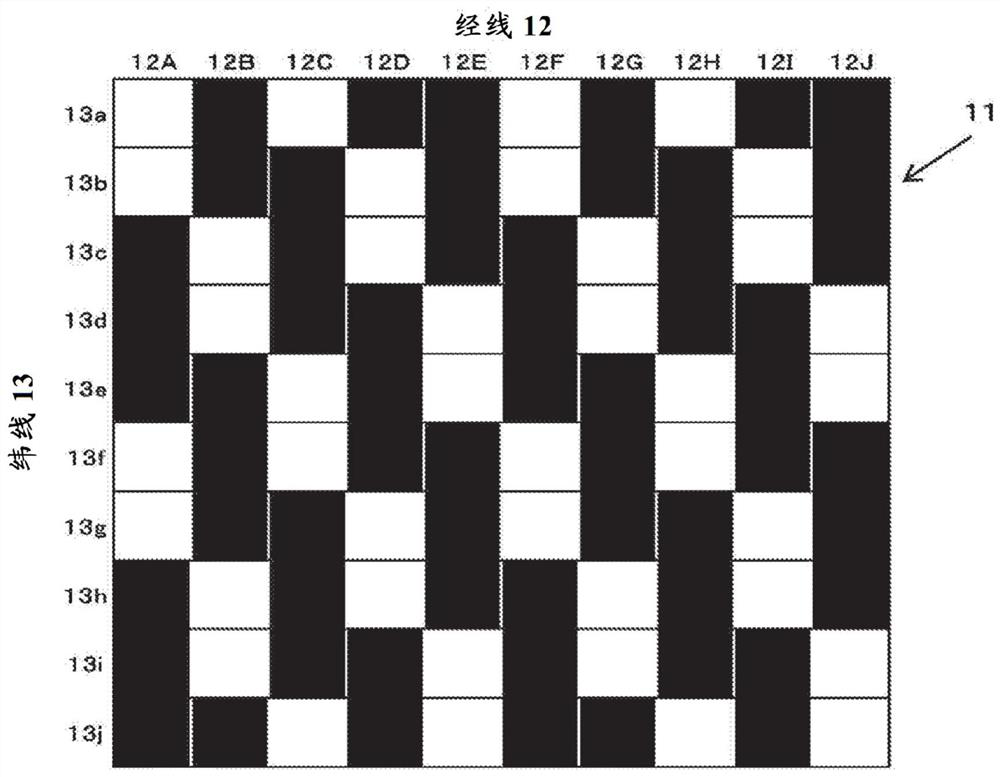

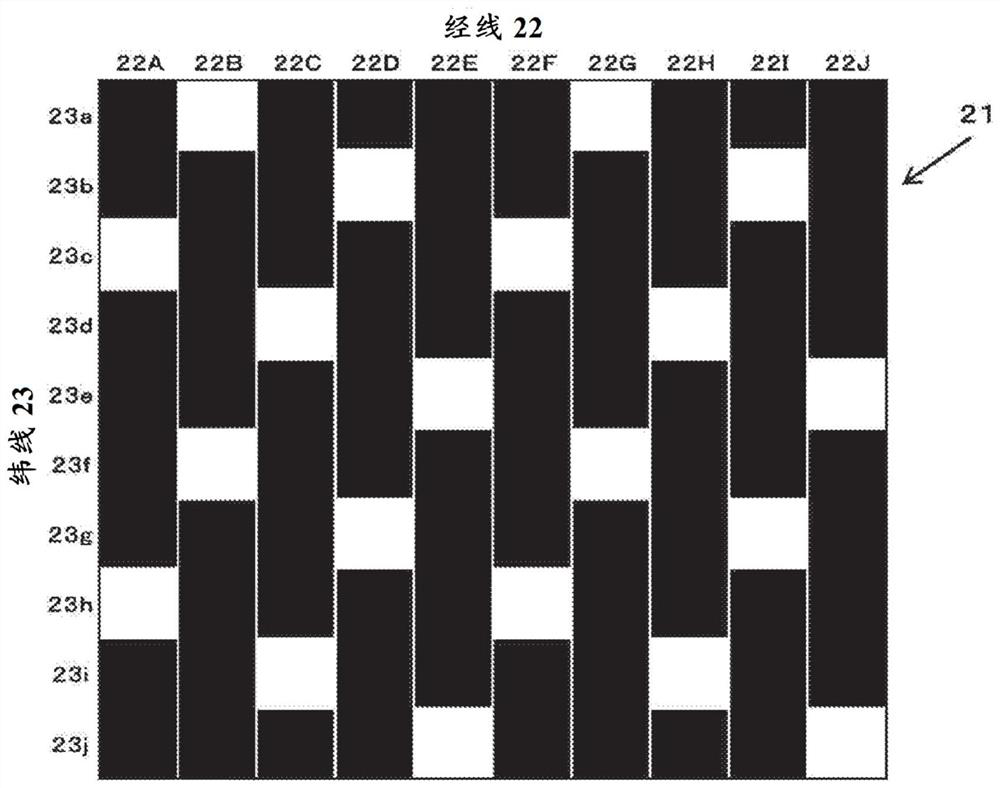

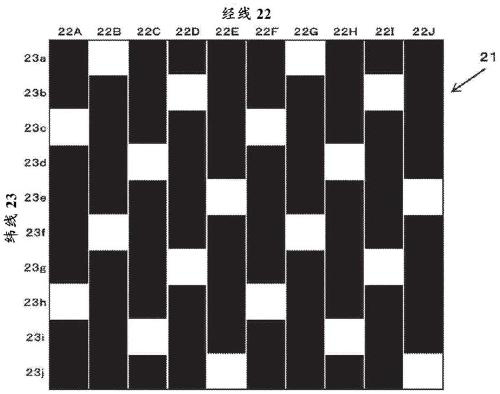

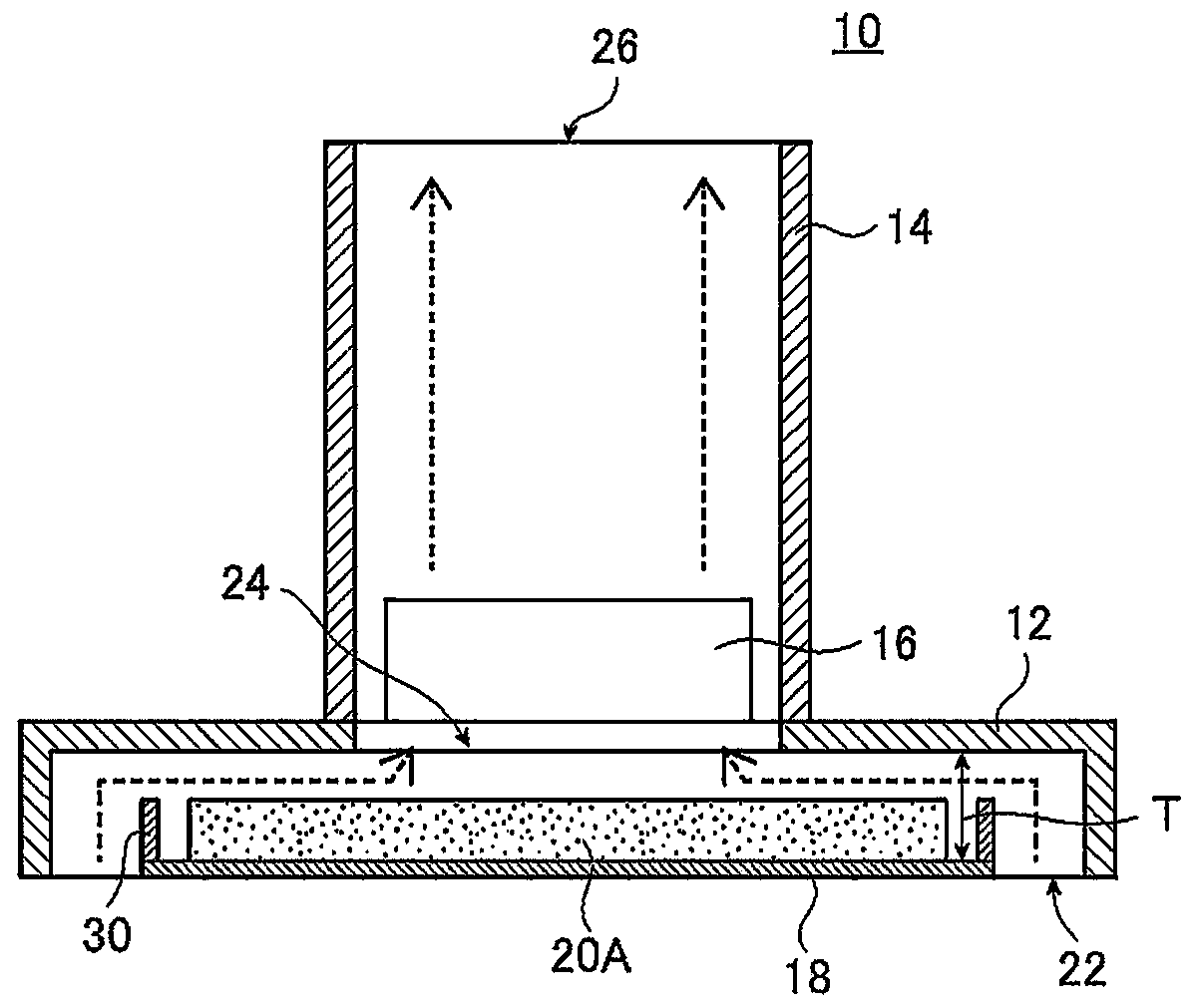

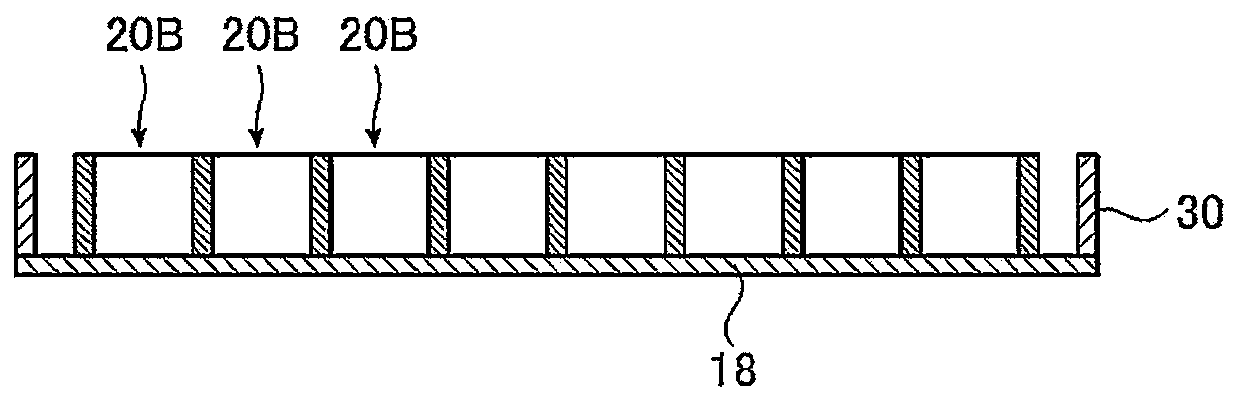

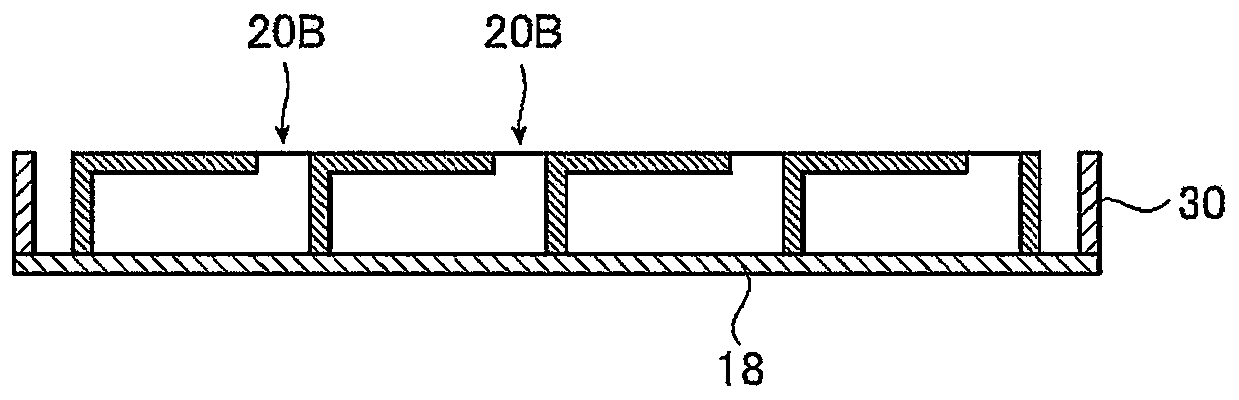

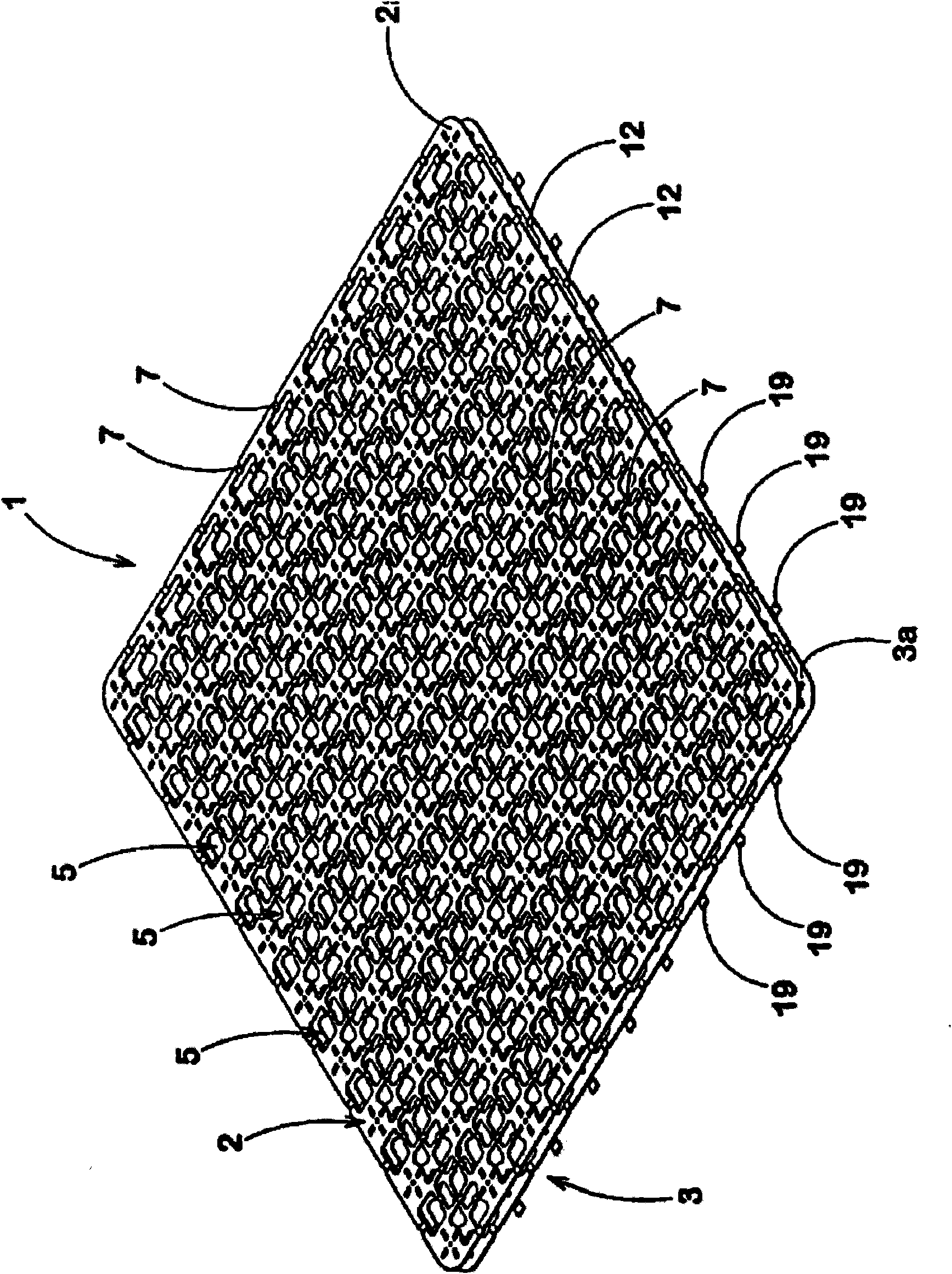

According to the present invention, there is provided a carbon fiber fabric for a gas diffusion layer of a fuel cell, which can reduce the thickness of the carbon fiber fabric when it is stacked in a fuel cell and improve the adhesion when the membrane electrode assembly and the separator are sandwiched and stacked. It also has excellent gas diffusivity in the fuel cell and can generate electricity efficiently. The carbon fiber fabric (1) for a fuel cell gas diffusion layer is formed by intertwining the warp (2) and the weft (3), and one of the warp (2) or the weft (3) is substantially untwisted. In addition, on one side of the carbon fiber fabric (1) for a fuel cell gas diffusion layer, the non-twisted yarn above the other yarn (the weft or the warp) interwoven with the warp (2) or the weft (3) as the non-twisted yarn The number of twisted yarns is greater than the number of untwisted yarns positioned below the other yarn.

Owner:NACHI-FUJIKOSHI +1

Applicator

The present invention provides an applicator capable of easily fixing a coating body and fixing a coating body in such a manner as to ensure a flow path of the coating liquid. An applicator is provided with a coating portion having a coating body, the coating portion having a core base for mounting the coating body and a fixing member having a plurality of protrusions protruding from the main body, and in a condition of puncturing the protrusions of the fixing member in the coating body, the fixing member is fixed to the core base so as to fix the coating body to the core base, and in the fixed state of the coating body, the coating portion is attached to the guide shaft.

Owner:MITSUBISHI PENCIL CO LTD

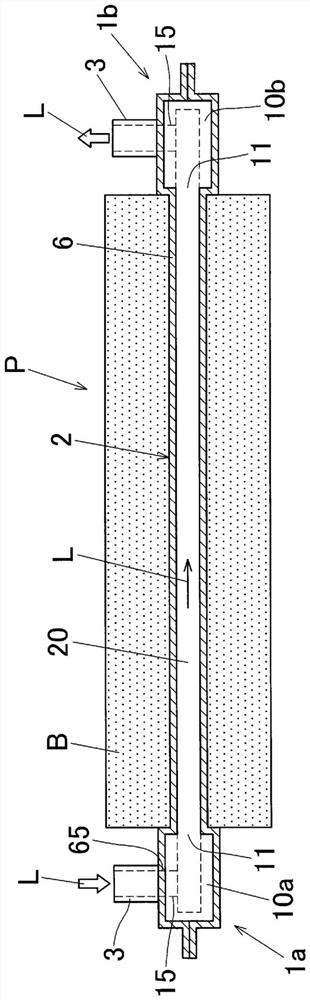

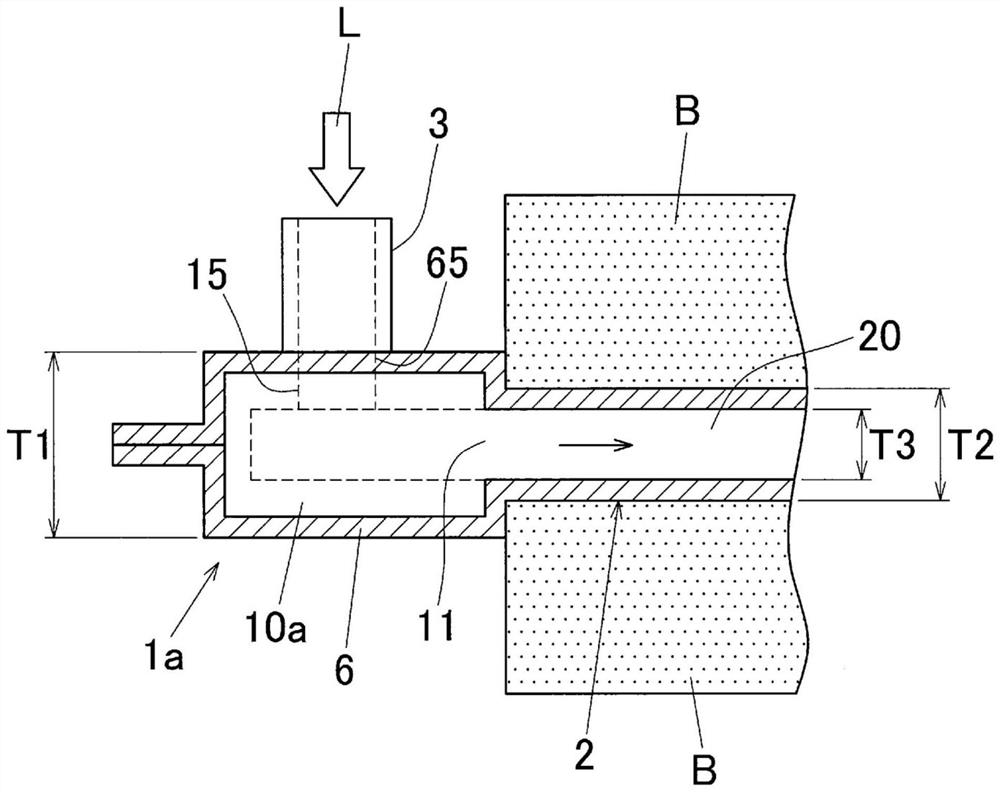

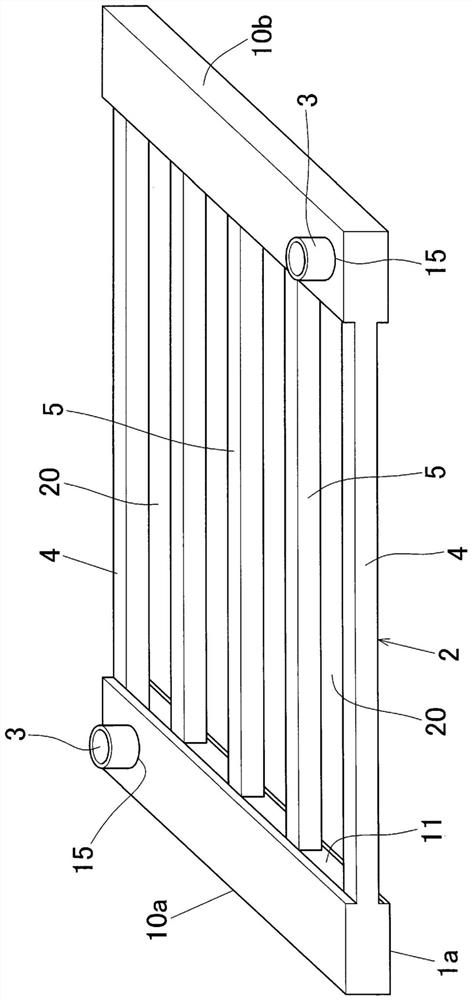

Heat exchanger

PendingCN114303276AAchieve thinningEnsure the flow pathSecondary cellsStationary conduit assembliesEngineeringMechanical engineering

Provided is a heat exchanger capable of improving the flowability of a heat exchange medium in an inlet / outlet forming part. The present invention relates to a heat exchanger provided with: a heat transfer unit (2) configured as a heat exchange flow path (20) through which a heat exchange medium (L) flows in a hollow section; and inlet / outlet forming parts (1a, 1b), the interior of which is connected to the heat exchange flow path (20) in a communicating manner and in which an inlet / outlet (15) through which the heat exchange medium (L) flows in and out is formed. At least a portion of the outer surface portion of the heat transfer portion (2) is configured from a cover sheet (6) which is a laminated material obtained by providing a resin cover layer on at least one surface side of a metal heat transfer layer, and the outer dimension thickness (T1) of the inlet / outlet forming portions (1a, 1b) is formed to be thicker than the outer dimension thickness (T2) of the heat transfer portion (2).

Owner:RESONAC CORPORATION

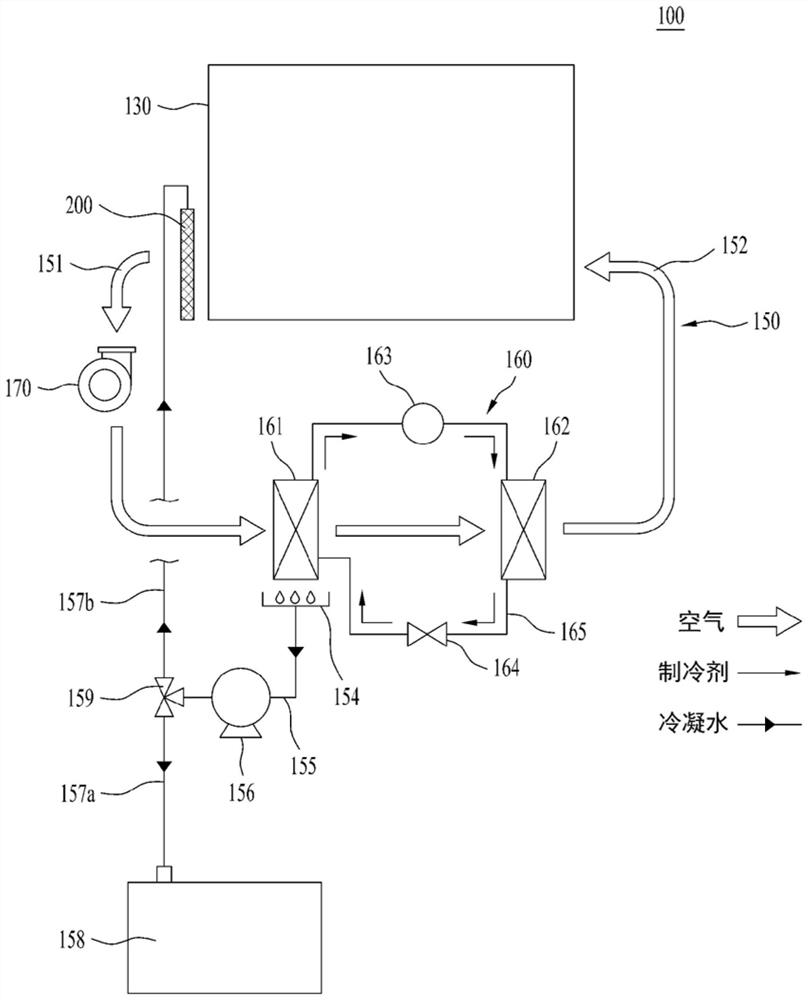

Clothing treatment apparatus

PendingCN113891968AEnsure the flow pathWashing machine with receptaclesTextiles and paperThermodynamicsEngineering

The present invention relates to a clothing treatment apparatus comprising: a heat pump having an evaporator, a compressor, a condenser, and an expansion valve, and applying heat to air circulating in a drum; an air flow path forming a movement path such that the air is circulated through the drum; a lint filter provided on the air flow path and collecting lint contained in the air; and a condensate water collecting part collecting condensate water generated in the evaporator and supplying the condensate water to the lint filter, wherein the condensate water supplied from the condensate water collecting part is supplied to the upper portion of the lint filter, and the lint collected in the lint filter is moved to the lower portion of the lint filter, thereby securing the air flow path of the lint filter.

Owner:LG ELECTRONICS INC

Carbon fiber woven fabric for fuel cell gas diffusion layer and fuel cell

This carbon fiber woven fabric for a fuel cell gas diffusion layer makes it possible to reduce thickness if layered inside a fuel cell, and to lower electrical resistance by increasing adhesion when the carbon fiber woven fabric is layered sandwiched between a membrane electrode assembly and a separator. At the same time, this carbon fiber woven fabric for a fuel cell gas diffusion layer has superior diffusing characteristics inside the fuel cell and can generate power efficiently. A carbon fiber woven fabric (1) for a fuel cell gas diffusion layer is formed by the interweaving of a warp (2) and a weft (3), and the threads of the warp (2) or the weft (3) are substantially non-twisted threads. Furthermore, on one surface of the carbon fiber woven fabric (1) for a fuel cell gas diffusion layer, the number of the non-twisted threads, of the warp (2) or the weft (3) non-twisted threads which are interweaved, which lay above the other thread (warp or weft) is greater than the number of thenon-twisted threads of the other thread which lays below.

Owner:NACHI-FUJIKOSHI +1

Range hood

ActiveCN111465806AEnsure the flow pathHigh soundproof performanceDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

In order to provide is a range hood which is small, can ensure a flow path for smoke, and has a good soundproof performance, and with which cleaning of oil stains and the like is easy. This range hoodhas: a suctioning part which has a suctioning opening and which sucks in air from below in the vertical direction; a connection opening that is connected to the suctioning part; a duct part that sends transports the air sucked in from the connection opening and exhausts the air from an exhaust opening to the outside; a blowing mechanism that is provided inside the duct part and that moves the airinside the duct part toward the exhaust opening; and a straightening plate that is disposed inside the suctioning opening of the suctioning part, or disposed so as to cover a portion of the suctioning opening. The distance between the suctioning part and the flow straightening plate is no more than 110 mm, and at least one soundproof structure is provided on the surface on the suctioning part side of the flow straightening plate between the straightening plate and the suctioning part.

Owner:FUJIFILM CORP

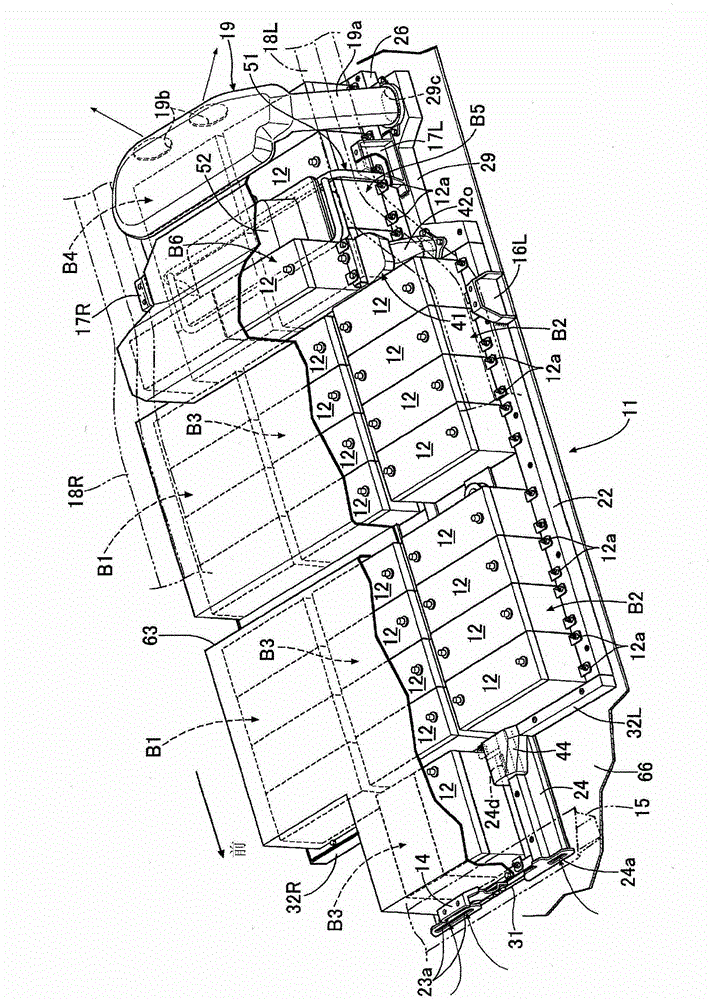

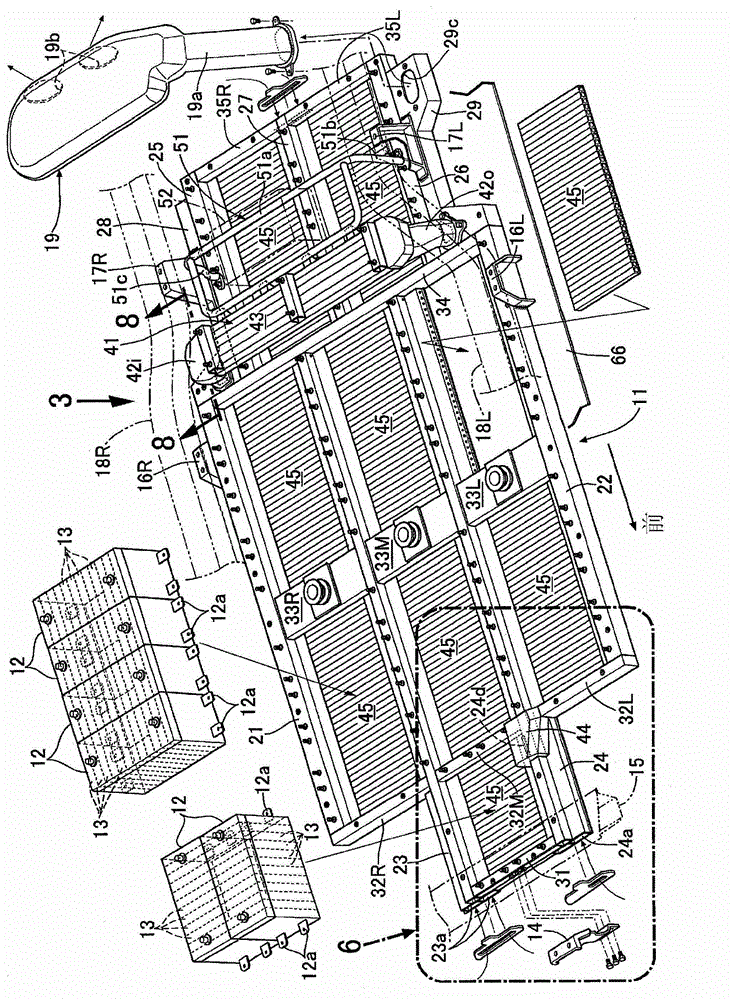

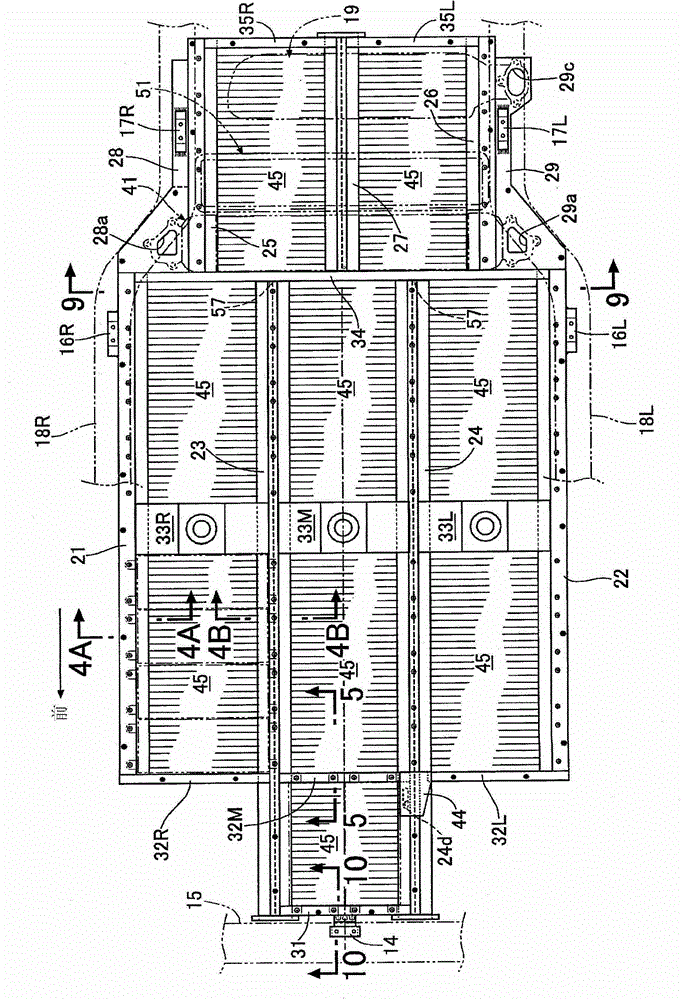

Battery Cooling Structure

ActiveCN103201895BNo pollutionReduce in quantityCell temperature controlElectric propulsion mountingDual functionCooling medium

A battery cooling structure is provided in which since a battery support member (43) that is disposed above a lower layer battery group (B4, B5) and supports an upper layer battery group (B6) on its upper face is formed so as to be hollow, and the upper layer battery group (B6) is cooled by a cooling medium that flows in an interior of the battery support member (43), due to the battery support member (43) having the dual function of supporting the upper layer battery group (B6) and cooling the upper layer battery group (B6), it is possible to cut the number of components and simplify the structure. Moreover, since the cooling medium flows in the interior of the battery support member (43) and does not come into direct contact with the upper layer battery group (B6), the upper layer battery group (B6) is not contaminated by the cooling medium.

Owner:HONDA MOTOR CO LTD

Spacing part for cooling body and air-conditioner pad using same

InactiveCN101919636ASimple structureImprove convenienceStuffed mattressesSpring mattressesBiomedical engineering

The invention relates to a spacing part for cooling a body and an air-conditioner pad using the same, wherein the spacing part for cooling the body is sheet-shaped and comprises a first sheet part and a second sheet part. The first sheet part has a first surface for forming the spacing part. The second sheet part is arranged in opposition to the first sheet part and has a second surface which is opposite to the first surface of the spacing part. The first sheet part comprises a first surface material part which is extended from the first surface and a plurality of first convex parts which are side-protuberant from the first surface material part to the second sheet part; and the second sheet part comprises a second surface material part which is extended from the second surface and a plurality of second convex parts which are side-protuberant from the second surface material part to the first sheet part. The inosculation of the first convex parts and the second convex parts enables the first surface material part and the second surface material part to be supported at intervals and to form an air flow path between the first surface material part and the second surface material part, and a plurality of air holes communicated with the air flow path are formed on a first surface part at least.

Owner:ATEX CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com