Spacing part for cooling body and air-conditioner pad using same

A body and air-conditioning technology, applied in mattresses, applications, spring mattresses, etc., can solve the problems of low production convenience, complex mold structure, and high production cost, and achieve improved production convenience, simple mold structure, and improved convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

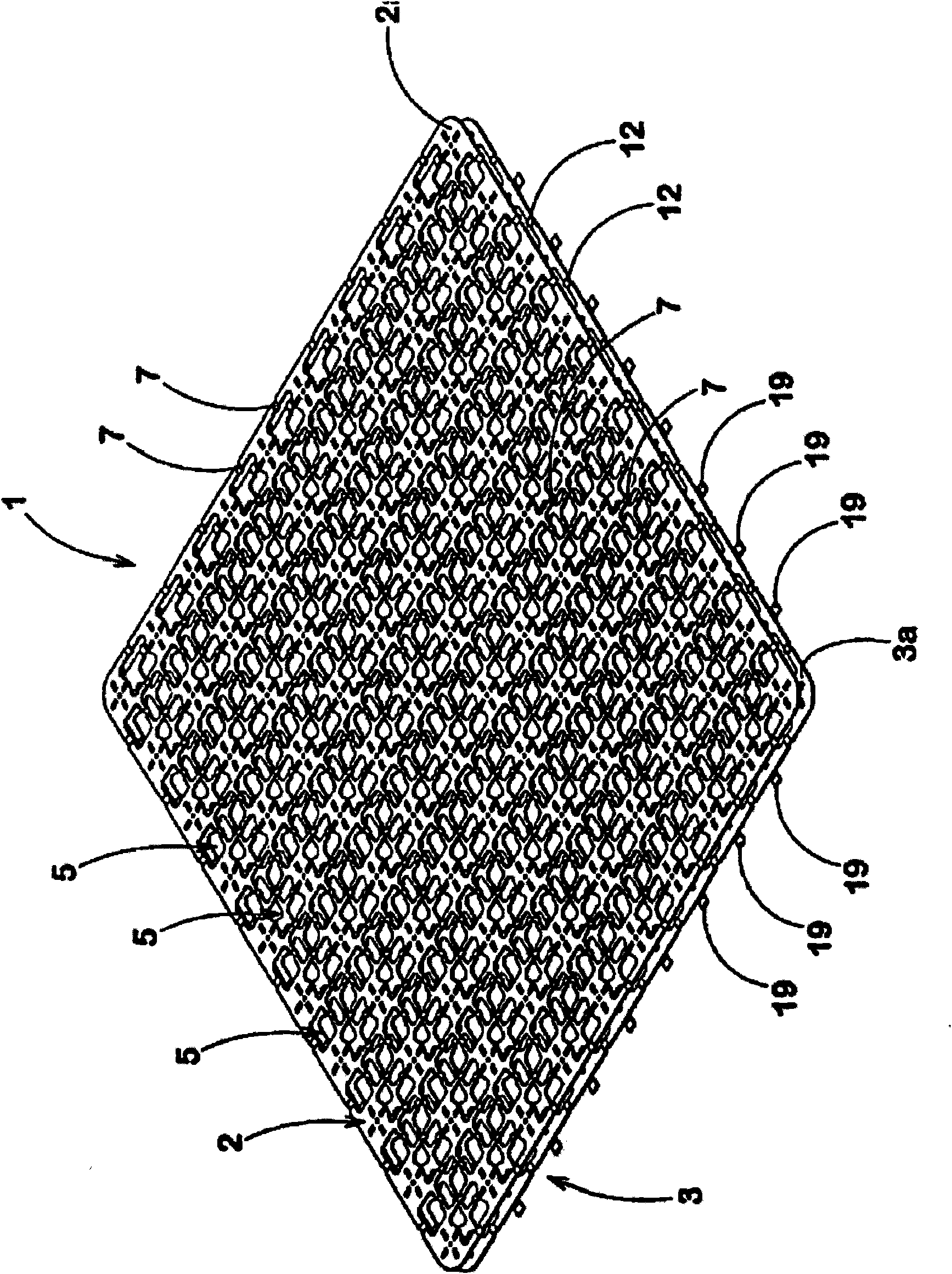

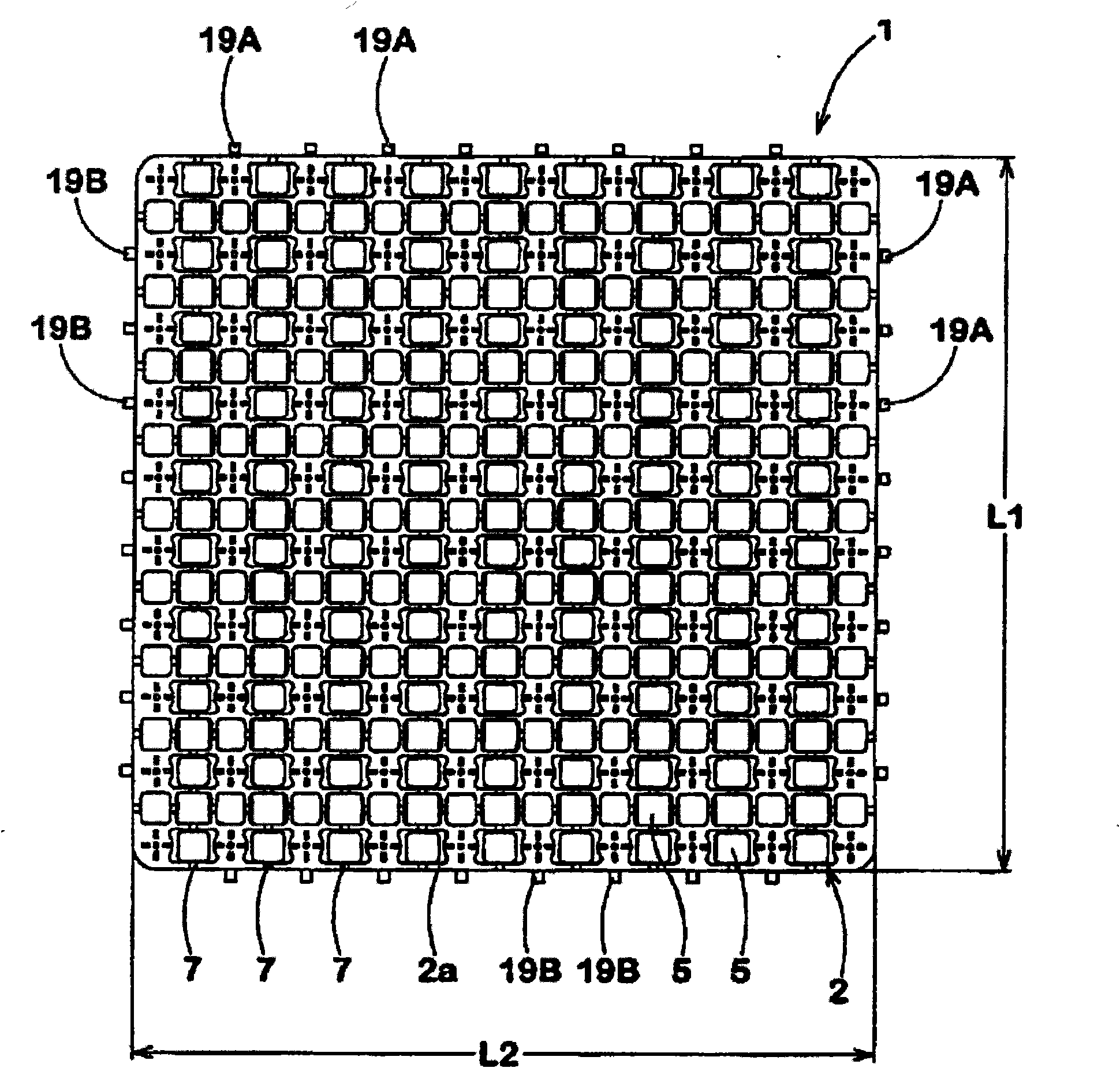

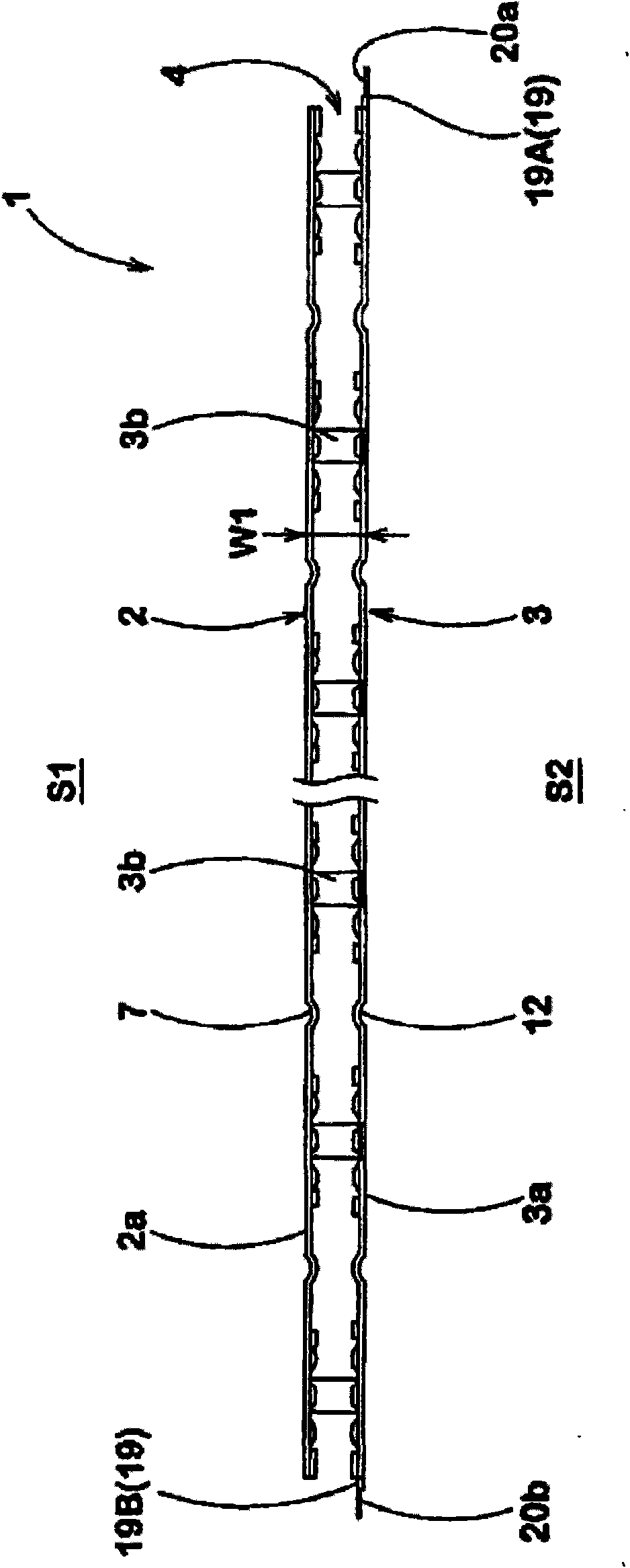

[0072] Please refer to figure 1 , 2 As shown in and 3, the body cooling spacer (hereinafter referred to as "spacer") 1 of the first embodiment of the present invention has an air flow path 4 for air to pass through inside, and can form a vertical length L1 and a horizontal width L2 It is about 400 mm to 500 mm, and the maximum thickness W1 is about 8 mm to 14 mm, which is approximately rectangular in the planar direction and has a small thickness. Furthermore, the spacer 1 can be deformed into a circular or polygonal shape, and its size can also be changed arbitrarily.

[0073] The spacer 1 includes a first piece 2 and a second piece 3, the first piece 2 is formed on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com