Shielding member and apparatus for single crystal growth

A growth device and crystal growth technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., to achieve the effect of suppressing radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0051] "Single crystal growth device"

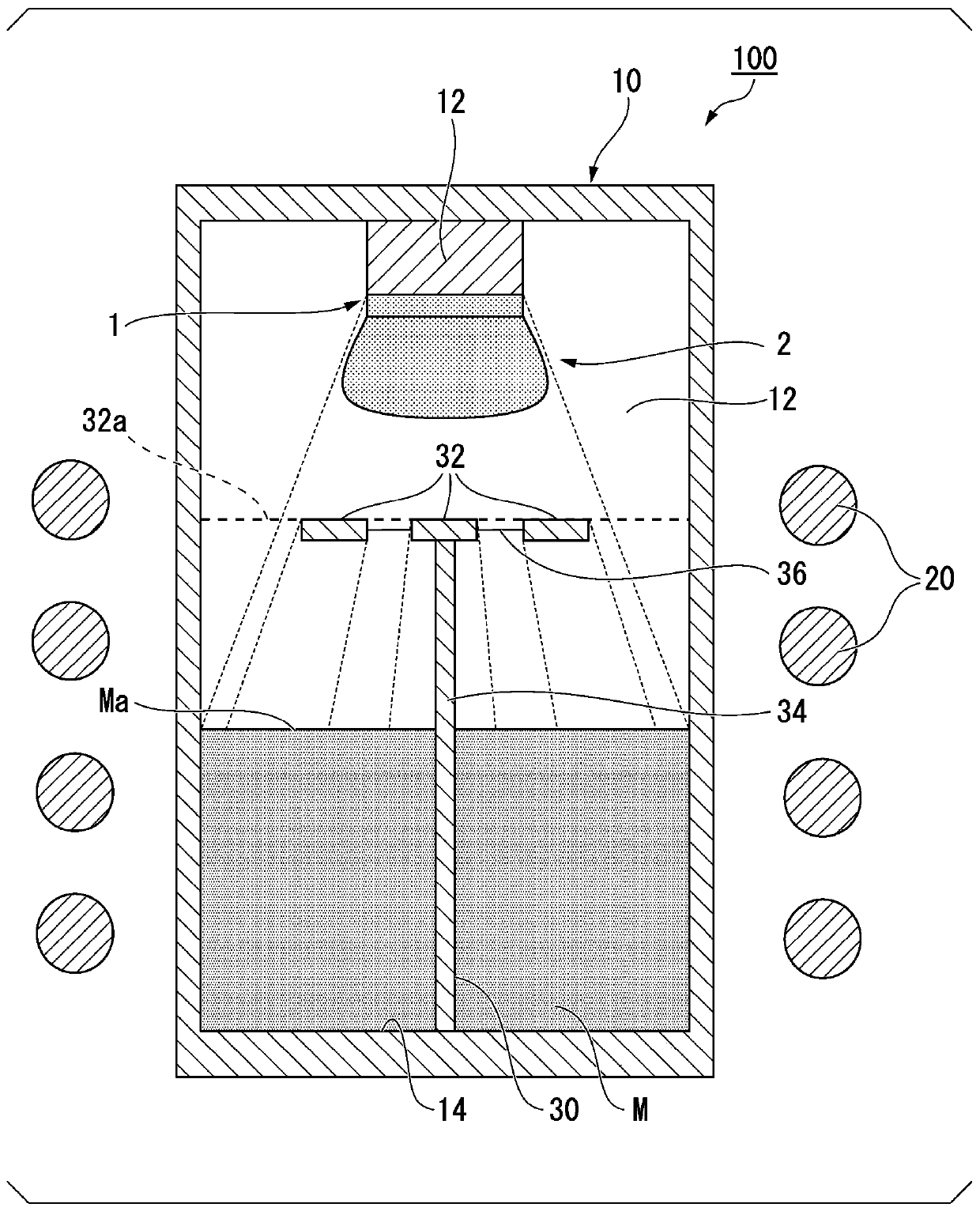

[0052] figure 1 It is a schematic cross-sectional view showing a preferred example of the single crystal growth apparatus of the first embodiment. figure 1 In , for easy understanding, the raw material M, the seed crystal 1 and the single crystal 2 are shown together. figure 1 The illustrated single crystal growth apparatus 100 includes a crystal growth container 10 , a coil (heating unit) 20 , and a shield member 30 .

[0053] The crystal growth container 10 has a space inside. The raw material M is filled in the inner bottom surface of the crystal growth container 10 . The inner bottom surface of the crystal growth container 10 serves as a raw material storage portion 14 . A crystal setting unit 12 is provided at a position facing the raw material M filled in the raw material storage unit 14 . The crystal setting part 12 is a part where the seed crystal 1 is set. For example, the crystal installation portion 12 protrudes toward t...

no. 2 Embodiment approach

[0076] "Single crystal growth device"

[0077] Figure 6 It is a schematic cross-sectional view of the single crystal growth apparatus of the second embodiment. For easy understanding, Figure 6 The raw material M, the seed crystal 1 and the single crystal 2 are simultaneously shown in FIG. figure 1 The illustrated single crystal growth apparatus 101 includes a crystal growth container 10 , a coil (heating unit) 20 , and a shield member 70 . The shape of the shielding member 70 and figure 1 The single crystal growth apparatus 100 shown is different. Other structures are the same, with the same symbols attached, and descriptions are omitted.

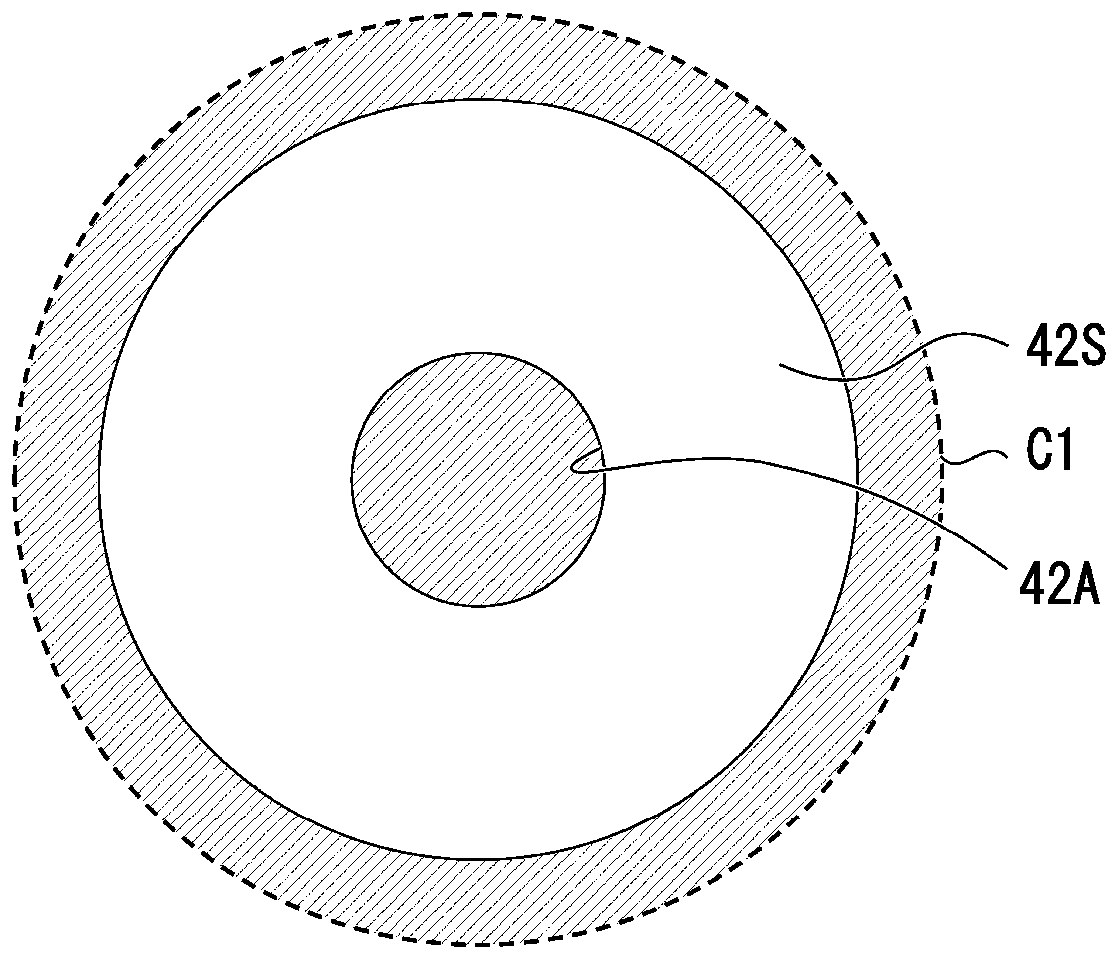

[0078] The shield member 70 includes a plurality of shield plates 72 , support portions 74 , and connection portions 76 . A plurality of shielding plates 72 become 2 sections, which is the same as figure 1 The shielding member 30 shown is different. Figure 7 It is a figure which projected the shielding member 70 of 2nd Embodiment...

Embodiment 1

[0092] "Example 1"

[0093] First, a crystal growth container provided with a columnar inner space was prepared. Then, SiC in a powder state was filled as a raw material from the inner bottom surface of the crystal growth container to a position of 30% of the height of the inner space. The crystal installation part was set as a circle with a diameter of 6 inches in plan view.

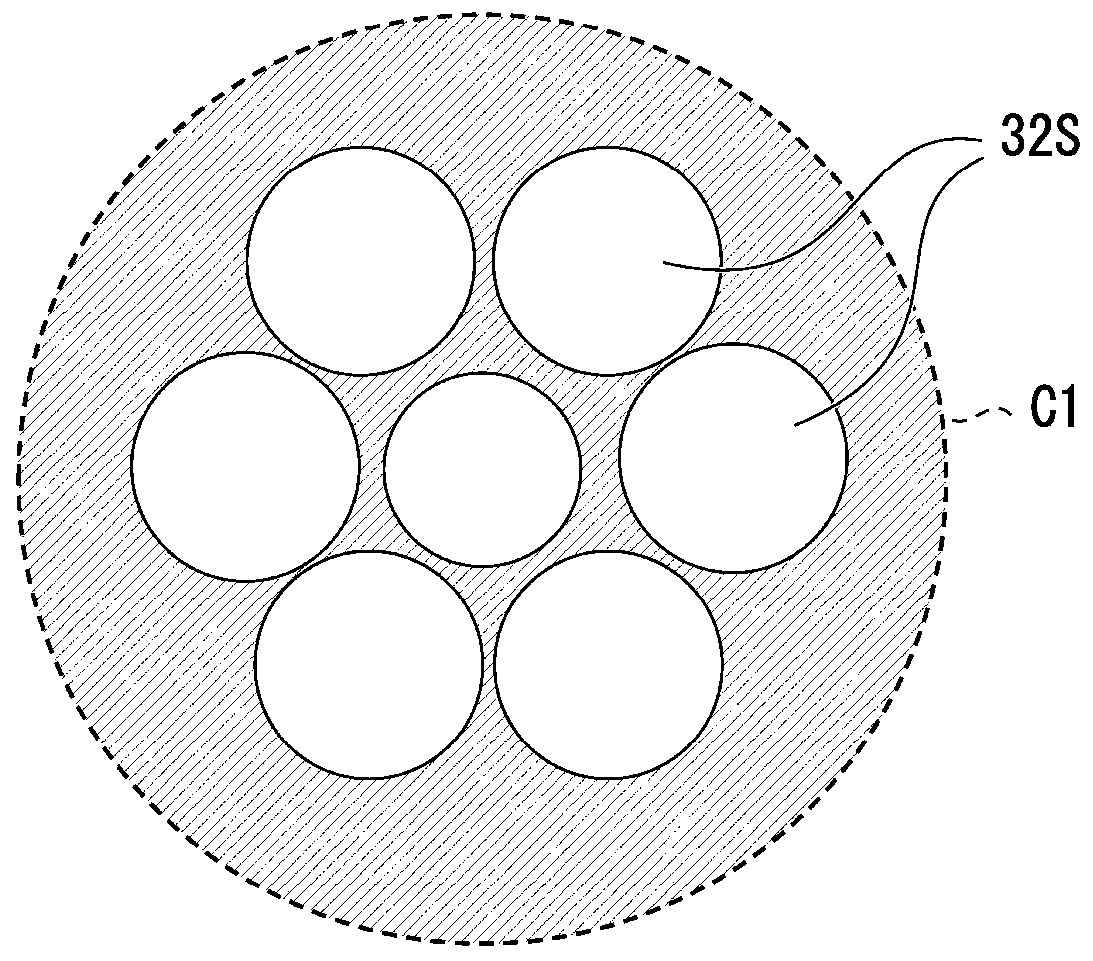

[0094] Furthermore, a shielding member is provided between the raw material and the crystal installation part. As the shielding member, three circular shielding plates in plan view are arranged in a hexagonal close-packed arrangement, that is, they are arranged on the same plane at equal distances from each other around the support portion. The respective areas of the shielding plates were set to 17% of the area of the inner bottom of the crystal growth container. In addition, the height of the arrangement of the shielding plates is designed so that the shielding ratio of the projected surface obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shading coefficient | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com