Range hood

A technology for range hood and air supply mechanism, which is applied in the direction of removing oil fume, household stove/stove, ventilation system, etc., can solve the problem of noise of the air supply mechanism, achieve high soundproof performance, ensure the flow path, and easily clean the oil stains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0206] As the cooker hood, Panasonic Corporation's FY-7HZCJ4 was used.

[0207] The distance between the suction part of the range hood and the rectifying plate is 40mm.

[0208] The size of the suction port is 748mm×600mm.

[0209] The size of the rectifier plate in the plane direction is 637 mm×468 mm, and the thickness is 0.5 mm.

[0210] The size of the connection port is 300mm×270mm.

[0211] In addition, the blower mechanism is disposed on the connection port side of the duct portion.

[0212] The following sound-proof structure was arranged on the rectifying plate of this range hood, and the noise when the suction was set to "strong" was recorded using an iPhone 5 (manufactured by Apple Inc.) connected to a microphone (iQ7, manufactured by Zoom Corporation) and carried out. Measurement.

[0213] As a sound-proof structure, two fine perforated sheets 20E are used aligned in a direction perpendicular to the rectifying plate 18 .

[0214] The fine perforated sheet 20E...

Embodiment 2

[0223] Except having used the following porous sound absorbing body 20A as a soundproof structure, the range hood was produced similarly to Example 1, and the noise was measured by the method similar to the above.

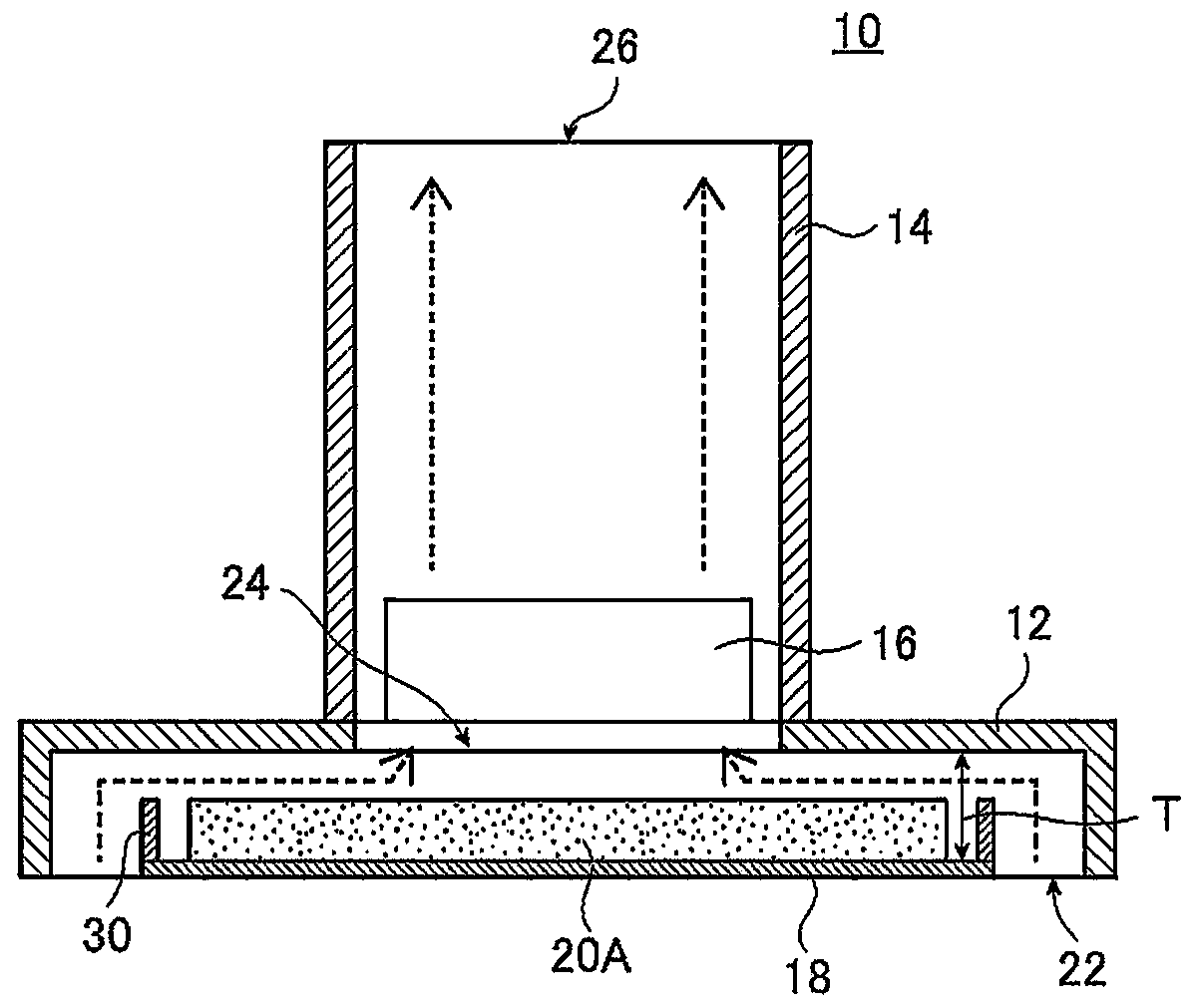

[0224] The porous sound absorbing body 20A was made of urethane (product name: CALMFLEX, manufactured by INOAC Corporation) having a size of 637 mm×468 mm and a thickness of 1 mm. like figure 1 In the example shown, the porous sound absorbing body 20A is provided on the rectifying plate 18 .

[0225] The results are shown in Figure 19 . Figure 19is a graph showing the relationship between frequency and microphone sound pressure level.

[0226] from Figure 19 It can be seen that by arranging the sound-proof structure on the rectifying plate, a high sound-proof effect can be obtained in the frequency band from 1000 Hz to 10000 Hz.

Embodiment 3

[0228] Except having used the following Helmholtz resonator 20C as a soundproof structure, the range hood was produced similarly to Example 1, and the noise was measured by the method similar to the above.

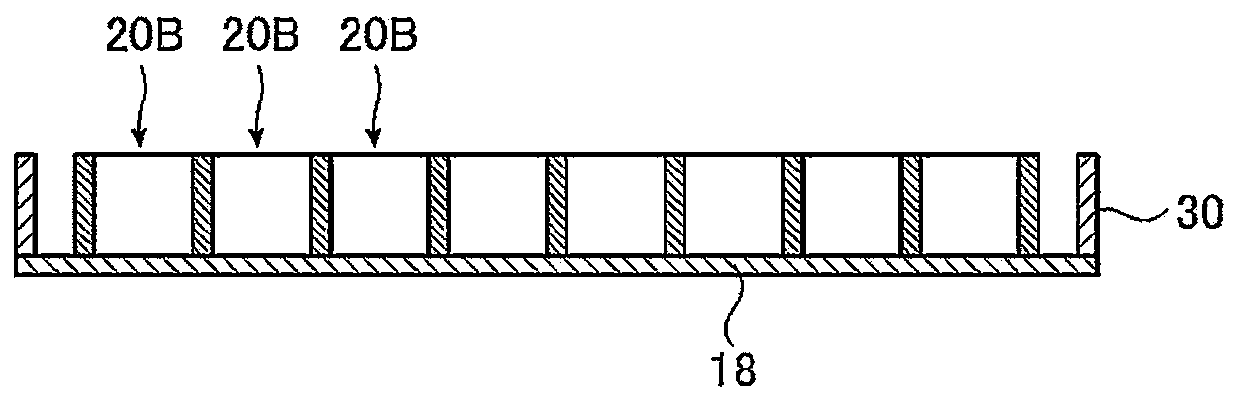

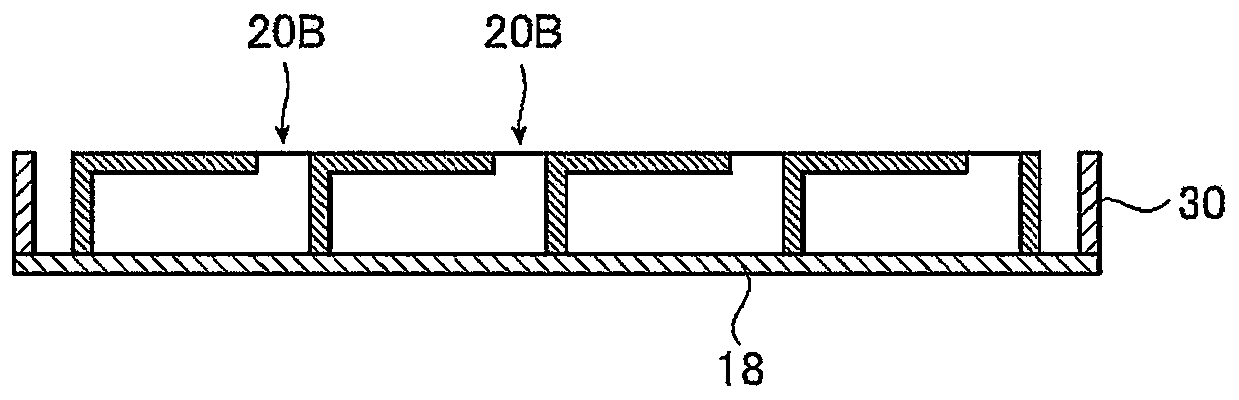

[0229] The Helmholtz resonator 20C is a paper honeycomb structure. A large number of honeycomb cores are arranged on the frame. The thickness of each honeycomb core in the vertical direction is 15 mm, and the distance between the opposing surfaces is 10 mm. The lower surface in the vertical direction of the frame is covered with kraft paper with a thickness of 1mm. In addition, as the perforated plate, an acrylic plate with a thickness of 1 mm was used, and through holes with a diameter of 1 mm were alternately arranged at intervals of 12 mm on the acrylic plate. A perforated plate is disposed on the vertically upper surface of the housing to form a Helmholtz resonator 20C.

[0230] The results are shown in Figure 20 . Figure 20 is a graph showing the relationship bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com