Battery Cooling Structure

A battery and structure technology, which is applied to the arrangement of secondary batteries, power unit cooling combined, battery temperature control, etc. , Prevent dumping, and achieve the effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

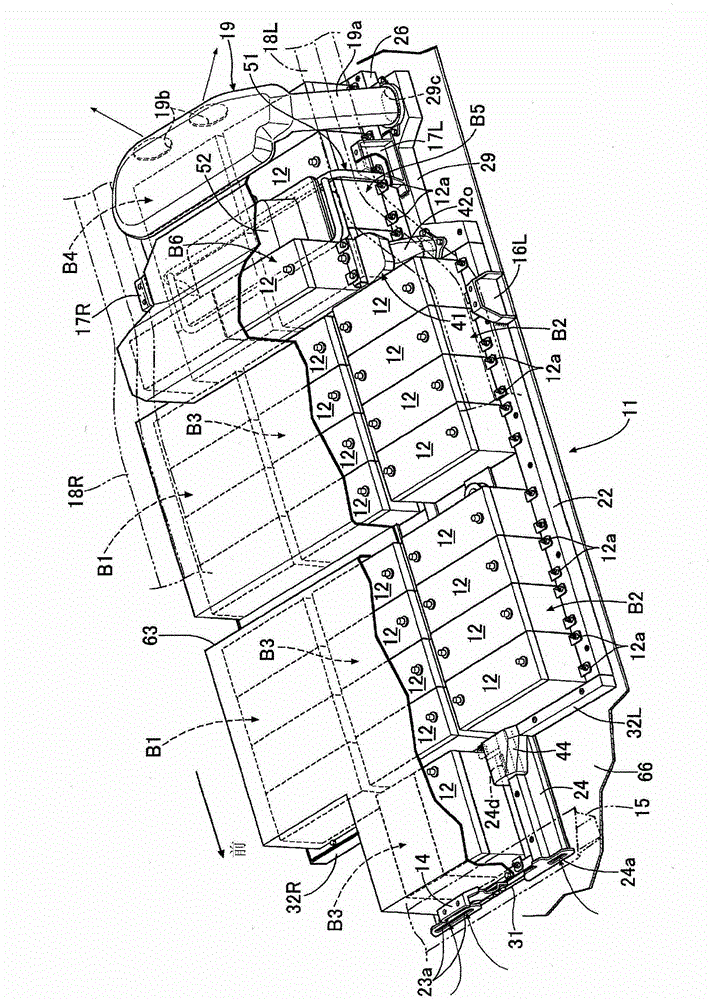

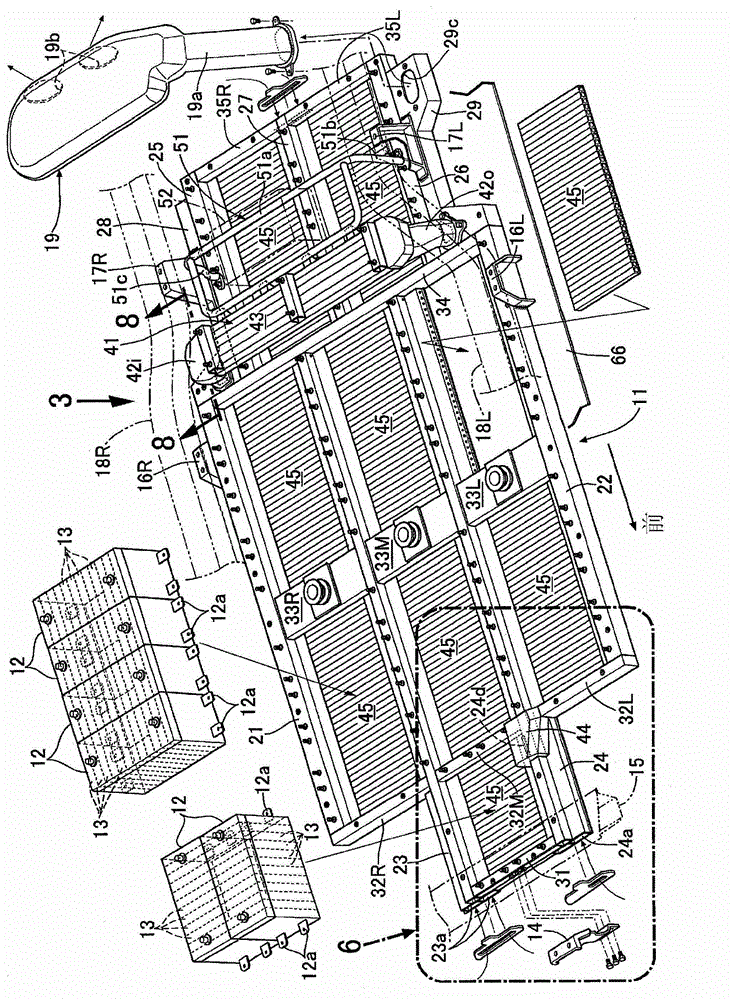

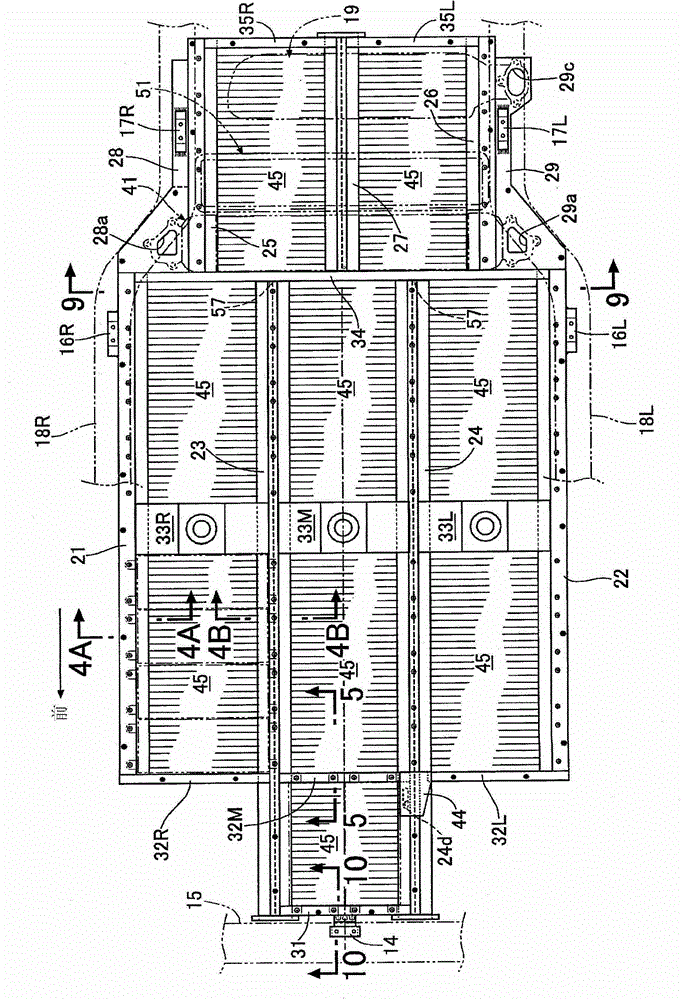

[0052] Such as Figure 1 ~ Figure 3 As shown, the battery unit that supplies electric power to a motor / generator serving as a driving power source of an electric vehicle includes: a plate-shaped tray 11; The shape of each battery module 12 is a rectangular parallelepiped, and a plurality of battery cells 13 electrically connected in series are accommodated therein. figure 2 ). Two brackets 12 a , 12 a protrude from both ends of the battery module 12 in the longitudinal direction. The brackets 12 a , 12 a are used to fix the battery module 12 to the tray 11 .

[0053]The mounting bracket 14 provided at the front of the panel 11 is coupled to the cross member 15 of the vehicle body, and the two mounting brackets 16L, 17L provided at the left rear of the panel 11 are coupled to the side frame 18L on the left side. Two mounting brackets 16R, 17R provided at the right rear portion of 11 are coupled to a right side frame 18R, whereby the battery unit is suspended and supported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com