Heat exchanger

A technology for heat exchangers and heat exchange media, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc. The effect of exchange performance, thinning, and improved flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]

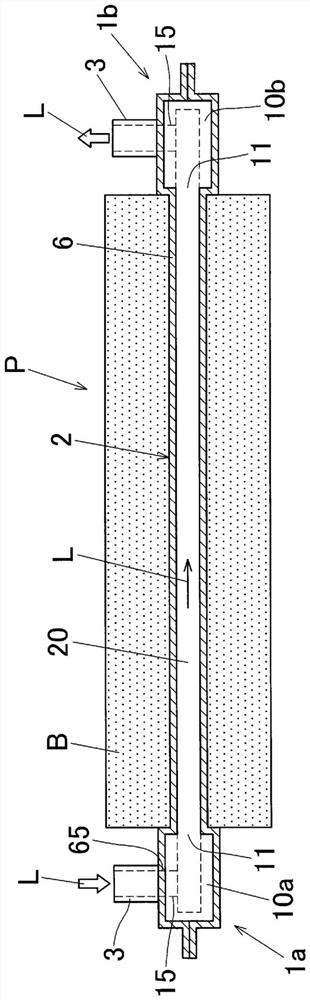

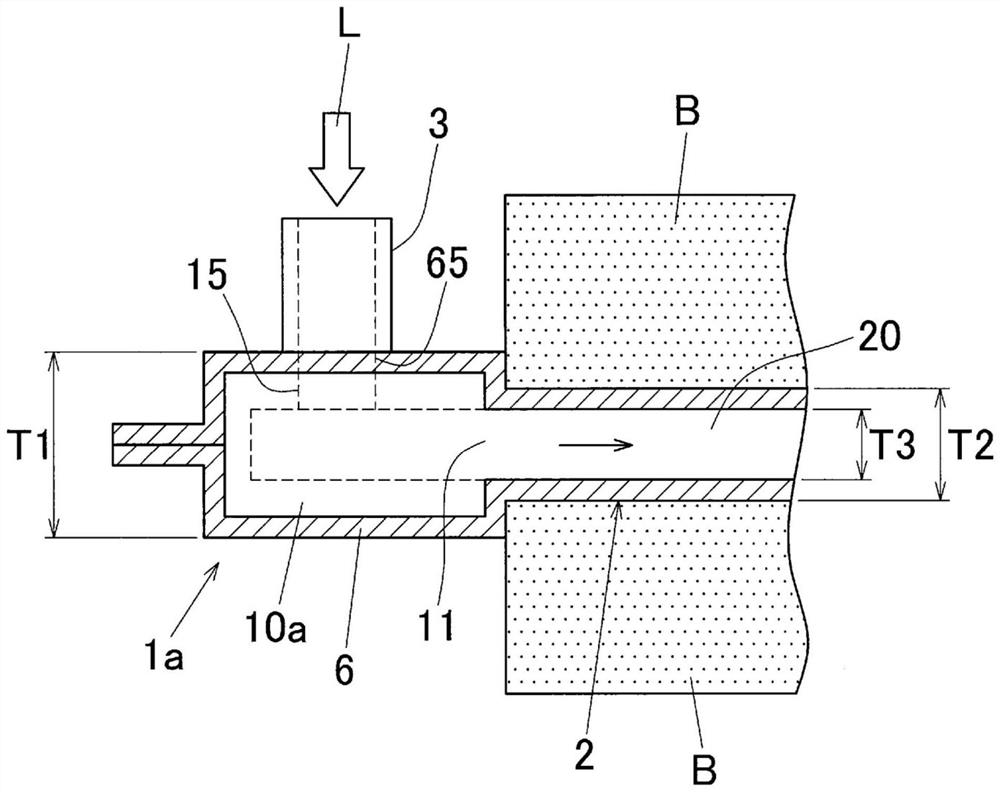

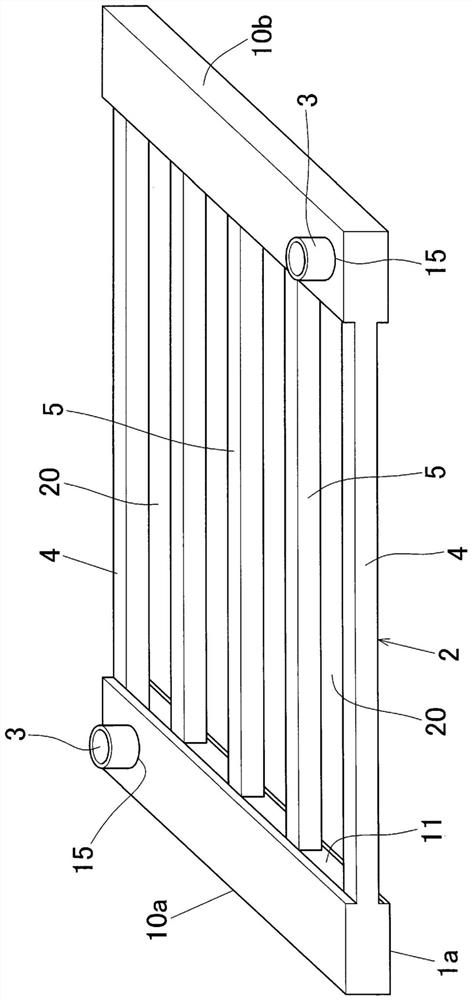

[0070] figure 1 It is a cross-sectional view showing a battery cooling unit using a heat exchange panel P as a heat exchanger according to the first embodiment of the present invention, figure 2 is an enlarged cross-sectional view showing the periphery of the inlet / outlet forming portion in the battery cooling unit, image 3 It is a perspective view showing a state in which the cover sheet is removed in the heat exchange panel P, Figure 4 It is a top view for explaining the flow of the coolant L of the heat exchange panel P. FIG. In addition, in the following description, in order to understand the invention easily, the figure 1 The up-and-down direction is taken as the "thickness direction" of the heat exchange panel P, the left-right direction is taken as the "longitudinal direction" of the heat exchange panel P, and the figure 1 Orthogonal direction of the paper ( Figure 4 The up and down direction) will be described as the "lateral direction" of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com