Water cooling plate unit applied to battery pack

A technology of water-cooled plates and battery packs, which is applied to electrical components, secondary batteries, battery temperature control, etc., and can solve problems such as increased manufacturing costs, high manufacturing costs, and excessive volume of the battery pack 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

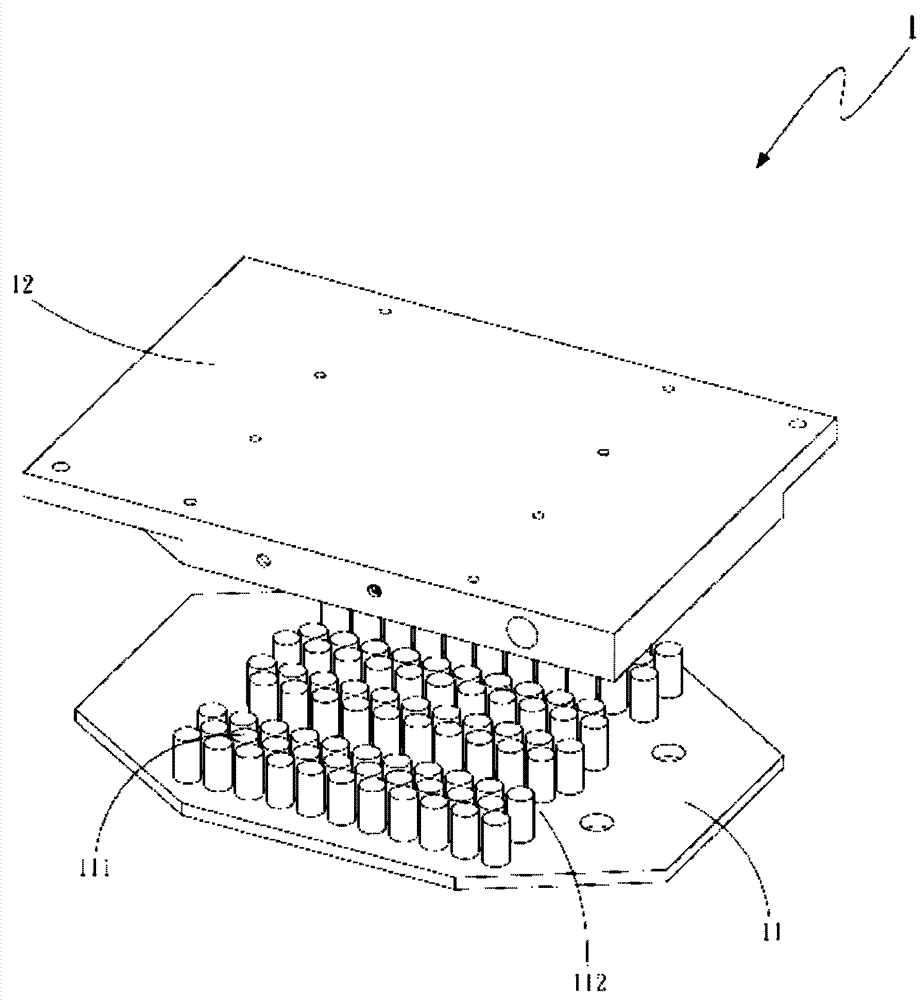

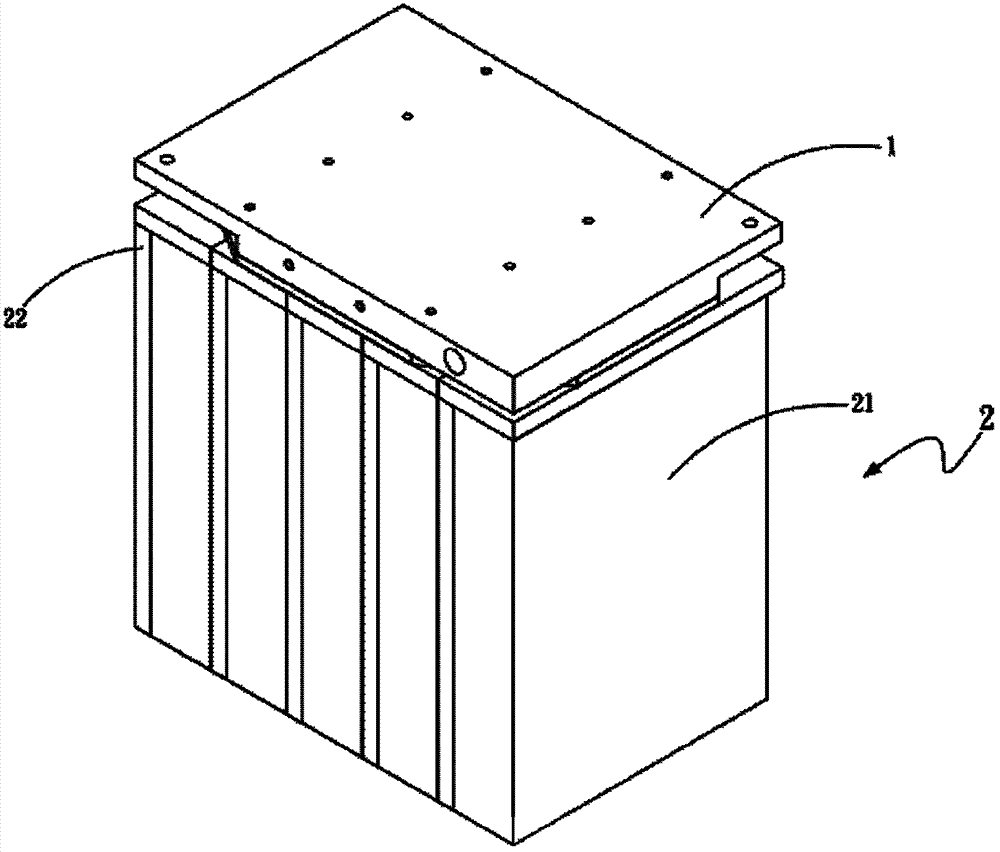

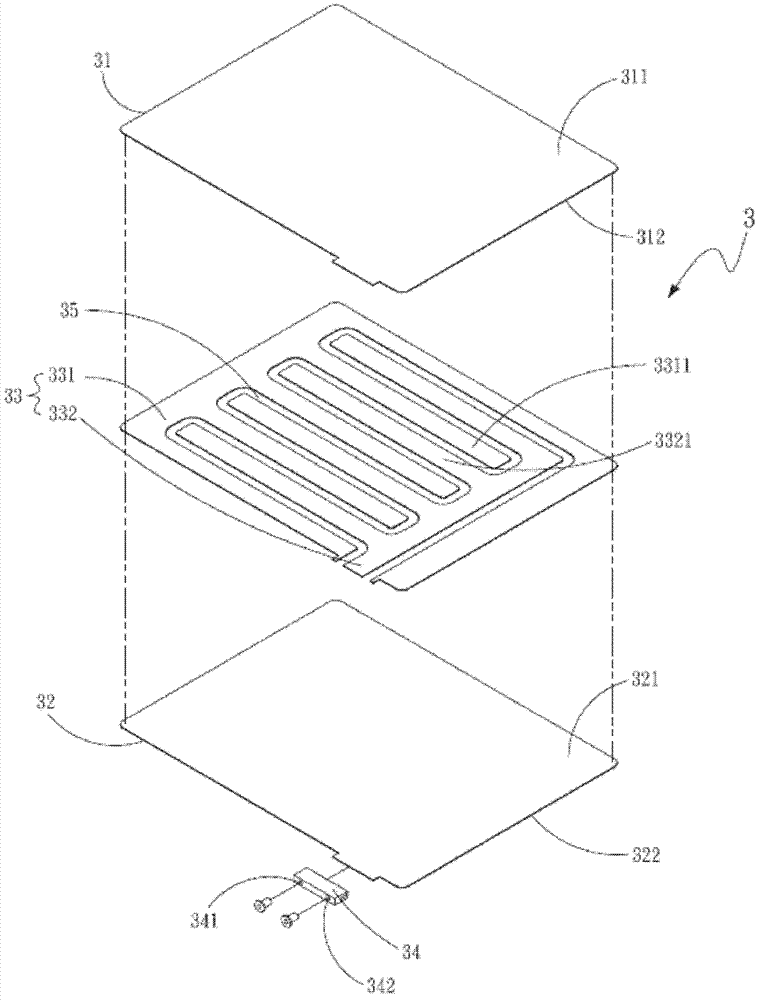

[0046] see figure 2 and image 3 As shown, it is a three-dimensional exploded view and a three-dimensional assembly view of the first preferred embodiment of the water-cooled plate unit applied to the battery pack of the present invention. As shown in the figure, the water-cooled plate unit 3 includes a first plate body 31 and a first plate body 31. Two plates 32, a channel structure 33 and a joint group 34, the two sides of the first plate 31 are respectively formed with a first side 311 and a second side 312, and the two sides of the second plate 32 are respectively formed with a first side Three sides 321 and a fourth side 322 , wherein the surface of the third side 321 is correspondingly covered with the surface of the second side 312 of the first plate body 31 .

[0047] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com