Lens module

A lens module and lens component technology, applied in the field of cameras, can solve the problem that the height of the lens component does not meet the needs of market development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

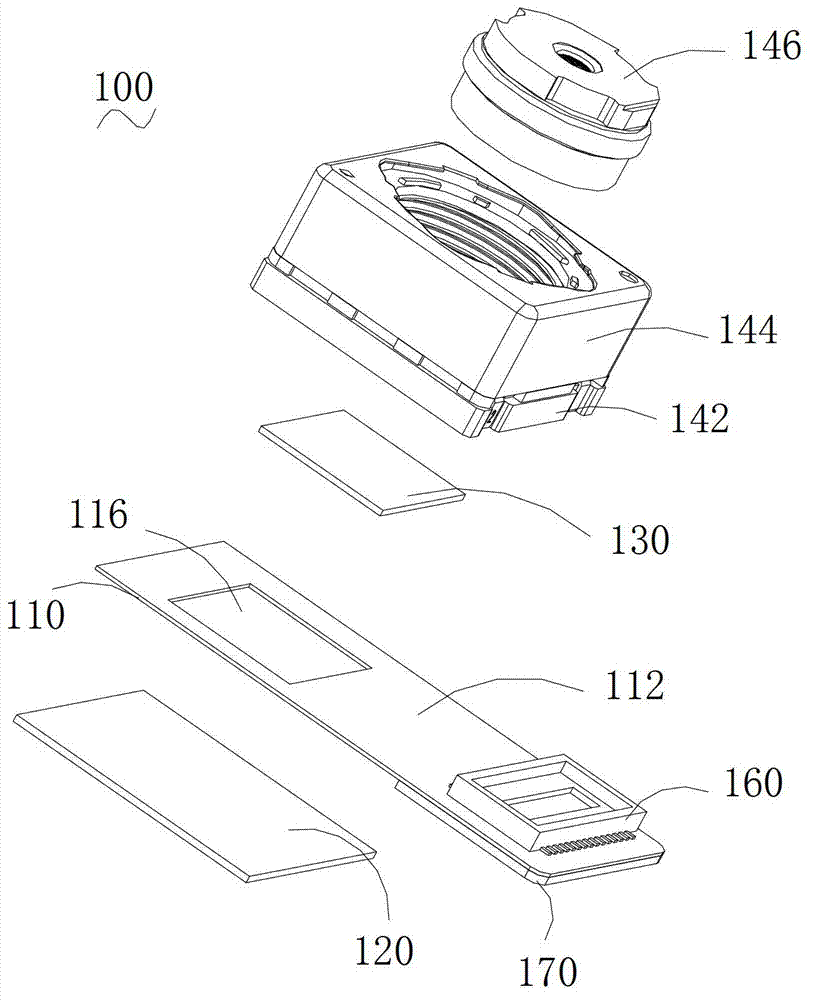

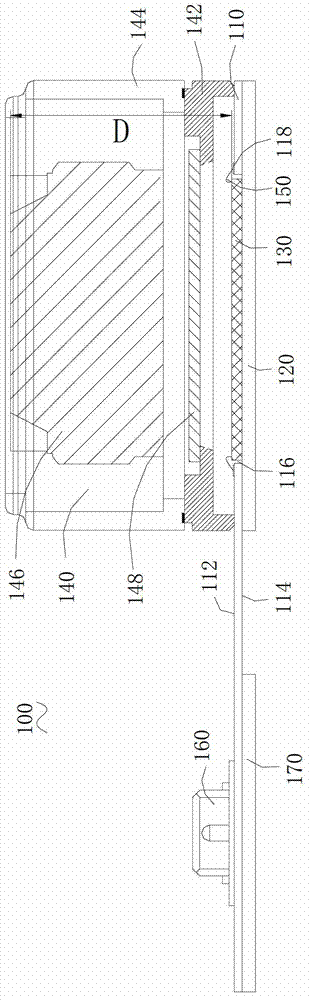

[0017] Please refer to figure 1 and figure 2 , this embodiment discloses a lens module 100 , including a flexible circuit board 110 , a reinforcement board 120 , a sensor 130 and a lens assembly 140 . The flexible circuit board 110 has a mounting surface 112 , a back surface 114 opposite to the mounting surface 112 , and a through hole 116 passing through the mounting surface 112 and the back surface 114 . The reinforcing plate 120 is mounted on the back surface 114 and covers the through hole 116 . The sensor 130 is installed on the reinforcement board 120 and received in the through hole 116 , and the lens assembly 140 is installed on the installation surface 112 of the flexible circuit board 110 . The through hole 116 absorbs part of the height of the sensor 130 , so that the height of the lens module 100 is at least reduced by the thickness of the flexible circuit board 110 , thereby realizing thinning of the lens module 100 .

[0018] In detail, the sensor 130 is past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com