Backlight module group and liquid crystal display device

A technology for backlight modules and display panels, which is applied in the directions of light guides, optics, optical components, etc., can solve the problems of difficulty in achieving thinning and large thickness of backlight modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

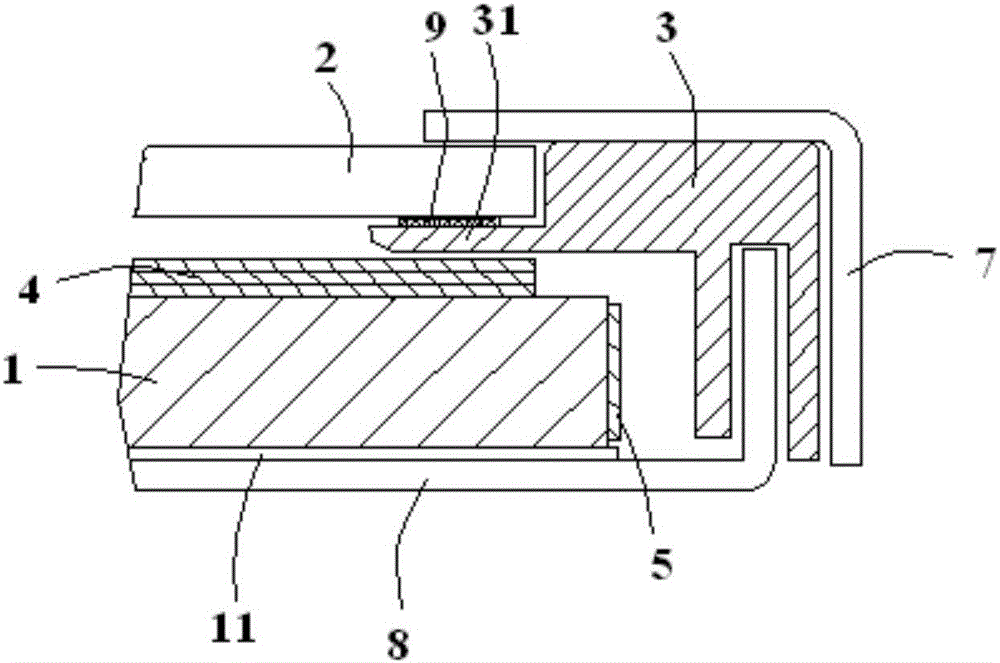

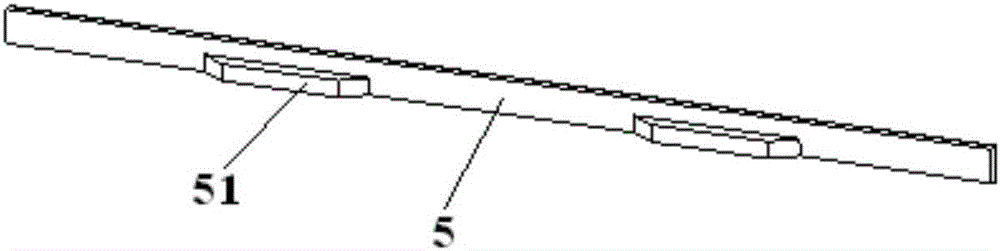

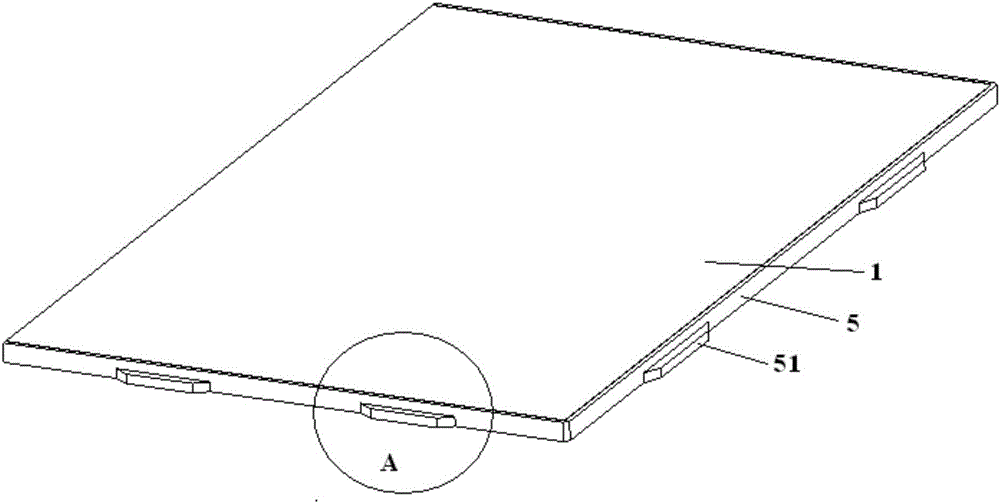

[0033] Such as Figure 2 to Figure 9 As shown, this embodiment provides a liquid crystal display device and a backlight module used therein.

[0034] Specifically, the backlight module of this embodiment includes a light guide plate 1 , a light blocking member 5 , and a plastic frame 3 . in:

[0035] The light guide plate 1 has a bottom surface and a light-emitting surface opposite to each other, and a plurality of sides connected between the bottom surface and the light-emitting surface, and the sides include a light-incident side and a non-light-incident side.

[0036] The light guide plate 1 is generally a rectangular plate. One of the two large surfaces of the rectangular plate is the bottom surface for light reflection, and a reflective sheet 11 may be provided outside it, while the other surface is a light-emitting surface for light emission. The bottom surface and the light-emitting surface are connected by multiple sides, at least one of which needs to be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com