Gas sensor unit

A gas sensor and sensor technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of reduced ventilation of filter components and inability to ventilate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

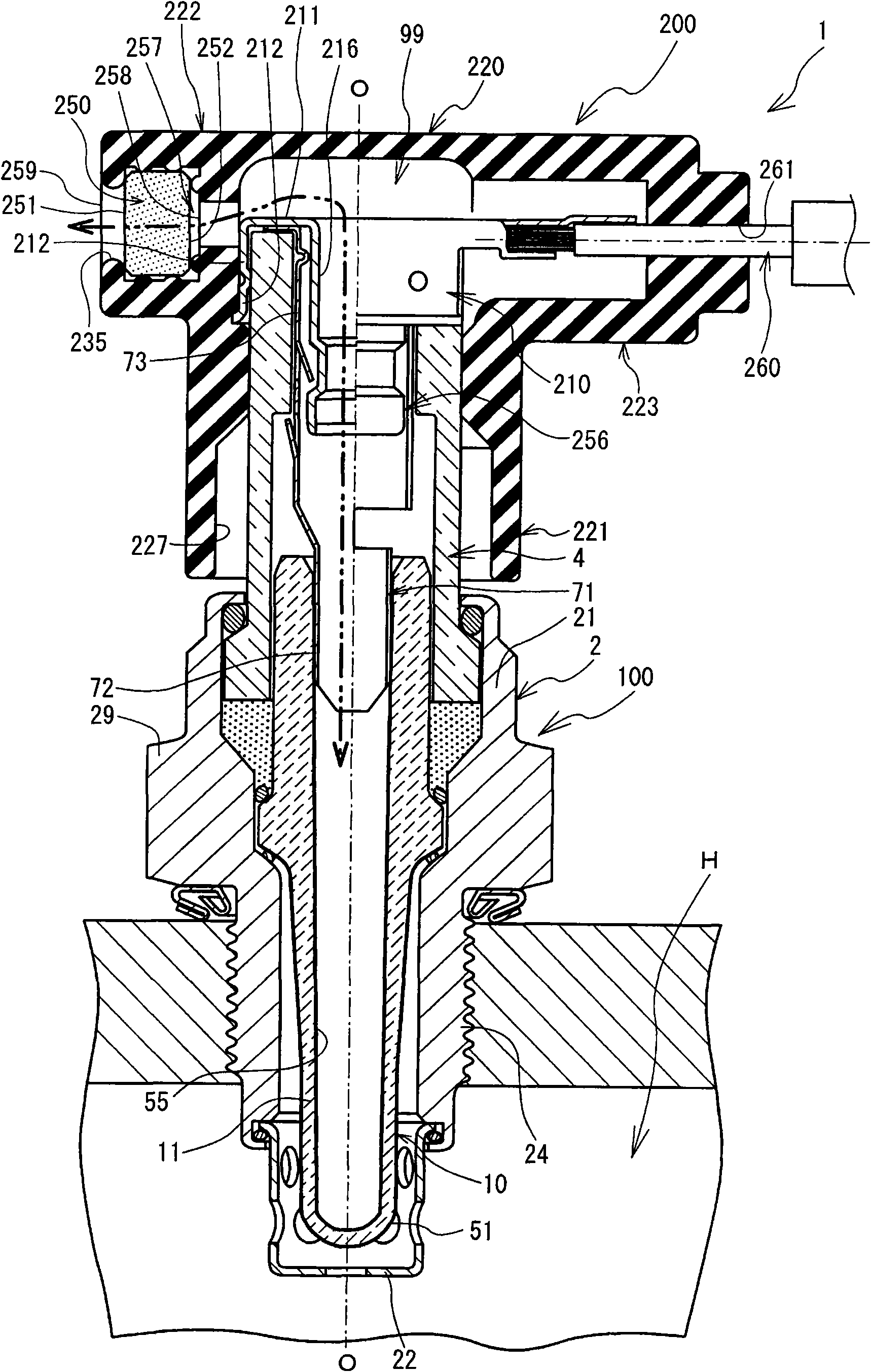

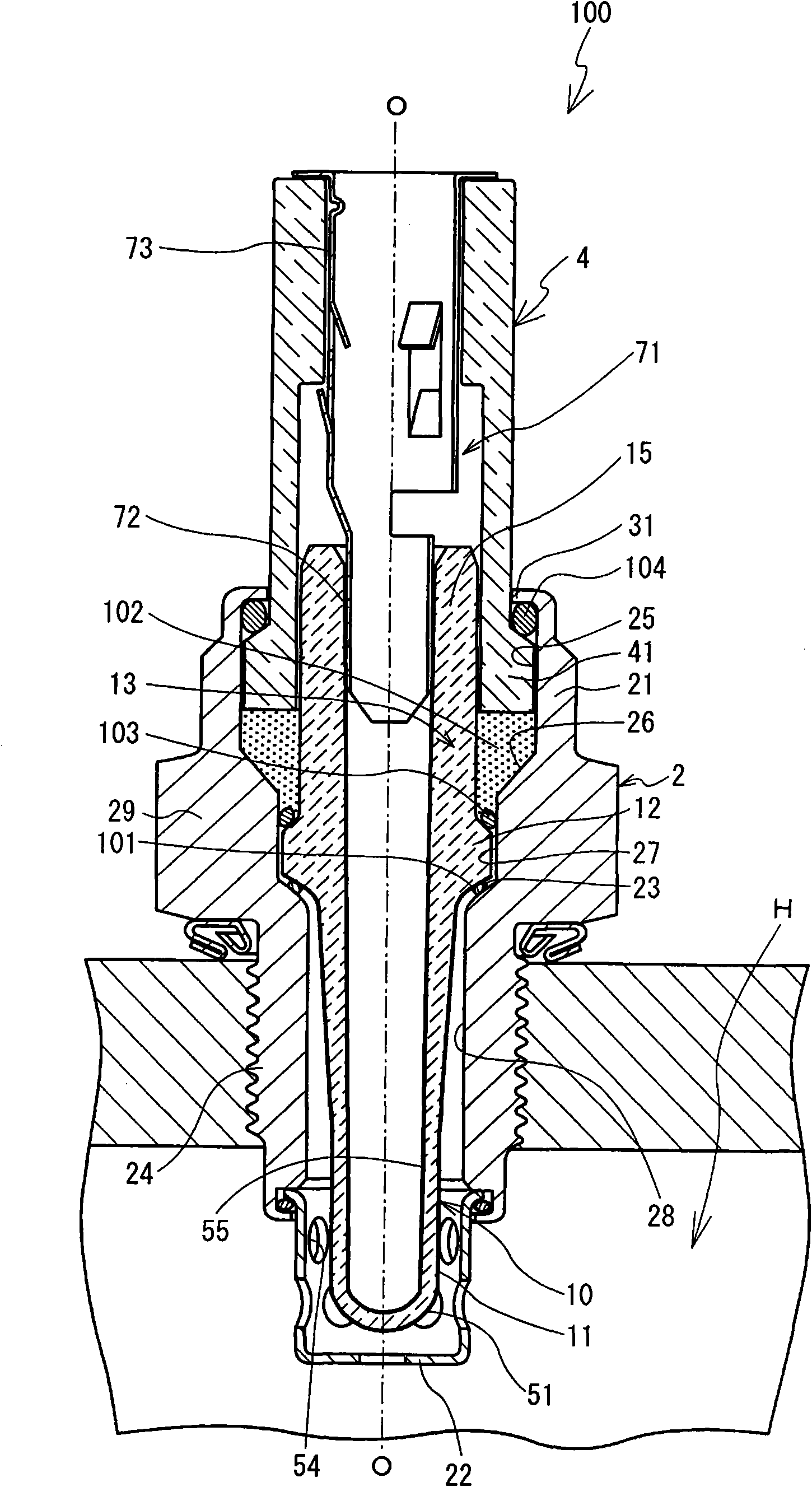

[0031] Next, a first embodiment of the gas sensor unit 1 that embodies the present invention will be described with reference to the drawings. The gas sensor unit 1 is installed and used in an exhaust path H of an automobile. In the following description, the side of the gas sensor unit 1 inserted into the exhaust path H in the axis O direction ( figure 1 The lower side in the middle) is regarded as the front end side of the gas sensor unit 1, and the side facing the opposite direction of this side ( figure 1 The upper side) is regarded as the rear end side.

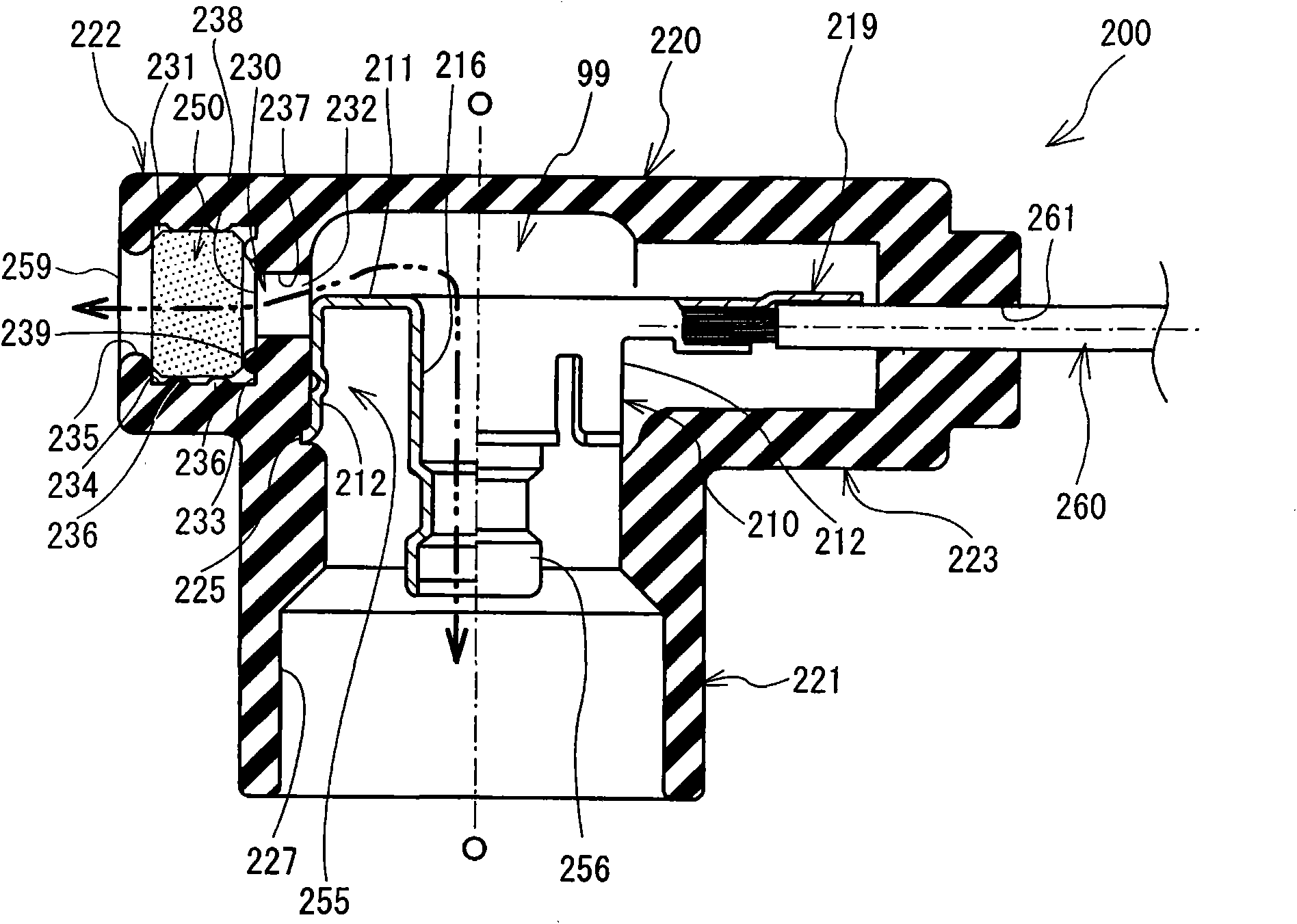

[0032] Such as figure 1 As shown, the gas sensor unit 1 includes an oxygen sensor 100 and a sensor cap 200 detachably attached to the oxygen sensor 100 at the rear end side of the oxygen sensor 100 . The oxygen sensor 100 has a built-in detection element 10 that is exposed to the exhaust gas for outputting a detection signal corresponding to the oxygen concentration in the exhaust gas. The sensor cap 200 is mounted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com