Master cylinder

A main body and cylinder technology, applied in the direction of hydraulic brake transmission, etc., can solve problems such as brake fluid supply limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

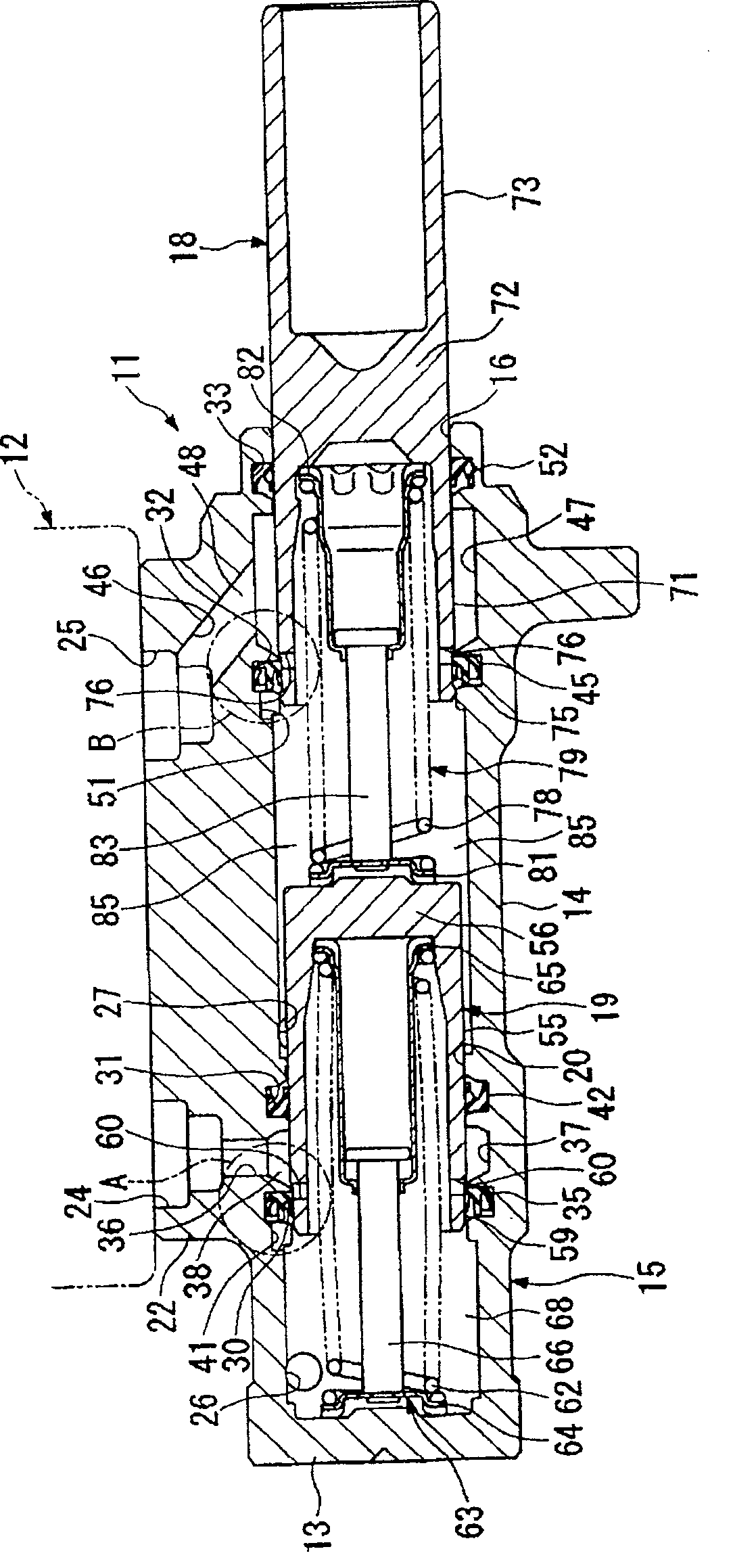

[0034] A master cylinder according to an embodiment of the present invention will be described with reference to the drawings.

[0035] figure 1 Reference numeral 11 denotes a master cylinder in this embodiment, which generates brake hydraulic pressure by a force corresponding to the operation amount of the brake pedal introduced through a brake booster not shown in the figure. A container 12 for supplying and discharging brake fluid is provided on its upper side.

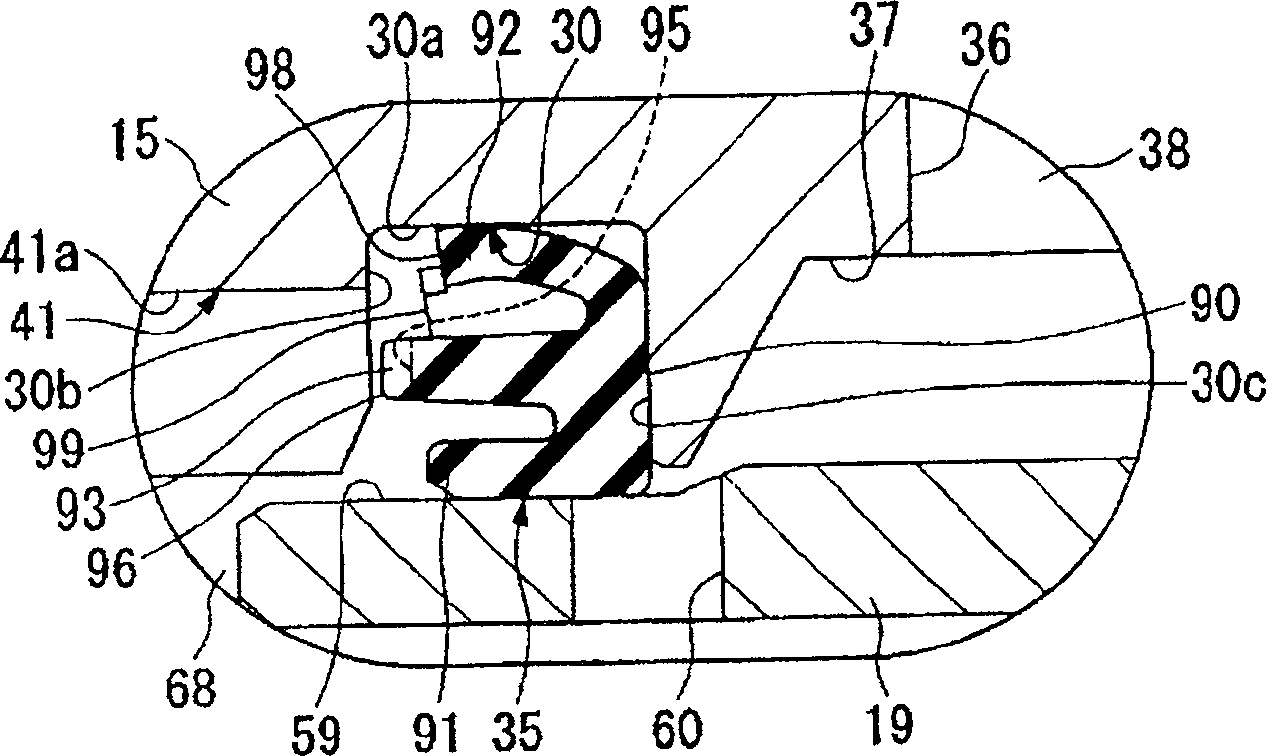

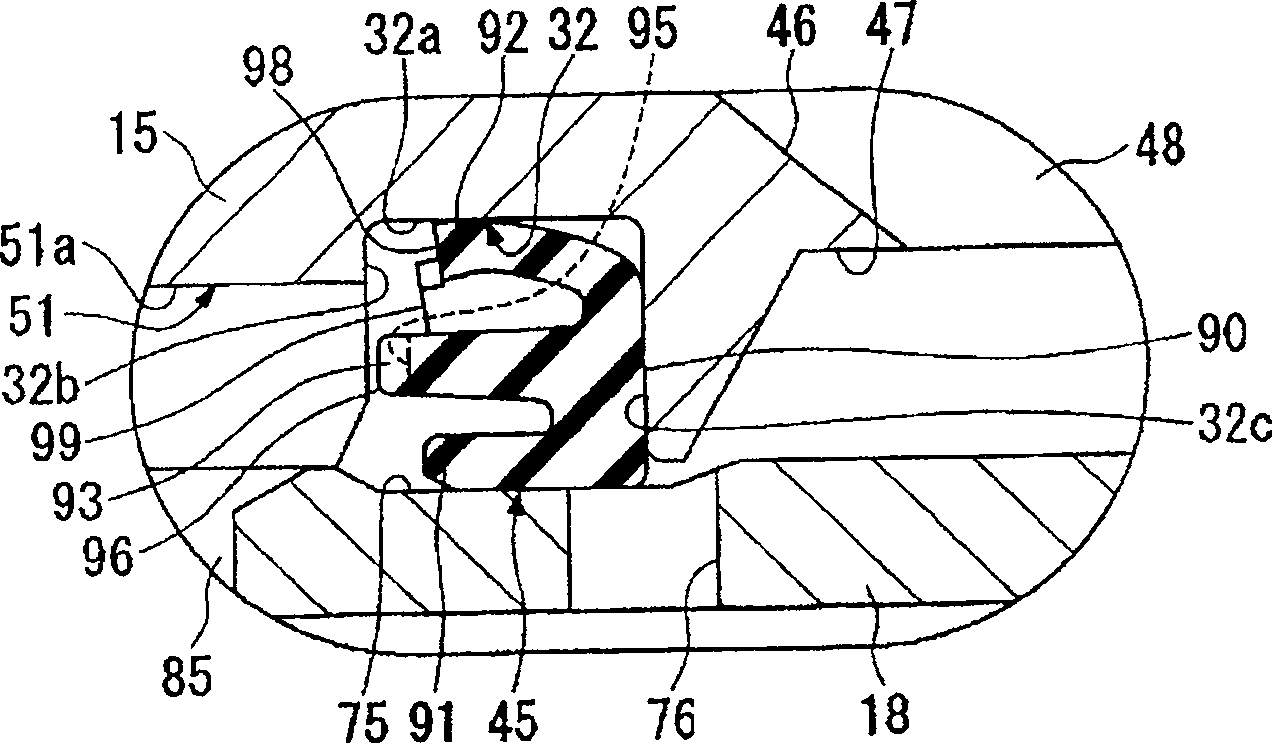

[0036] The master cylinder 11 is a tandem master cylinder having: a cylinder main body 15 which is processed from one material into a bottomed cylindrical shape having a bottom 13 and a cylinder portion 14, and which is disposed on the vehicle in a transverse posture; a primary piston (piston ) 18 , which is slidably inserted into the opening portion 16 side of the cylinder main body 15 ; The primary piston 18 and the secondary piston 19 are slidably guided on a sliding inner diameter portion 20 having a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com