Hot processing clamp

A fixture and component technology, applied in the field of heat treatment fixtures, can solve problems such as difficulty in ensuring mechanical strength and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

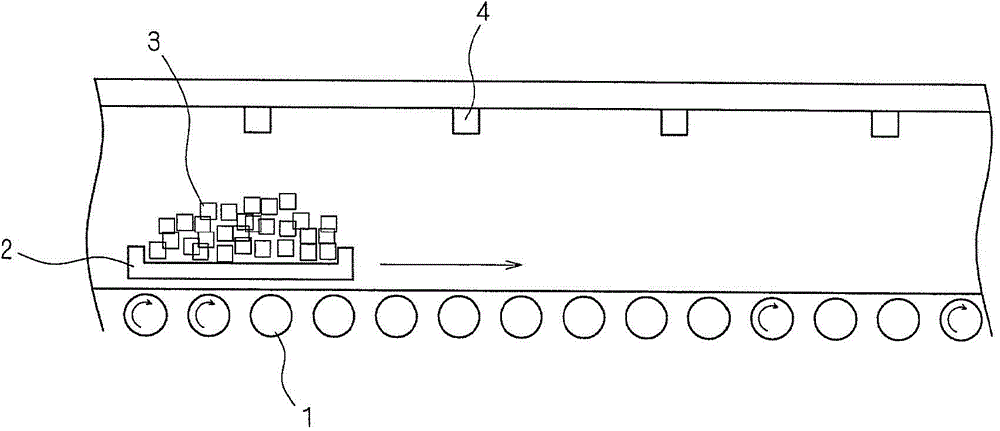

[0037] figure 1 It is a schematic diagram showing the structure of a heating device using a conventional heat treatment jig. figure 1 Shown in the so-called rolling heating device. Such as figure 1 As shown, a plurality of rotatable rollers 1 are provided on the bottom surface of the furnace (heat treatment furnace) of the heating device, and chip-shaped (ceramic) electronics are randomly placed on the loading surface of the heat treatment jig 2. Components 3, such as laminated bodies such as chip-shaped ceramic capacitors and chip-shaped inductors, and the above-mentioned electronic components 3 are passed through the heating furnace along the direction of the arrow in the figure. The heated shielding gas is sprayed from the gas injection port 4 in the upper part of the heating furnace, and the passing chip-like electronic component 3 is heat-treated. It goes without saying that the gas injection port 4 is not necessarily provided at the upper part of the heating furnace, ...

Embodiment approach 2

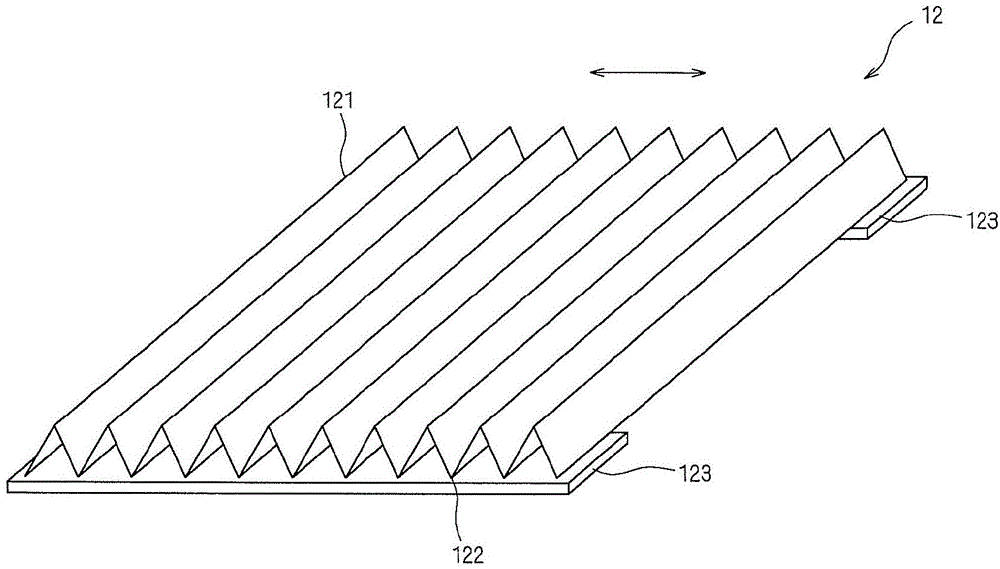

[0053] The heat treatment jig 12 of Embodiment 2 is the same as Embodiment 1 in that it has a loading surface provided with a plurality of through holes (first through holes), and the loading surface is composed of accordion-shaped concavities and convexities that are alternately and repeatedly folded into peaks and valleys. face composition. What is different from Embodiment 1 is that instead of reinforcing plate 123, the bottom and side portions of both ends in the direction perpendicular to the direction (folding direction) in which peaks and valleys are alternately and repeatedly formed are provided with L-shaped cross-sections. Enhanced parts.

[0054] Figure 5 It is a perspective view showing the structure of the heat treatment jig 12 according to Embodiment 2 of the present invention. Such as Figure 5 As shown, the loading surface of the jig 12 for heat treatment is formed by alternately and repeatedly folding a metal plate having a plurality of through holes, such...

Embodiment approach 3

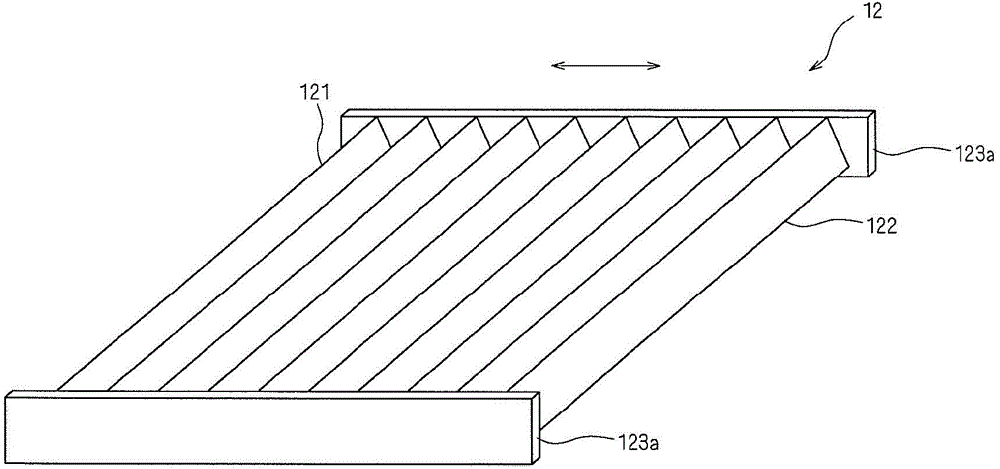

[0072] The jig 12 for heat treatment according to Embodiment 3 of the present invention will be described below. The heat treatment jig 12 of the present embodiment is the same as Embodiment 1 in that it has a loading surface provided with a plurality of through holes (first through holes), and the loading surface is composed of a concertina-shaped concave-convex surface that is alternately and repeatedly folded into peaks and valleys. to form. In addition, the reinforcing plate 123a is provided as the first reinforcing member, which is combined with that in Embodiment 1. image 3 The structure described is the same. However, this embodiment Figure 8 and Figure 9 As shown, the heat treatment jig 12 includes a guide member 131 . Figure 8 is a stereogram, Figure 9 is a side view.

[0073] In the heat treatment jig 12 of this embodiment, a guide member 131 for connecting the pair of first reinforcement members to each other is provided between the reinforcement plates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com