Exhaust gas throttle valve for engines

An exhaust throttle valve, engine technology, applied in the direction of engine components, engine control, combustion engine, etc., to achieve the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

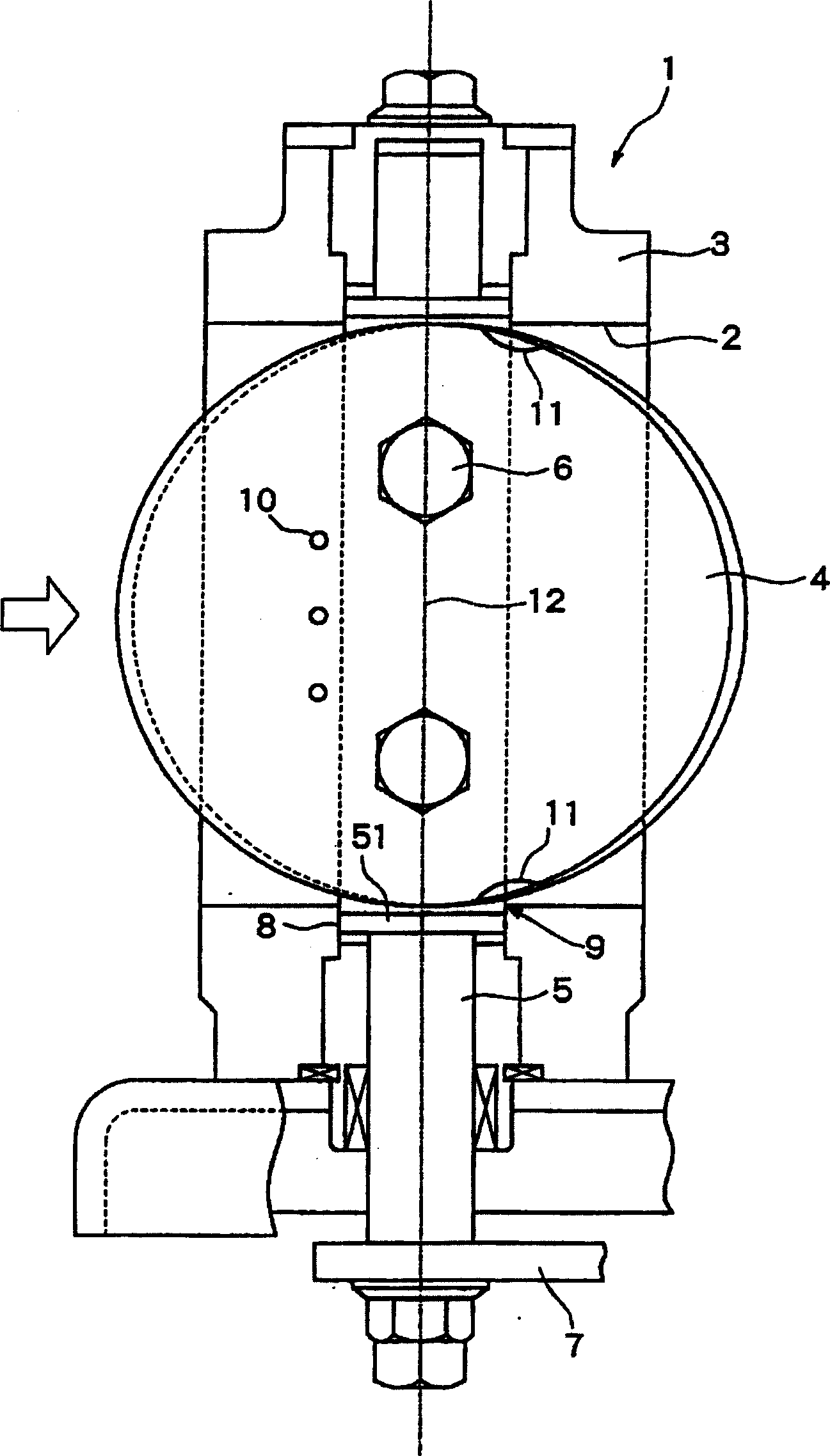

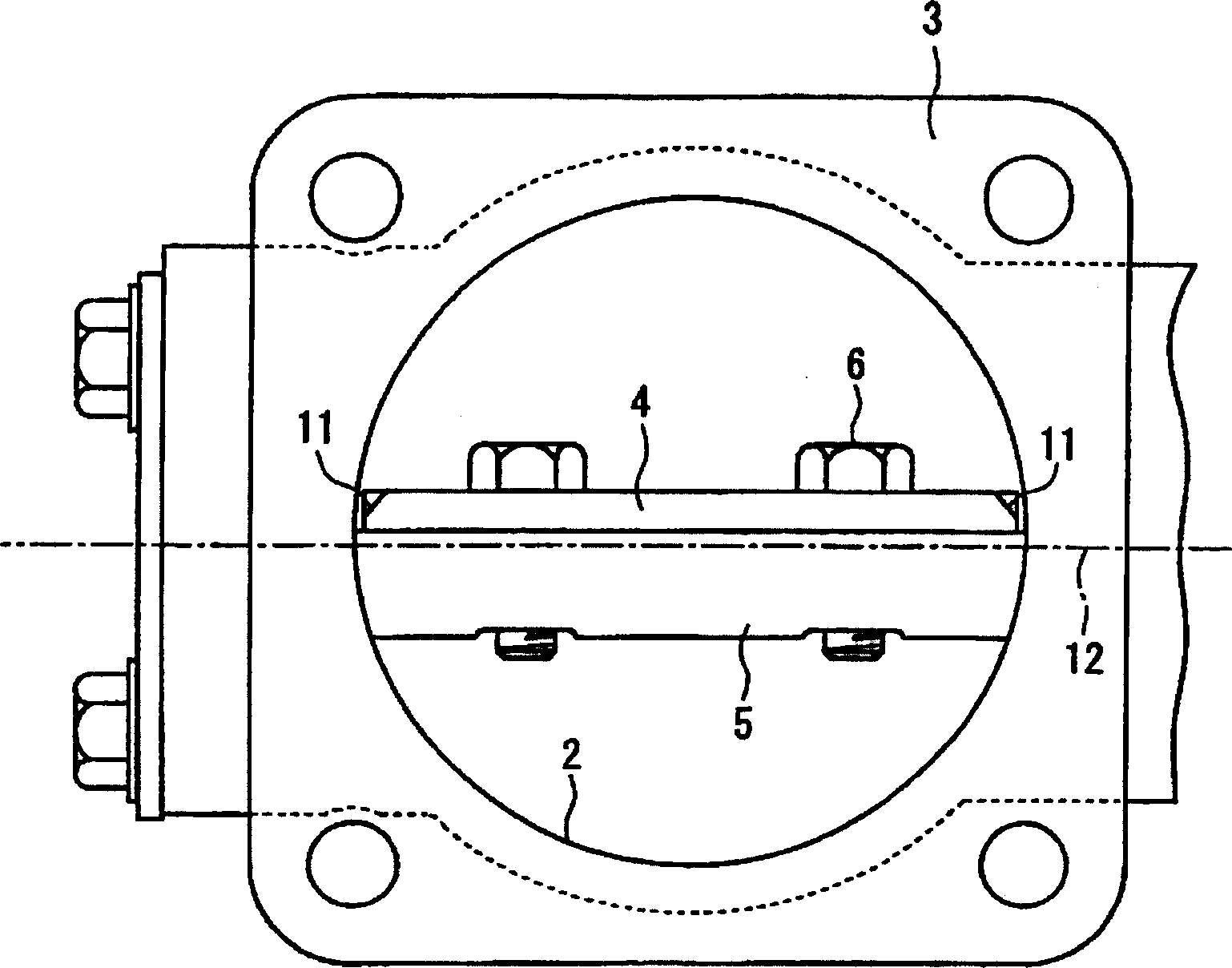

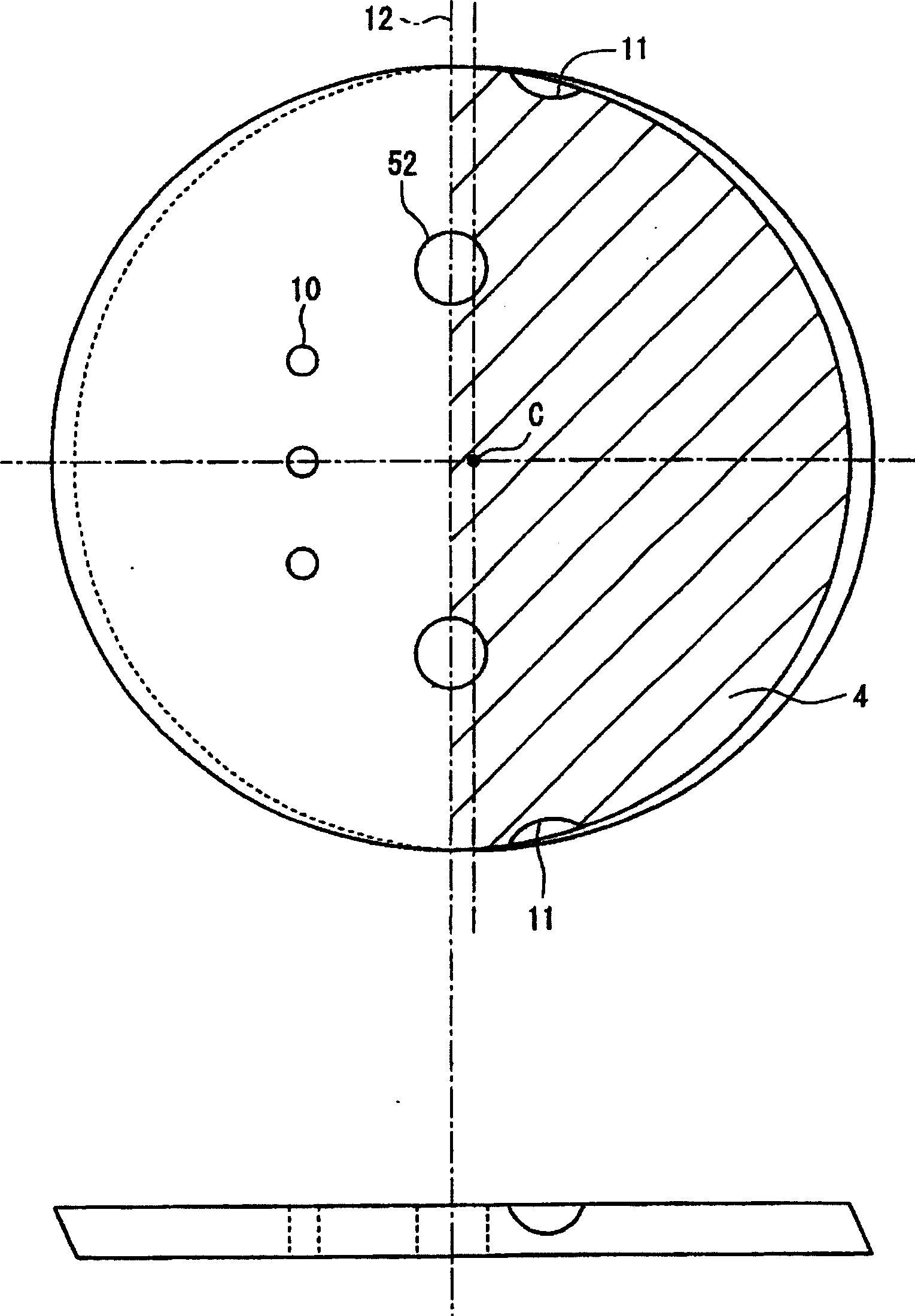

[0040] Hereinafter, an exhaust throttle valve according to the present invention will be described with reference to the drawings. However, the present invention relates to the exhaust throttle valve itself, the structure and action of the applicable exhaust gas aftertreatment device and Figure 8 It is the same as shown, so its detailed description is omitted here. In addition, the exhaust throttle valve of the present invention is different from the conventional example ( Figure 7 ) and corresponding parts of the device are marked with the same symbols.

[0041] figure 1 , figure 2 The exhaust throttle valve of the present invention shown with Figure 7 Similarly, it is a butterfly valve provided in the valve body 3 forming the exhaust gas passage 2 . Install valve shaft 5 of valve body 4 also with Figure 7 The valve shaft has the same shape, has both ends embedded in the insertion hole 8 formed on the valve body 3, and a flat surface in the middle of the fixed valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com