Hollow fiber membrane module and its operation method

An operation method and technology of hollow fiber membranes, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of increased liquid resistance of separation membranes, blocked pores of separation membranes, and reduced cleaning effect of medicinal liquids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0474] Hereinafter, although an Example and a comparative example are given and this invention is concretely demonstrated, this invention is not limited to these Examples.

[0475] The performance evaluation method of the hollow fiber membrane is as follows.

[0476]

[0477] A small module with an effective length of 200mm consisting of 4 porous hollow fiber membranes was produced. Send distilled water to the module at a temperature of 25°C and a filter pressure difference of 16kPa for 1 hour, and measure the resulting permeated water (m 3 ), converted into unit time (h) and unit membrane area (m 2 ) value, and then converted to the pressure (50kPa) to obtain the pure water permeability (m 3 / m 2 / hr). In addition, the unit membrane area is calculated from the average outer diameter and the effective length of the porous hollow fiber membrane.

[0478]

[0479] Using a tensile testing machine (TENSILON (registered trademark) / RTM-100, manufactured by Toyo Bordowin Co....

reference example 1

[0523] (Reference example 1) Manufacturing method of hollow fiber membrane A

[0524] 36% by weight of a vinylidene fluoride homopolymer (KF1300 manufactured by KLEHA Co., Ltd., weight average molecular weight: 417,000, number average molecular weight: 221,000) and 64% by weight of γ-butyrolactone were dissolved at 150°C. The Tc of this vinylidene fluoride homopolymer solution was 48°C. The solution was set up with 2 gear pumps, pressurized to 2.0MPa on the pipeline between them, and stayed at 99-101°C for 20 seconds, and then discharged from the outer tube of the double-tube die, while the γ - An 85% by weight aqueous solution of butyrolactone was discharged from the inner tube of the double tube die, and was solidified by staying in a cooling bath at a temperature of 25° C. consisting of an 85% by weight aqueous solution of γ-butyrolactone for 20 seconds. The obtained porous hollow fiber had a columnar structure with a thickness uniformity of 0.62, a columnar structure occu...

reference example 2

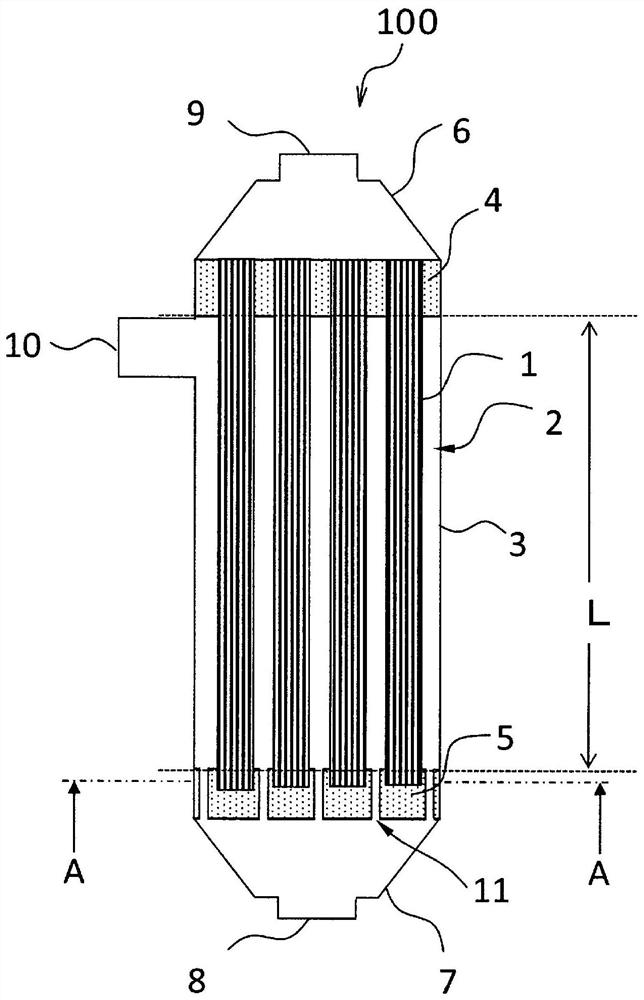

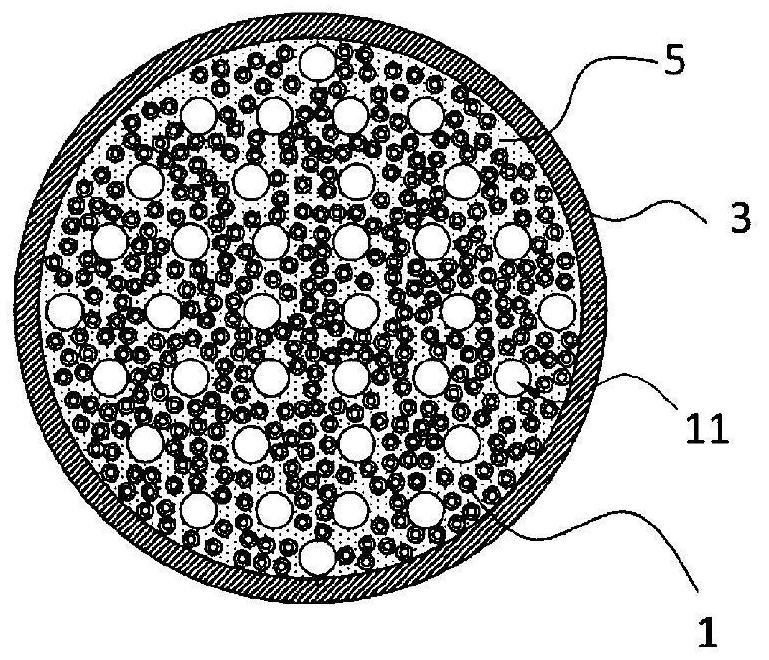

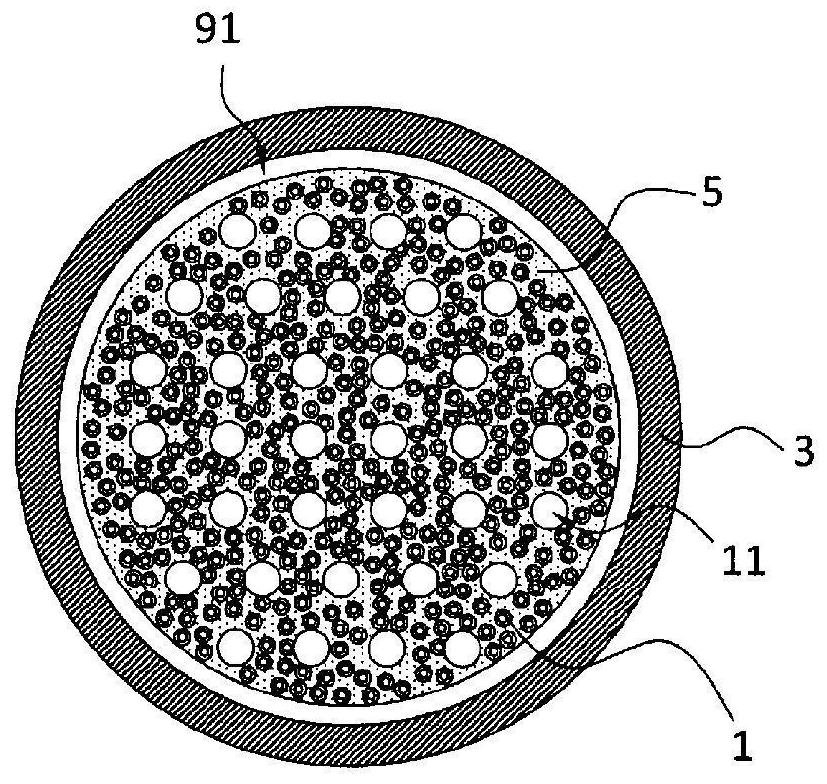

[0526] (Reference example 2) Production of hollow fiber membrane module

[0527] The method for producing the hollow fiber membrane module will be described below.

[0528] The hollow fiber membrane was cut into a length of 1800 mm, immersed in a 30% by mass glycerin aqueous solution for 1 hour, and then air-dried. The hollow fiber membrane was heat-treated in water vapor at 125° C. for 1 hour, air-dried, and cut into lengths of 1200 mm. The predetermined number of hollow fiber membranes thus obtained are bundled into one bundle. One end of the hollow fiber membrane bundle was sealed with a silicone adhesive (SH850A / B, manufactured by Toray Dow Corning Co., Ltd., two components were mixed at a mass ratio of 50:50).

[0529] On the inner surface of the polysulfone cylindrical case 3 (inner diameter 150 mm, outer diameter 170 mm, length 1150 mm), the area to which the hollow fiber membrane is to be bonded was previously sanded with sandpaper (#80) and degreased with ethanol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com