Mixing/charging port for medical treatment

A technology for medical use and co-injection, applied in other medical devices and other directions, can solve the problems of rising cost, complex structure, easy to be polluted and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

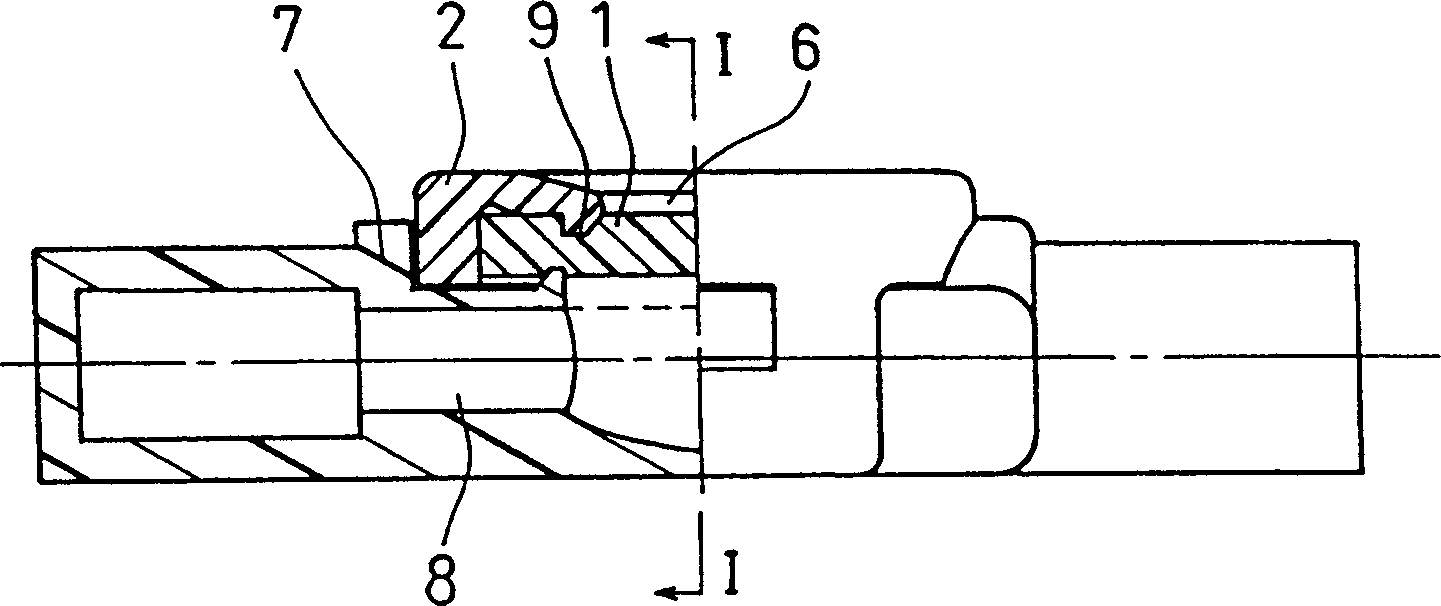

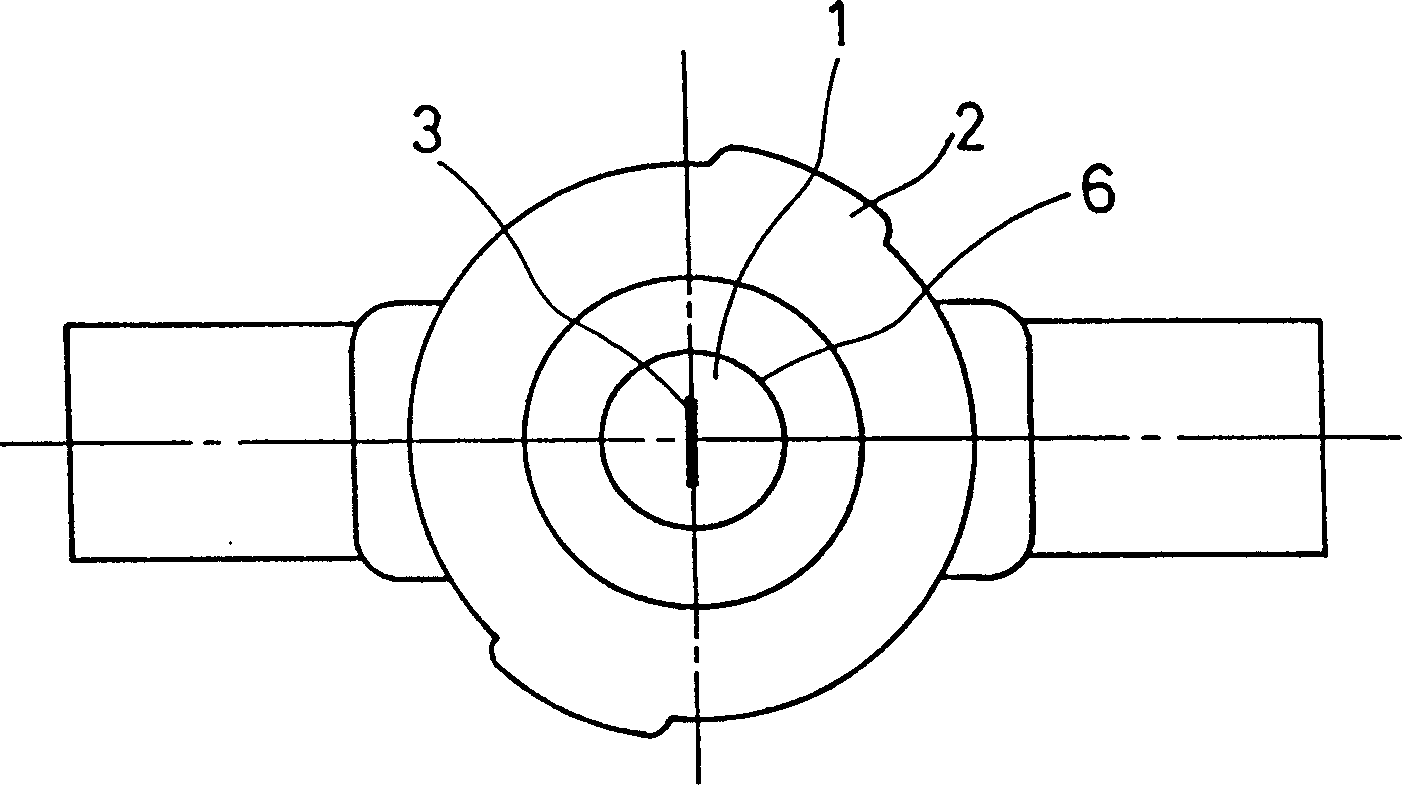

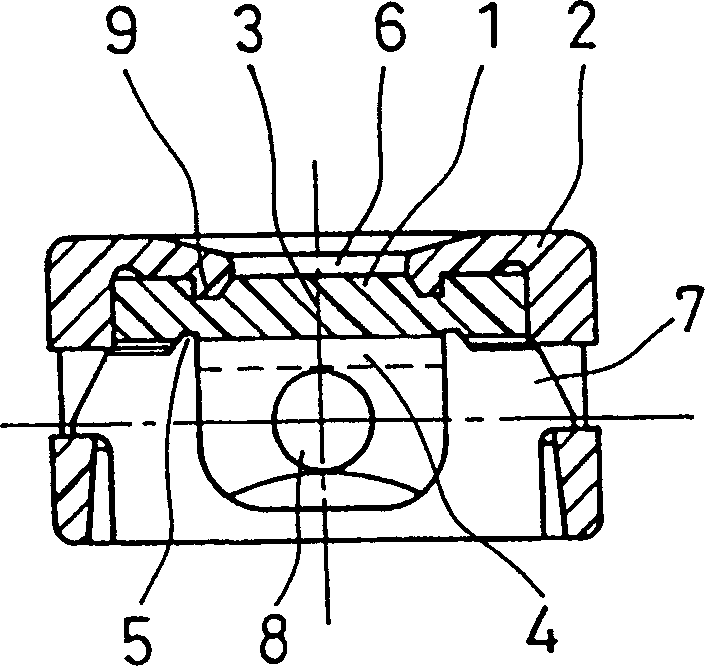

[0047] The mixed injection port for medical use of the present invention is mainly composed of a valve for opening and closing the flow path, a cap for holding the valve, and an insert locking mechanism formed on the cap. Hereinafter, respective constituent requirements will be described.

[0048] First, the cap is not particularly limited in its form as long as it can firmly hold (hold) the valve when it is inserted into or pulled out from the valve. For example, if Figure 1B As shown, when the cap 2 covering at least the upper peripheral portion of the valve 1 is formed except for the central portion (open) of the front side of the valve 1, it is easy to observe the insertion site of the quasi-needle, and it is possible to prevent accidental contact from occurring. contamination of the valve surface. It is more effective by providing a taper (inclination) of a gentle slope on the front side of the cap 2 . Furthermore, the lower side of the cap 2 or the valve 1 preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com