A Chromium Plating Method for the Inner Hole of Parts with Reduced Diameter

A technology of parts and inner holes, which is applied in the field of chrome plating of inner holes of variable diameter parts, can solve the problems of poor uniformity of coating thickness and achieve the effect of improving the uniformity of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

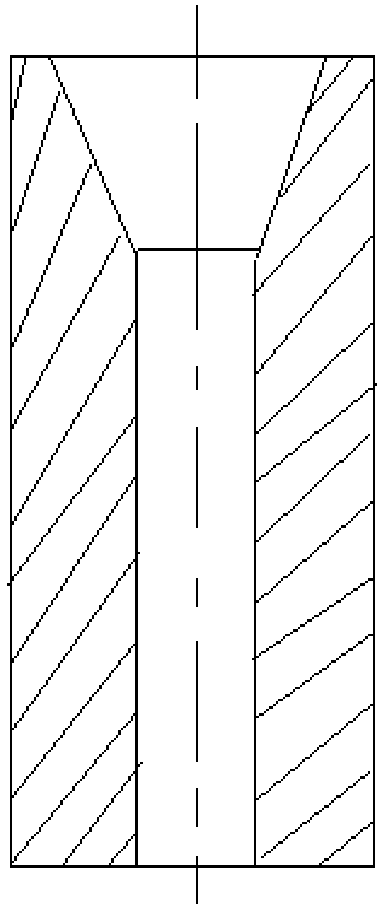

[0015] The invention provides a chrome-plating method for the inner hole of a variable-diameter part. The inner hole of the part includes a conical hole section and a straight hole section. The small end of the conical hole is connected to the straight hole section and has the same diameter. The specific steps include:

[0016] Step 1. Clean the surface of the inner hole of the part, and connect a lengthening pipe at both ends of the part. The inner diameter of the lengthening pipe is the same as the inner diameter of the straight hole section of the part; clamp the part on the chrome-plated cathode hanger;

[0017] Step 2. Lift the parts into the plating tank and preheat for 10 minutes;

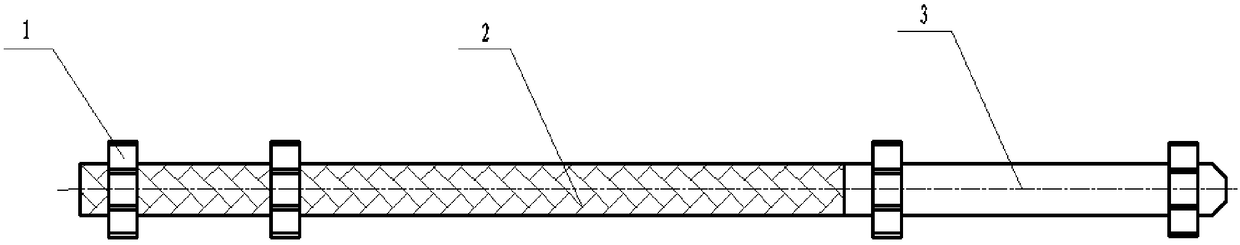

[0018] Step three, such as figure 1 As shown, the anode rod is lengthened to 1200mm, its effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com