A kind of self-polishing type low surface energy polyurethane and its preparation method and application

A low surface energy, polyurethane technology, applied in polyurea/polyurethane coatings, biocide-containing paints, coatings, etc., can solve the problems of slow self-polishing speed, dirt adhesion, growth speed, dirt adhesion, etc., to achieve suitable for large-scale Production, good anti-fouling, effect in mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

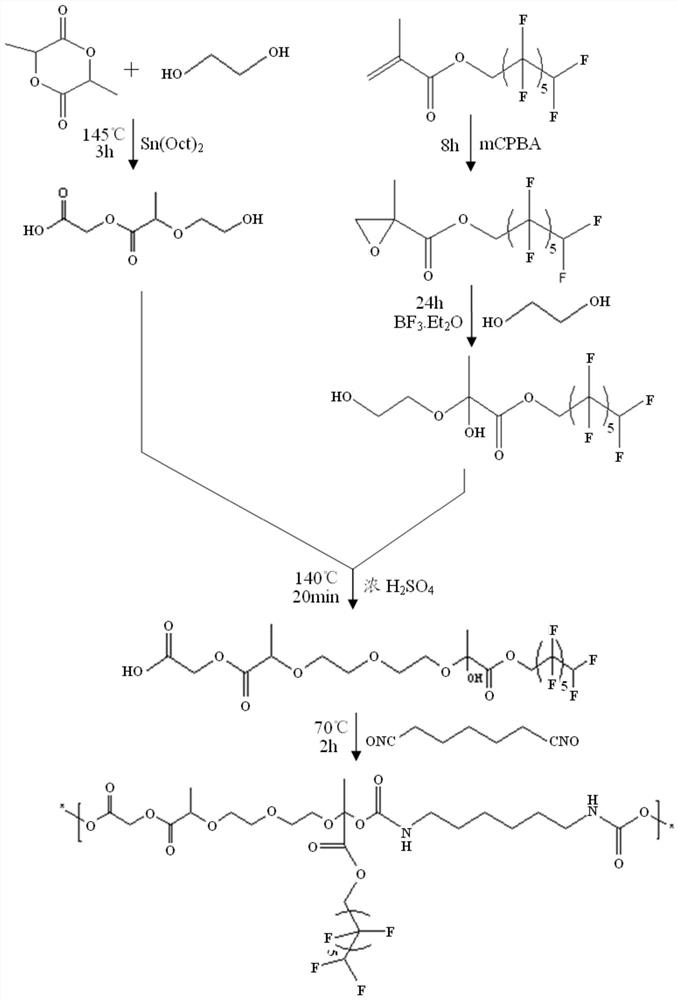

[0055] The present invention also provides a method for preparing the self-polishing low surface energy polyurethane described in the above technical solution, comprising the following steps:

[0056] a) mixing the cyclic monomer, the polyol and the catalyst, and performing the first reaction to obtain the first reaction product;

[0057] b) mixing fluorine-containing vinyl monomers, solvents, catalysts and polyols, and performing a second reaction to obtain a second reaction product;

[0058] c) mixing the first reaction product obtained in step a), the second reaction product obtained in step b) and the catalyst, and performing a third reaction to obtain a third reaction product;

[0059] d) washing and dewatering the third reaction product obtained in step c) successively, then mixing with diisocyanate, and performing the fourth reaction to obtain self-polishing low surface energy polyurethane;

[0060] The steps a) and b) are not limited in sequence.

[0061] In the pres...

Embodiment 1

[0092] (1) Add 2 g of lactide, 0.86 mL of dehydrated ethylene glycol and 0.025 mL of stannous octoate into a three-necked flask with a stirrer and a thermometer, and react at 145° C. for 3 h under nitrogen protection to obtain the first reaction product.

[0093] (2) Add 5.55g of dodecafluoroheptyl methacrylate to another three-necked flask with a stirrer, add 20mL of tetrahydrofuran, then add 5.55g of m-chloroperoxybenzoic acid, stir and react at room temperature for 8h, and then Add 0.86 mL of dehydrated ethylene glycol and 0.036 g of boron trifluoride ether solution, stir and react at room temperature for 24 hours to obtain the second reaction product.

[0094] (3) Add the first reaction product obtained in step (1), 0.0064 g of concentrated sulfuric acid, to the second reaction product obtained in step (2), and react at 140° C. for 20 min to obtain a third reaction product.

[0095] (4) Wash the third reaction product obtained in step (3) with water, dry it in vacuum to re...

Embodiment 2

[0099] (1) Add 2.5g of lactide, 1.08mL of dehydrated polyethylene glycol and 0.03mL of stannous octoate into a three-necked flask with a stirrer and a thermometer, and react at 120°C for 4 hours under nitrogen protection to obtain the first reaction product.

[0100] (2) Add 6.94g of dodecafluoroheptyl methacrylate to another three-necked flask with a stirrer, add 20mL of xylene, then add 6.94g of m-chloroperoxybenzoic acid, and stir the reaction at room temperature for 8h, Then, 1.08 mL of dehydrated polyethylene glycol and 0.045 g of boron trifluoride ether solution were added, and the mixture was stirred and reacted at room temperature for 12 hours to obtain the second reaction product.

[0101] (3) Add the first reaction product obtained in step (1), 0.008 g of concentrated sulfuric acid, to the second reaction product obtained in step (2), and react at 120° C. for 10 min to obtain a third reaction product.

[0102] (4) Wash the third reaction product obtained in step (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com