Heat transfer tubes and a heat exchanger using the same

A technology of heat transfer tubes and heat transfer components, which is applied in the field of heat exchangers and heat transfer tubes. It can solve the problems of inability to use pressure-resistant small-diameter tubes, difficulty in compaction, and increased pressure loss. The heat transfer efficiency will not Effects of reduction, constant cross-sectional area of flow path, and improvement of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0141] First, a first embodiment of the present invention will be described with reference to the drawings.

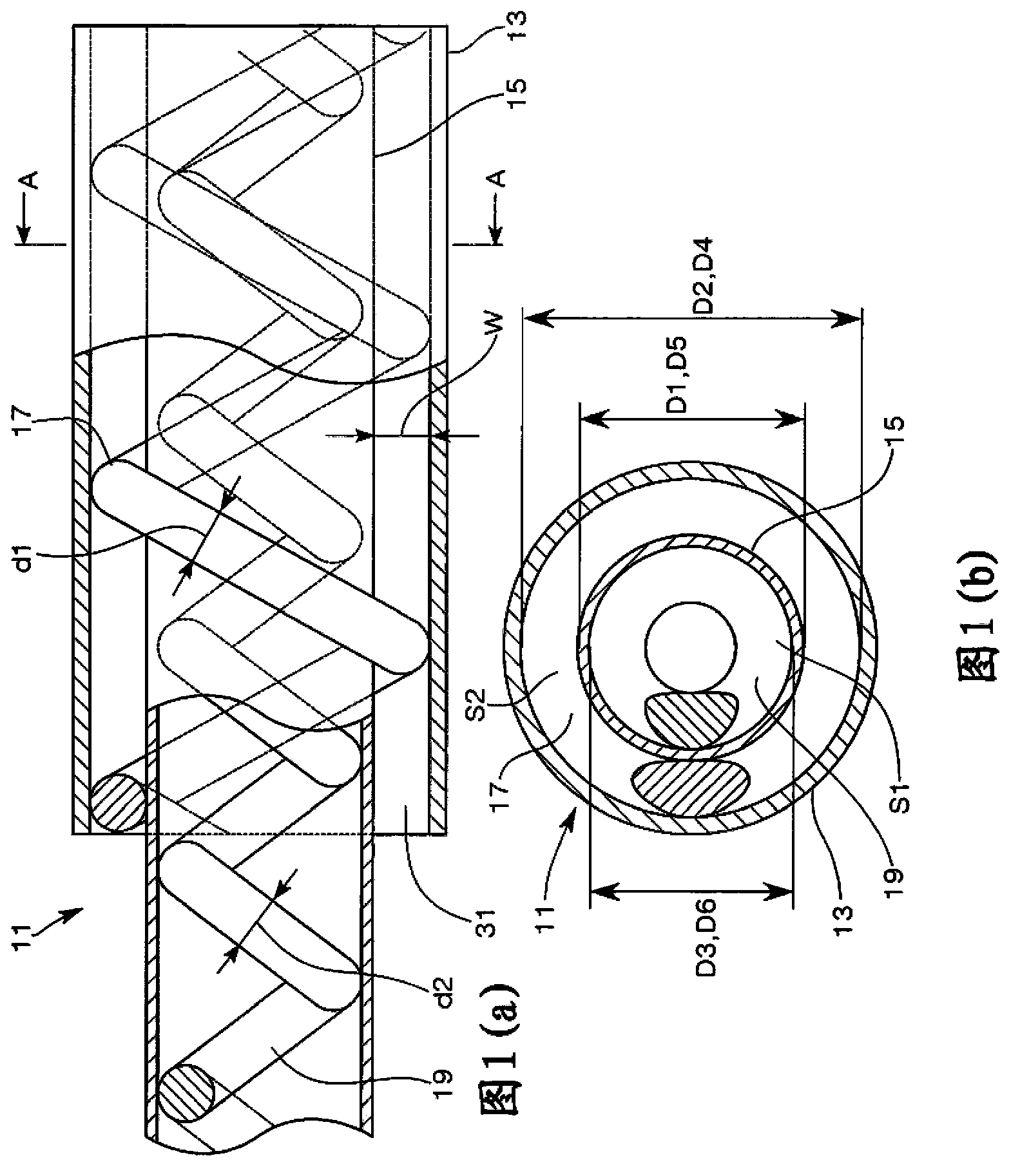

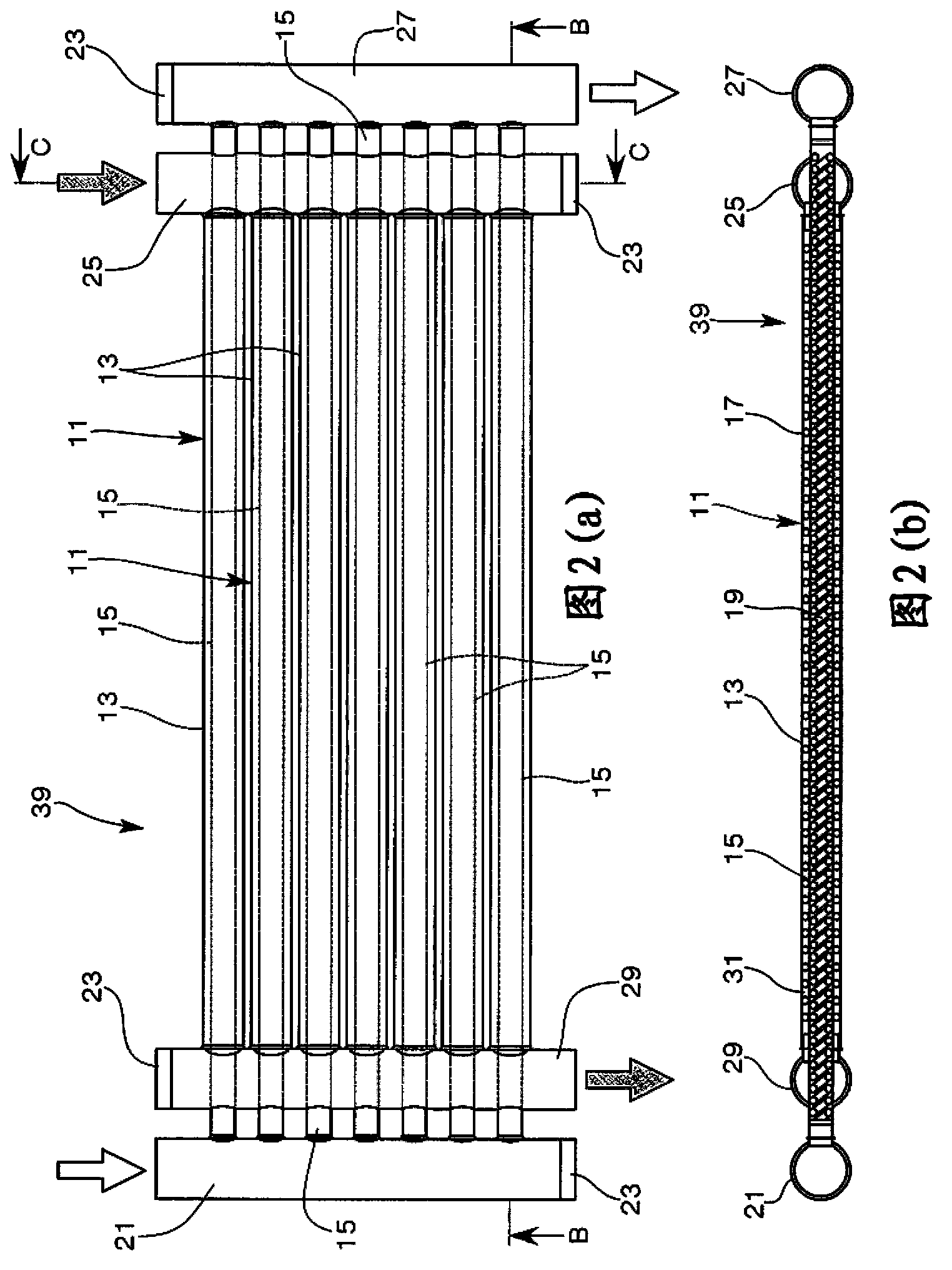

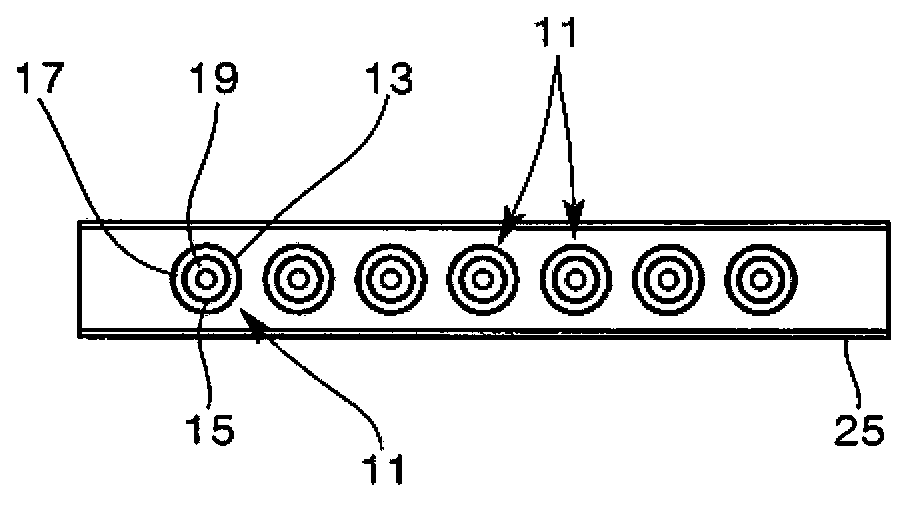

[0142] Fig. 1 (a) is a schematic enlarged sectional view showing the heat transfer tube of the present invention, Fig. 1 (b) is a diagram showing the A-A sectional view of Fig. 1 (a), and Fig. The plan view of the heat transfer tube column unit of the heat exchanger of the heat pipe, Fig. 2 (b) is the figure that represents the B-B line sectional view of this plan view, image 3 It is the C-C side sectional view of the heat transfer tube row unit shown in Fig. 2 (a), Fig. 2 (b), Figure 4 It is a partially enlarged sectional view of the sectional view shown in FIG. 2( b ).

[0143] The heat transfer tube 11 of this embodiment includes an outer tube 13 , an inner tube 15 , a gap support member 17 , and a support member 19 .

[0144] The outer tube 13 includes a straight thin tube, the inner tube 15 is inserted into the outer tube 13 , and both ends of the outer tube 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com