Lower die, production method of lower die, method for producing glass gob, and method for producing glass molded body

A manufacturing method, glass molding technology, applied in glass molding, glass pressing, manufacturing tools, etc., can solve problems such as air cannot be discharged, achieve the effect of preventing air accumulation, preventing substrate degradation, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

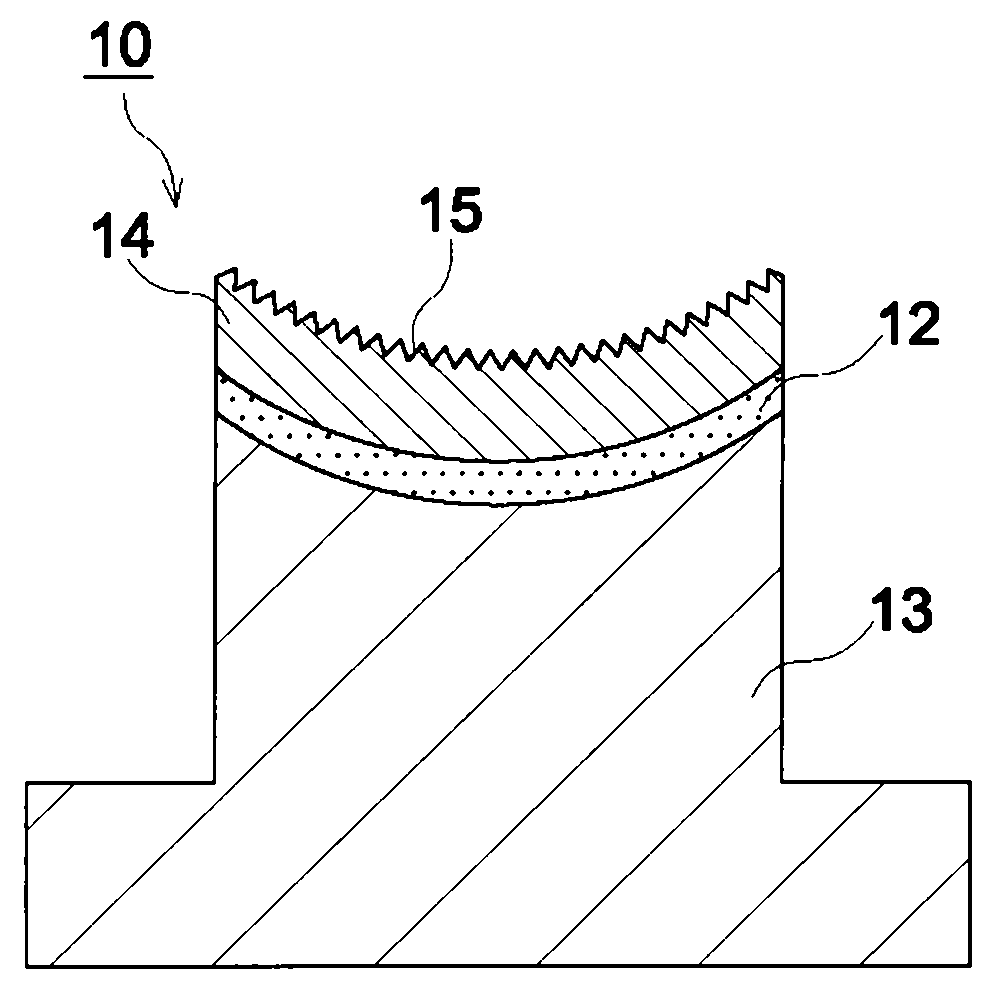

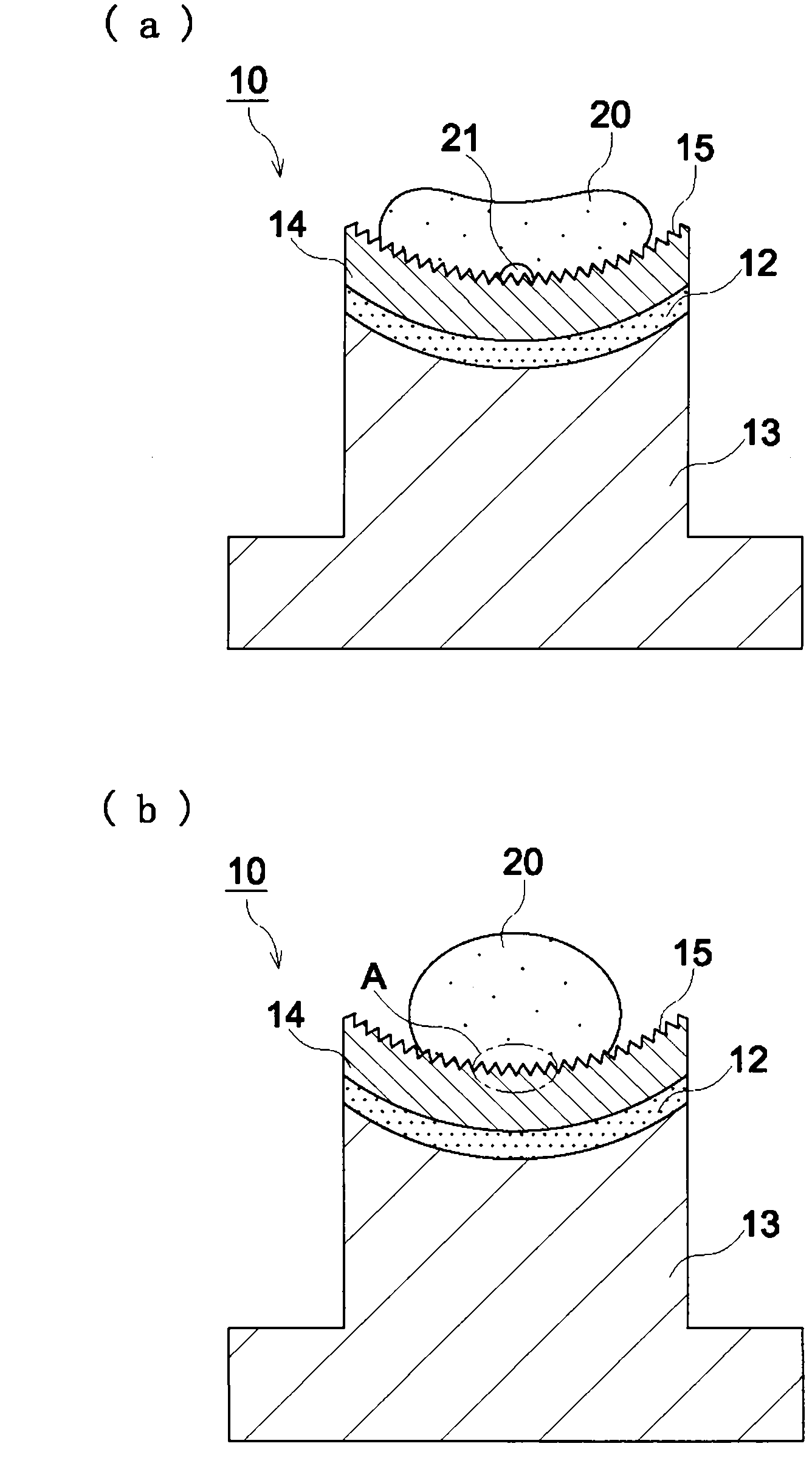

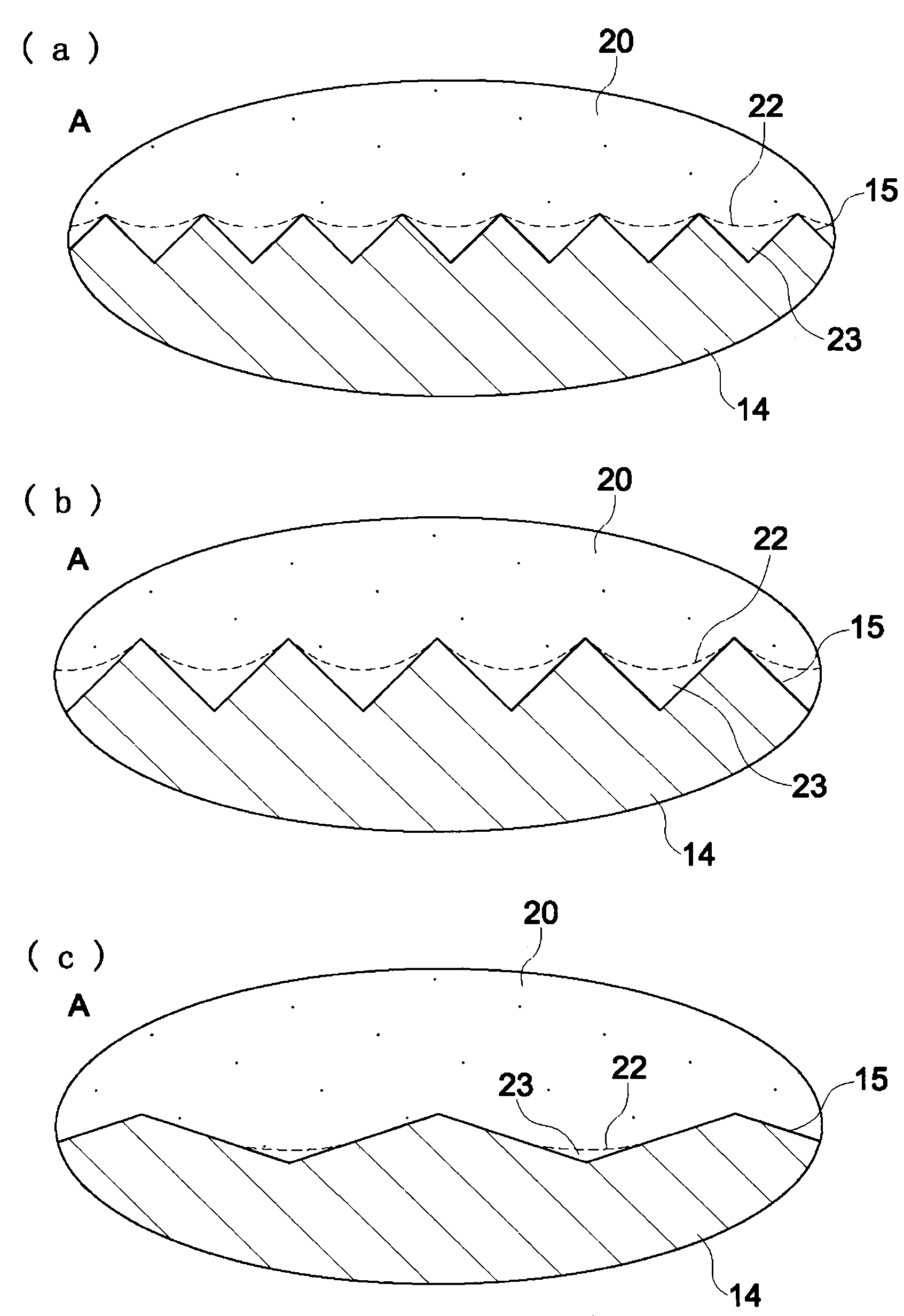

[0124] according to Figure 7 In the flow shown, a glass molded body was produced. The manufactured glass molding had an outer diameter of 7 mm and a center thickness of 3.5 mm.

[0125] First, as shown in Table 1, four types of lower molds 10 (Examples 1 to 4) were prepared. The base material 13 adopts a superhard material mainly composed of tungsten carbide. The materials described in Table 1 were formed as the intermediate layer 12, and then a chromium metal film was formed as the cover layer 14. The thickness of the intermediate layer 12 is 0.3 μm, and the thickness of the covering layer is 0.5 μm, both of which are formed by the sputtering method.

[0126] After the coating layer 14 is formed, the surface 15 of the coating layer 14 is immersed in an etching solution for roughening treatment. As the etching solution, a commercially available chromium etching solution (ECR-2 manufactured by Nacalai Tesque Co., Ltd.) containing cerium ammonium nitrate was used.

[0127]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com