Method for controlling strip shape of cold-rolled strip steel

A control method and strip shape technology, which is applied in the field of cold-rolled strip steel, can solve the problem of inability to obtain the optimal control output of tilting roll device, work roll bending device, intermediate roll bending device, and mechanical component wear plate shape control effect , actuator saturation and other issues, to achieve the effect of eliminating actuator saturation, improving the quality of cold-rolled strip shape control, and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

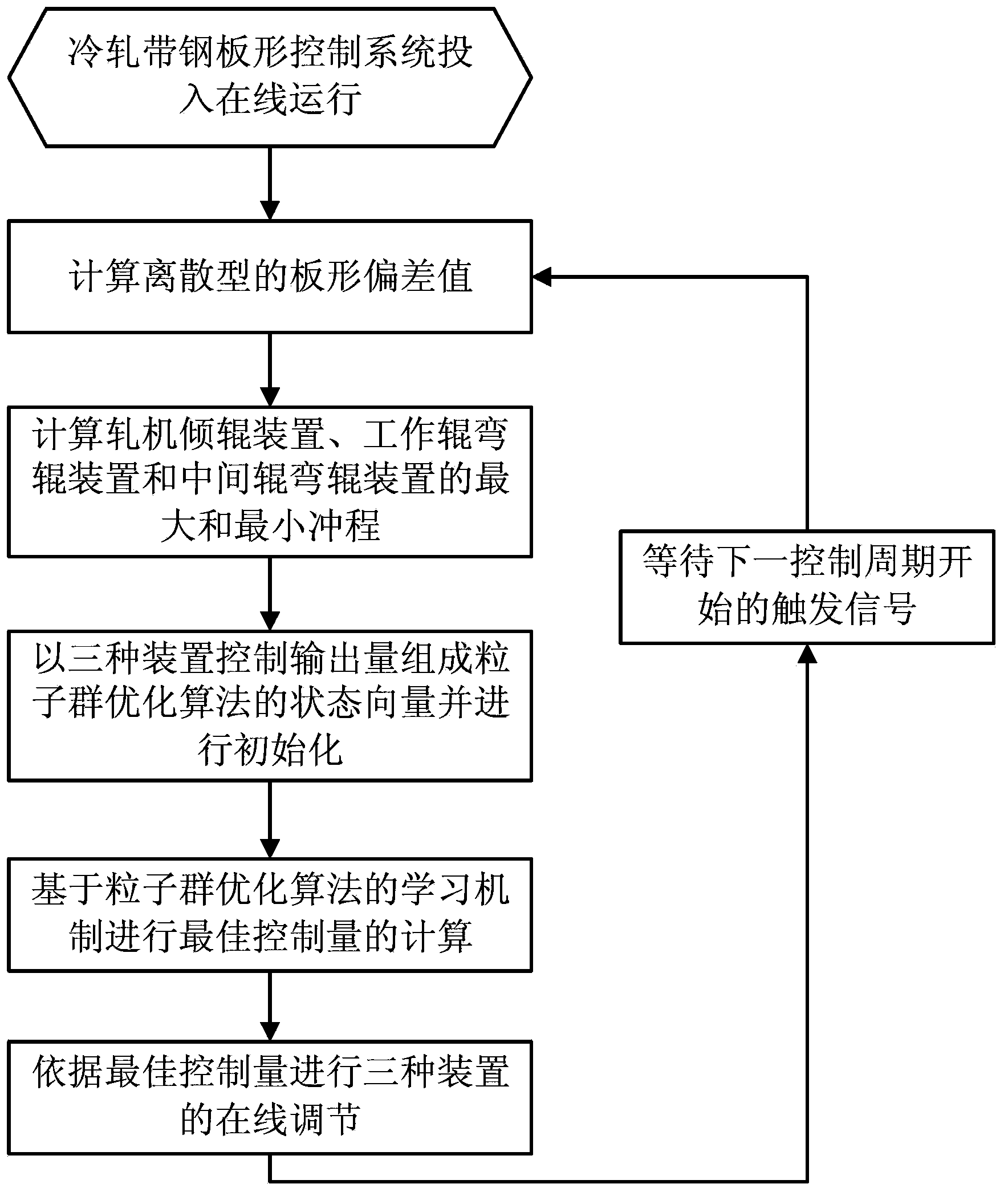

[0036] figure 1 It is a flowchart of an embodiment of the present invention, and it includes the following steps:

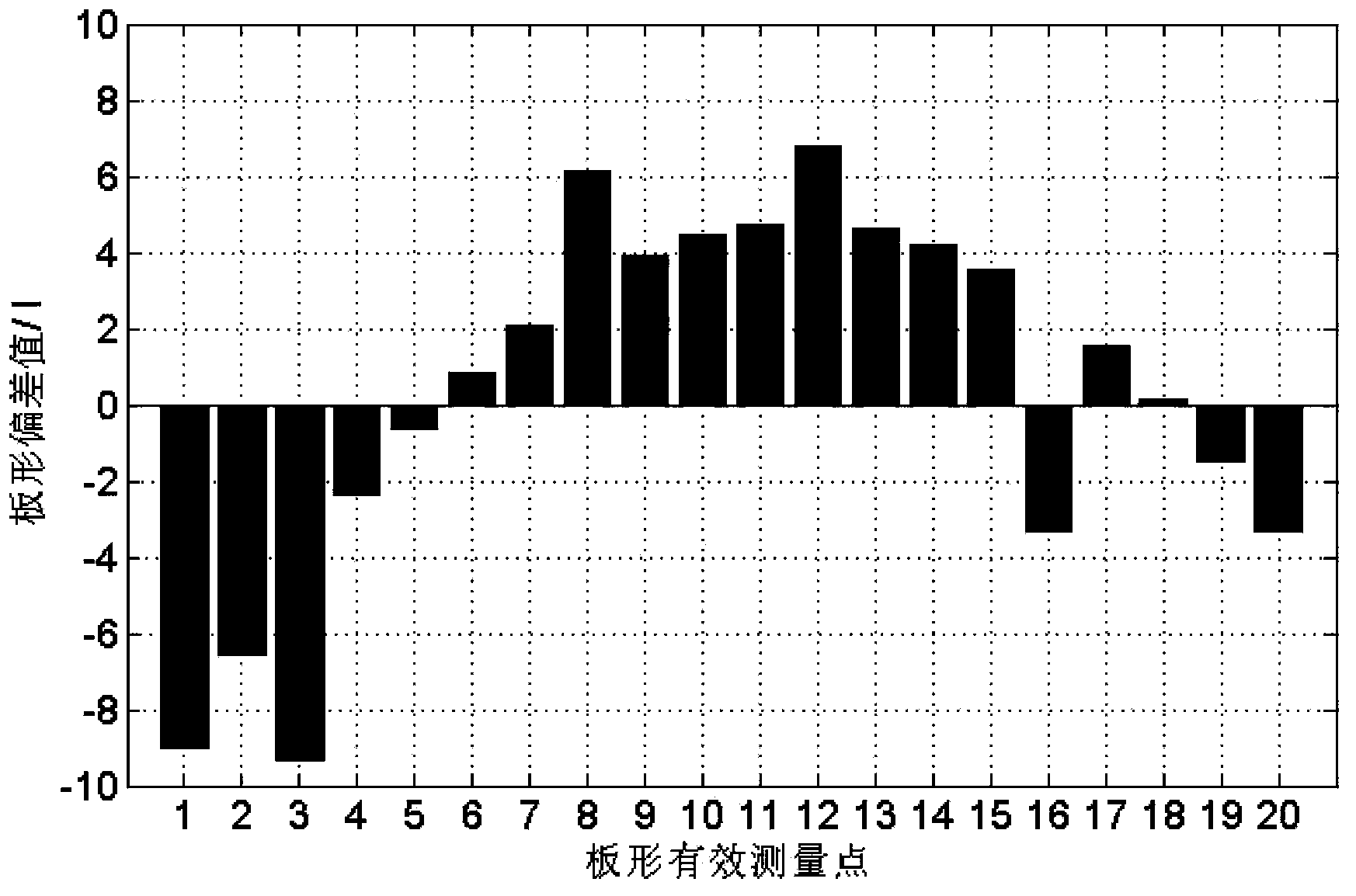

[0037] 1) Receive the target flatness distribution signal set according to the rolling process requirements and the actual flatness distribution signal measured online by the contact flatness meter installed on the exit side of the rolling mill, and calculate the difference between the two to obtain a discrete The plate shape deviation value δ i , i=1,2,...,n, where n is the number of effective measuring points for the plate shape;

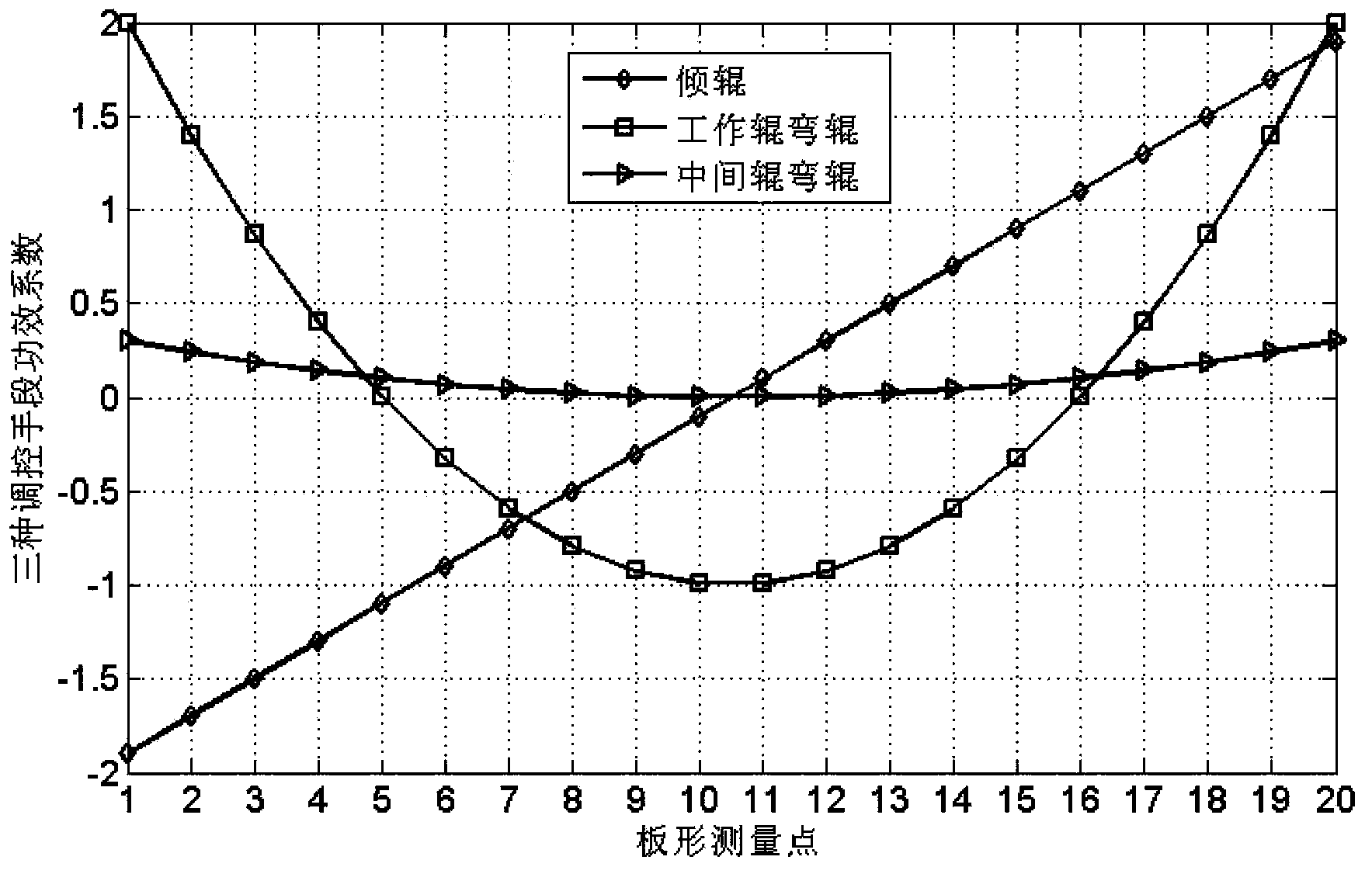

[0038] 2) Receive the real-time position signals of the three devices of rolling mill tilting device, work roll bending device and intermediate roll bending device, and consider the action limits of the three devices and the limit position constraints of the three devices in a single control cycle, according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com