A bell type sealed liquid heavy metal rotating device

A liquid heavy metal, rotating device technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of affecting the magnetic field strength performance of the magnetic pole rotor, complex structure, unable to meet the needs of high-speed and ultra-high temperature experiments, etc., to avoid the ability to rotate and drive The effect of falling, the overall structure design is simple, easy to realize and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

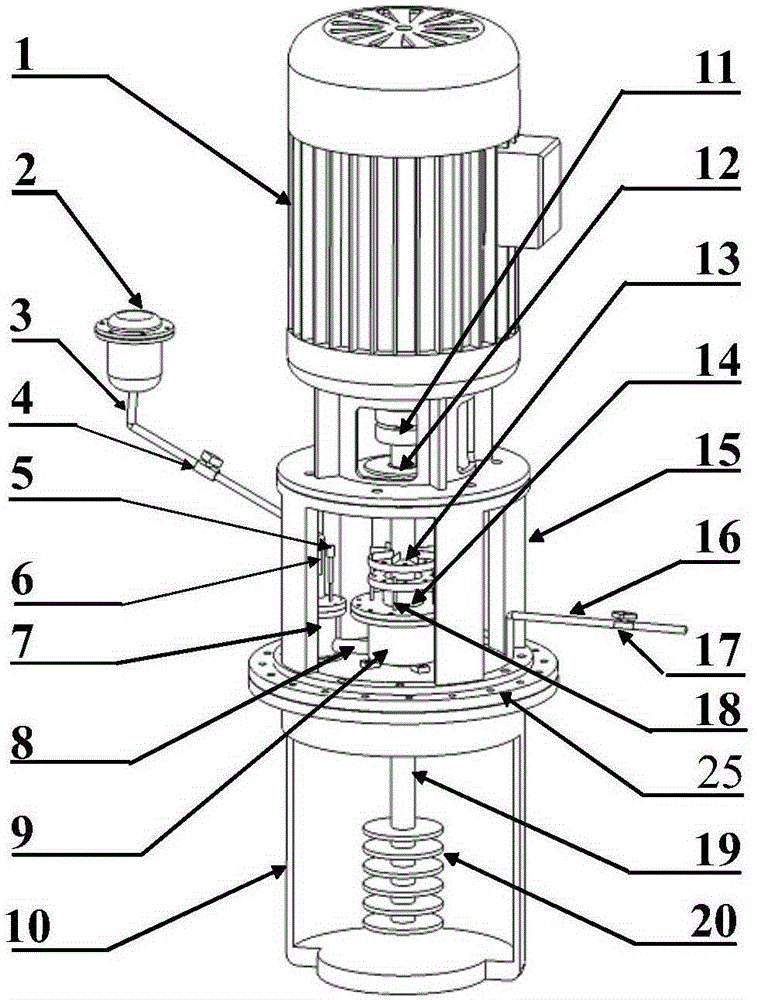

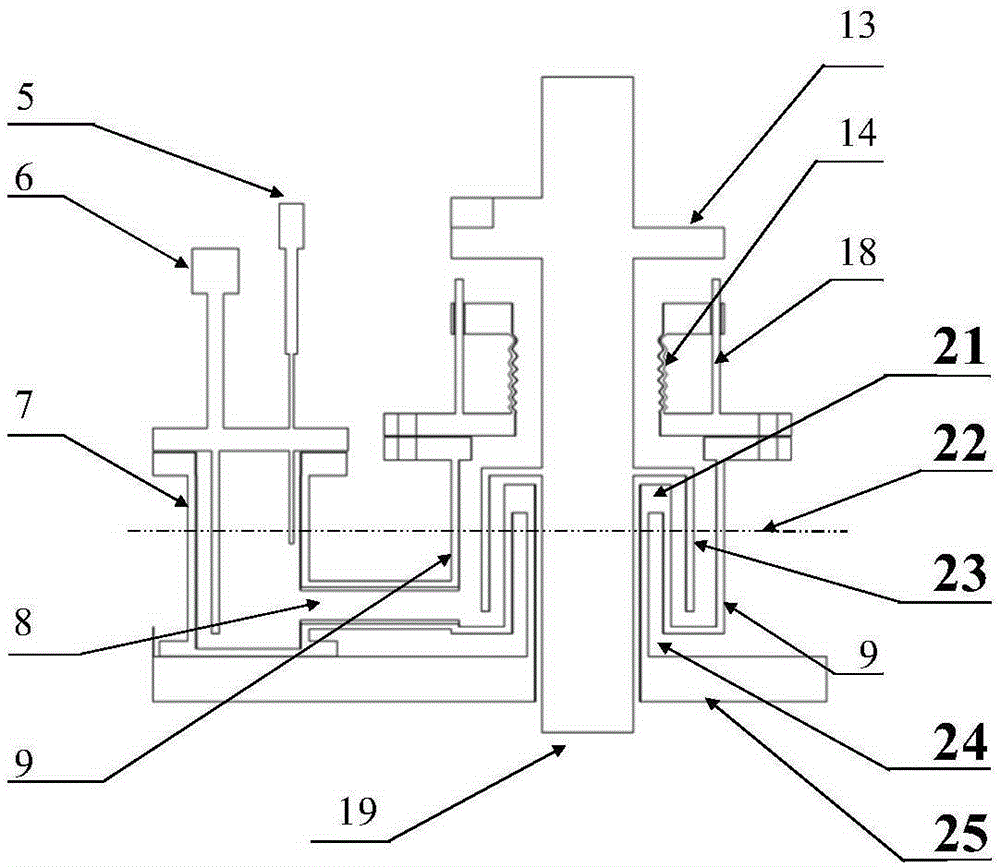

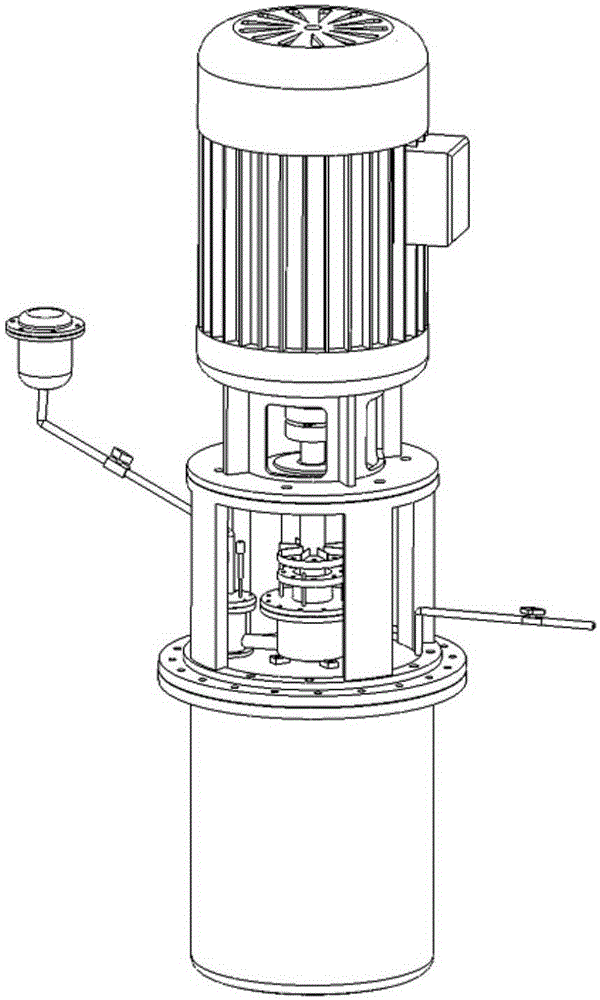

[0021] Such as figure 1 , figure 2 , image 3 As shown, the performance research device of the liquid heavy metal mechanical pump of the present invention mainly includes: the collecting tank 10 is located in the lower part of the whole device, the middle part is the motor bracket 15 for supporting the frequency conversion motor 1 on the upper part of the device, and the drive shaft 19 is connected to the frequency conversion through the coupling 11 The motor 1 is connected, from the coupling 11 down, followed by the roller system 12 for fixing the drive shaft 19, below is the fan blade flange 13 welded to the drive shaft, and the upper end of the fan blade flange 13 is designed with fan blades. When the fan blade flange 13 rotates with the drive shaft 19, an air flow can be generated, and the drive shaft 19 bearing above the flange can dissipate heat and reduce temperature, and prevent the heat from continuing to transfer upward and damaging the frequency conversion motor 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com