Flame retardant butyl pressure sensitive adhesive

A technology of pressure-sensitive adhesives and butyl adhesives, applied in the field of pressure-sensitive adhesives, can solve the problems of poor heat resistance, adhesion, and stickiness, and achieve excellent flame retardancy, enhanced heat resistance, and tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

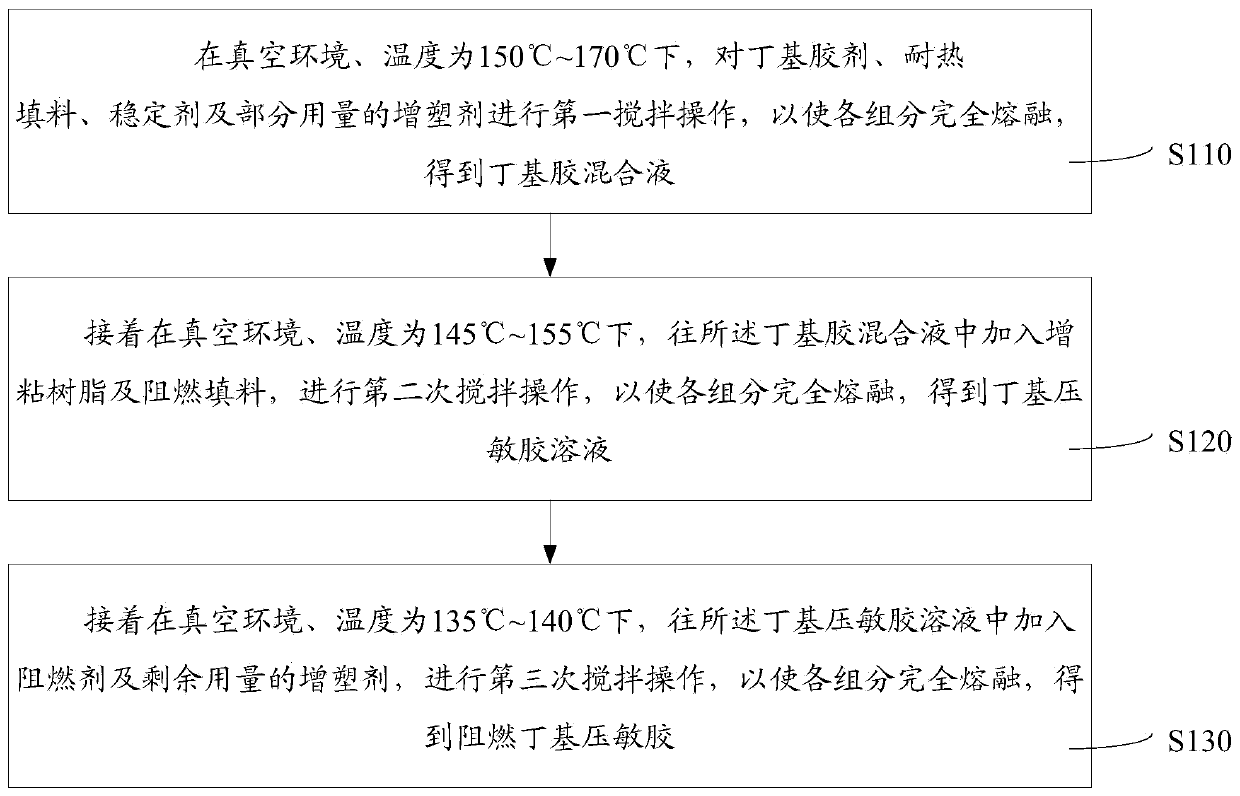

Method used

Image

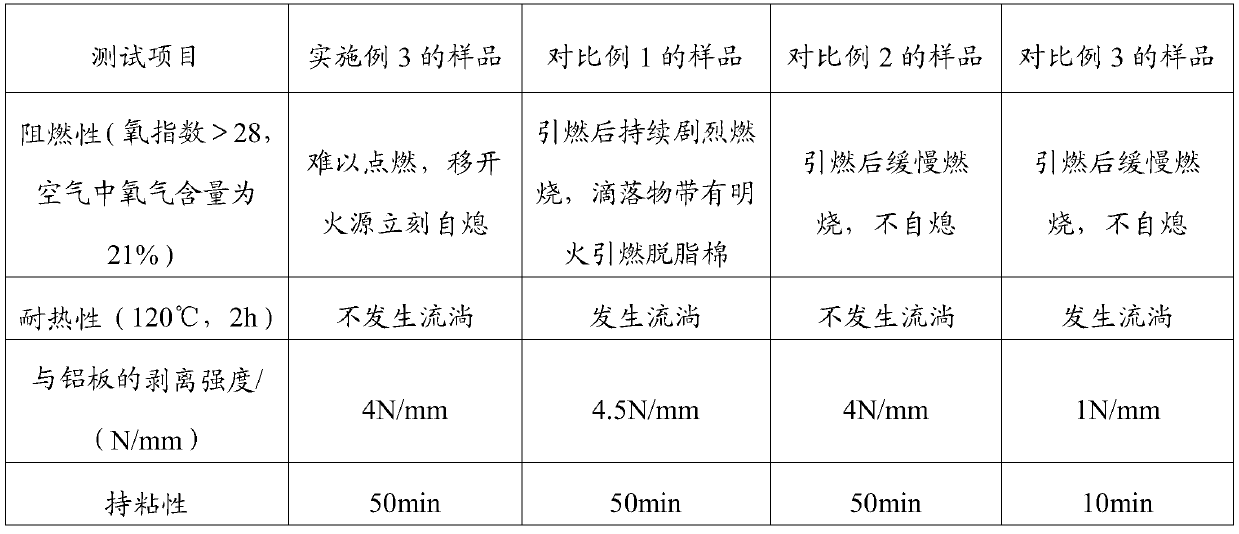

Examples

Embodiment approach

[0029] In order to better illustrate the above-mentioned flame-retardant butyl pressure-sensitive adhesive, so as to better understand the concept of the above-mentioned flame-retardant butyl pressure-sensitive adhesive. In one embodiment, a flame-retardant butyl pressure-sensitive adhesive includes the following components in parts by mass: 20-35 parts of plasticizer, 20-25 parts of butyl adhesive, 3-10 parts of heat-resistant filler, and 3-10 parts of flame-retardant filler 6-20 parts, 5-15 parts of flame retardant, 1-5 parts of stabilizer and 20-30 parts of tackifying resin. It should be noted that a suitable amount of plasticizer, butyl adhesive, stabilizer and tackifying resin can be combined to form a butyl pressure sensitive adhesive with high tensile strength, high elasticity and high viscosity. Among them, butyl adhesive mainly contains butyl rubber, which provides cohesion, strength and heat resistance for butyl pressure-sensitive adhesives. Plasticizers reduce the ...

Embodiment 1

[0056] S111, in a vacuum environment at a temperature of 170 ° C, for 10kg butyl rubber, 10kg bromobutyl rubber, 5kg calcium carbonate, 2kg talcum powder, 3kg calcined kaolin, 0.5kg2,6-tertiary butyl-4-methyl Base phenol, 0.5kg 2-phenylbenzimidazole-5-sulfonic acid and 28kg polyisobutene were stirred for 1h at a stirring rate of 50rpm / min, so that each component was completely melted to obtain a butyl rubber mixture;

[0057] S121, then add 5 kg of petroleum resin, 15 kg of phenolic resin, 5 kg of magnesium hydroxide, 5 kg of aluminum hydroxide and 10 kg of zinc borate into the butyl rubber mixture in a vacuum environment at a temperature of 145° C., at a rate of 60 rpm / min. Stirring at a stirring rate of 0.5h, so that each component is completely melted to obtain a butyl pressure-sensitive adhesive solution;

[0058] S131, then add 4kg of brominated diphenylethane, 1kg of antimony trioxide and 7kg of chlorinated paraffin to the butyl pressure-sensitive adhesive solution in a ...

Embodiment 2

[0060] S112, in a vacuum environment at a temperature of 150 ° C, for 10kg butyl rubber, 15kg bromobutyl rubber, 1kg calcium carbonate, 1kg talcum powder, 1kg calcined kaolin, 3kg2,6-tertiary butyl-4-methyl Phenol, 2kg 2-phenylbenzimidazole-5-sulfonic acid and 16kg polyisobutylene were carried out, stirred at a stirring rate of 70rpm / min for 0.5h, so that each component was completely melted, and a butyl rubber mixture was obtained;

[0061] S122, then add 10kg of petroleum resin, 20kg of phenolic resin, 1kg of magnesium hydroxide, 1kg of aluminum hydroxide and 4kg of zinc borate into the butyl rubber mixture in a vacuum environment at a temperature of 155°C, at a rate of 40rpm / min Stirring at a stirring speed for 1 h, so that each component is completely melted to obtain a butyl pressure-sensitive adhesive solution;

[0062] S133, then add 13kg of brominated diphenylethane, 2kg of antimony trioxide and 4kg of chlorinated paraffin to the butyl pressure-sensitive adhesive solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com