Waterproof coiled material with high flame retardance

A waterproof coiled material, high flame-retardant technology, applied in building insulation materials, roofs using flexible materials, building components, etc., can solve the problems of fast diffusion, large smoke, fierce fire, etc., and achieve the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

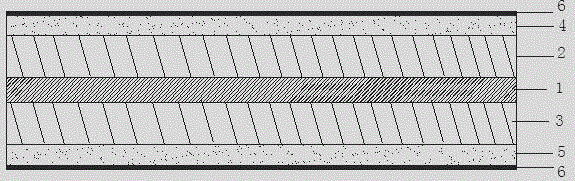

[0028] like figure 1 As shown, the present invention relates to a high flame-retardant waterproof roll material and a preparation method thereof. The waterproof roll material includes the following structure: a glass fiber mat 1, the upper surface of the glass fiber felt 1 is provided with a first waterproof layer 2, and the glass fiber felt 1 is provided with a first waterproof layer 2. The lower surface of the fiber mat 1 is provided with a second waterproof layer 3 , the upper surface of the first waterproof layer is provided with a first flame-retardant layer 4 , and the lower surface of the second waterproof layer is provided with a second flame-retardant layer 5 . Wherein, the glass fiber felt 1 is an alkali glass fiber felt, the first waterproof layer 2 and the second waterproof layer 3 are SBS modified asphalt layers, and the first flame retardant layer 4 and the second flame retardant layer 5 are It is a polystyrene / graphene nanocomposite material.

[0029] Wherein, ...

Embodiment 2

[0035] The invention relates to a high flame-retardant waterproof coiled material and a preparation method thereof. The waterproof coiled material comprises the following structure: a glass fiber felt, a first waterproof layer is provided on the upper surface of the glass fiber felt, and a first waterproof layer is provided on the lower surface of the glass fiber felt. There is a second waterproof layer, the upper surface of the first waterproof layer is provided with a first flame retardant layer, and the lower surface of the second waterproof layer is provided with a second flame retardant layer. Wherein, the glass fiber felt is an alkali glass fiber felt, the first waterproof layer and the second waterproof layer are SBS modified asphalt layers, and the first flame retardant layer and the second flame retardant layer are polystyrene / Graphene nanocomposites.

[0036] Wherein, the SBS modified asphalt layer includes the following components by weight fraction: 40 parts of as...

Embodiment 3

[0042]The invention relates to a high flame-retardant waterproof coiled material and a preparation method thereof. The waterproof coiled material comprises the following structure: a glass fiber felt, a first waterproof layer is provided on the upper surface of the glass fiber felt, and a first waterproof layer is provided on the lower surface of the glass fiber felt. There is a second waterproof layer, the upper surface of the first waterproof layer is provided with a first flame retardant layer, and the lower surface of the second waterproof layer is provided with a second flame retardant layer. Wherein, the glass fiber felt is an alkali glass fiber felt, the first waterproof layer and the second waterproof layer are SBS modified asphalt layers, and the first flame retardant layer and the second flame retardant layer are polystyrene / Graphene nanocomposites.

[0043] Wherein, the SBS modified asphalt layer includes the following components by weight fraction: 60 parts of asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com