Sealing pyrolyzing furnace achieving continuous feeding and discharging

A pyrolysis furnace, feeding and discharging technology, applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of poor sealing effect, low thermal efficiency, low pyrolysis efficiency, etc., and achieve good promotion and application value, structure Reasonable design and high pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

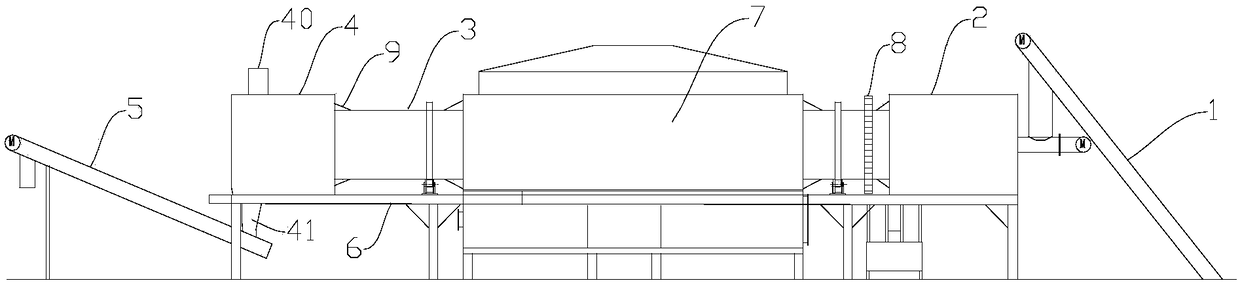

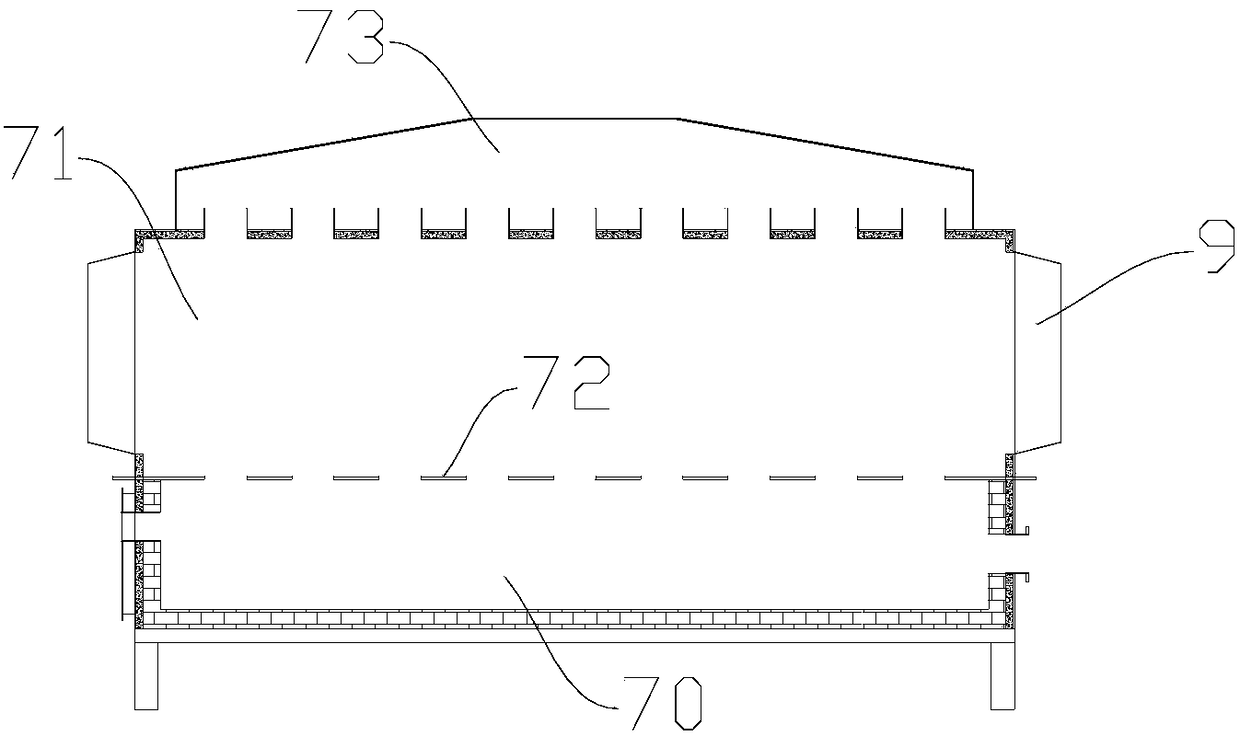

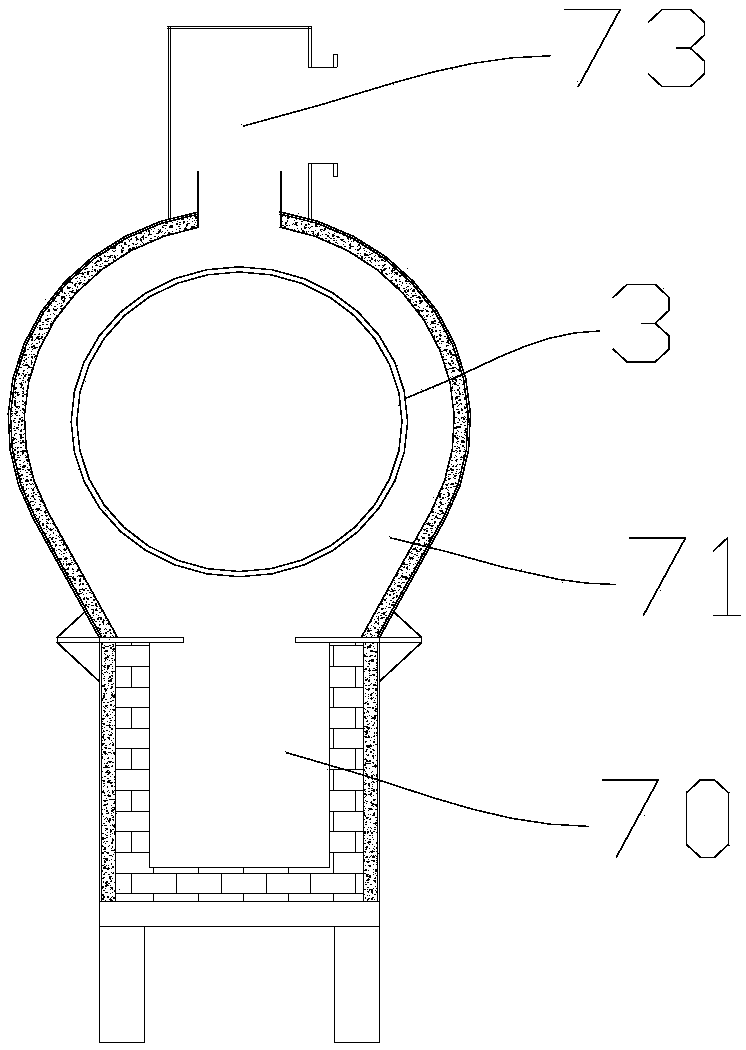

[0033] Such as Figures 1 to 5 As shown, the present invention provides a sealed pyrolysis furnace that continuously feeds and discharges materials, which includes a screw feeder 1, a feed bin 2, a pyrolysis furnace barrel 3, a discharge bin 4, and a screw outlet that are sequentially connected along the material conveying direction. Feeder 5, the feed bin 2 and the discharge bin 4 are fixedly arranged on the frame 6, the top of the discharge bin 4 is provided with a pyrolysis gas outlet, and the bottom is provided with a pyrolysis carbon outlet, and the pyrolysis The furnace drum 3 is supported above the frame 6 by a number of supporting rollers, and the outer wall of the pyrolysis furnace d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com