Method and device for producing 1,3-propylene glycol by utilizing microbial conversion

A technology for microbial transformation and propylene glycol, applied in the field of bioengineering, can solve the problems of increasing by-products, unable to effectively reduce the generation of by-products, etc., and achieve the effects of improving the conversion rate, facilitating the stable period of fermentation, and improving the level of fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

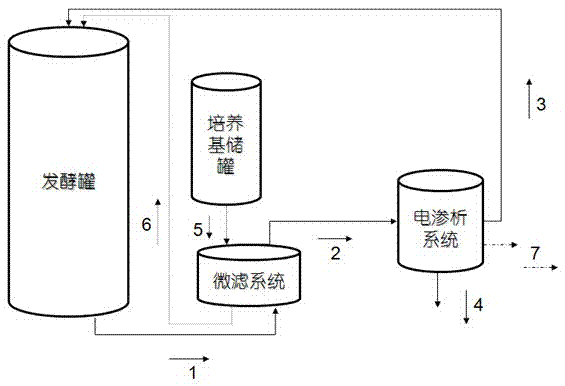

Image

Examples

Embodiment 1

[0033] (1) Take liquid-preserved Klebsiella ( Klebsieblla pneumoniae ) 5mL of strain preservation solution was added to a 3L first-class seed tank containing 2.5L of seed medium for activation and cultivation of strains. After culturing for 24h, the dry weight of the cells reached 2.5g / L, and the cells were transferred to a secondary seed tank containing 22.5L of medium for expansion culture. After culturing for 18 hours, the dry weight of the cells reached 2.6 g / L, the cultivation was terminated, and the obtained seed liquid was inoculated into the fermenter. Cultivation conditions: the nitrogen ventilation rate was 0.1 vvm, the stirring revolution was 300 rpm, the cultivation temperature was 37°C, and the pH was adjusted to 7 with 5 M NaOH.

[0034] (2) Pass the seed liquid obtained in step (1) through a pipeline and press it into a fermenter containing 225L of fermentation medium by aseptic nitrogen. During the fermentation process, nitrogen was introduced to maintain a...

Embodiment 2

[0043] (1) Take liquid-preserved Klebsiella ( Klebsieblla pneumoniae ) 25mL of strain preservation solution was added to a 3L first-class seed tank containing 2.5L of seed medium for activation and cultivation of strains. After culturing for 18h, the dry weight of the cells reached 2.0g / L, and the cells were transferred to a secondary seed tank containing 22.5L of medium for expansion culture. After culturing for 18 hours, the dry weight of the cells reached 2.5 g / L, the cultivation was terminated, and the obtained seed liquid was inoculated into the fermentor. Cultivation conditions: the nitrogen ventilation rate was 0.1 vvm, the stirring revolution was 200 rpm, the cultivation temperature was 37°C, and the pH was adjusted to 6.5 with 5 M NaOH.

[0044] (2) Pass the seed liquid obtained in step (1) through a pipeline and press it into a fermenter containing 225L of fermentation medium by aseptic nitrogen. During the fermentation process, nitrogen was introduced to maintai...

Embodiment 3

[0052] (1) Take liquid-preserved Klebsiella ( Klebsieblla pneumoniae ) Add 15mL of strain preservation solution to a 3L first-class seed tank containing 2.5L of seed medium for activation and cultivation of strains. After culturing for 24 hours, the dry weight of the cells reached 3.2 g / L, and was transferred to a secondary seed tank containing 22.5 L of medium for expansion culture. After culturing for 18 hours, the dry weight of the cells reached 3.0 g / L, the cultivation was terminated, and the obtained seed liquid was inoculated into the fermenter. Cultivation conditions: the nitrogen ventilation rate was 0.1 vvm, the stirring revolution was 200 rpm, the cultivation temperature was 37°C, and the pH was adjusted to 6.8 with 5 M NaOH.

[0053](2) Pass the seed liquid obtained in step (1) through a pipeline and press it into a fermenter containing 225L of fermentation medium by aseptic nitrogen. During the fermentation process, nitrogen was introduced to maintain an anaero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com