Quick cold start system and quick cold start method for fuel cell

A fuel cell and cold start technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as long start-up time, achieve the effects of lowering output efficiency, improving structural design, and increasing heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

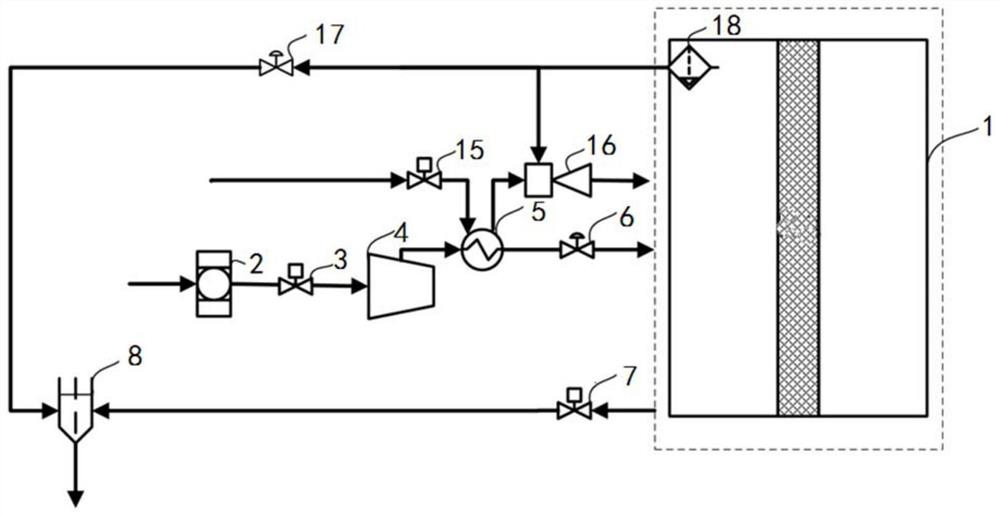

[0027] This embodiment provides a fuel cell rapid cold start system and its control method. The fuel cell rapid cold start system includes a controller and an air subsystem and a hydrogen subsystem respectively connected to the stack 1. The air subsystem includes a back pressure valve 7 and the air filter 2, air compressor 4, intercooler 5 and air intake shut-off valve 6 connected in sequence, the intake air shut-off valve 6 is connected with the air inlet of the electric stack 1, and the back pressure valve 7 is respectively connected with the exhaust pipe 8 and the The air outlet of the electric stack 1 is connected, and the hydrogen subsystem includes a water separator 18, a drain solenoid valve 17, a proportional valve 15 and an ejector 16 connected in sequence, and the ejector 16 is connected with the hydrogen inlet of the electric stack 1, and the water separator 18 are respectively connected to the hydrogen outlet of the electric stack 1, the ejector 16 and the drain sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com