Method for continuously casting sheet band by dual roller

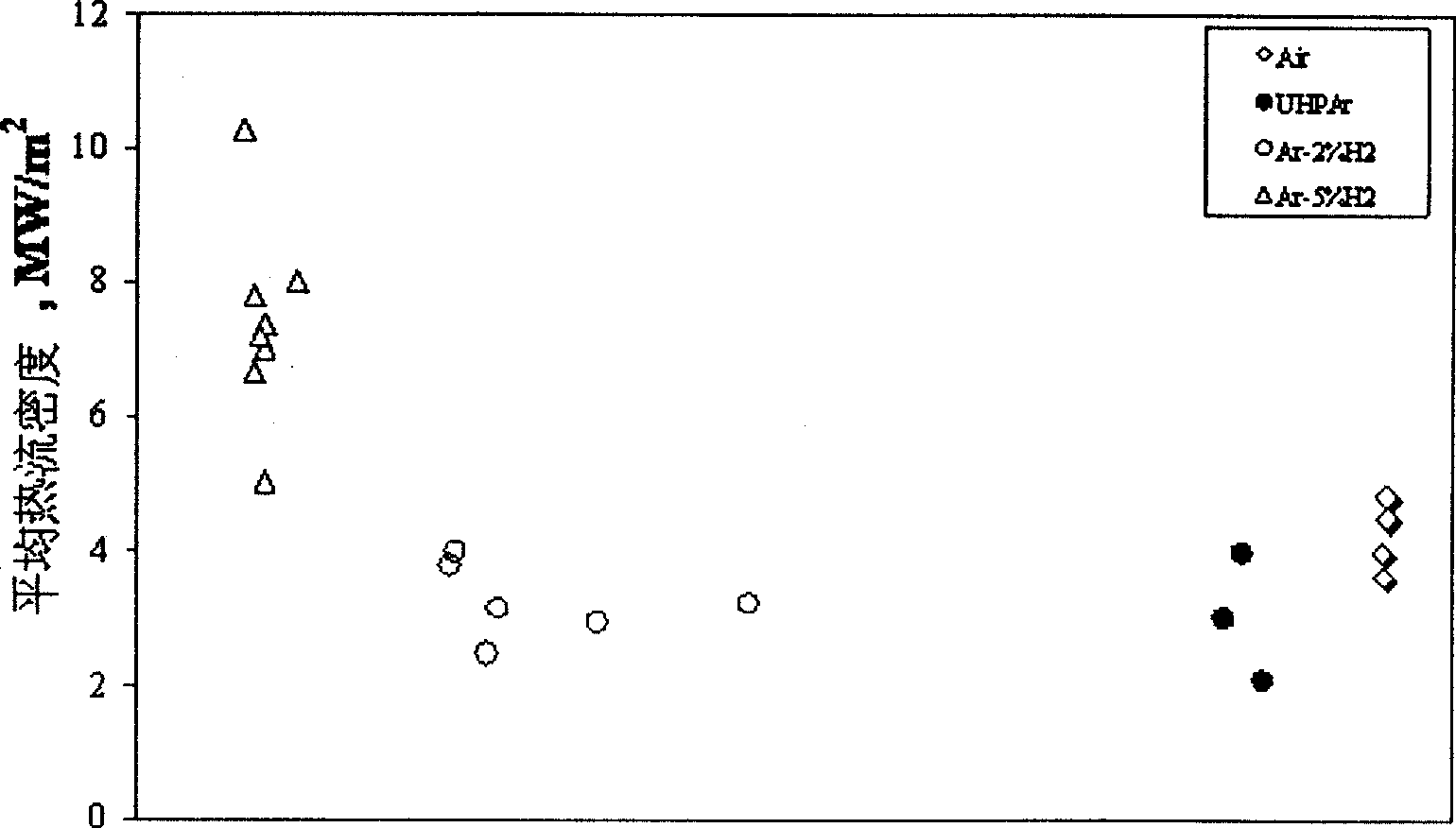

A twin-roll thin strip continuous casting and casting strip technology, which is applied in metal rolling and other directions, can solve problems such as limited effect, complicated equipment, and inconvenient operation, and achieve the effects of improving production efficiency, reducing surface roughness, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

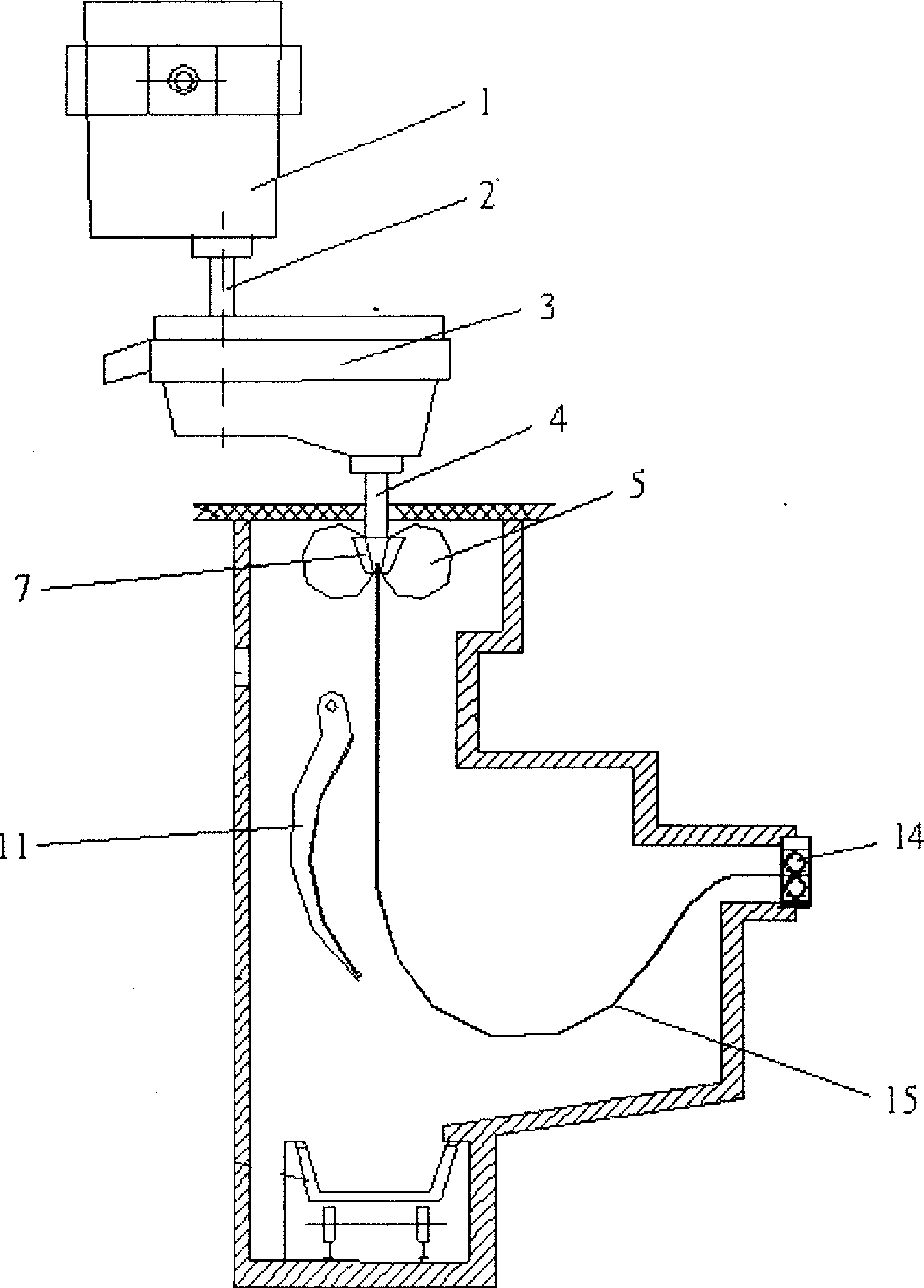

[0025] see figure 1 , figure 2 Shown, strip continuous casting method of the present invention is realized by following steps:

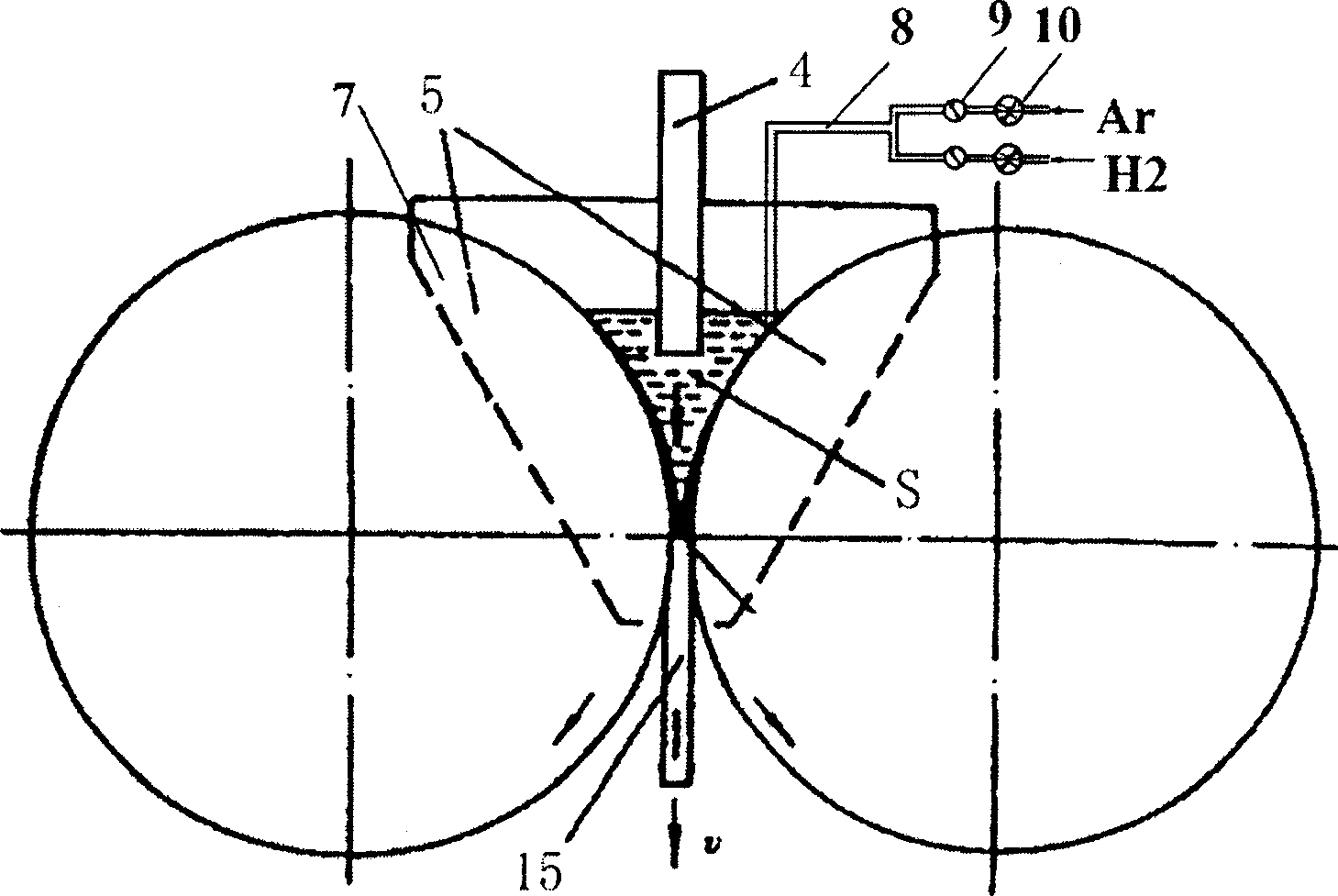

[0026] A. Before pouring, open the argon and hydrogen valves, and control the ratio of argon and hydrogen according to the process requirements of different cast strip quality to generate mixed gas;

[0027] B. Enter the mixed gas into the molten pool formed by the rotating water-cooled crystallization 5 rollers through the gas introduction pipe 8, so that the mixed gas is filled with the airtight chamber 7;

[0028] C. At the beginning of pouring, the molten steel enters the molten pool filled with argon and hydrogen gas mixture from the ladle 1 through the long nozzle 2, the tundish 3 and the submerged nozzle 4, and the molten steel S is cooled by the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com