Eutectic soldering device and application thereof

A technology of eutectic welding and gas nozzle, applied in auxiliary devices, welding equipment, electrical components, etc., can solve problems such as oxidation, lack of gas protection devices, and affecting eutectic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

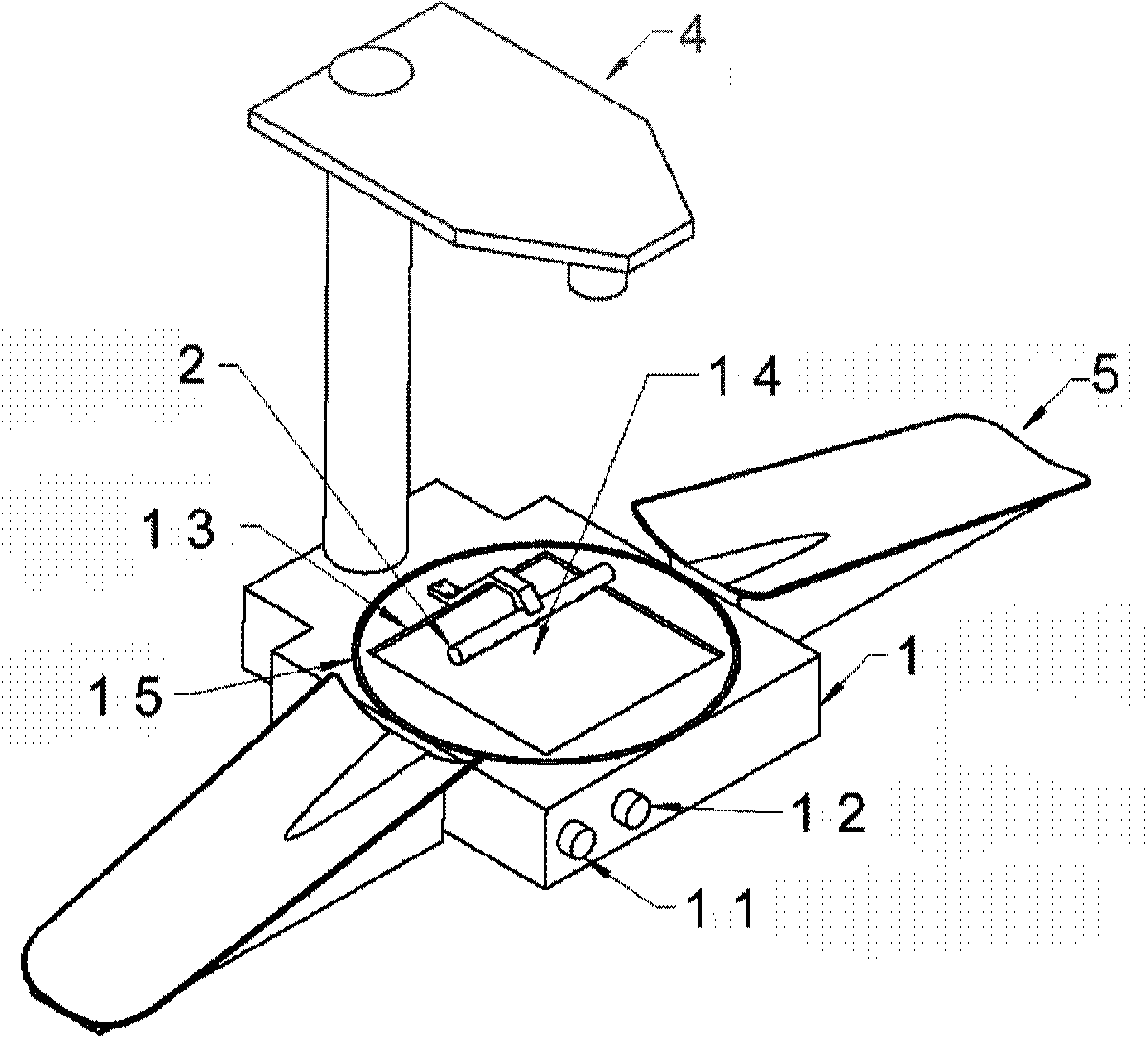

[0041] In an embodiment of the present invention, a hot stage and a gas protection device suitable for chip eutectic welding are provided, such as figure 1 As shown, the device includes a heating stage for eutectic welding, and the heating stage 1 has a temperature adjustment knob 11 and a gas flow knob 12 for adjusting temperature and gas flow. There is a layer of heat insulating pad 13 on the upper surface of the heating stage 1, the material of the heat insulating pad 13 is polyimide, the middle part of the heat insulating pad 13 is a cuboid, and the cuboid is the eutectic region 14 of the chip. A hot stage air outlet is left on the top of the hot stage 1 .

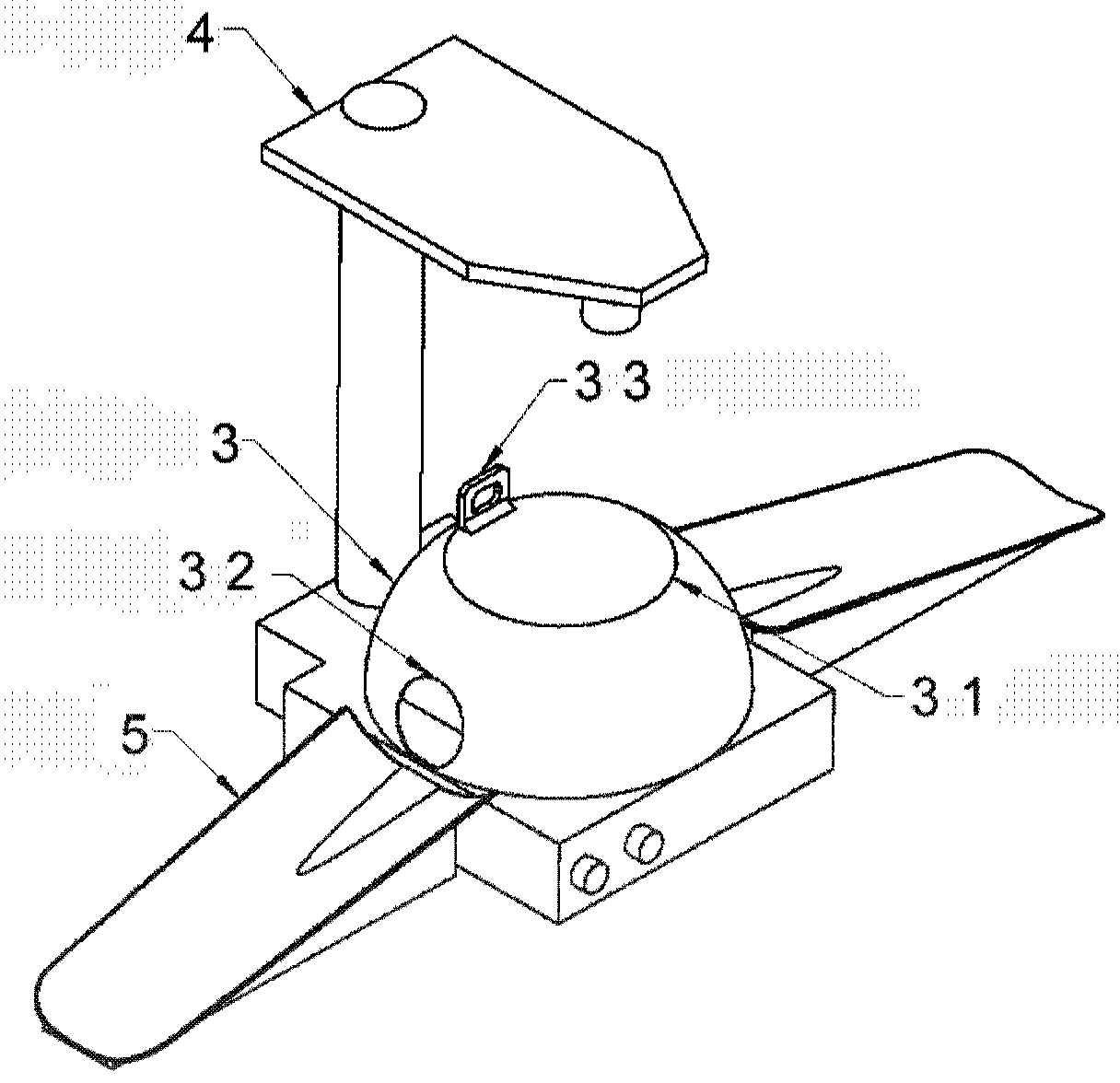

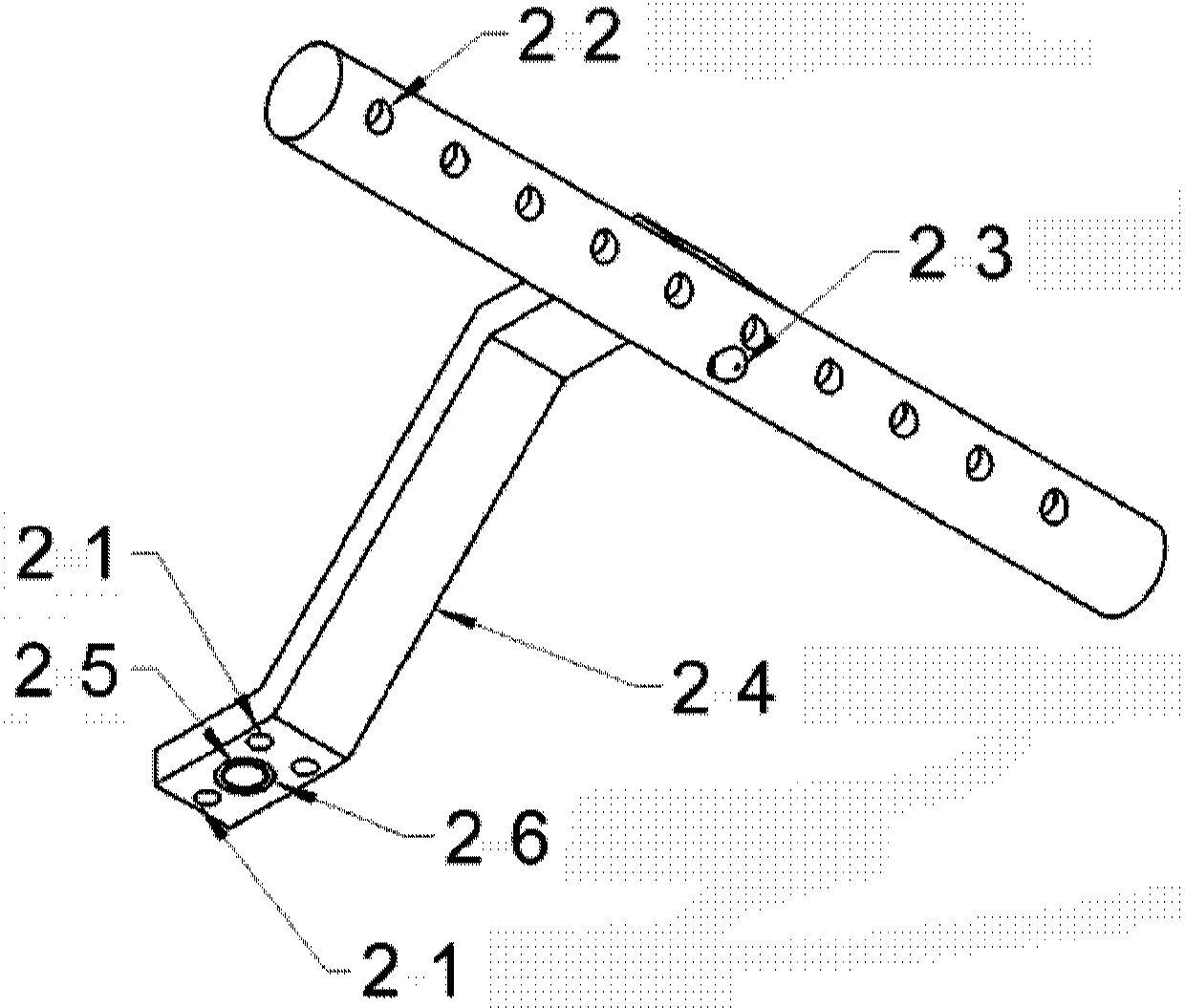

[0042] Such as figure 2 with 3 As shown, a hot stage and gas protection device suitable for chip eutectic soldering includes a gas shower head 2 with an array of exhaust holes 22 . The gas shower head 2 is placed above the hot stage 1 , and the inert gas or nitrogen gas is discharged through the exhaust hole 22 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com