Power distribution cabinet door with high-temperature self-locking function

A technology for power distribution cabinets and cabinet doors, which is applied in the layout of substation/power distribution device shells, electrical components, and wing fans, can solve problems such as inability to conduct induction, inability to cool the inside of the distribution cabinet, and inability to seal the cabinet doors. Achieve the effect of avoiding flame entry, increasing safety, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 6 Shown:

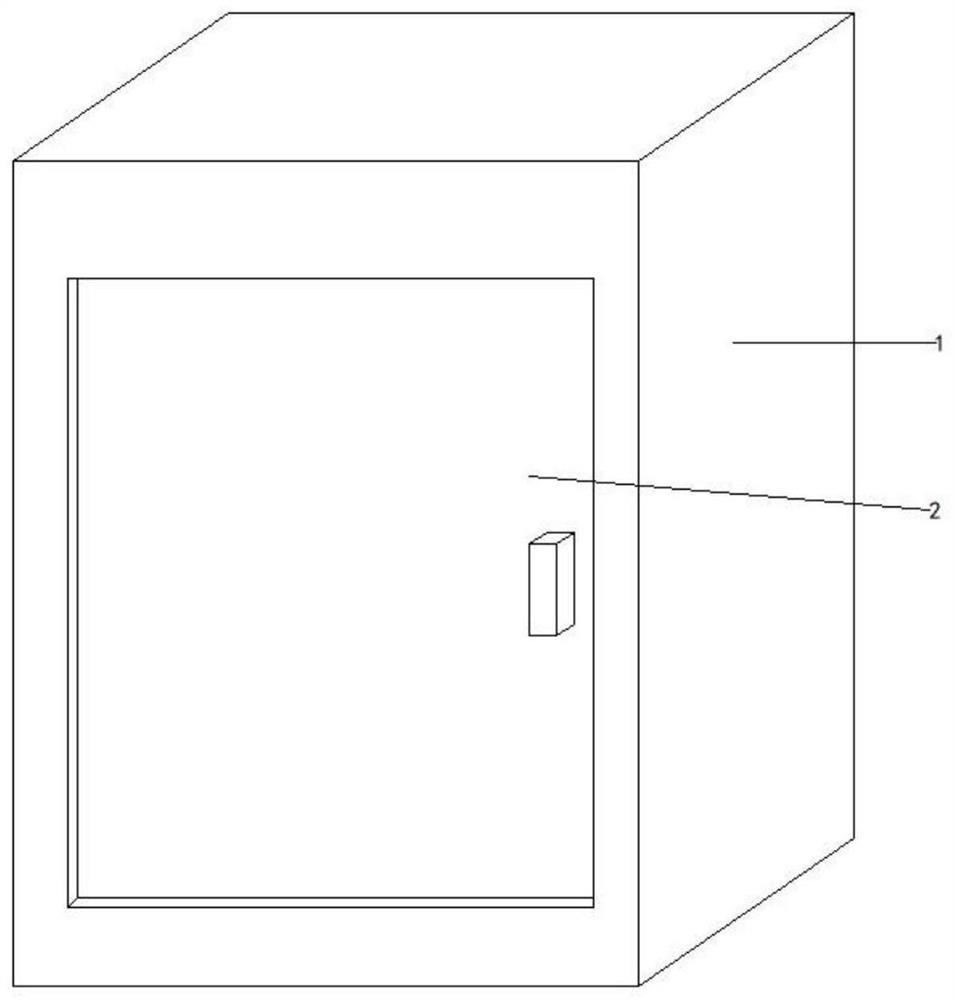

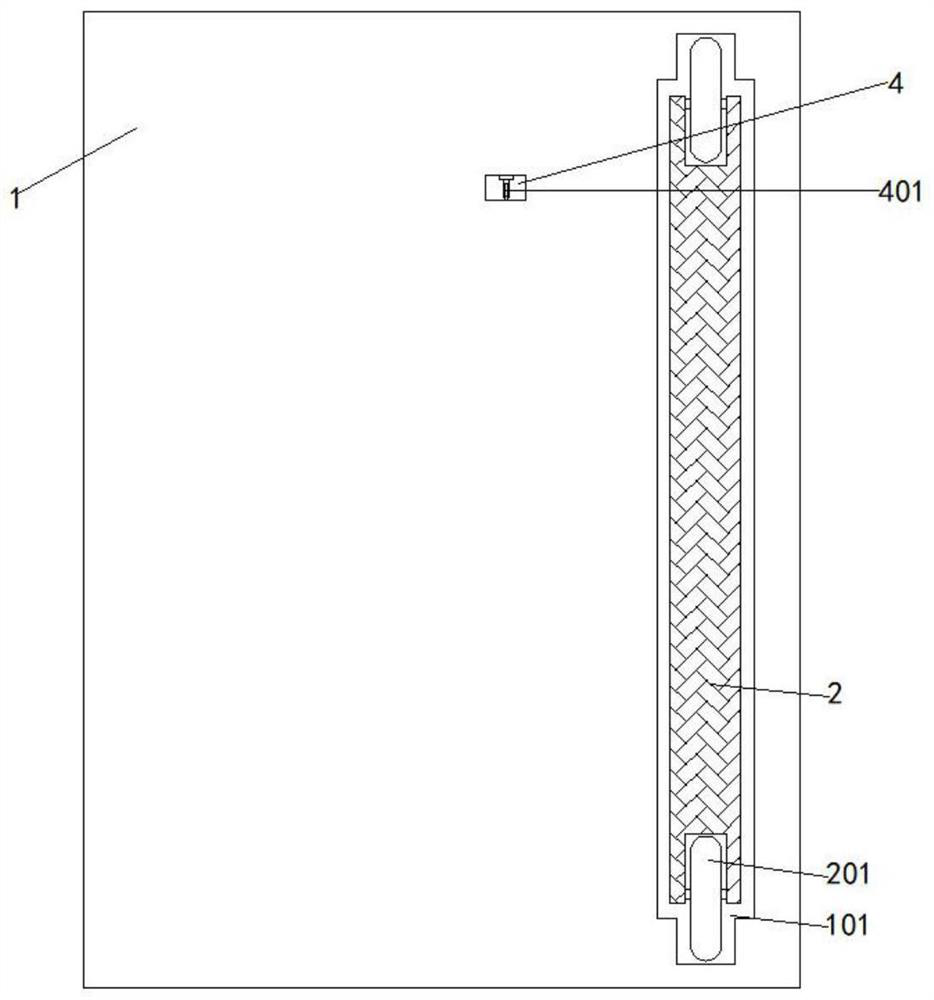

[0028] The present invention provides a high-temperature self-locking power distribution cabinet door, the high-temperature self-locking power distribution cabinet door includes: power distribution cabinet 1, chute 101, cabinet door 2 and pulley 201, inside the power distribution cabinet 1 A chute 101 is provided at the top and bottom of one side, and a cabinet door 2 is slid between the two chute 101 through a pulley 201 . The inside of the power distribution cabinet 1 is respectively provided with a self-locking structure and a sealing structure.

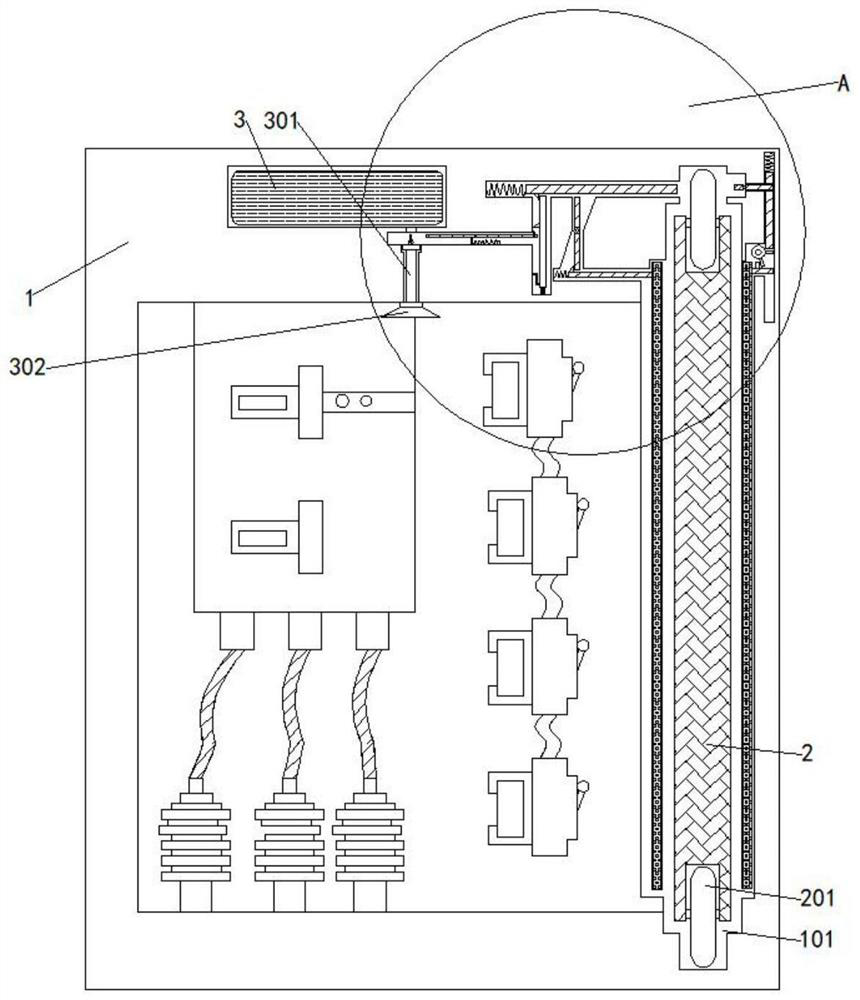

[0029] as attached figure 2 , 3 , 4, 5, and 6, wherein the self-locking structure includes: a groove A4, a glass tube 401, a slider A402, a triangular block A403, a groove C407, a block 408 and a triangular block C409, wherein the power distribution One side of the cabinet 1 is hollow with a groove A4, and the bottom of the groove A4 is fixedly installed with a glass tu...

Embodiment 2

[0035] as attached image 3 , 4 , 5, the present invention also includes a cooling structure, the cooling structure is located in the middle of the power distribution cabinet 1, the cooling structure includes: carbon dioxide storage box 3, injection pipe 301, opening and closing valve 3011, injection port 302, groove B404, The slider B405 and the soft hook 406, wherein the carbon dioxide storage box 3 is fixedly installed in the middle of the upper part of the power distribution cabinet 1, the injection pipe 301 is fixedly installed under the carbon dioxide storage box 3, and the opening and closing valve 3011 is nested outside the injection pipe 301, and The opening and closing valve 3011 switch extends into the groove B404, and the groove B404 and the opening and closing valve 3011 switch are located on the same horizontal plane, and the injection port 302 is fixedly installed under the injection pipe 301, and the injection port 302 is located above the inside of the power d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com