Building power cable rubber material, and preparation method thereof

A rubber material and electric power technology, applied in the field of building electric cable rubber material and its preparation, can solve the problems of the cable being easily damaged, unable to meet the requirements, and the requirements for the flame retardancy and heat resistance of the cable are very large, so as to increase the volume, Improve processing technology and reduce the effect of thermal oxygen attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

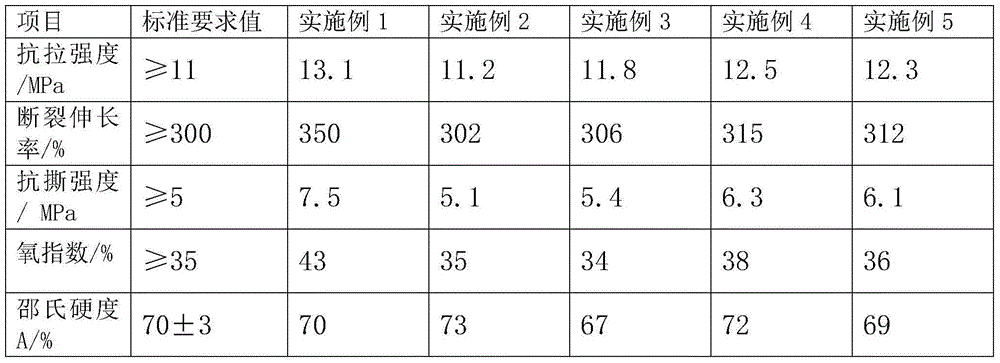

Examples

Embodiment 1

[0025] A kind of construction power cable rubber material according to the present invention, its raw material comprises by weight: 36 parts of silicone rubber, 13 parts of chlorinated polyethylene, 2.5 parts of zinc oxide, 3.0 parts of magnesium oxide, 2.0 parts of stearic acid, polyester 17 parts of isobutylene, 8 parts of zinc methacrylate, 4 parts of boric acid, 10 parts of white carbon black, 6 parts of calcined clay, 1.9 parts of vulcanizing agent DCP, 1.9 parts of vulcanization aid TMPTMA, 1.2 parts of anti-aging agent RD, coupling agent 1.3 parts, Sb 2 o 3 0.52 parts, 0.58 parts of chlorinated paraffin, Mg(OH) 2 0.45 servings.

[0026] A kind of preparation method of cable rubber material for construction electric power of the present invention comprises:

[0027] S1, masticating the silicone rubber and chlorinated polyethylene to obtain masticated rubber, wherein the masticating time is 2.5 minutes, and the masticating temperature is 75° C.;

[0028] S2. Add zinc ...

Embodiment 2

[0033] A kind of construction power cable rubber material according to the present invention, its raw material comprises by weight: 30 parts of silicone rubber, 18 parts of chlorinated polyethylene, 1 part of zinc oxide, 5 parts of magnesium oxide, 1 part of stearic acid, 22 parts of isobutylene, 5 parts of zinc methacrylate, 6 parts of boric acid, 6 parts of white carbon black, 9 parts of calcined clay, 1.2 parts of vulcanizing agent DCP, 2.2 parts of vulcanizing aid TMPTMA, 0.6 parts of anti-aging agent RD, coupling 2.5 parts of agent, Sb 2 o 3 0.18 parts, 0.90 parts of chlorinated paraffin, Mg(OH) 2 0.1 part.

[0034] A kind of preparation method of cable rubber material for construction electric power of the present invention comprises:

[0035] S1, masticating the silicone rubber and chlorinated polyethylene to obtain masticated rubber, wherein the masticating time is 2-3min, and the masticating temperature is 70°C;

[0036] S2. Add zinc oxide, magnesium oxide, steari...

Embodiment 3

[0041] A kind of cable rubber material for construction electric power according to the present invention, its raw material comprises by weight: 45 parts of silicone rubber, 8 parts of chlorinated polyethylene, 4 parts of zinc oxide, 1 part of magnesium oxide, 3 parts of stearic acid, polystyrene 12 parts of isobutylene, 12 parts of zinc methacrylate, 2 parts of boric acid, 15 parts of white carbon black, 3 parts of calcined clay, 2.6 parts of vulcanizing agent DCP, 1.6 parts of vulcanization aid TMPTMA, 1.5 parts of anti-aging agent RD, coupling 0.5 part of agent, Sb 2 o 3 0.80 parts, 0.22 parts of chlorinated paraffin, Mg(OH) 2 0.8 servings.

[0042] A kind of preparation method of cable rubber material for construction electric power of the present invention comprises:

[0043] S1, masticating the silicone rubber and chlorinated polyethylene to obtain a masticated rubber, wherein the masticating time is 3 minutes, and the masticating temperature is 70° C.;

[0044] S2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com