Flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

A technology of alloy material and flame retardant, which is applied in the field of flame retardant CPVC-ABS alloy material and its preparation, can solve the problem of not being able to extinguish the flame, and achieve the effect of good flame retardant effect and less dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

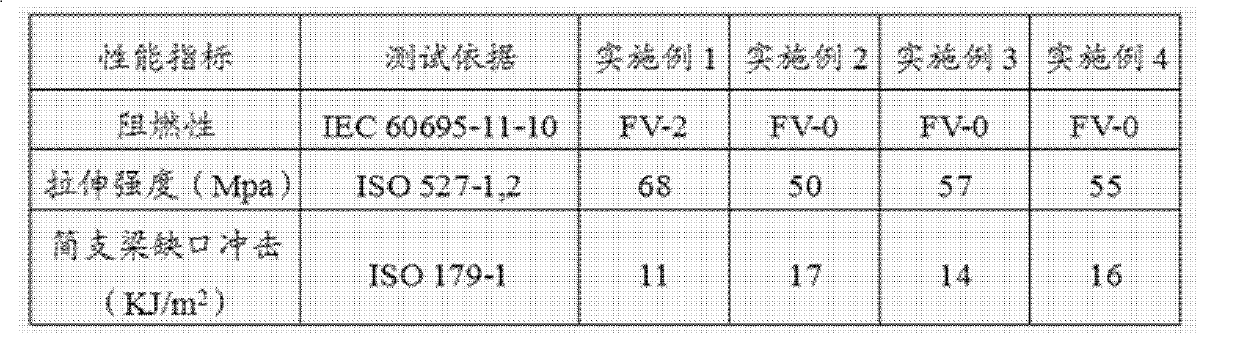

Embodiment 1

[0028] Weigh 80 parts of CPVC, 10 parts of ABS, 1 part of sodium antimonate, 5 parts of calcium stearate and 0.5 part of polyethylene wax, put the above materials into a high-speed mixer and mix them evenly; Mixing was carried out in the mill for 2 minutes, and the temperature of the two-roll mill was 180°C. Put the kneaded material in a flat vulcanizing machine, press molding for 10 minutes under the conditions of a template temperature of 190° C. and a pressure of 10 MPa, and cold pressing for 5 minutes. The sample strips were prepared according to the ISO standard with a sample preparation machine, and tested according to the standard after being placed under the conditions of a constant temperature of 23 ° C and a humidity of 50% for 48 hours. The test results are shown in Table 1.

Embodiment 2

[0030] Weigh 40 parts of CPVC, 50 parts of ABS, 10 parts of sodium antimonate, 0.5 parts of barium stearate and 3 parts of polyethylene wax, put the above materials into a high-speed mixer and mix them evenly; Mixing was carried out in the mill for 6 minutes, and the temperature of the two-roll mill was set at 185°C. Put the kneaded material in a flat vulcanizing machine, press molding for 12 minutes under the conditions of a template temperature of 195° C. and a pressure of 15 MPa, and cold pressing for 8 minutes. The sample strips were prepared according to the ISO standard with a sample preparation machine, and tested according to the standard after being placed under the conditions of a constant temperature of 23 ° C and a humidity of 50% for 48 hours. The test results are shown in Table 1.

Embodiment 3

[0032] Weigh 60 parts of CPVC, 30 parts of ABS, 5 parts of antimony trioxide, 3 parts of zinc stearate and 2 parts of polyethylene wax, put the above materials into a high-speed mixer and mix them evenly; Mixing was carried out in the open mill for 5 minutes, and the temperature of the two-roll open mill was set at 185°C. Put the kneaded material in a flat vulcanizing machine, press molding for 8 minutes under the conditions of a template temperature of 195° C. and a pressure of 12 MPa, and cold pressing for 10 minutes. The sample strips were prepared according to the ISO standard with a sample preparation machine, and tested according to the standard after being placed under the conditions of a constant temperature of 23 ° C and a humidity of 50% for 48 hours. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com