Composite intumescent flame retardant and preparation method thereof

An intumescent flame retardant and composite intumescent technology, which is applied in the field of flame retardant, can solve the problems of large addition amount, limited popularization and use, and deterioration of the mechanical properties of the polymer matrix, so as to increase the interlayer spacing, improve compatibility, and reduce environmental hazards. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

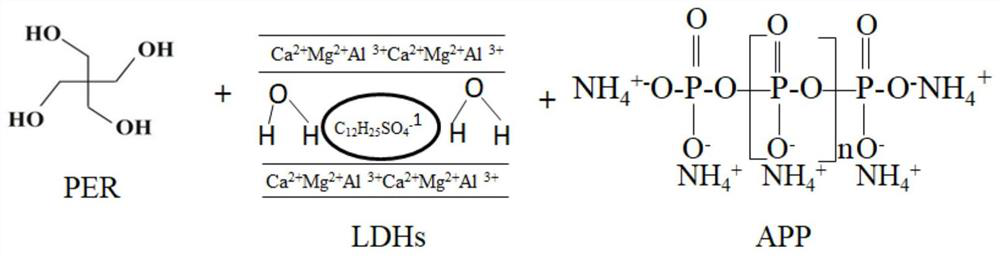

Method used

Image

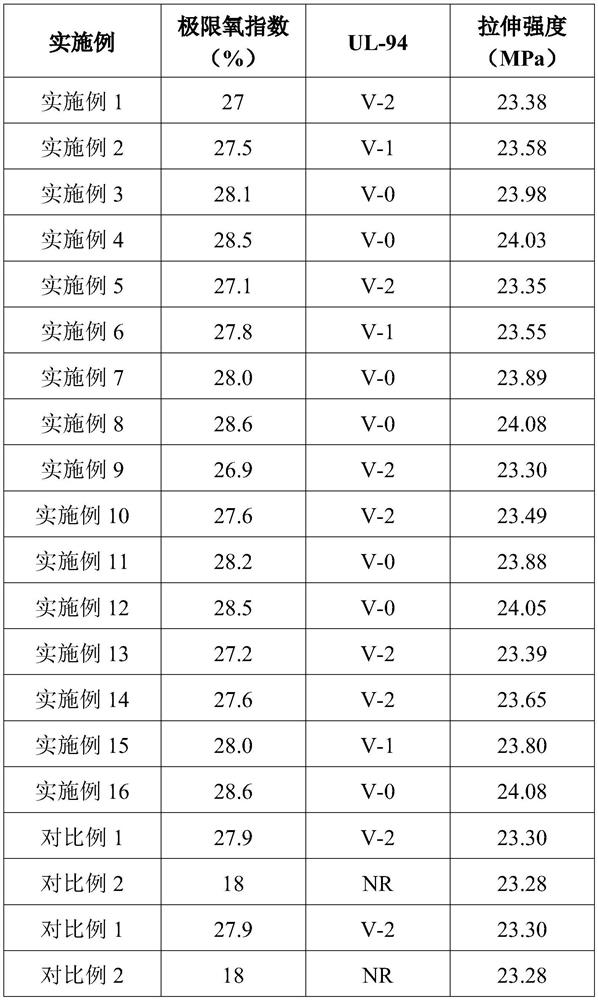

Examples

Embodiment 1

[0031] The preparation method of the sodium oleate modified calcium magnesium aluminum hydrotalcite of dodecyl sulfate radical type is as follows:

[0032] (1) Using the co-precipitation method, take 0.06mol Ca (NO 3 ) 2 4H 2 O, 0.12molMg(NO 3 ) 2 ·6H 2 O and 0.06molAl(NO 3 ) 3 9H 2 Dissolve O in carbon dioxide-free water and mark it as solution A. Dissolve 1mol NaOH in carbon dioxide-free water and mark it as solution B. Add solutions A and B to the flask respectively, stir at room temperature, keep the pH at 9, and complete the dropwise addition Continue stirring for 1 hour, crystallize at 60°C for 13 hours, filter with suction, wash with carbon dioxide-free water until neutral, dry at 60°C, grind, pass through a 60-80 mesh sieve (177-250 μm), and record it as CaMgAl-LDHs .

[0033] (2) Using the ion exchange method, take 15g CaMgAl-LDHs and 16.2g sodium dodecyl sulfate (SDS) and dissolve them in decarbonated water, stir for 13 hours at room temperature, filter with...

Embodiment 2

[0038] The preparation method of the sodium oleate modified calcium magnesium aluminum hydrotalcite of dodecyl sulfate radical type is as follows:

[0039] (1) Using the co-precipitation method, take 0.06mol Ca (NO 3 ) 2 4H 2 O, 0.12molMg(NO 3 ) 2 ·6H 2 O and 0.06molAl(NO 3 ) 3 9H 2 Dissolve O in carbon dioxide-free water and mark it as solution A. Dissolve 1mol NaOH in carbon dioxide-free water and mark it as solution B. Add solutions A and B to the flask respectively, stir at room temperature, keep the pH at 9, and complete the dropwise addition Continue stirring for 1 hour, crystallize at 60°C for 13 hours, filter with suction, wash with carbon dioxide-free water until neutral, dry at 60°C, grind, pass through a 60-80 mesh sieve (177-250 μm), and record it as CaMgAl-LDHs .

[0040] (2) Using the ion exchange method, take 15g CaMgAl-LDHs and 16.2g sodium dodecyl sulfate (SDS) and dissolve them in decarbonated water, stir for 13 hours at room temperature, filter with...

Embodiment 3

[0045] The preparation method of the sodium oleate modified calcium magnesium aluminum hydrotalcite of dodecyl sulfate radical type is as follows:

[0046] (1) Using the co-precipitation method, take 0.06mol Ca (NO 3 ) 2 4H 2 O, 0.12molMg(NO 3 ) 2 ·6H 2 O and 0.06molAl(NO 3 ) 3 9H 2 Dissolve O in carbon dioxide-free water and mark it as solution A. Dissolve 1mol NaOH in carbon dioxide-free water and mark it as solution B. Add solutions A and B to the flask respectively, stir at room temperature, keep the pH at 9, and complete the dropwise addition Continue stirring for 1 hour, crystallize at 60°C for 13 hours, filter with suction, wash with carbon dioxide-free water until neutral, dry at 60°C, grind, pass through a 60-80 mesh sieve (177-250 μm), and record it as CaMgAl-LDHs .

[0047] (2) Using the ion exchange method, take 15g CaMgAl-LDHs and 16.2g sodium dodecyl sulfate (SDS) and dissolve them in decarbonated water, stir for 13 hours at room temperature, filter with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com