Ternary hybrid flame retardant, flame-retardant polylactic acid material and preparation methods thereof

A technology of polylactic acid materials and ternary hybridization, which is applied in the field of flame-retardant polylactic acid materials and their preparation, and ternary hybrid flame retardants, can solve problems such as low limiting oxygen index and poor flame-retardant effect, and achieve improved mechanical properties. performance, low environmental hazards, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

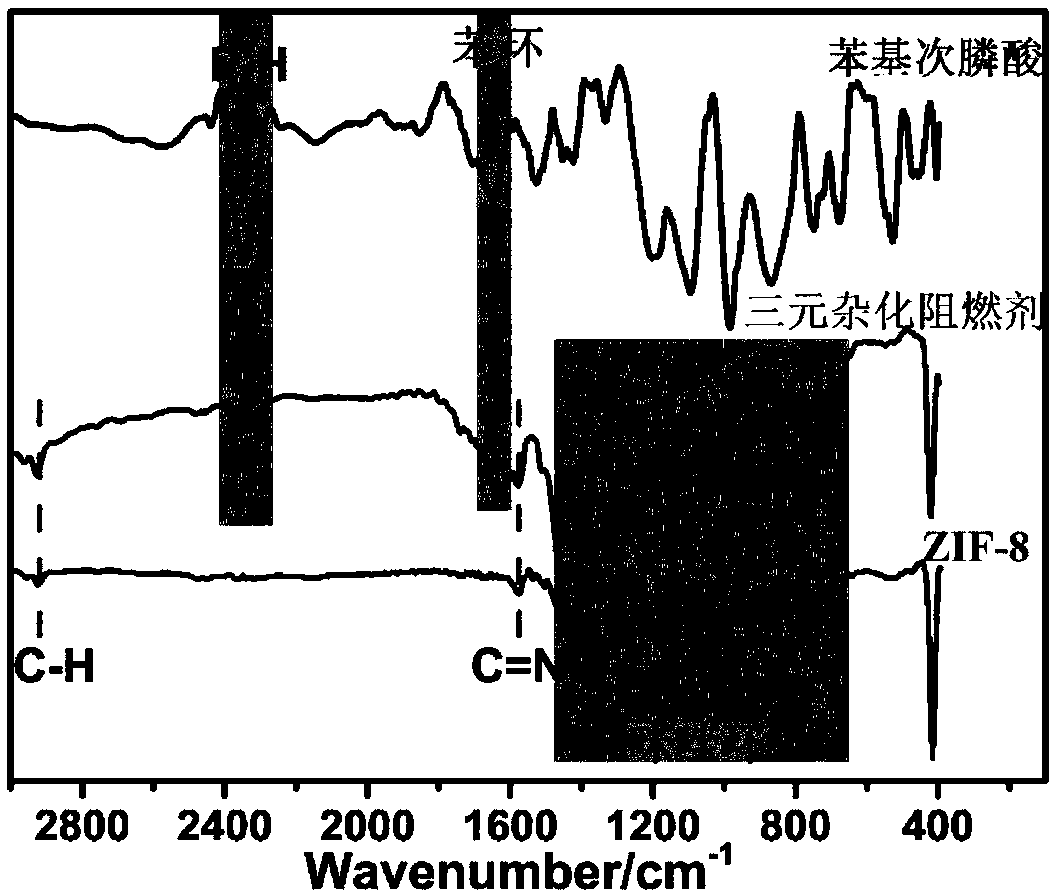

[0024] Preparation of ternary hybrid flame retardant:

[0025] (1) Utilize the graphene oxide prepared by the Hummers method, weigh 0.163g graphene oxide and pour it into 100ml methanol solution, and ultrasonically disperse it evenly; weigh 2g phenylphosphinic acid and add it to the above graphene oxide In the dispersion liquid, stir magnetically for 4-5 hours under the heating condition of 80-90 ℃, centrifuge, wash with alcohol, and dry.

[0026] (2) Weighing 1.602g 2-methylimidazole and 1.487g zinc nitrate hexahydrate were dissolved in 100ml methanol respectively; added successively to the 100ml methanol dispersion of prepared graphene oxide grafted phenylphosphinic acid, at room temperature Stir for 1-2 hours, centrifuge, wash with alcohol, and dry.

Embodiment 2

[0028] Weigh 9.8g of polylactic acid particles, add them to 40ml chloroform solution and magnetically stir for 2h to dissolve them completely; weigh 0.2g ternary hybrid flame retardant, add them to 20mL chloroform solution and ultrasonically disperse them for 2h, pour them Put it into the chloroform solution of polylactic acid and stir for 4 hours, use a film coater to coat a film on a glass plate, place it at room temperature for 24 hours to evaporate the solvent, then release it with warm water, put it in an oven, and place it at 50°C for 72 hours. Measured according to GB / T2406-1993 standard test method, the tensile strength is 44.1±0.3MPa, the limiting oxygen index is 25.0%, the peak heat release rate (PHRR) is 316.2W / g, and the vertical burning level is V-2 level.

Embodiment 3

[0030] Weigh 9.75g of polylactic acid particles, add them to 40ml chloroform solution and magnetically stir for 2h to dissolve them completely; weigh 0.25g ternary hybrid flame retardant, add them to 20mL chloroform solution and ultrasonically disperse them for 2h, pour them Put it into the chloroform solution of polylactic acid and stir for 4 hours, use a film coater to coat a film on a glass plate, place it at room temperature for 24 hours to evaporate the solvent, then release it with warm water, put it in an oven, and place it at 50°C for 72 hours. Measured according to GB / T2406-1993 standard test method, the tensile strength is 43.2±0.6MPa, the limiting oxygen index is 27.0%, the peak heat release rate (PHRR) is 352.9W / g, and the vertical burning level is V-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com