Patents

Literature

81results about How to "Reduce burn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of flame-retardant viscose fiber and preparation method thereof

ActiveCN102286799AIncreased residue on ignitionImprove high temperature resistanceArtificial filaments from viscosePolymer scienceSodium metasilicate

The invention discloses a fire-retardant viscose fiber and a preparation method thereof, wherein a silicon and aluminum composite fire retardant is contained in the fire-retardant viscose fiber and the preparation method of the fire-retardant fiber comprises the steps of: obtaining a spinning solution through taking cellulose pulps as a raw material and subjecting to the processing steps of yellowing, dissolving, defoaming and filtering, subjecting the spinning solution to spinning and forming in a coagulating bath, subjecting to post-processing steps of washing and desulfurization, adding right amount of sodium metasilicate and sodium metasilicate solution into a cellulose viscose solution which is dissolved to any process before the spinning and then uniformly mixing. According to the invention, the silicon and aluminum composite fire retardant is utilized to ensure that the fire-retardant effect of the prepared fire-retardant viscose fiber is greatly increased and the high temperature and alkaline resistances of the fire-retardant viscose are greatly increased; and therefore, the fire-retardant viscose fiber can be popularized and applied in high-temperature environments such as the fields of high-temperature filter media, filter materials and the like.

Owner:赛得利(盐城)纤维有限公司

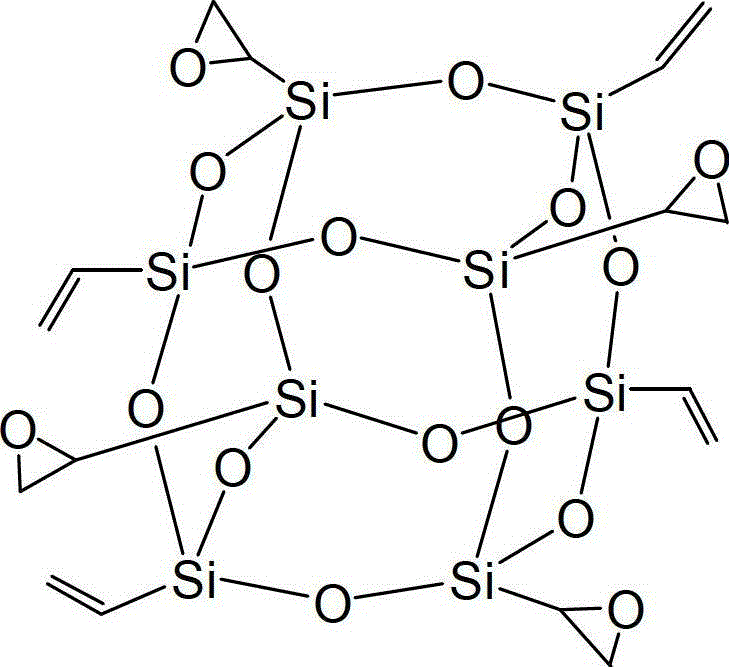

POSS/PA6 (polyhedral oligomeric silsesquioxane/polycaprolactam) composite material and preparation method thereof

ActiveCN102977592AHigh strengthIncreased application temperature rangeSilicon organic compoundsCombustionAntioxidant

The invention provides a POSS / PA6 (polyhedral oligomeric silsesquioxane / polycaprolactam) composite material and a preparation method thereof. The composite material is prepared from 70-99 parts of PA6, 1-30 parts of POSS, 0.1-1 part of antioxidant and 0.1-1 part of lubricant through mixing, granulating and extruding. According to the invention, the novel POSS monomer is used and added into the PA6, so that the intensity of the composite material is enhanced, the application temperature range of the composite material is enlarged, the composite material has high oxidation resistance and water resistance, the flammability and combustion rate of the composite material are reduced, and the composite material has high glass transition temperature and low heat conductivity.

Owner:HEFEI GENIUS NEW MATERIALS

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

Preparation method of high-flame-retardancy expandable graphite

The invention relates to a preparation method of high-flame-retardancy expandable graphite, which comprises the following steps: oxidizing graphite by using concentrated sulfuric acid / nitric acid mixture, nitric acid / phosphoric acid mixture, fuming nitric acid or concentrated sulfuric acid together with a solid strong oxidizer which accounts for 5-60 wt% of graphite, wherein the reaction temperature is 15-50 DEG C, and the reaction time is 10-100 minutes; after the reaction finishes, filtering, and washing with water until the pH value is 4-7, thereby obtaining the primary expandable graphite; and reacting the primary expandable graphite with guanidine salt solution at 20-80 DEG C for 20-200 minutes, carrying out repeated vacuum filtration, washing with water until the pH value is 6-7, and baking at 40-80 DEG C for 10-72 hours to obtain the high-flame-retardancy expandable graphite. The method provided by the invention intercalates guanidine salts into the interlayer of the expandable graphite, enhances the expansion ratio and flame retardancy, and can be widely used for flame retardancy for plastics, rubber, paint, foam and various other materials.

Owner:SOUTH CHINA UNIV OF TECH

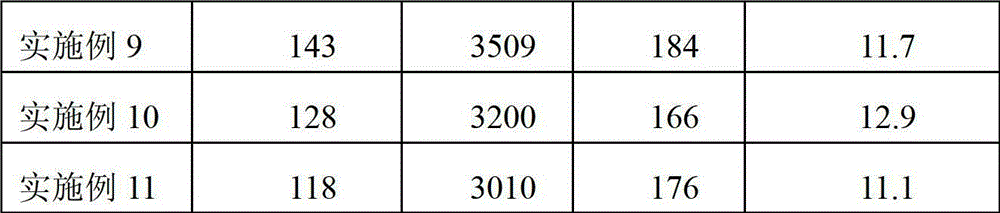

Intumescent flame retardant, flame-retardant polylactic acid material and preparation methods of intumescent flame retardant and flame-retardant polylactic acid material

The invention discloses an intumescent flame retardant, a flame-retardant polylactic acid material and preparation methods of the intumescent flame retardant and the flame-retardant polylactic acid material. The intumescent flame retardant consists of a chitosan salt and ZIF-8@GO in a mass ratio of (96-80):(4-20), the chitosan salt is prepared by reacting 2-carboxyethyl(phenyl)phosphinic acid withchitosan, and the ZIF-8@GO is prepared by loading a zeolite imidazate framework material ZIF-8 on graphene oxide; a chloroform solution of polylactic acid and a chloroform dispersion liquid of an intumescent flame retardant are blended according to a mass ratio of 95:5 by adopting a solution blending method, and coating is performed to prepare the flame-retardant polylactic acid material. The flame-retardant polylactic acid material is simple in formula, halogen-free and environment-friendly, the mechanical property and flame-retardant property of polylactic acid are remarkably improved, themolten drop phenomenon of the flame-retardant polylactic acid material is obviously weakened, a continuous and compact carbon layer is generated after combustion, and the effects of heat insulation and oxygen insulation are achieved.

Owner:南京塑煌新材料科技有限公司

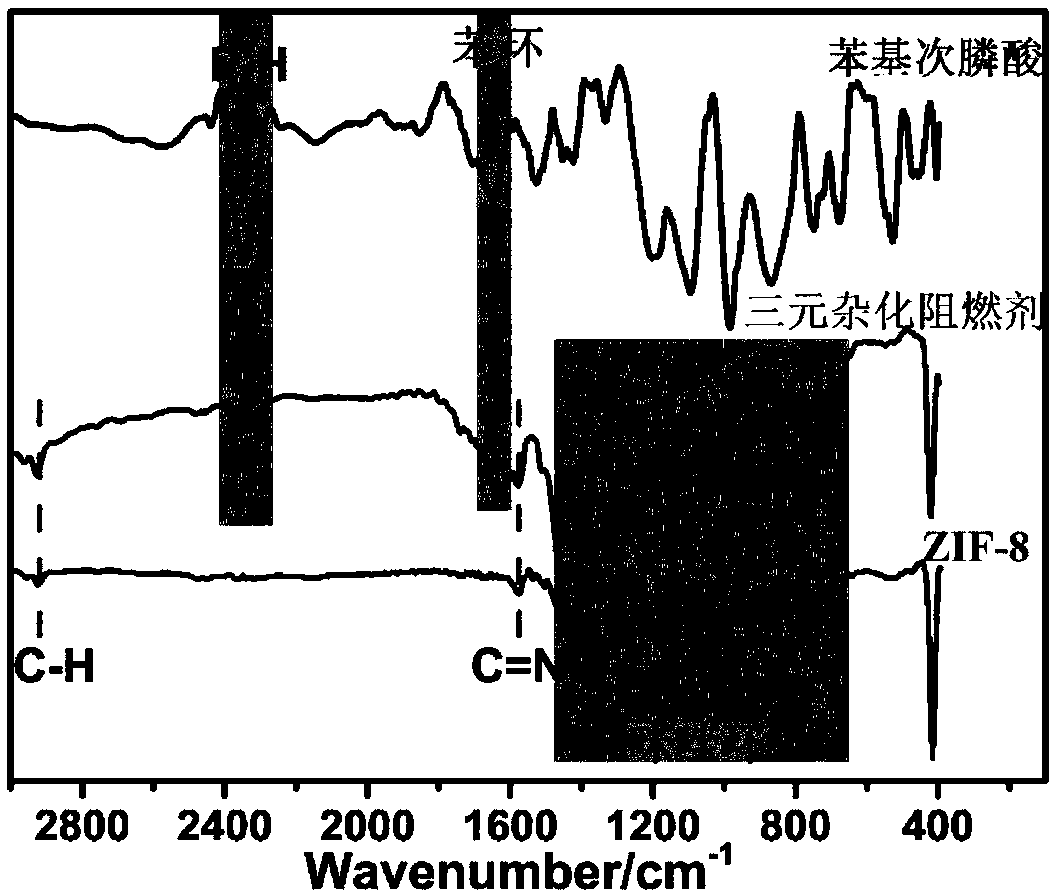

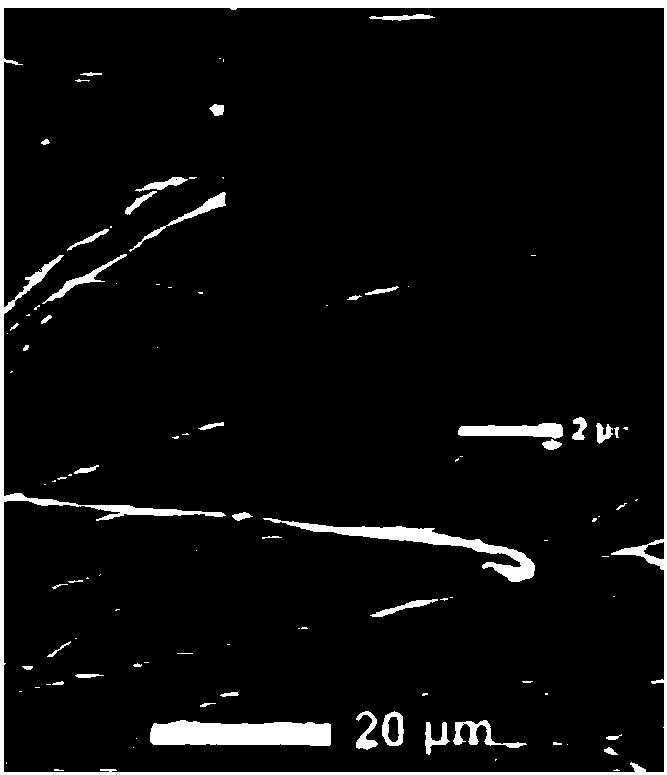

Ternary hybrid flame retardant, flame-retardant polylactic acid material and preparation methods thereof

The invention discloses a ternary hybrid flame retardant, a flame-retardant polylactic acid material and preparation methods thereof. The ternary hybrid flame retardant comprises graphene oxide, phenylphosphinic acid and a zeoliticimidazate framework material ZIF-8. The ternary hybrid flame retardant polylactic acid material comprises polylactic acid and the ternary hybrid flame retardant in the mass ratio of (97.5-98.0):(2.5-2.0). The preparation methods comprise the steps of grafting the phenylphosphinic acid onto the graphene oxide by utilizing an oxygen-containing functional group of the graphene oxide and loading the surface of the graphene oxide with ZIF-8 to obtain the ternary hybrid flame retardant; mixing a chloroform solution of the polylactic acid with a chloroform dispersion liquid of the ternary hybrid flame retardant in proportion by adopting a solution mixing method. and coating to obtain the ternary hybrid flame retardant polylactic acid material. The ternary hybrid flame-retardant polylactic acid material disclosed by the invention has the advantages that the material is simple in formula, free of halogen, friendly to environment and high in flame retardant efficiency; the mechanical properties are remarkably improved; the molten drop phenomenon is reduced; and a continuous and compact carbon layer is formed after combustion to play the roles of heat insulationand oxygen insulation.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of expansible graphite with flame retardant property

The invention discloses a preparation method of expansible graphite with a flame retardant property. The preparation method comprises the following steps: dissolving ammonium polyphosphate and potassium dichromate accounting for 20%-50% of the mass of the ammonium polyphosphate in a phosphoric acid having the mass fraction of 75% to form a phosphoric acid solution in which the concentration of the ammonium polyphosphate is 0.02g / ml-2g / ml; taking a mixed solution of sulfuric acid and nitric acid or a concentrated sulfuric acid solution and oxidizing graphite by use of potassium dichromate accounting for 10-20% of the mass of the graphite to obtain a primary expansible graphite; reacting the phosphoric acid solution with the primary expansible graphite at a temperature in the range of 70-80 DEG C, after the reaction is finished, filtering and washing with water until the pH is in the range of 6-7, and drying at 100 DEG C for 6-12 hours to obtain the expansible graphite with the flame retardant property. The preparation method of the expansible graphite with a flame retardant property is characterized in that a phosphorous compound is inserted between the layers of the graphite so that the adhesion of the prepared expansible graphite with the high flame retardant property to each other can be improved so that a better flame retardant effect can be achieved, in addition to a relatively high expansion volume of the expansible graphite.

Owner:无锡市新颖密封材料厂

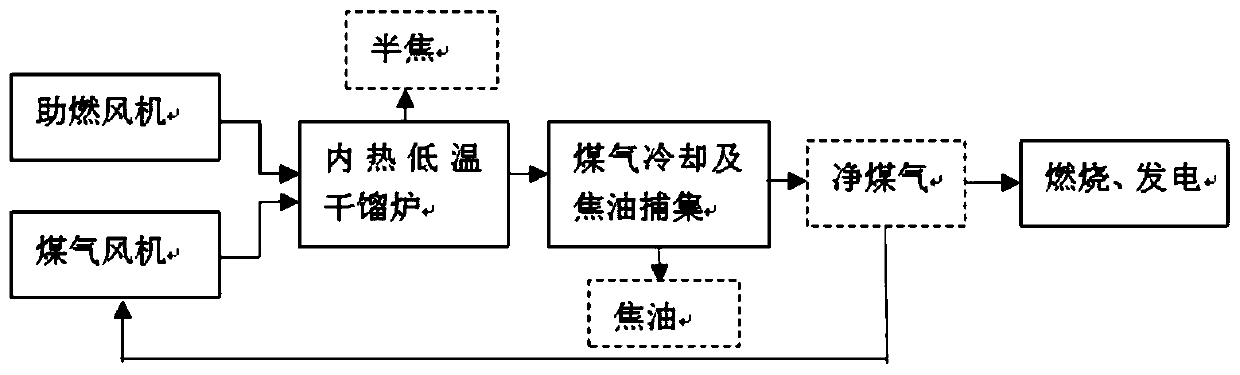

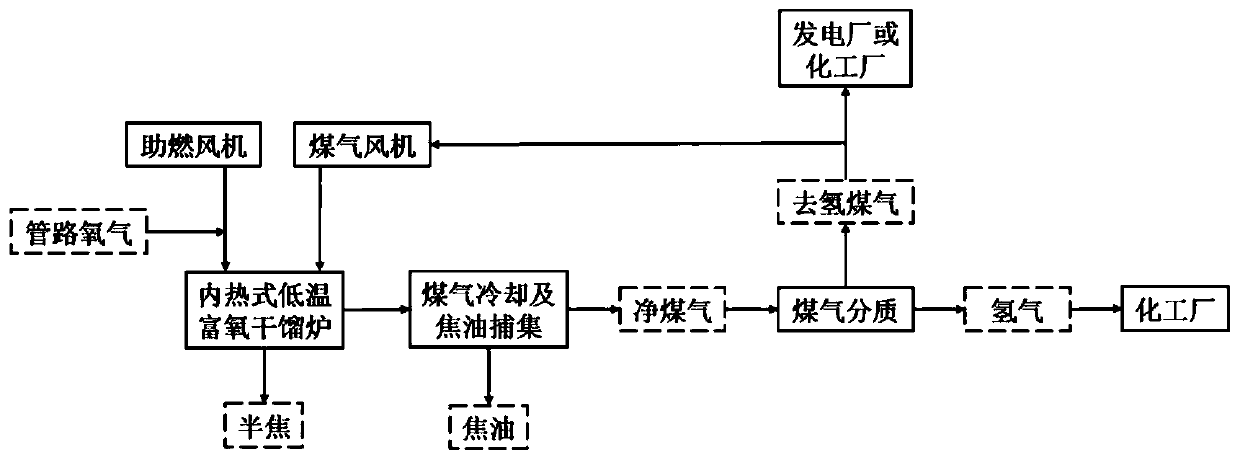

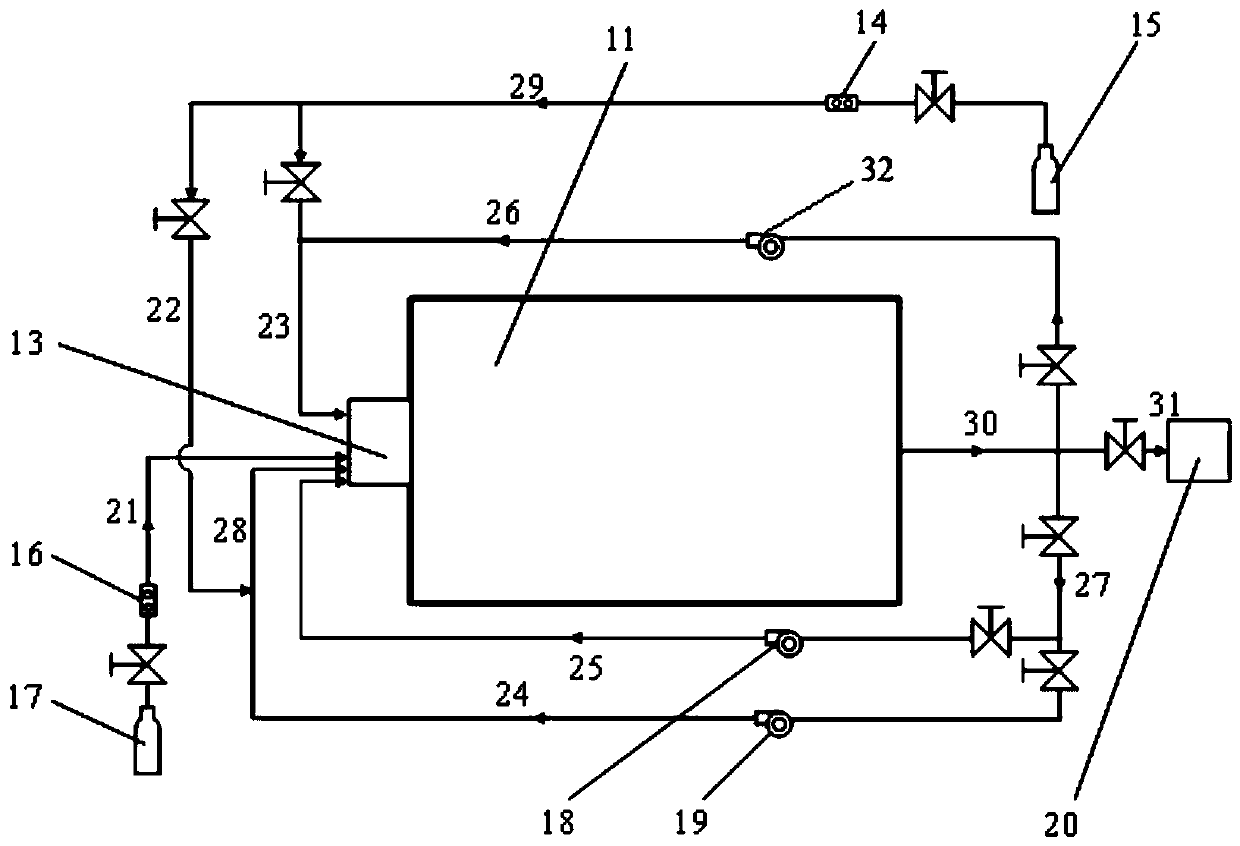

Internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas

ActiveCN111187632AAchieving long-term operationQuality improvementSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas. The process comprises the following steps: introducing dehydrogenated coal gas, air and oxygen into an internal heating type low-temperature destructive coal distillation furnace; mixing the air and the oxygen to form oxygen-enriched combustion-supporting gas; and subjecting the dehydrogenized coal gas and the oxygen-enriched combustion-supporting gas to oxygen-enriched combustion in the internal heating type low-temperature destructive coal distillation furnace, wherein the volume fraction of oxygen in the oxygen-enriched combustion-supporting gas is greater than or equal to 30%. A step of acquiring the dehydrogenated coalgas comprises the following sub-steps: carrying out coal gas cooling and tar trapping on coal gas generated by the internal heating type low-temperature destructive coal distillation furnace to obtain purified coal gas; separating and removing hydrogen in the purified gas so as to obtain the dehydrogenated gas. According to the invention, the flame length and the flame temperature of a flame pathcan better meet the requirements of a low-temperature destructive distillation process, the influence of too high combustion speed of oxygen-enriched destructive distillation high-hydrogen-content coal gas is reduced, the long-period operation of an oxygen-enriched destructive distillation process device and the stable quality of dry distillation products are realized, and the high-added-value gradient utilization of the coal gas can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

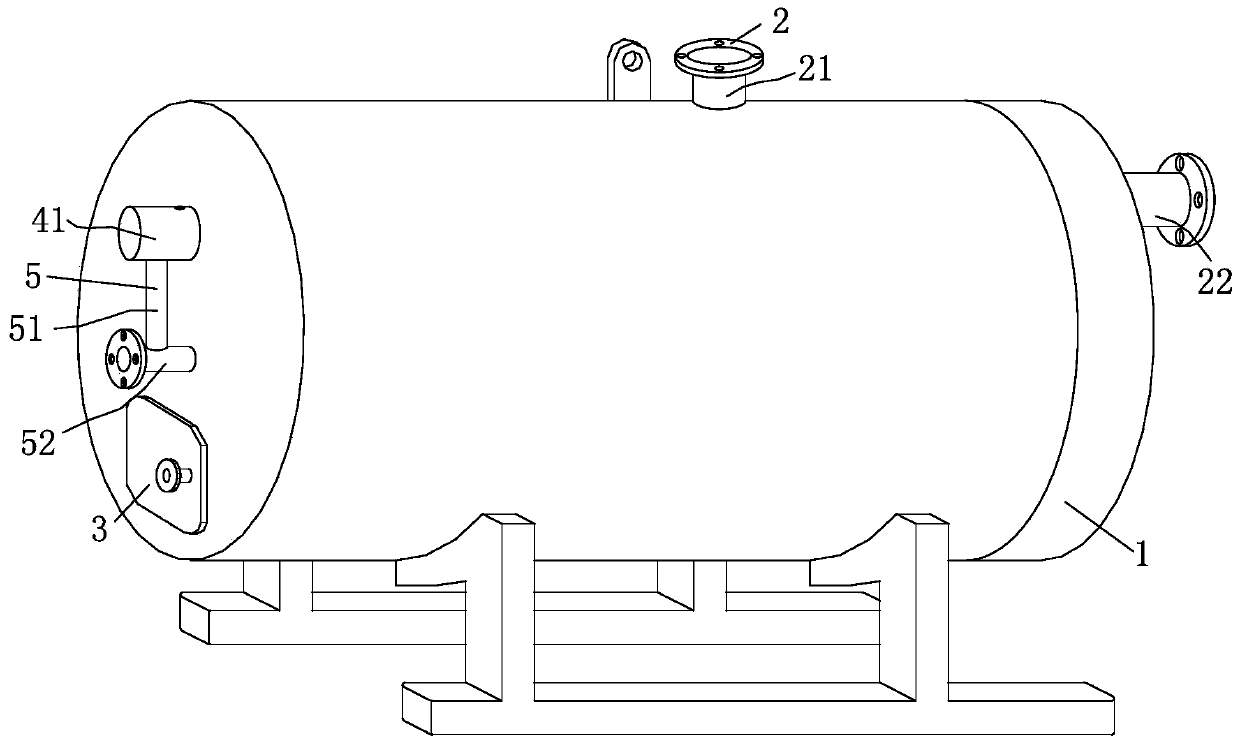

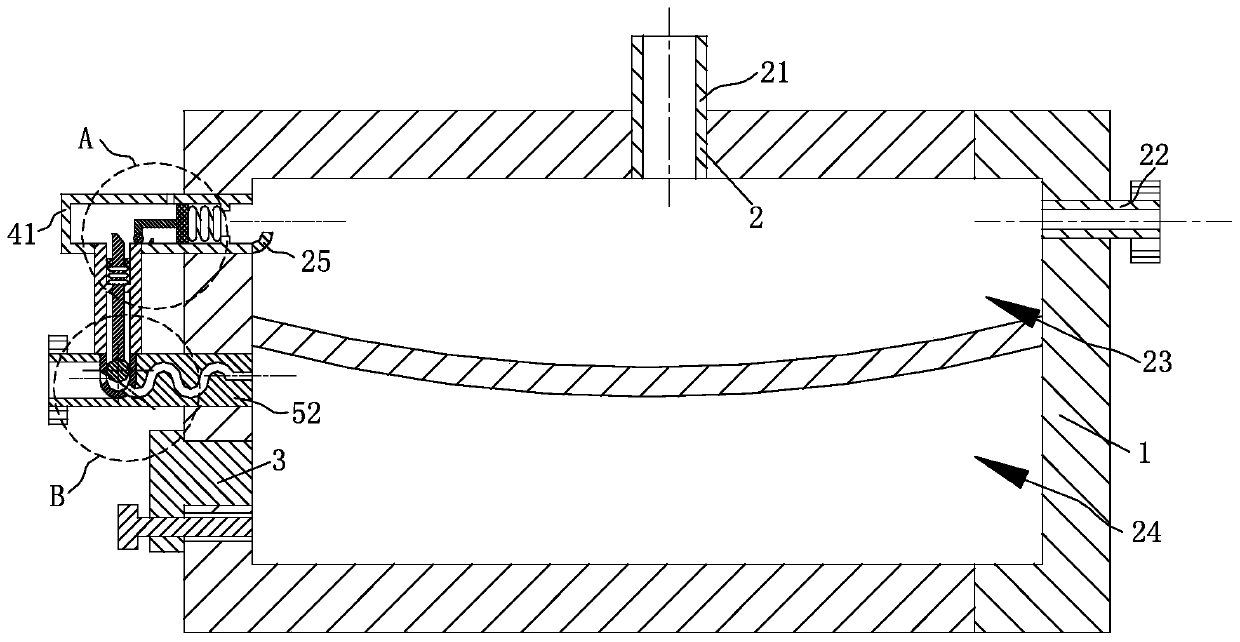

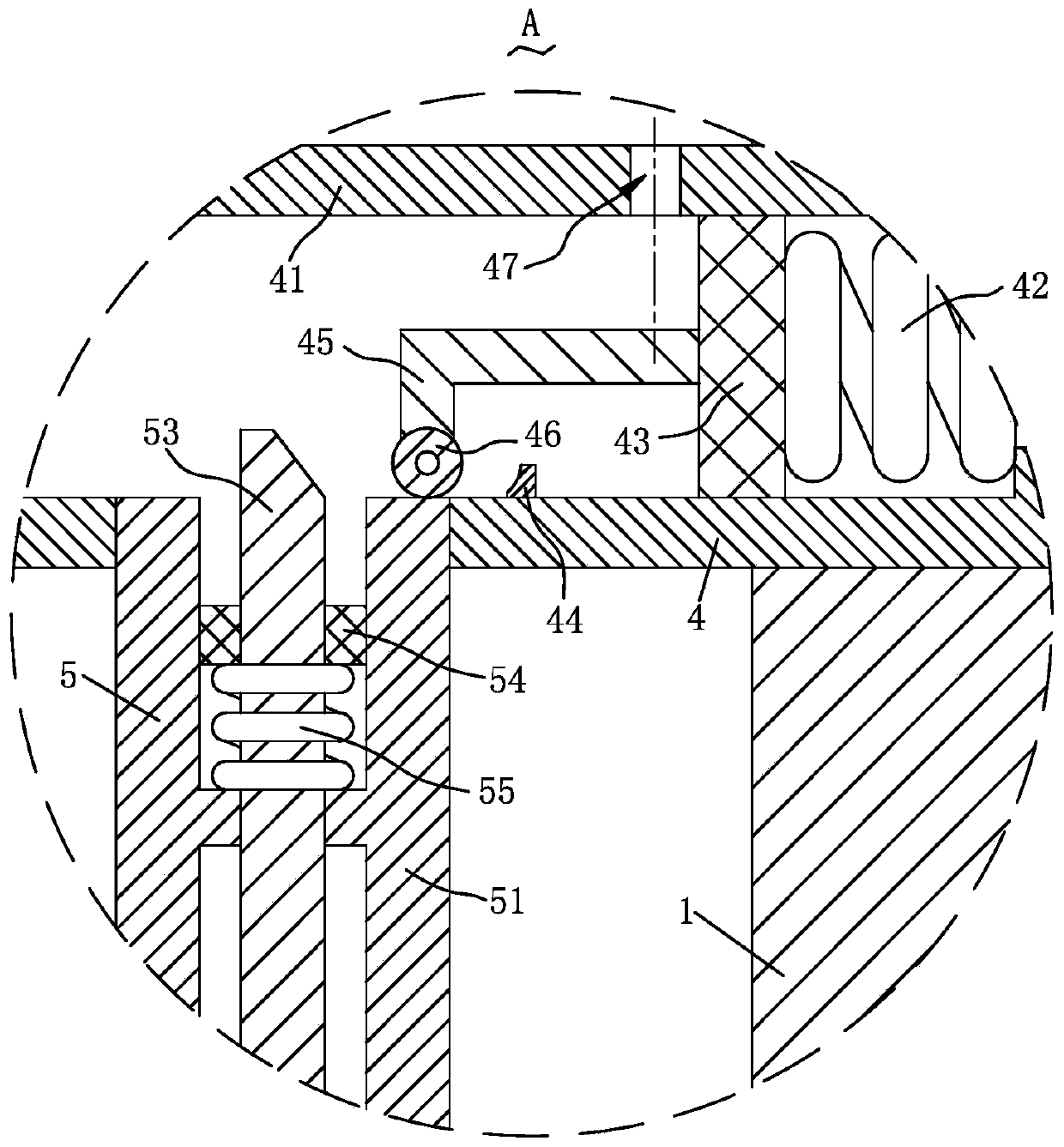

Industrial boiler

ActiveCN110332510AAvoid damageReduce lossesAir/fuel supply for combustionSteam boilersInternal pressureCombustion

The invention relates to the technical field of boilers, in particular to an in industrial boiler. The industrial boiler comprises a boiler body, a switch door, a storage mechanism, a pressure reliefstructure and an air inlet mechanism. The boiler body for supplying coal to combust and exchange heat is connected to the switch door for adding coal, the boiler body is connected to the storage mechanism used for adding water and discharging steam, the boiler body is connected to the pressure relief structure for relieving pressure of water vapor, the boiler body is connected to the air inlet structure for conveying oxygen to combust the coal, and the air inlet structure is connected to the pressure relief structure; and the pressure relief structure is matched with the air inlet structure touse. The oxygen flux in a storage room is reduced while the pressure of the water vapor in a water storage room is relieved by means of the pressure relief structure, the combustion rate of the coalin the storage room is reduced, and the boiler body is prevented from being damaged as a result of too large pressure in the water storage room, so that the water vapor generation capacity in the pressure relief process of the water storage room is reduced, the water vapor amount flowing from a pressure relief port is reduced, and the loss of the water vapor relived in pressure is reduced.

Owner:日照菁英传媒科技有限公司

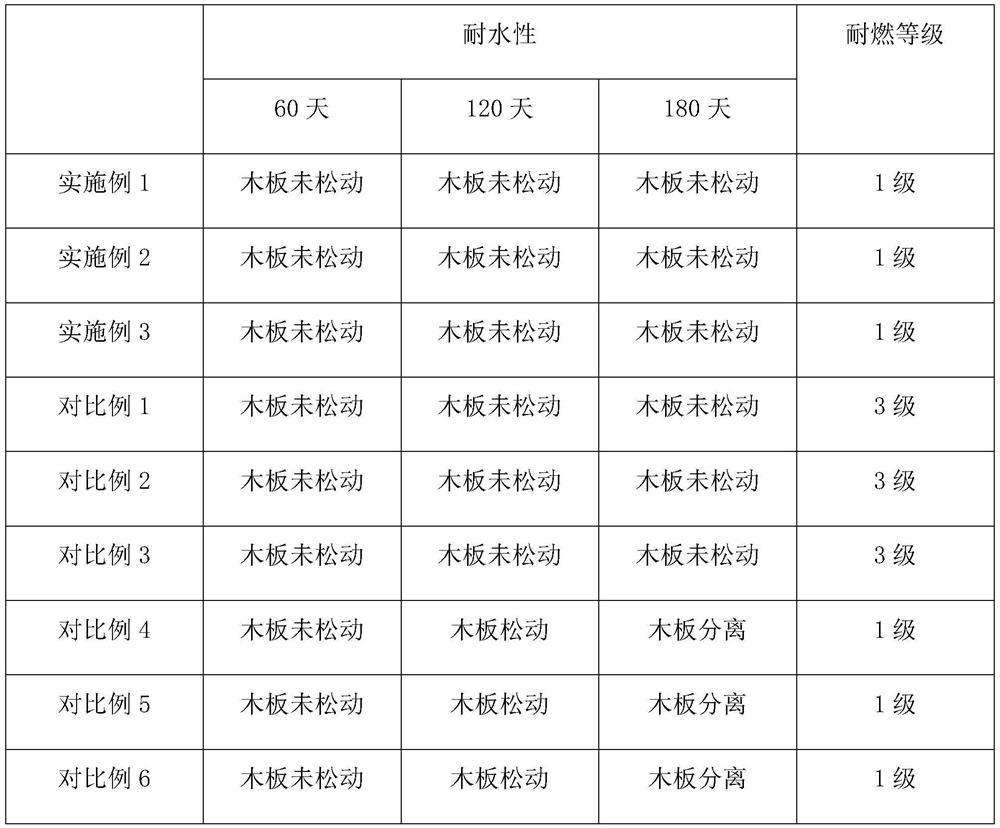

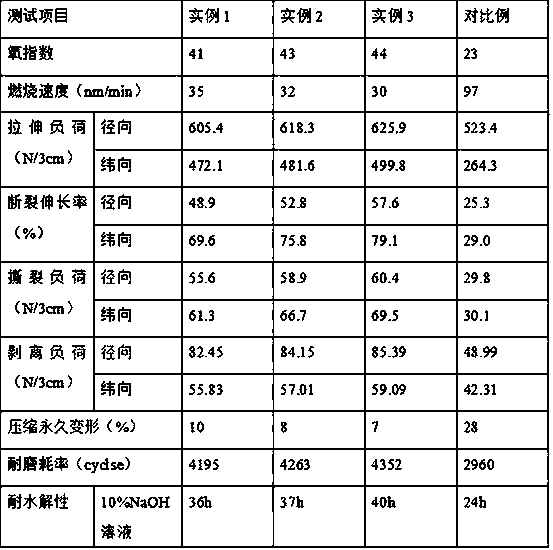

Water-based formaldehyde-free adhesive for flame-retardant composite board and preparation method thereof

ActiveCN113004857AHigh tensile strengthImprove wear resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveMaterials science

The invention discloses a water-based formaldehyde-free adhesive for a flame-retardant composite board and a preparation method thereof. The adhesive is mainly prepared from a fumaric acid-aluminum complex, a 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide compound, a microencapsulated isocyanate and defatted bean flour. During high-temperature combustion, isocyanate generated by decomposition of defatted bean flour and isocyanate generated by decomposition of polyurethane react with fumaric acid to form an imine structure, the 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and the imine structure are subjected to an addition reaction to generate a nitrogen-containing compound, the nitrogen-containing compound is thermally decomposed during combustion to generate ammonia inert gas, the combustible gas concentration and the combustion rate are reduced; the nitrogen-containing compound is subjected to a nitrogen-containing reaction to form a nitrogen-containing flame retardant, and the concentration and combustion rate of combustible gas are reduced. The nitrogen-containing compound is combusted to form a carbon layer, molten drops are reduced, and the flame retardant property is improved. The adhesive prepared by the method improves the water resistance on the basis of a water-based adhesive, does not contain aldehyde groups, does not release formaldehyde to pollute the environment, has good flame retardant property, can effectively slow down the combustion rate of the composite board, and has very high practicability and production value.

Owner:上海德万家企业发展(集团)有限公司

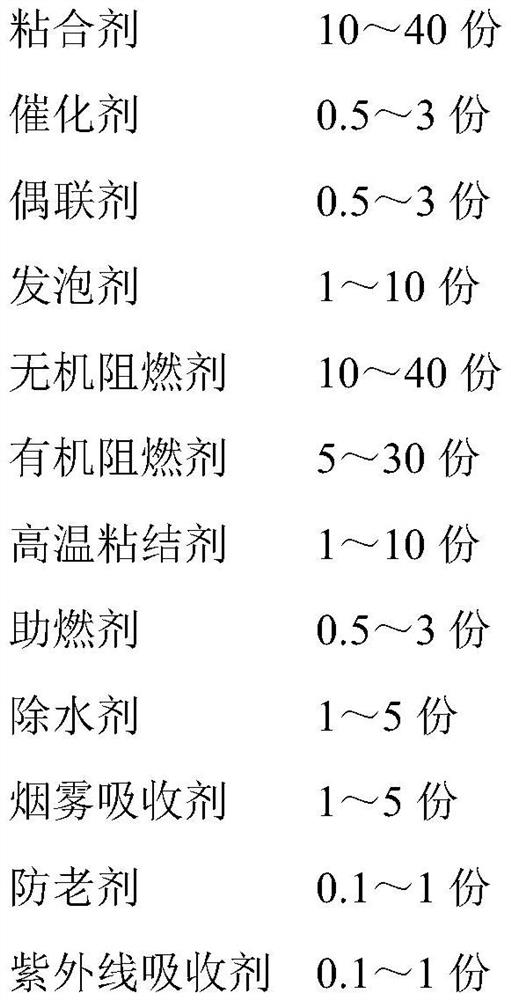

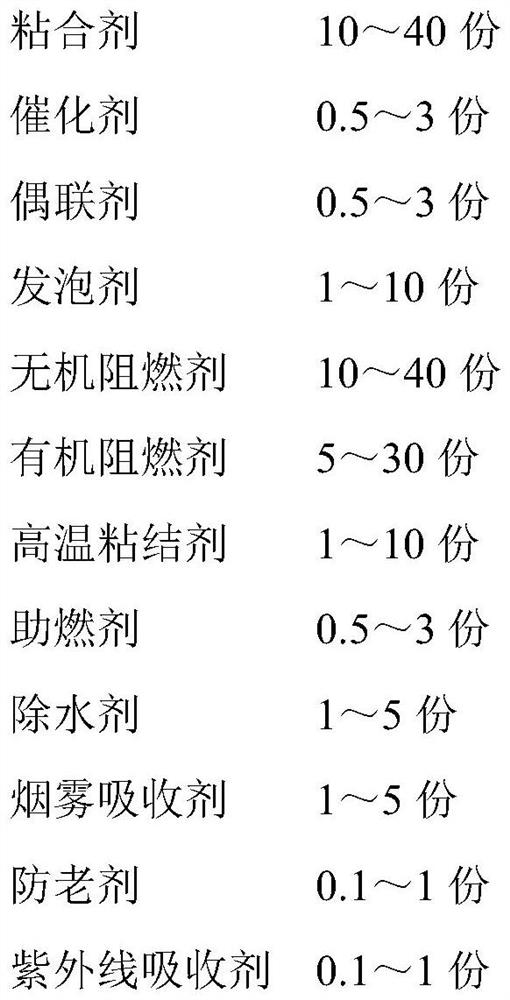

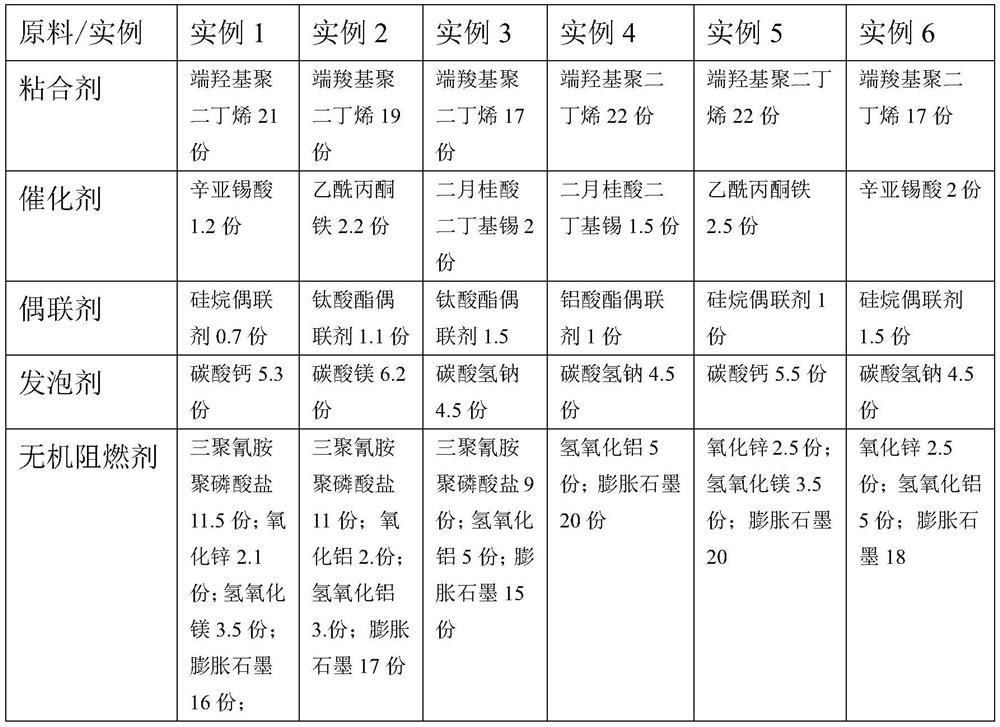

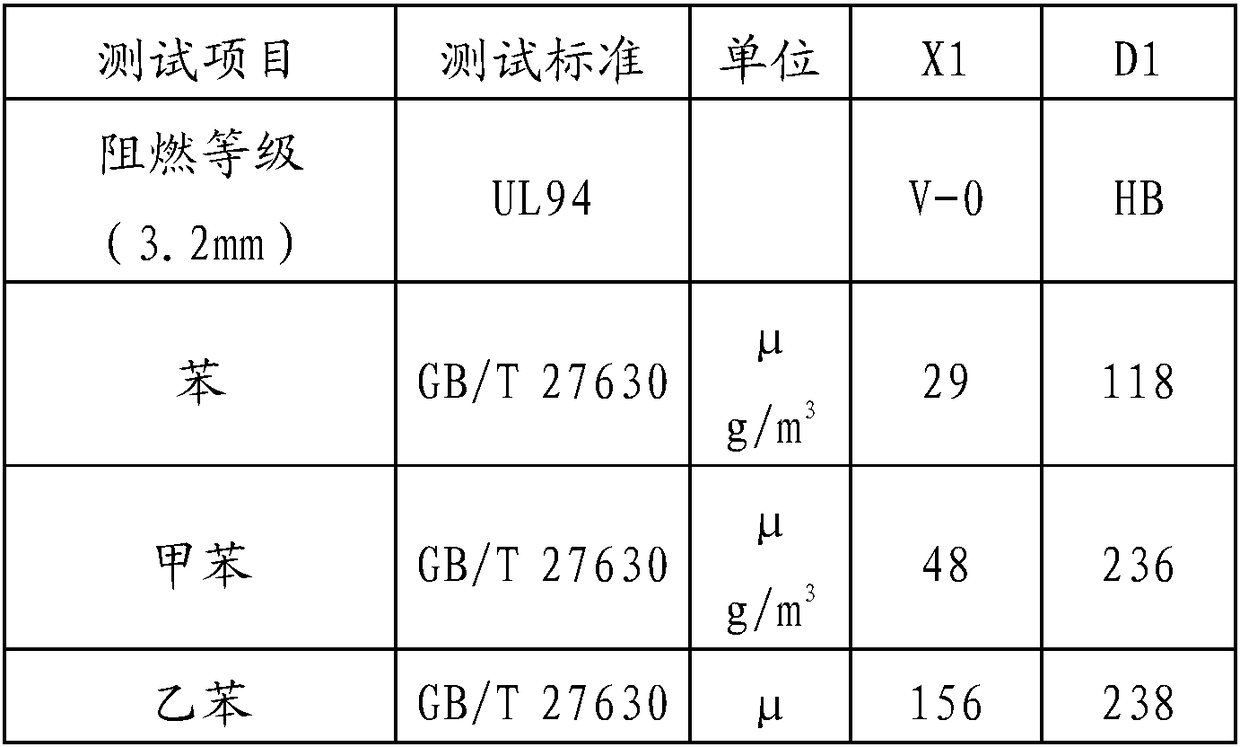

Intumescent flame-retardant heat-insulating fireproof coating and preparation method thereof

ActiveCN113122124ADelayed ignitionQuick releaseFireproof paintsAnti-corrosive paintsPtru catalystAdhesive

The invention relates to an intumescent flame-retardant heat-insulating fireproof coating and a preparation method thereof, the intumescent flame-retardant heat-insulating fireproof coating is formed by mixing a component A, a component B and an auxiliary agent, the component A comprises an adhesive, a catalyst, a coupling agent, a foaming agent, an inorganic flame retardant, an organic flame retardant, a high-temperature adhesive, a combustion improver, a water removal agent, a smoke absorbent, an anti-aging agent and an ultraviolet absorbent; the component B comprises a curing agent, a plasticizer and a chain extender; and the auxiliary agent is a diluent. The intumescent flame-retardant heat-insulating fireproof coating has the advantages that the intumescent flame-retardant heat-insulating fireproof coating is suitable for protection of various indoor and outdoor materials, particularly suitable for occasions with high fireproof performance requirements, such as electric power, information and petrochemical industries, can delay object ignition or reduce the combustion speed of a protected base material, can quickly release heat after the surface temperature of the intumescent flame-retardant heat-insulating fireproof coating exceeds 290 DEG C, a carbon flocculent isolation layer is formed through expansion, and conduction of the heat effect is isolated.

Owner:宋成镇

Highly-efficient bamboo charcoal organic fertilizer and preparation method thereof

InactiveCN105272582AImprove adsorption capacityQuality improvementFertilizer mixturesAzotobacter chroococcumHouttuynia

The invention discloses a highly-efficient bamboo charcoal organic fertilizer. The fertilizer comprises components with the following parts by weight: 3 to 5 parts of humic acid, 10 to 20 parts of alfalfa hay, 0.3 to 0.7 part of castor oil, 10 to 20 parts of herba andrographitis, 10 to 16 parts of cordate houttuynia, 12 to 14 parts of tobacco stems, 20 to 30 parts of bamboo charcoal, 0.03 to 0.08 part of a microbial bacterium liquid, and 0.02 to 0.06 part of an auximone, wherein the microbial bacterium liquid comprises components with the following parts by weight: 0.01 to 0.03 part of a rhizobium liquid, 0.01 to 0.02 part of an azotobacter chroococcum liquid, and 0.01 to 0.03 part of a bacillus megatherium liquid; the concentrations of the three bacterium liquids are all 3.4*10<7> / ml; the auximone comprises components with the following parts by weight: 0.01 to 0.03 part of vitamin B, and 0.01 to 0.03 part of brassinolide; the components go through pretreatment, mixing, fermentation, extrusion molding and low-temperature drying to obtain the finished product. The fertilizer provided by the invention has the advantages that bamboo charcoal, microbial bacteria and other components are effectively combined, so that organic substances and nitrogen sources in the air can be effectively absorbed and transformed into necessary auximones for plants through microbial fermentation, which can effectively promote plant growth, increase the yield, facilitate loosening of plate lands, and improve the air quality; the fertilizer is environment-friendly and highly-efficient.

Owner:宋永平

Preparation method of low-VOC flame-retardant composite filling material

InactiveCN109320775AImprove flame retardant performanceImprove VOC performanceCalcium silicatePolyolefin

The invention relates to a preparation method of a low-VOC flame-retardant composite filling material. Boehmite is crushed in a crushing machine and is sieved by a 500-mesh sieve; then, the boehmite,bentonite and hydroxyapatite are sufficiently mixed and are stirred for 40 to 60 min in a high-speed stirring machine to obtain a mixture; next, tetrabromobisphenol S ether and nanometer calcium silicate are added into the mixture, and are subjected to sufficient stirring and mixing for 20 to 40 min; cooling is performed to reach the room temperature; the low-VOC flame-retardant composite fillingmaterial is obtained. By using the technical scheme, the low-VOC flame-retardant composite filling material is synthesized; the functions of improving the polyolefin flame-retardant performance and VOC performance can be improved at the same time; important popularization values are realized.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

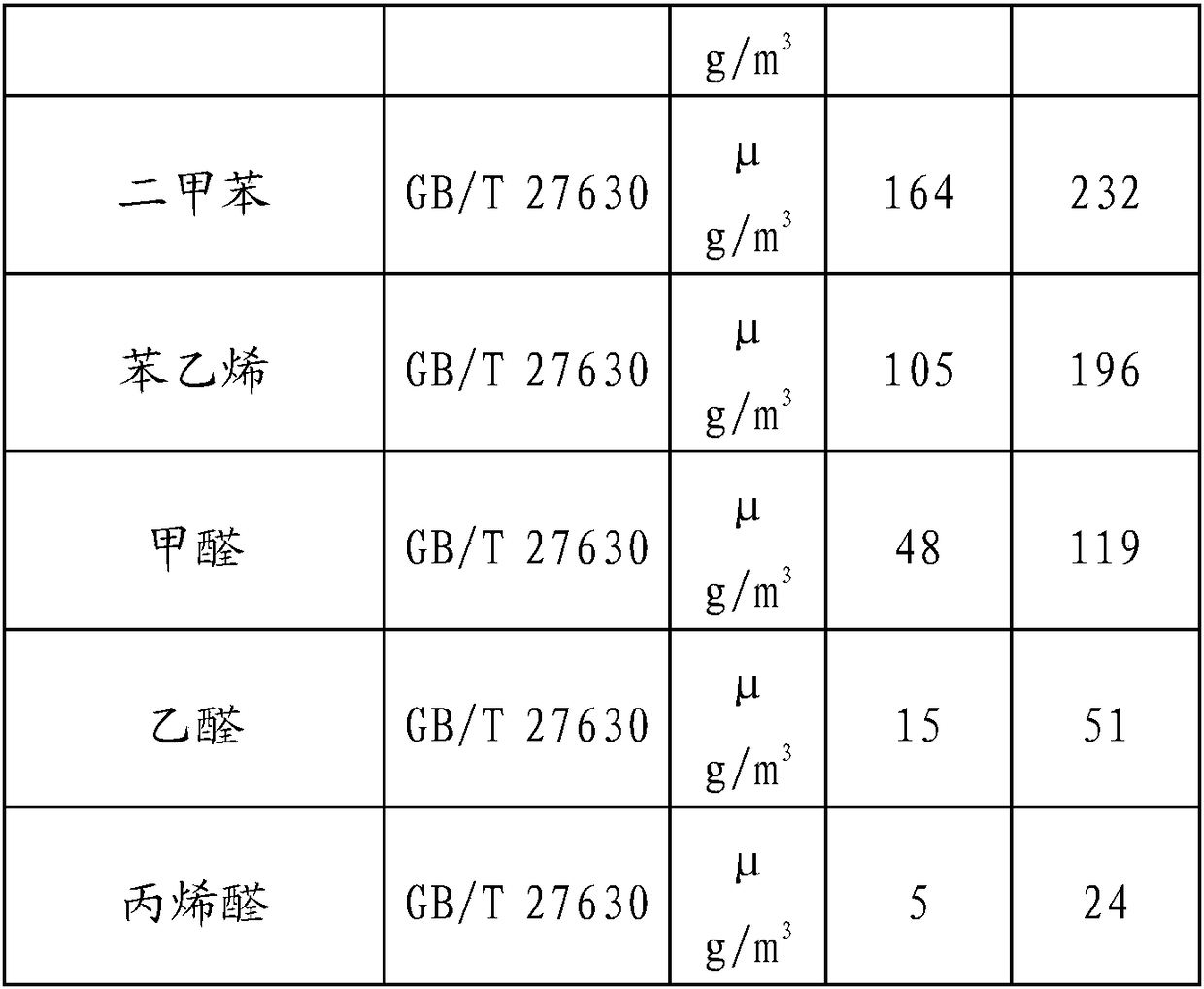

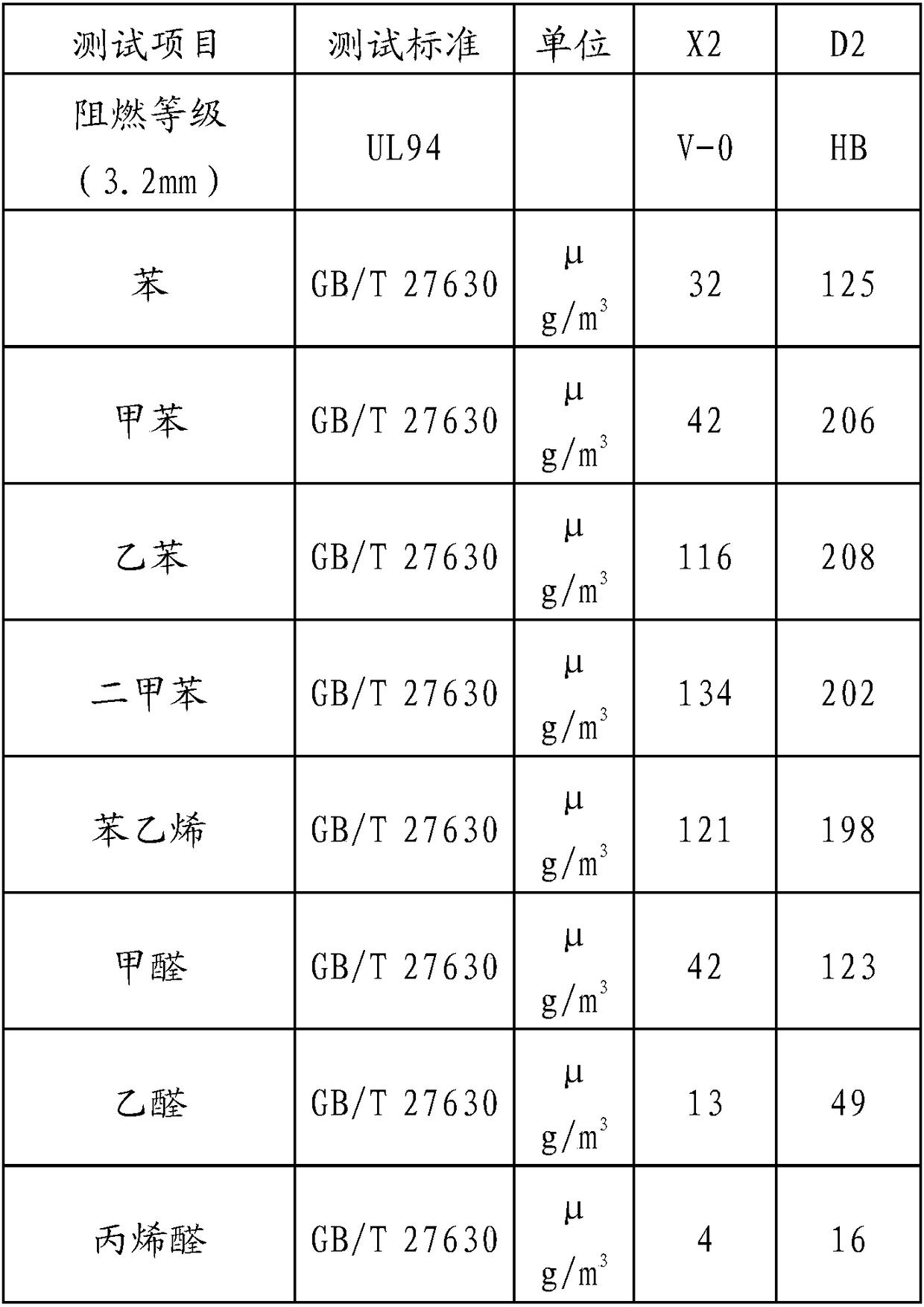

Preparation method of flame-retarding type polyurethane synthetic leather

PendingCN108219643AHigh strengthReduce surface temperatureFireproof paintsPolyurea/polyurethane coatingsTectorial membraneAluminum Ion

The invention relates to the technical field of preparation of polyurethane synthetic leather and in particular relates to a preparation method of flame-retarding type polyurethane synthetic leather.The polyurethane synthetic leather with high strength and strong flame-retarding performance is prepared by taking a woven fabric as a substrate, and polyurethane resin, modified self-made magnesium-aluminum hydrotalcite powder and self-made silica sol as a reinforcing agent, and adding with red phosphorus, calcium carbonate and the like; firstly, the self-made magnesium-aluminum hydrotalcite is prepared through a salt-alkali co-precipitation method; the self-made magnesium-aluminum hydrotalcite is subjected to surface modification by utilizing sodium tripolyphosphate; P3O10<5-> and magnesiumions and aluminum ions in the self-made magnesium-aluminum hydrotalcite are subjected to coordinating bonding reaction, so that one layer of protection film is formed; the self-made magnesium-aluminumhydrotalcite is adopted so that the surface temperature of the substrate is reduced and a flame-retarding effect is realized; the red phosphorus can react with an ester group in polyurethane at hightemperature, so that thermal cracking and volatilization of a polymer is reduced and oxygen and heat are isolated; furthermore, the strength and the flame-retarding performance of the polyurethane synthetic leather is improved, and the polyurethane synthetic leather has a wide application prospect.

Owner:梅庆波

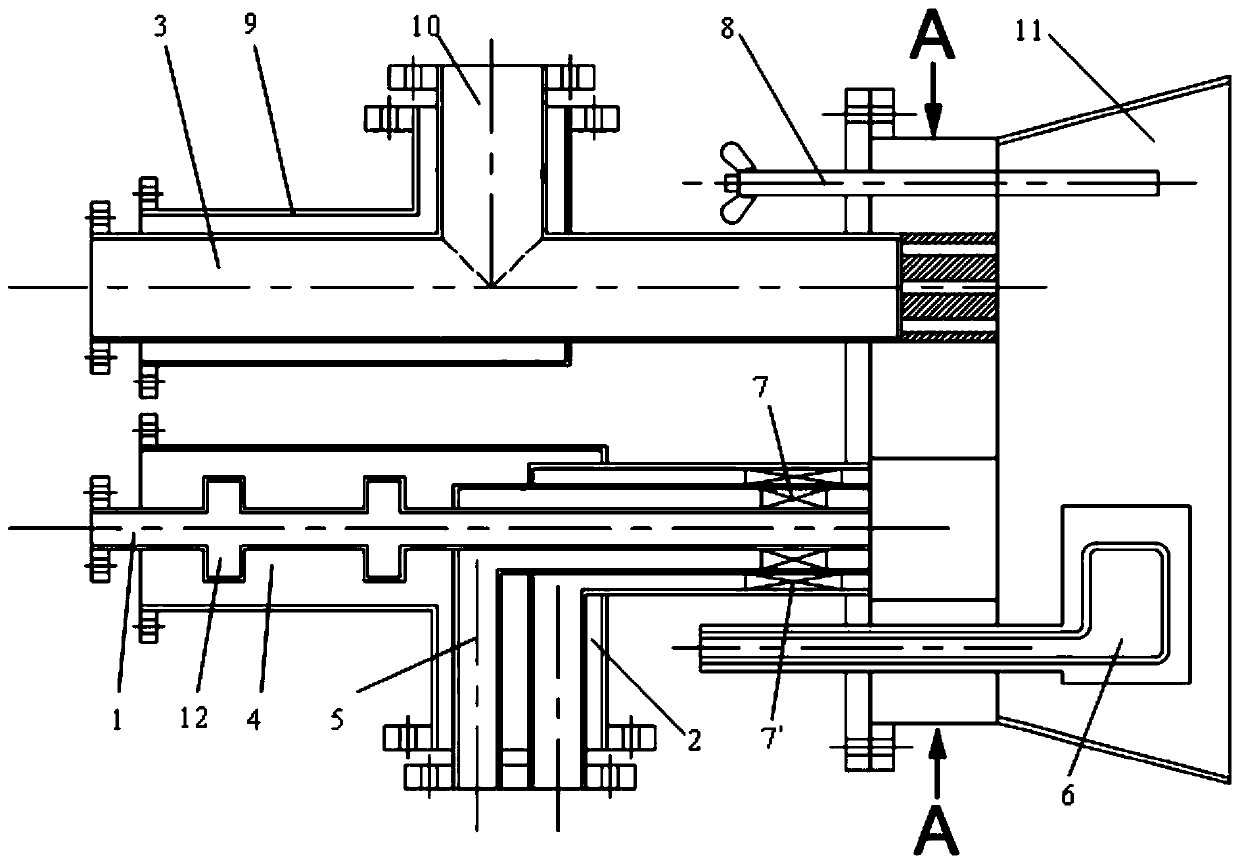

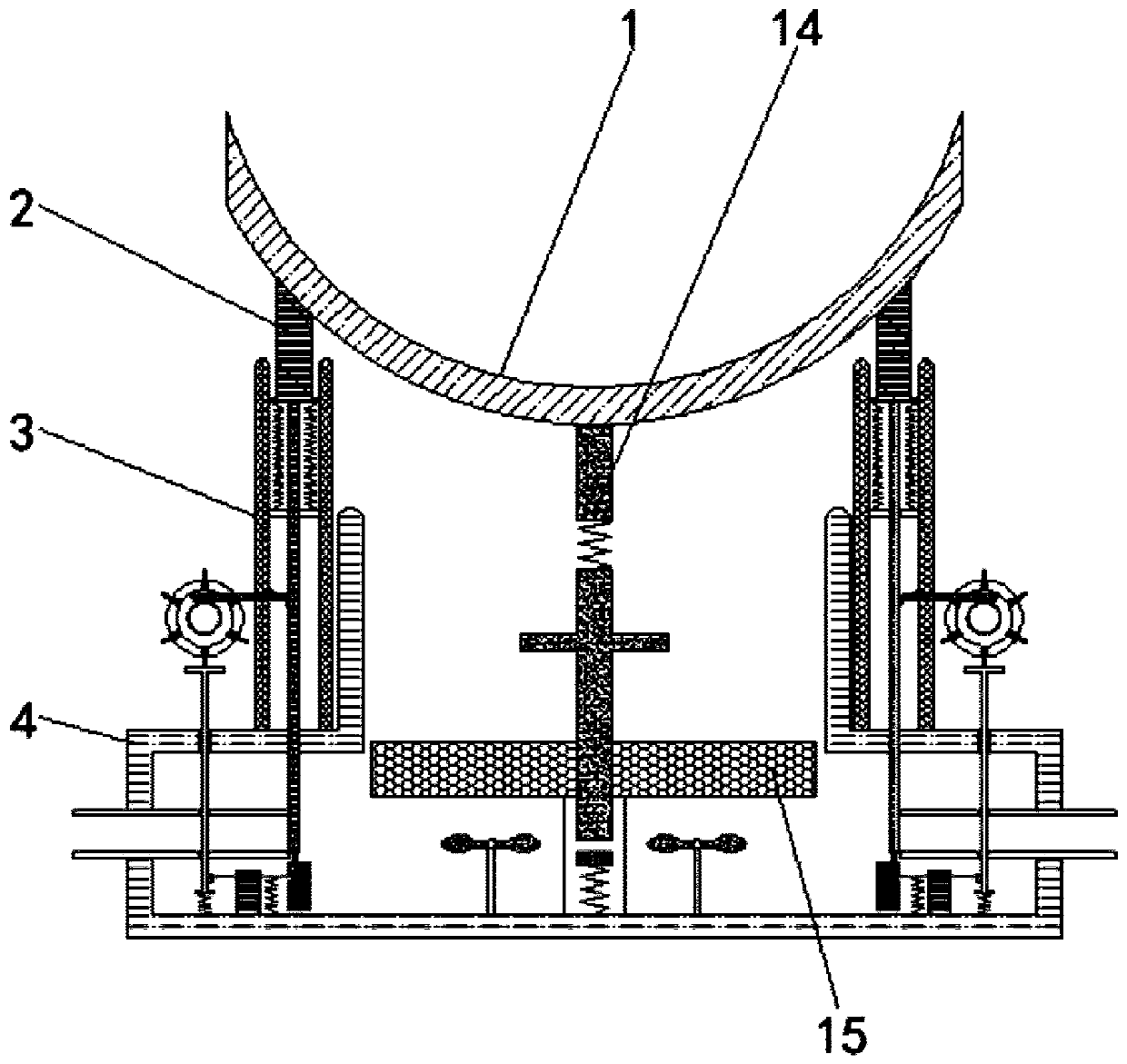

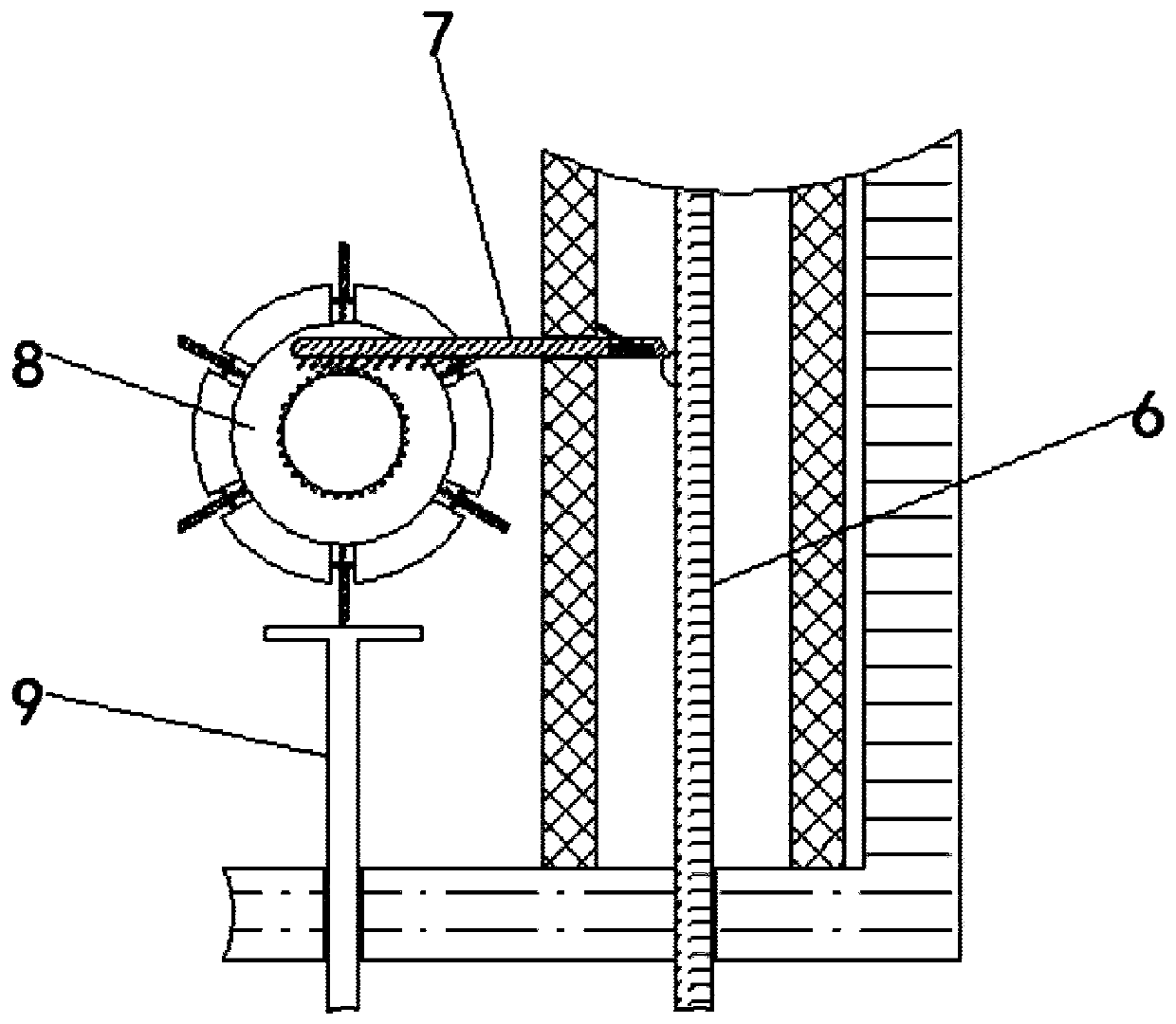

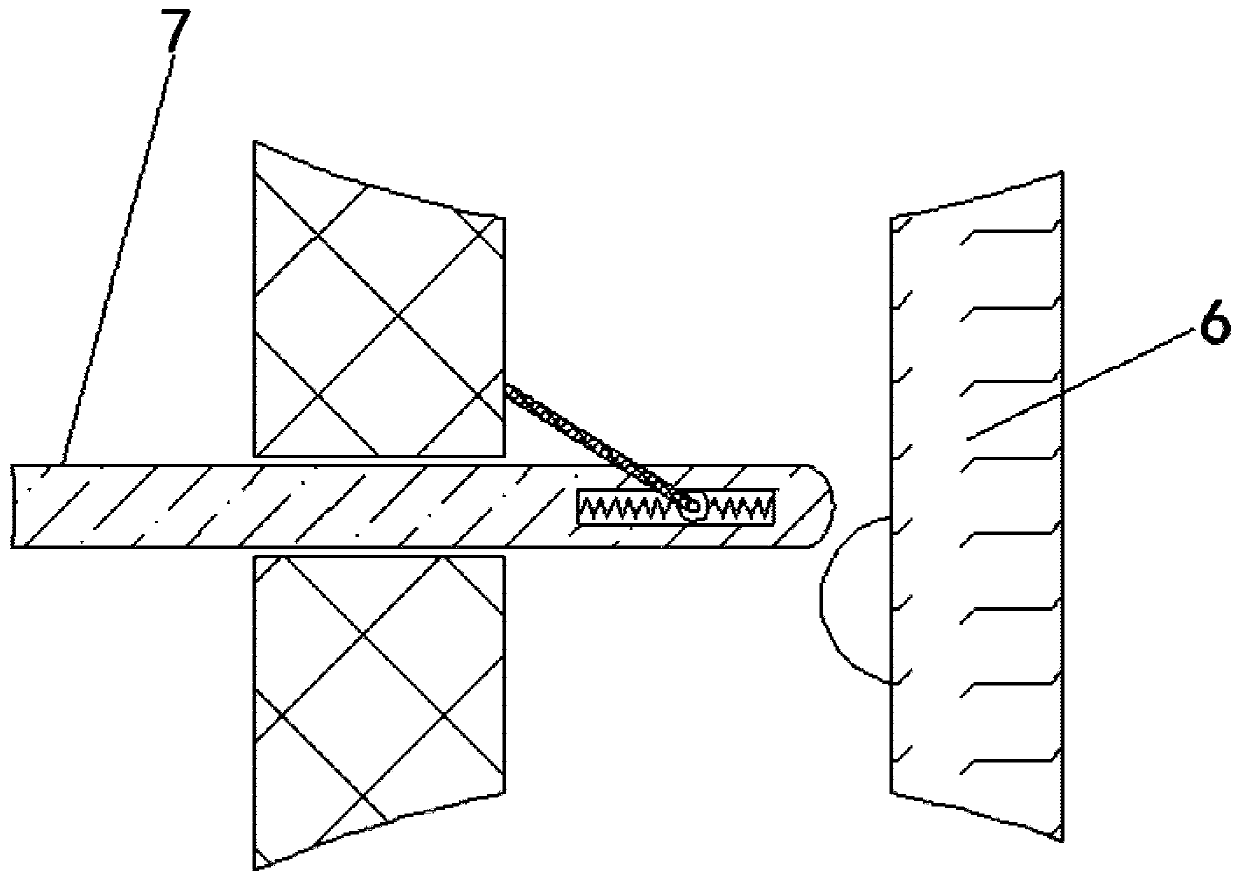

Hydrogen-vapor oxygen-rich flameless burner

ActiveCN110410787AReduce burn rateImprove securityIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHydrogenCombustion chamber

The invention belongs to the field of flameless burners, and particularly discloses a hydrogen-vapor oxygen-rich flameless burner. A hydrogen spraying pipe is connected with a burning chamber. A firstvapor spraying pipe sleeves the outer side of the hydrogen spraying pipe and is connected with the burning chamber and used for spraying vapor to the burning chamber at the preheating stage. A primary air spraying pipe sleeves the outer side of the first vapor spraying pipe and is connected with the burning chamber and used for spraying primary air to the burning chamber at the preheating stage.A secondary air spraying pipe is connected with the burning chamber and used for spraying secondary air to the burning chamber at the flameless burning stage. The burning chamber is used for providingspace for oxygen-rich burning of the hydrogen. According to the hydrogen-vapor oxygen-rich flameless burner, the primary air and the hydrogen are separated through the vapor, the burning rate of thehydrogen can be effectively reduced, and therefore the safety of the burner is improved; after the preset temperature is reached, the secondary air spraying pipe is switched to provide the oxygen to achieve flameless burning of the hydrogen, and it can be guaranteed that the temperature in the burner is evenly distributed; and therefore potential safety hazards generated by hydrogen burning are avoided.

Owner:武汉鼎博丰智能科技有限公司

Flame retardant material and preparation method thereof and automobile engine trim cover

The invention discloses a flame retardant material and a preparation method thereof and an automobile engine trim cover. The preparation method of the flame retardant material comprises the following steps of: stirring high-purity montmorillonoid in a high-speed stirrer at a high speed, adding 10-30 percent by weight of adjuvant when the temperature of the high-purity montmorillonoid reaches 85-95 DEG C, and continuously stirring to obtain organic montmorillonoid; adding 20-30 percent by weight of polypropylene to the organic montmorillonoid, stirring for 5-10min in a low-speed stirrer at a low speed, and carrying out extrusion and granulation in a high-shear double-screw extruder to obtain nanometer organic master batch of the high-content montmorillonoid; and mixing the nanometer organic master batch and the polypropylene according to a proportion of 5-8 percent by weight, and carrying out extrusion and granulation in a low shear double-screw extruder to obtain the flame retardant material. Tests show that the flame retardant material has improved mechanical property which is 50 percent higher than that of the traditional polypropylene composite material. The flame retardant material disclosed by the invention has the advantages of improving the flame retardant performance and increasing the anti-aging performance and is particularly suitable for production of the automobile engine trim cover.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

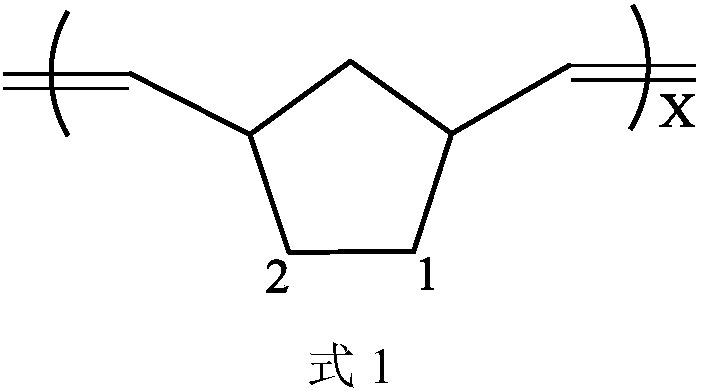

Functional polymer, polymer electrolyte membrane, flame-retardant polymer electrolyte composite membrane and preparation method thereof, and lithium ion battery

ActiveCN108341932AGood flame retardant functionFast deliveryElectrolytesSecondary cells servicing/maintenancePolymer electrolytesLithium-ion battery

The invention relates to a functional polymer, a polymer electrolyte membrane, a flame-retardant polymer electrolyte composite membrane and a preparation method thereof, and a lithium ion battery, andbelongs to the technical field of lithium ion batteries. The functional polymer comprises a polymer chain composed of structural units. A flame-retardant group and a lithium ion-conducting group areconnected to the site 1 or 2 of the structural unit of the polymer chain. A mole ratio of the flame-retardant group to the lithium ion-conducting group is 1: (2 to 4). The flame-retardant group provides a good flame-retardant function for the functional polymer. The lithium ion-conducting group can accelerate a transport velocity of Li<+> in the functional polymer. The flame-retardant polymer electrolyte composite membrane has the advantages of high electrical conductivity and strong flame retardant properties and has a potential application value in the field of lithium ion batteries.

Owner:DO FLUORIDE CHEM CO LTD

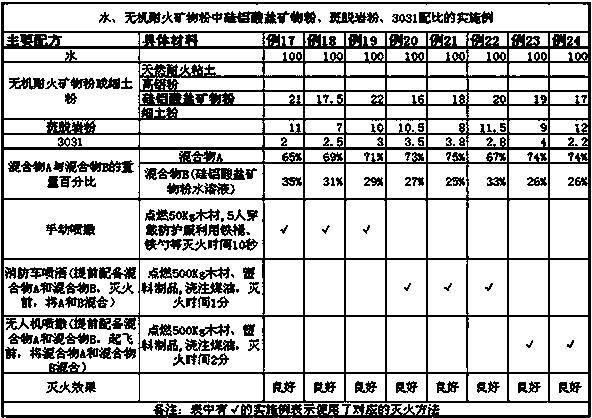

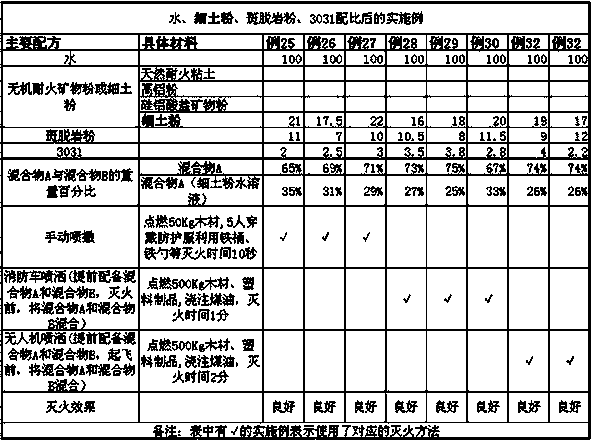

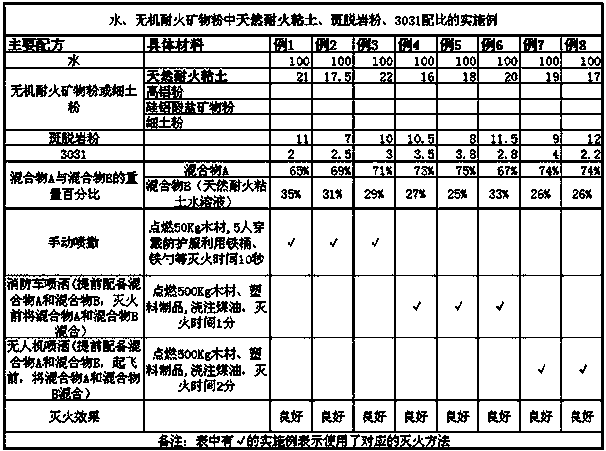

Multifunctional environment-friendly fire extinguishing liquid, and preparation and use method thereof

ActiveCN110368632AGood dispersionIncrease surface areaFire extinguisherFire protectionAqueous solution

The invention relates to a multifunctional environment-friendly fire extinguishing liquid and a preparation and use method thereof, and belongs to the field of fire protection. The fire extinguishingliquid is prepared from the following components: tap water, inorganic fire-resistant mineral powder or fine earth powder, bentonite powder and a 3031 fire retardant, the weight part ratio of the water, a mixture of the inorganic fire-resistant mineral powder or the fine earth powder, the bentonite powder and the 3031 fire retardant is 100: (10 to 20): (10 to 20): (2 to 4), wherein the weight partratio of a mixed water solution of the bentonite powder and the 3031 fire retardant to the weight percentage ratio of a water solution of the inorganic fire-resistant mineral powder or the fine earthpowder is (65 to 75%) : (25 to 35%). Through the cooling function, the inhibition function, the isolation function and the suffocation function of the fire extinguishing liquid, the fire extinguishing effect of the fire extinguishing liquid can be improved, the fire extinguishing speed is accelerated, fire losses are reduced, and property and life of people are saved.

Owner:刘运喜

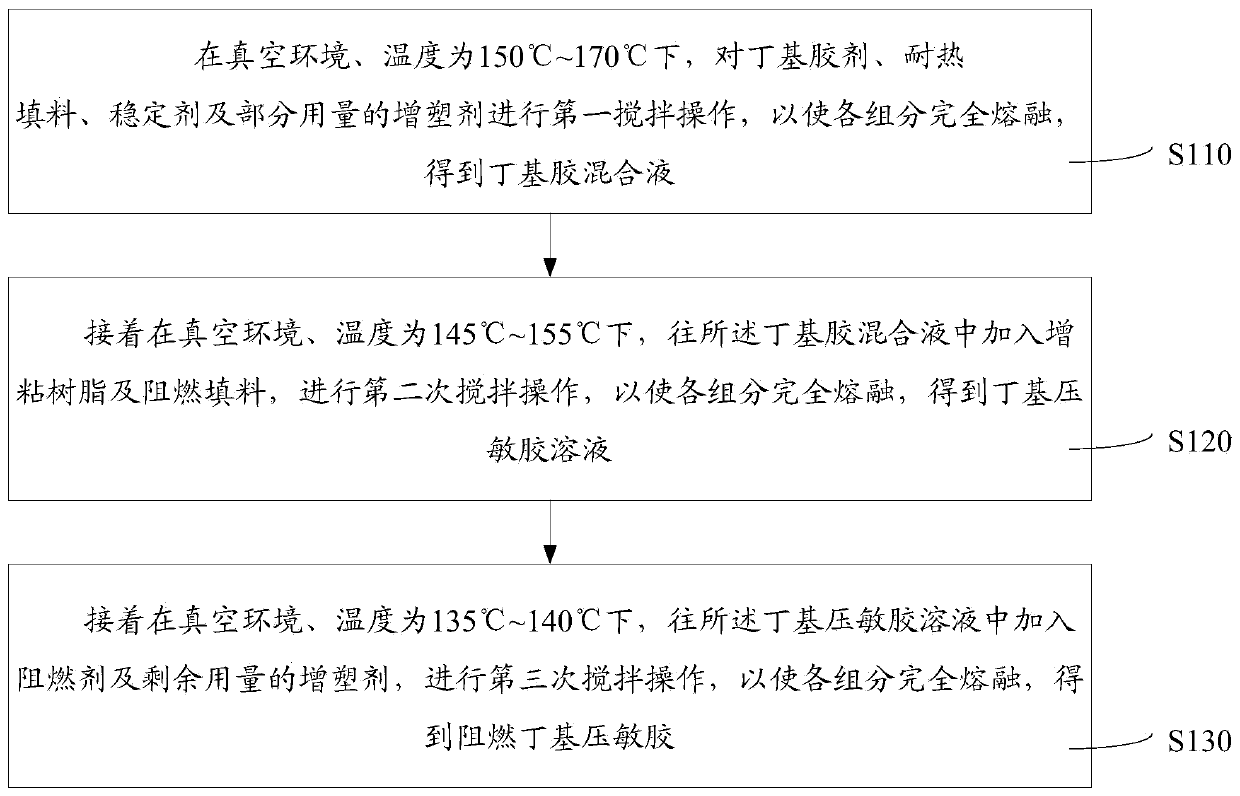

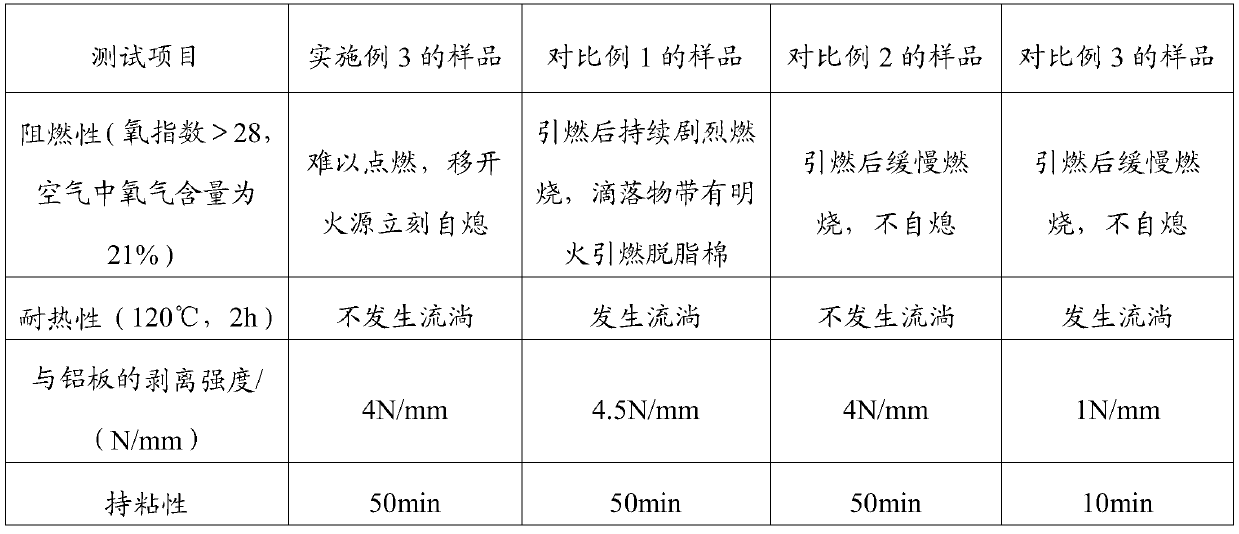

Flame retardant butyl pressure sensitive adhesive

ActiveCN110295020AIncrease stickinessReduce hardnessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMolecular networkWater vapor

The invention relates to the field of pressure-sensitive adhesives and discloses a flame-retardant butyl pressure-sensitive adhesive, which comprises the following components in parts by mass: 20-35 parts of a plasticizer, 20-25 parts of butyl rubber, 3-10 parts of a heat-resistant filler, 6-20 parts of a flame-retardant filler, 5-15 parts of a flame retardant, 1-5 parts of a stabilizer and 20-30parts of tackifying resin. The heat-resistant filler is uniformly embedded in the molecular network of the butyl rubber, thereby improving the cohesive energy of the butyl rubber and reducing the deformation and sliding of the molecular network of the butyl rubber under the action of high temperature, and further improving the heat resistance of the flame-retardant butyl pressure-sensitive adhesive. The flame-retardant filler and the flame retardant are synergistically flame-retardant, wherein the flame-retardant filler may decompose to generate water vapor during combustion to reduce the surface temperature of a combustion substance and isolate part of oxygen, thus playing a flame-retardant role; the flame retardant can capture free radical OH<-> in the flame when burning to restrain theflame, and is also attached to the surface of the flame retardant butyl pressure-sensitive adhesive to isolate the air.

Owner:HUIZHOU NENGHUI CHEM CO LTD

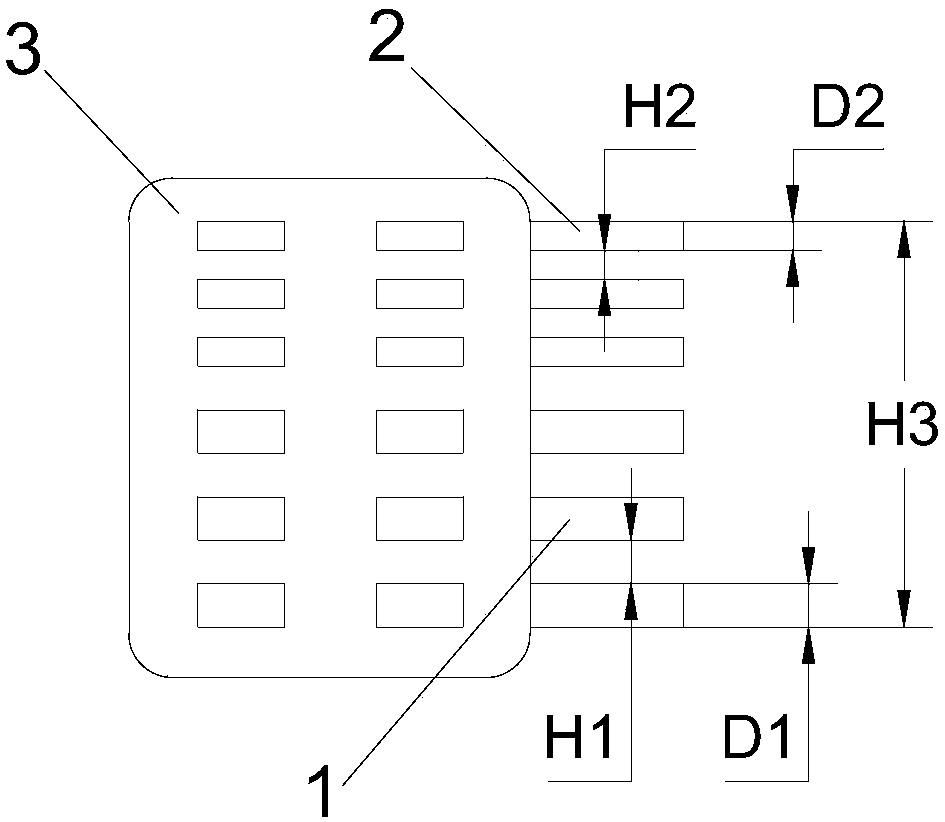

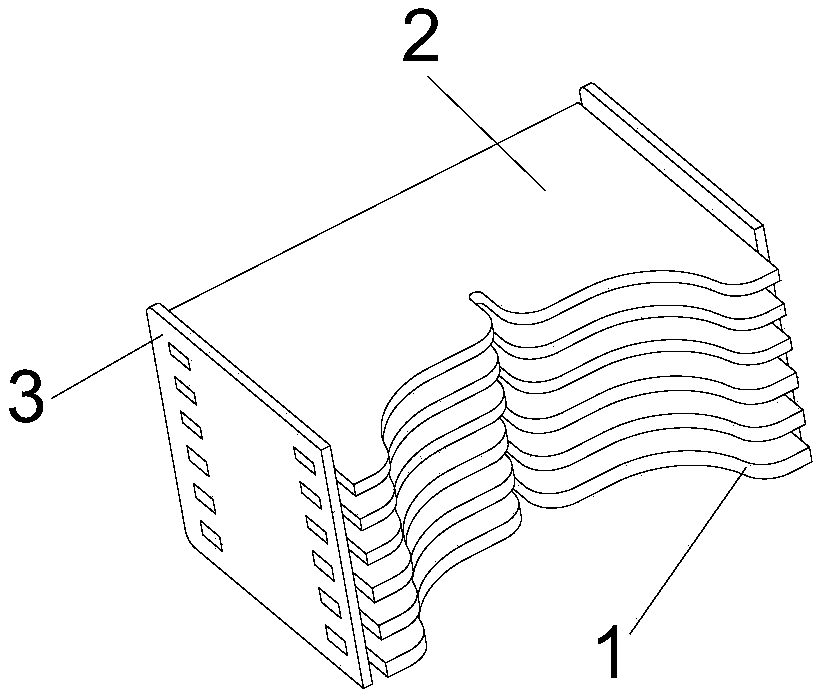

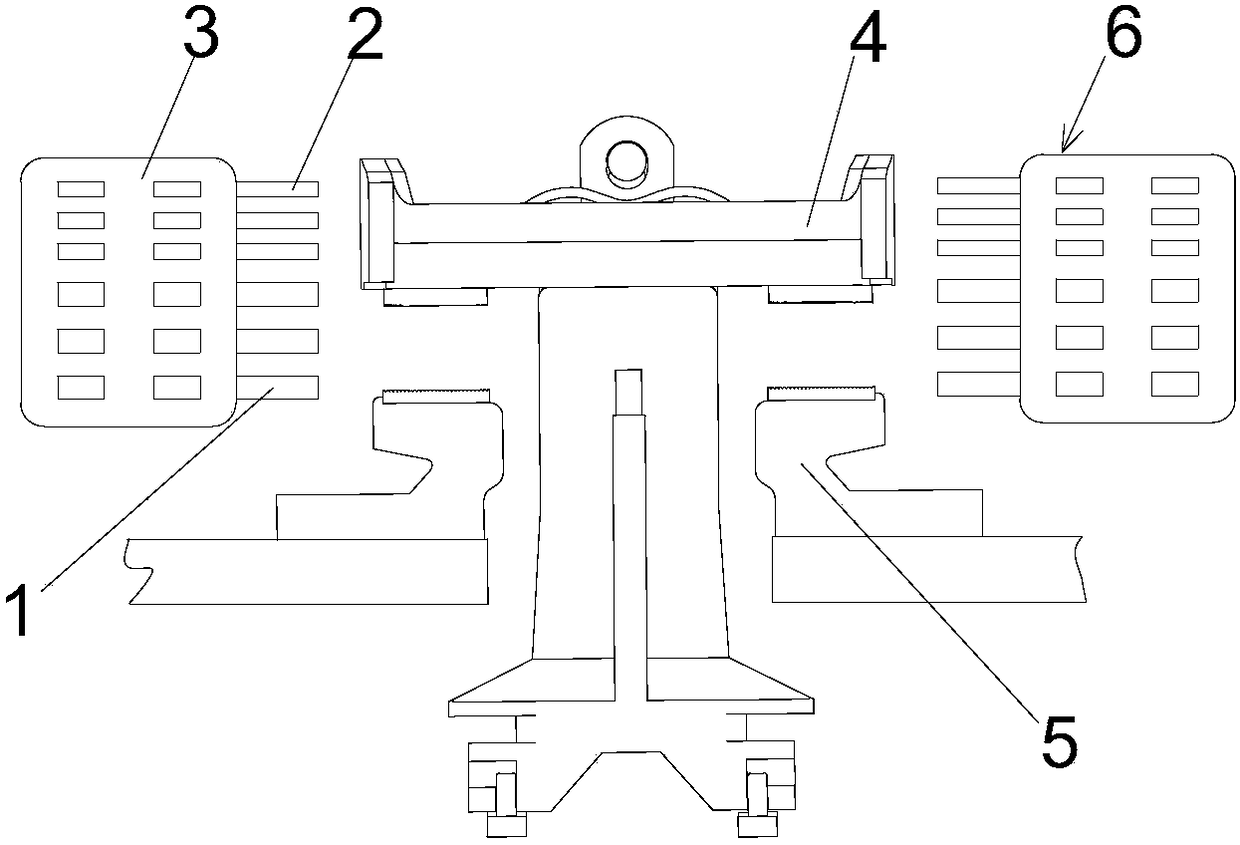

Arc extinguishing system and arc extinguishing chamber

PendingCN108320950AReduce burn rateImprove arc burn resistanceElectric switchesArc erosionMechanical engineering

The invention provides an arc extinguishing chamber, which comprises two side plates and an arc extinguishing grid plate group fixedly arranged between the two side plates. The arc extinguishing gridplate group comprises a plurality of first arc extinguishing grid plates and a plurality of second arc extinguishing grid plates. The plurality of first arc extinguishing grid plates are arranged under the plurality of second arc extinguishing grid plates; the thickness of each first arc extinguishing grid plate is larger than that of each second arc extinguishing grid plate; and the space betweentwo adjacent first arc extinguishing grid plates is larger than the space between two adjacent second arc extinguishing grid plates. The invention also provides an arc extinguishing system, which comprises the arc extinguishing chamber and a static contact and a moving contact opposite to the arc extinguishing chamber. The moving contact can be contacted with or separated from the static contact.By carrying out differentiated setting on the thickness of each arc extinguishing grid plate of the arc extinguishing grid plate group and the space between two adjacent arc extinguishing grid plates, arc erosion resistance is improved, and electrical life is improved.

Owner:SOOAR TIANJIN ELECTRICAL EQUIP CO LTD

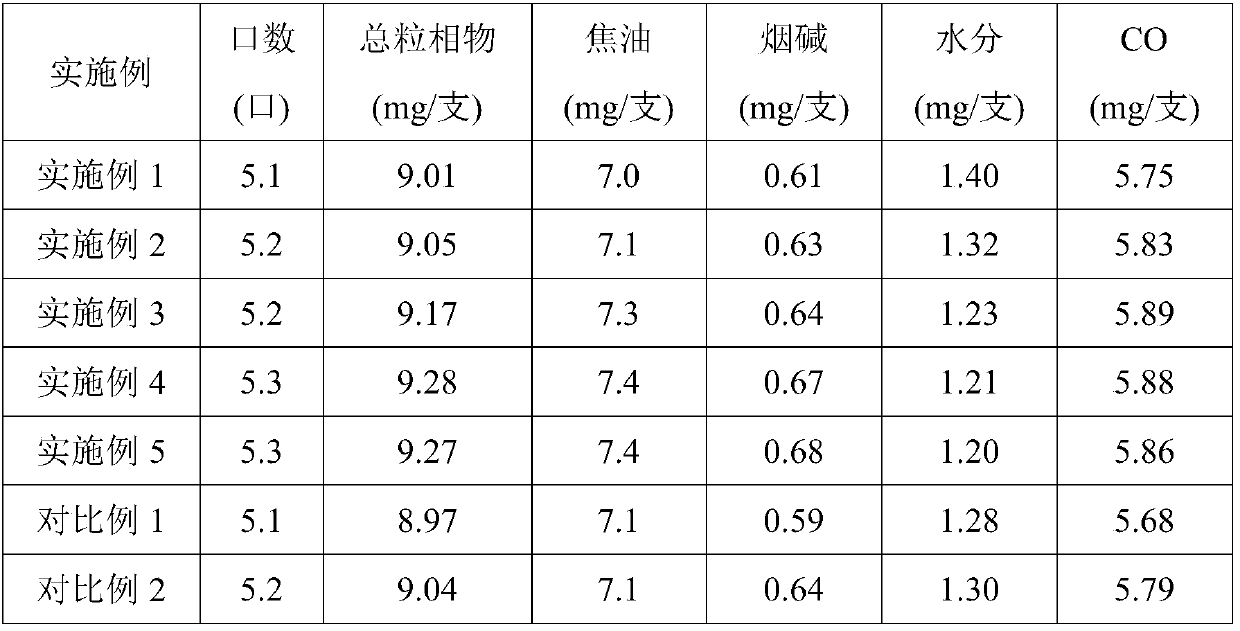

Flame retardant for thin cigarettes, preparation method and applications thereof

InactiveCN110924221AReduce burn rateImprove sensory qualityNatural cellulose pulp/paperPaper coatingFire retardant

The invention discloses a flame retardant for thin cigarettes, wherein the flame retardant comprises aluminum dihydrogen phosphate and PEG. The invention further discloses applications of the flame retardant, wherein the flame retardant is applied to preparation of fin cigarette paper. The invention further discloses applications of the thin cigarette paper, wherein the thin cigarette paper is applied to preparation of thin cigarette paper capable of regulating the combustion rate of a thin cigarette. The invention further discloses a preparation method of the thin cigarette paper capable of regulating the combustion rate of the thin cigarette. By using the thin cigarette paper capable of regulating the combustion rate of the thin cigarette, the combustion rate of a thin cigarette can be effectively regulated, the phenomenon of cigarette end falling caused by overlong combustion cone is reduced, irritation can be remarkably reduced, the ash wrapping effect after cigarette combustion isimproved, and the combustion quality and the consumption experience of thin cigarettes are effectively improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

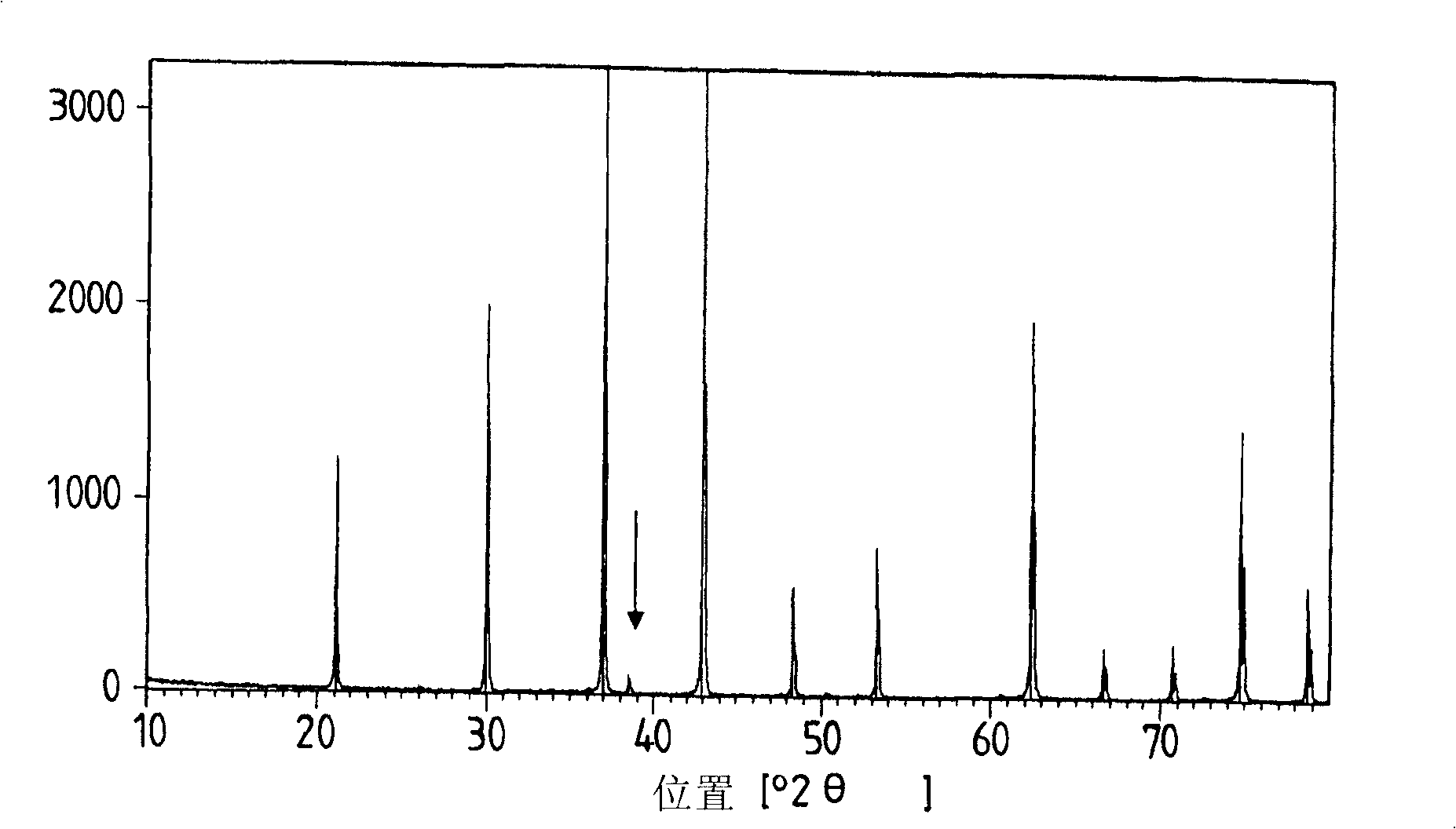

Organic compound

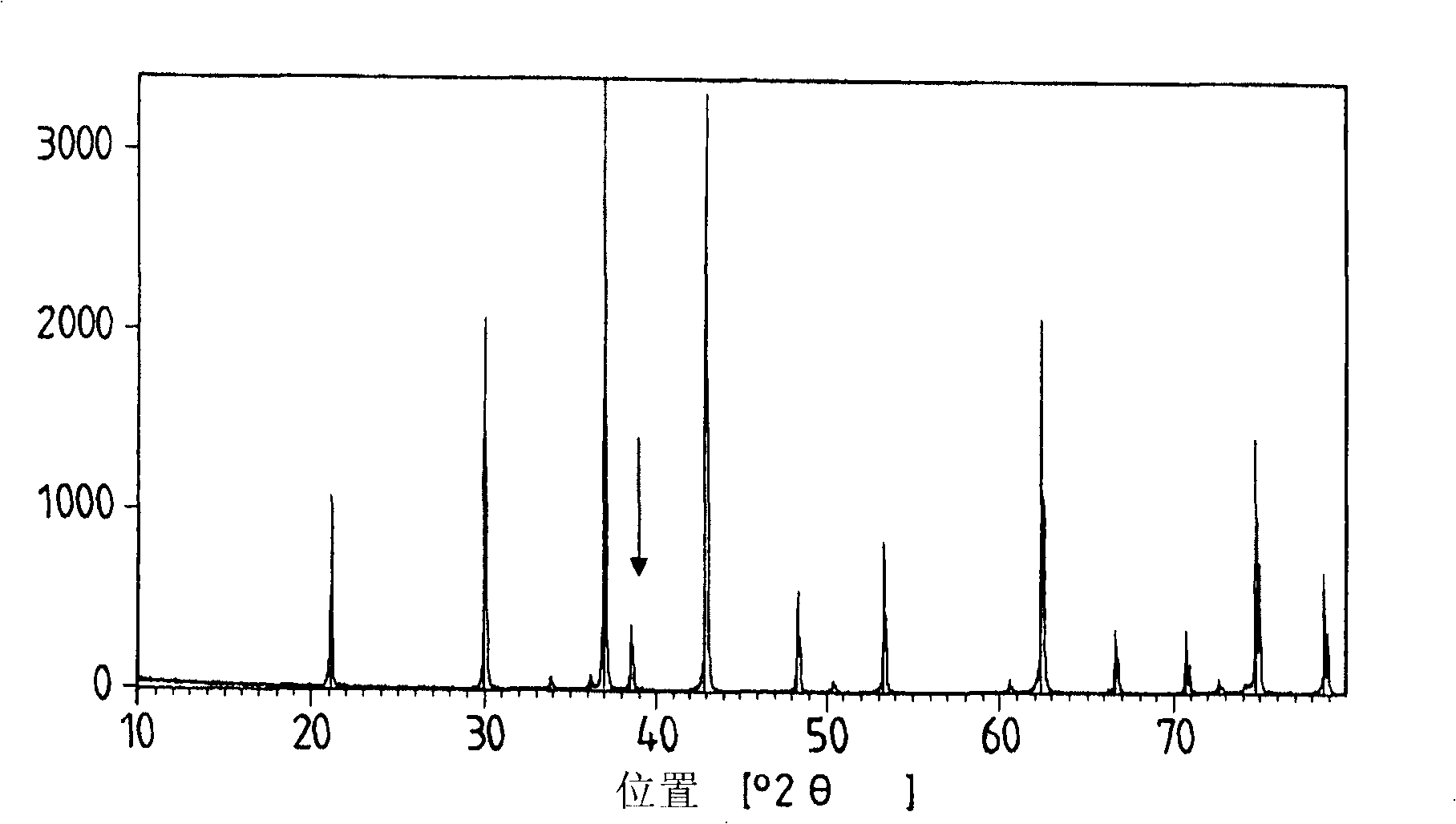

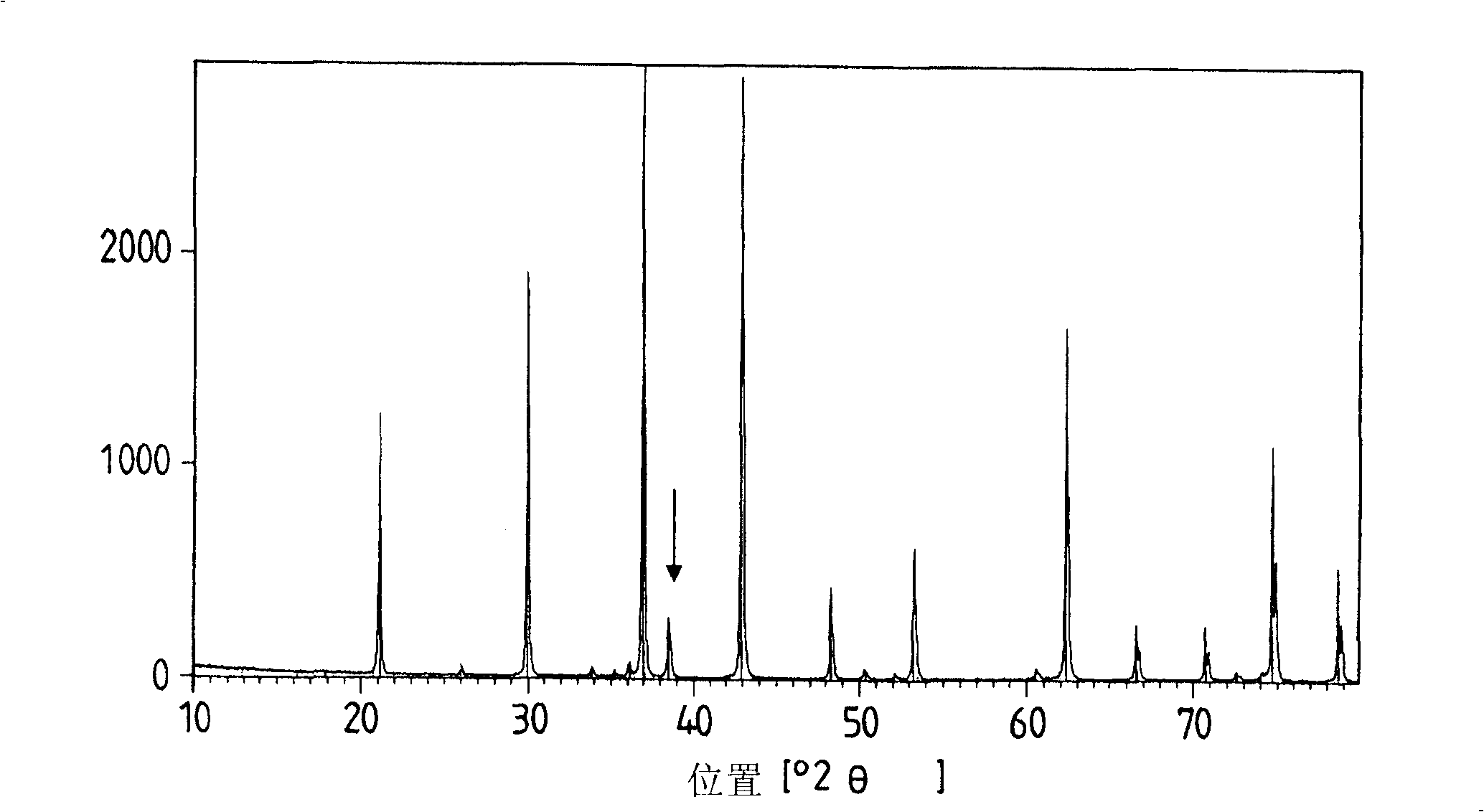

Disclosed is a niobium suboxide powder for the manufacture of capacitors with higher break down voltages, higher temperatures of operation and elongated lifetimes. The powder is doped with nitrogen which is at least partly present in the form homogeneously distributed, x-ray detectable Nb2N-crystal domains.

Owner:H C STARCK GMBH

Energy-saving cooking range capable of saving energy at frying interval

InactiveCN111594877AChange the output temperatureReduce burn rateDomestic stoves or rangesLighting and heating apparatusMechanical engineeringPressure sensing

The invention discloses an energy-saving cooking range capable of saving energy at a frying interval. The energy-saving cooking range comprises a pot body; carrying rods are fixedly connected with thebottom of the pot body; carrying pipes are in sliding fit with the side faces of the carrying rods; a stove body is fixedly connected with the bottoms of the carrying pipes; a blast pipe is arrangedon the side face of the stove body in a penetrating and inserting manner; an extruding rod is arranged on the side face of the blast pipe in a penetrating and inserting manner; a transitional spring is fixedly connected with the bottom of a transitional rod; a wind shield is fixedly connected with the bottom of the transitional spring; a clamping rod is in sliding fit with the side, close to the blast pipe, of the wind shield; a fixed block is in sliding fit with the side face of the clamping rod; an air receiving rod is fixedly connected between the carrying rods and with the bottom of the pot body; and a pressure sensing switch is arranged at the bottom of the air receiving rod. Through cooperative application of the carrying rods and the transitional rod, the energy-saving cooking rangecan realize the effect of adjusting the coal combustion rate at a frying interval to further change the stove body output temperature.

Owner:赵国良

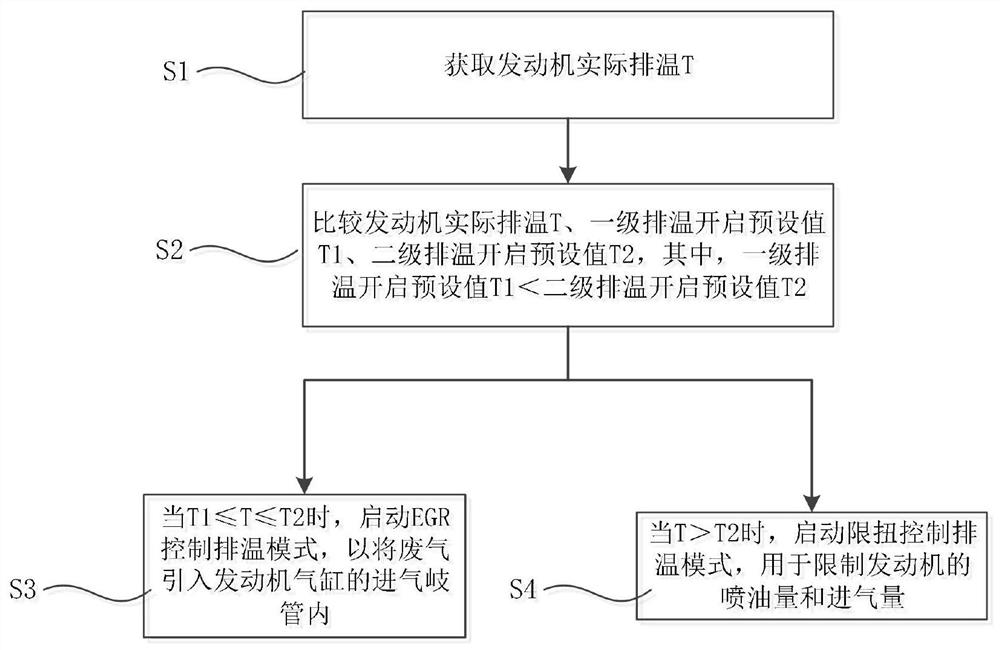

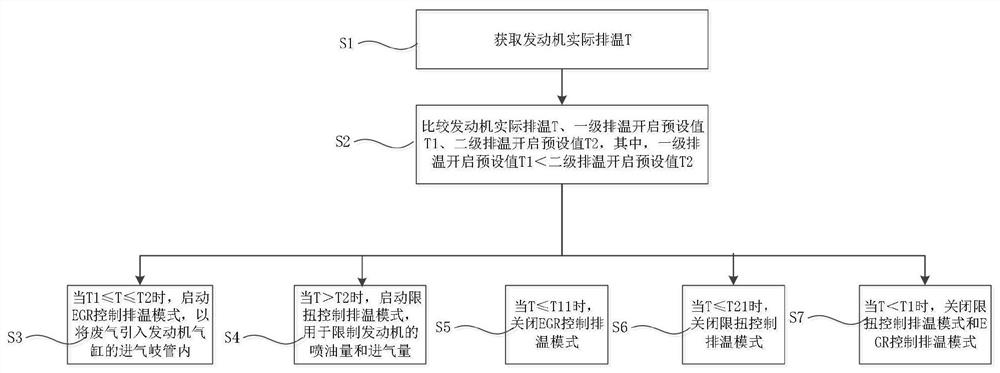

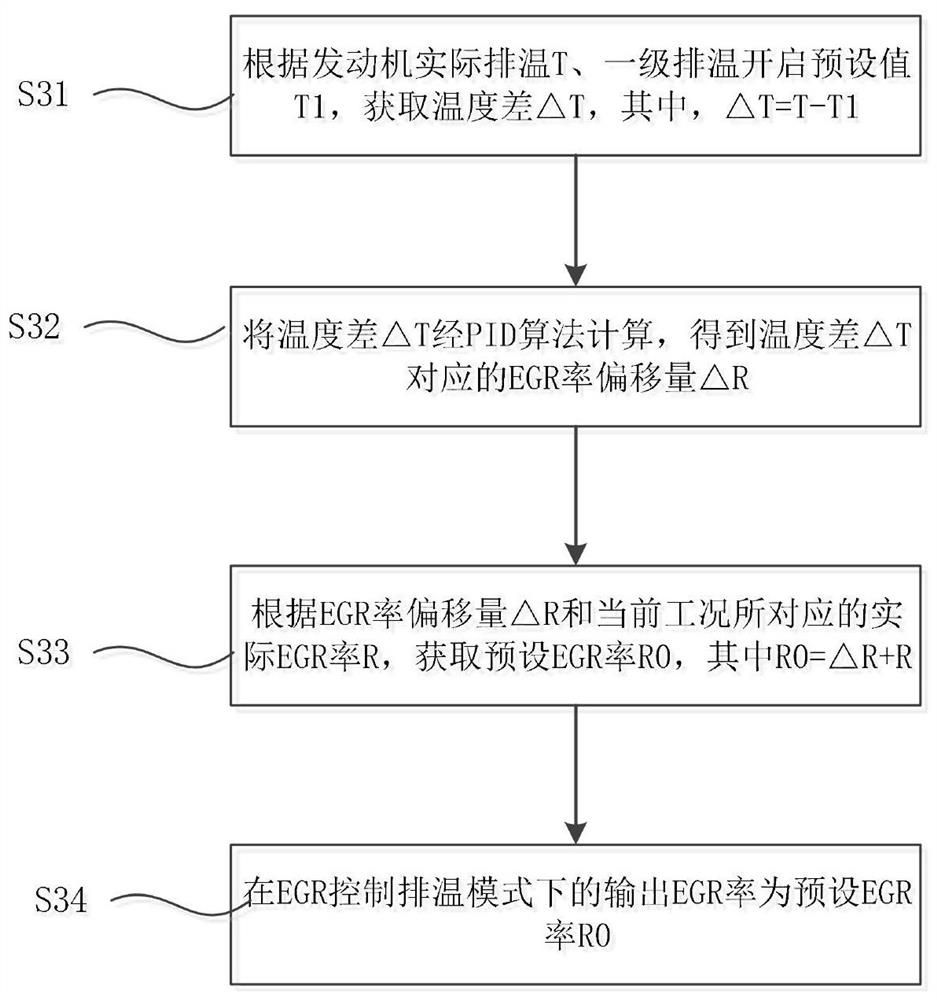

Engine exhaust temperature control method and engine

PendingCN113339148AGuaranteed reliabilityEnsure consistencyElectrical controlInternal combustion piston enginesExhaust fumesTemperature control mode

The invention belongs to the technical field of vehicles, and discloses an engine exhaust temperature control method and an engine. The engine exhaust temperature control method comprises the following steps that the actual exhaust temperature T of the engine is obtained; the actual exhaust temperature T of the engine, the first-stage exhaust temperature starting preset value T1 and the second-stage exhaust temperature starting preset value T2 are compared, and the first-stage exhaust temperature starting preset value T1 is smaller than the second-stage exhaust temperature starting preset value T2; when T is larger than or equal to T1 and smaller than or equal to T2, the EGR control exhaust temperature mode is started, so that exhaust gas is connected into an intake manifold of an engine cylinder; and when T is larger than T2, the torque-limiting exhaust temperature control mode is started, and the fuel injection quantity and the air inflow of the engine are limited. According to the engine exhaust temperature control method, different exhaust temperature control modes are selected according to the actual exhaust temperature T of the engine to achieve hierarchical control over the exhaust temperature of the engine, compared with the prior art that the exhaust temperature is directly controlled through torque limiting, the control flexibility is improved, the output power of the engine is increased to a certain degree, and the user experience is improved.

Owner:WEICHAI POWER CO LTD +1

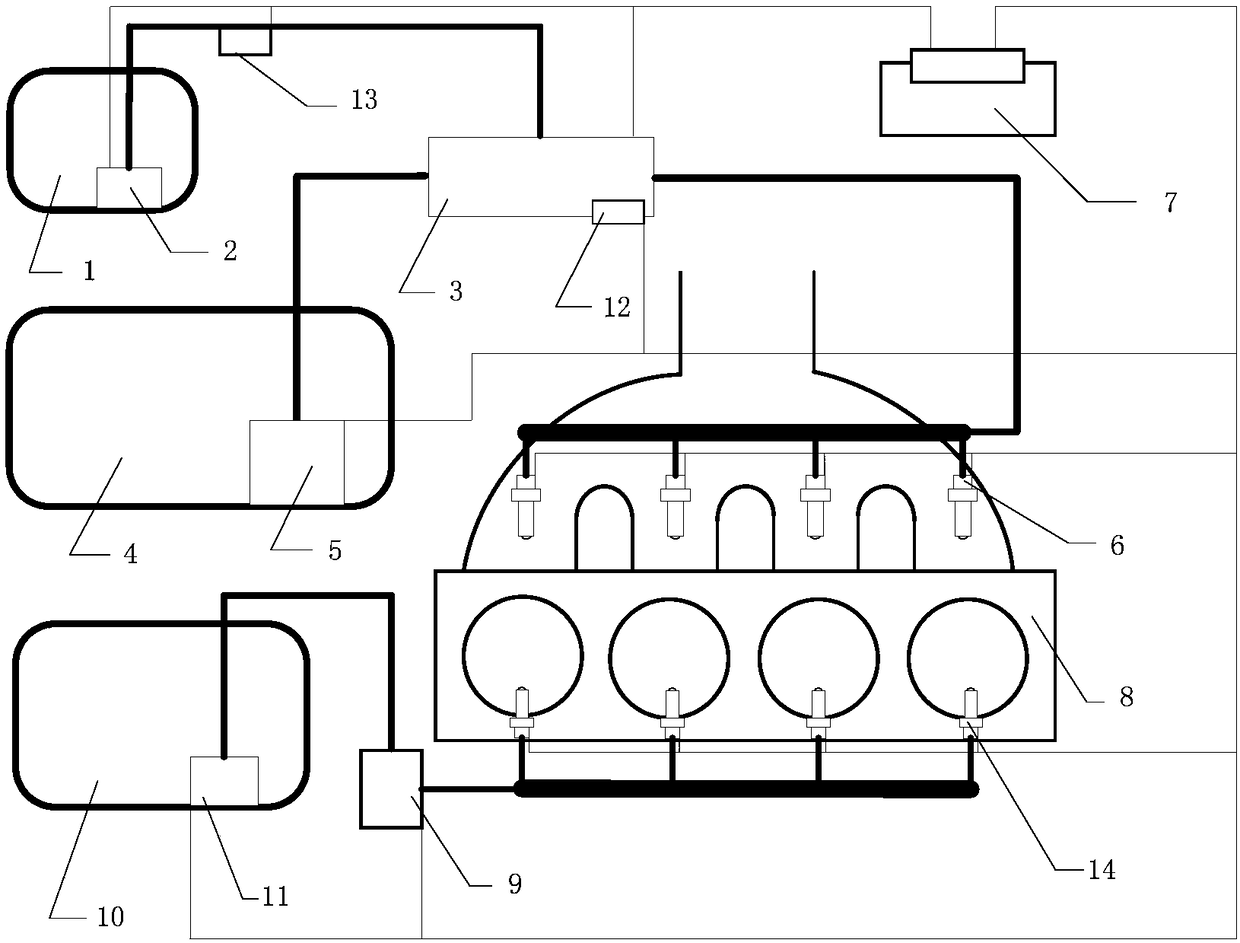

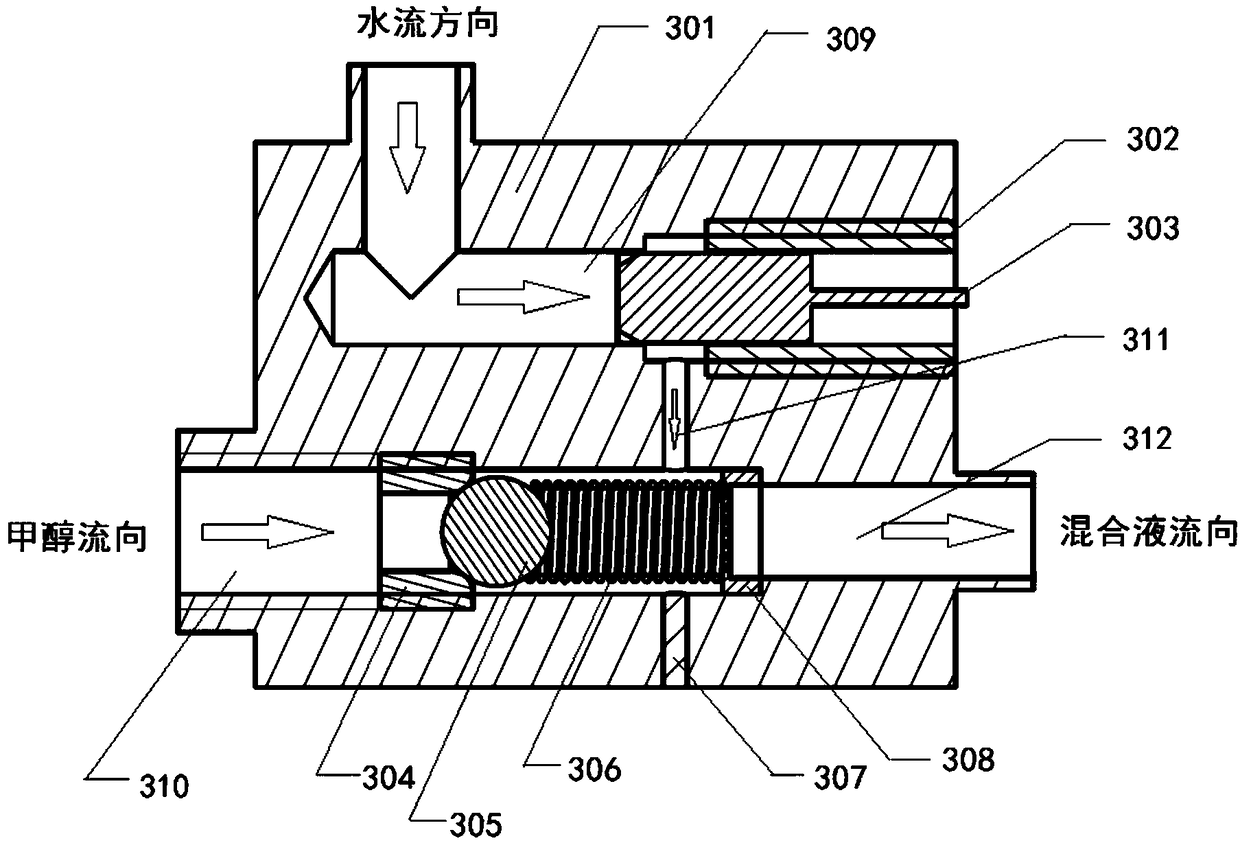

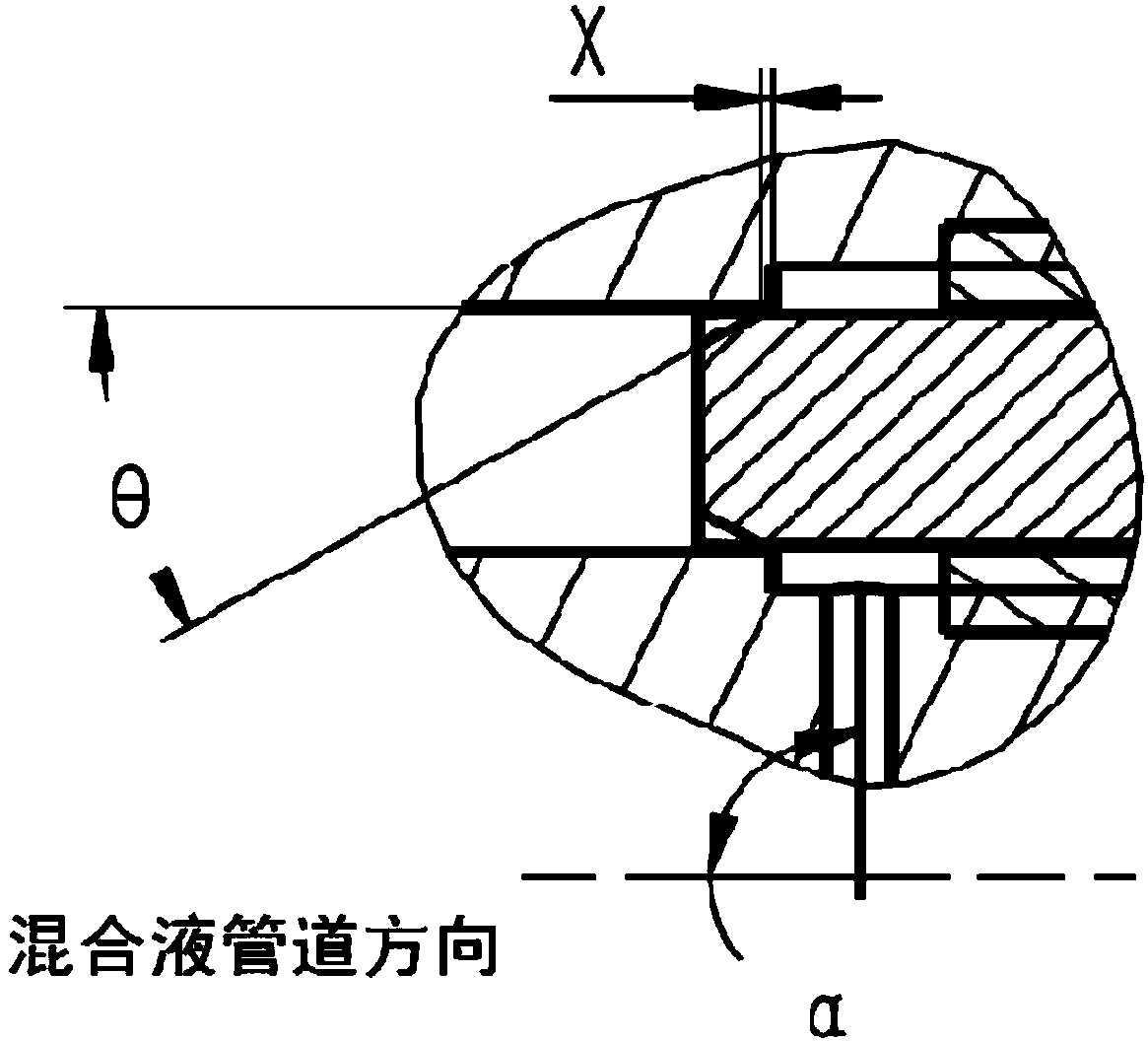

Water adding and spraying system and method for alcohol engine

InactiveCN108533422AReduce burn rateAvoid knockingNon-fuel substance addition to fuelInternal combustion piston enginesInlet temperatureTop dead center

The invention discloses a water adding and spraying system for an alcohol engine. The water adding and spraying system for the alcohol engine comprises a diesel oil supply device, a diesel oil spraying device, an alcohol supply device, an alcohol spraying device, an engine electronic control unit and an engine body, and is characterized in that after alcohol fuel which is discharged from the alcohol supply device is mixed with water discharged from a water supply system in an alcohol and water mixer, the mixture is discharged to the alcohol spraying device and is sprayed into the engine. On the basis of a methanol / diesel double-combustion engine, the characteristic of ultimate mutual solubility of water and methanol, the alcohol and water mixer is added on an alcohol delivering track, theair inlet temperature is reduced when in high load by use of the advantage of high latent heat of evaporation, then the temperature when a top dead center is compressed is reduced, the engine combustion rate is reduced, detonation of the engine is avoided, thus, the methanol substitution rate of the engine can be increased, a double-fuel combustion region is expanded, the thermal efficiency of theengine is improved, and NOx and particulate emission of the engine are reduced.

Owner:CHINA FIRST AUTOMOBILE

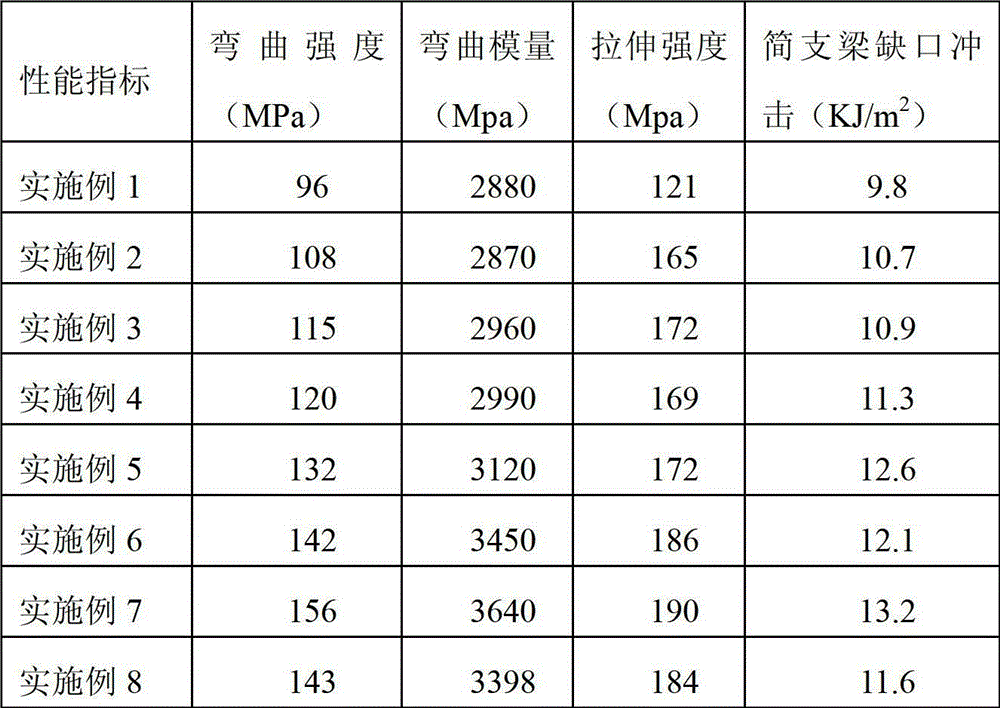

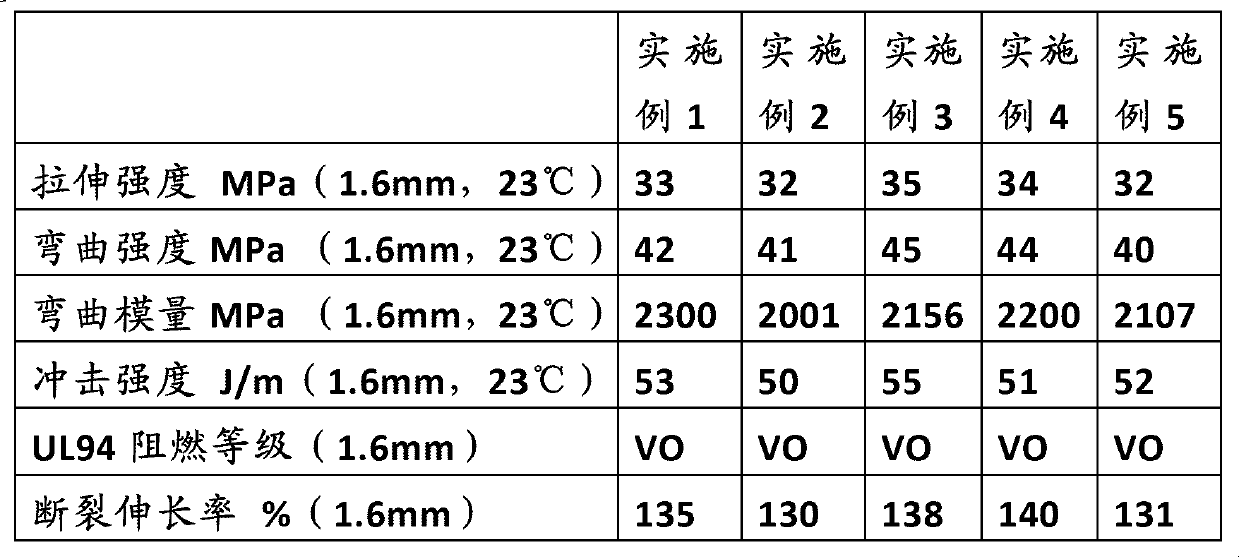

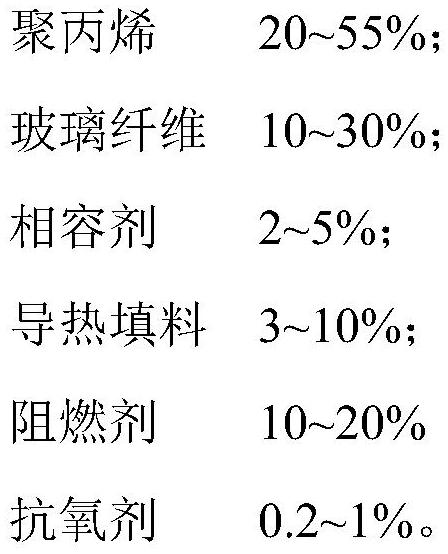

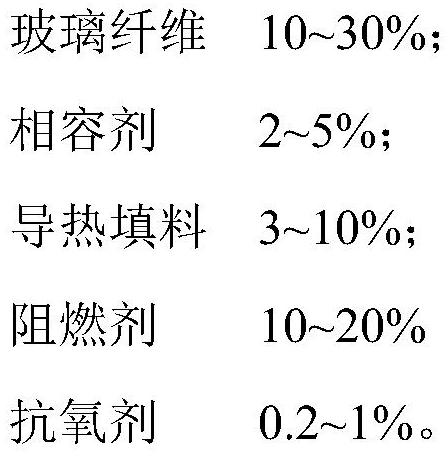

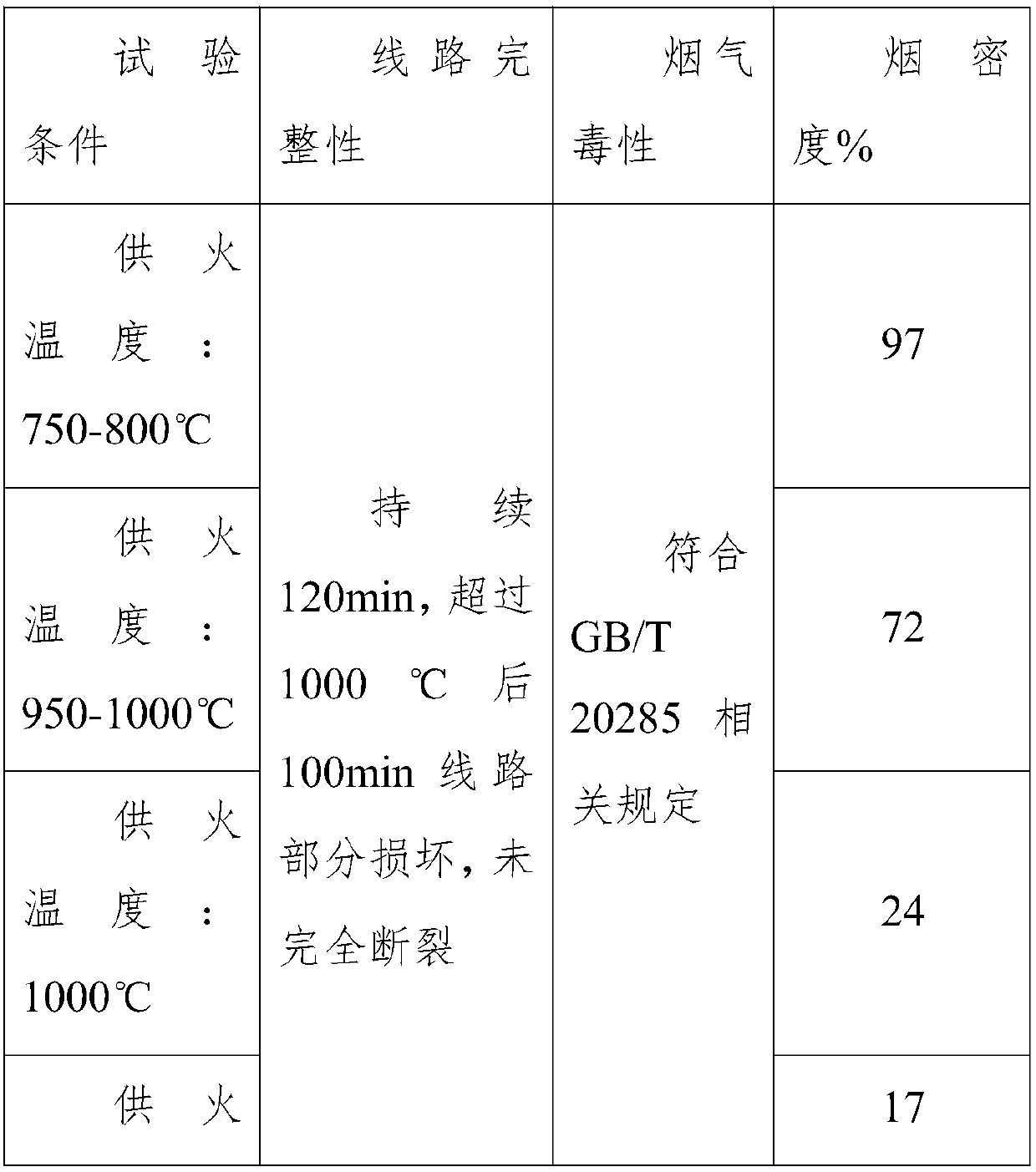

Flame-retardant glass fiber reinforced polypropylene material with low dielectric constant and high thermal conductivity and preparation method thereof

PendingCN114230921AImprove mechanical propertiesExcellent dielectric propertiesDielectricCapacitance

The invention provides a flame-retardant glass fiber reinforced polypropylene material with low dielectric constant and high thermal conductivity and a preparation method of the flame-retardant glass fiber reinforced polypropylene material. The flame-retardant glass fiber reinforced polypropylene material comprises the following components in percentage by mass: 20-55% of polypropylene, 10-30% of low dielectric glass fiber, 0-5% of a compatilizer, 10-20% of a halogen-free flame retardant, 0-10% of a thermal conductive filler and 0.2-1% of an antioxidant. By introducing the low-dielectric glass fiber material, the good dielectric property of the composite material is ensured, and meanwhile, the glass fiber provides good mechanical property and thermal stability for the material; silicon carbide is added as a heat-conducting filler, so that the heat conductivity coefficient of the material is effectively improved, and rapid accumulation of heat in a device is avoided; and the high-efficiency hindered phenol and thioether composite antioxidant and the compatilizer are selected, so that the obtained sample has more excellent weather resistance. The glass fiber reinforced polypropylene material disclosed by the invention has the characteristics of low dielectric, high heat conductivity, excellent flame retardance and the like, and meets the requirements of parts such as a capacitor energy storage shell, a junction box and a precision electronic instrument shell on materials.

Owner:SHANGHAI PRET COMPOSITES +3

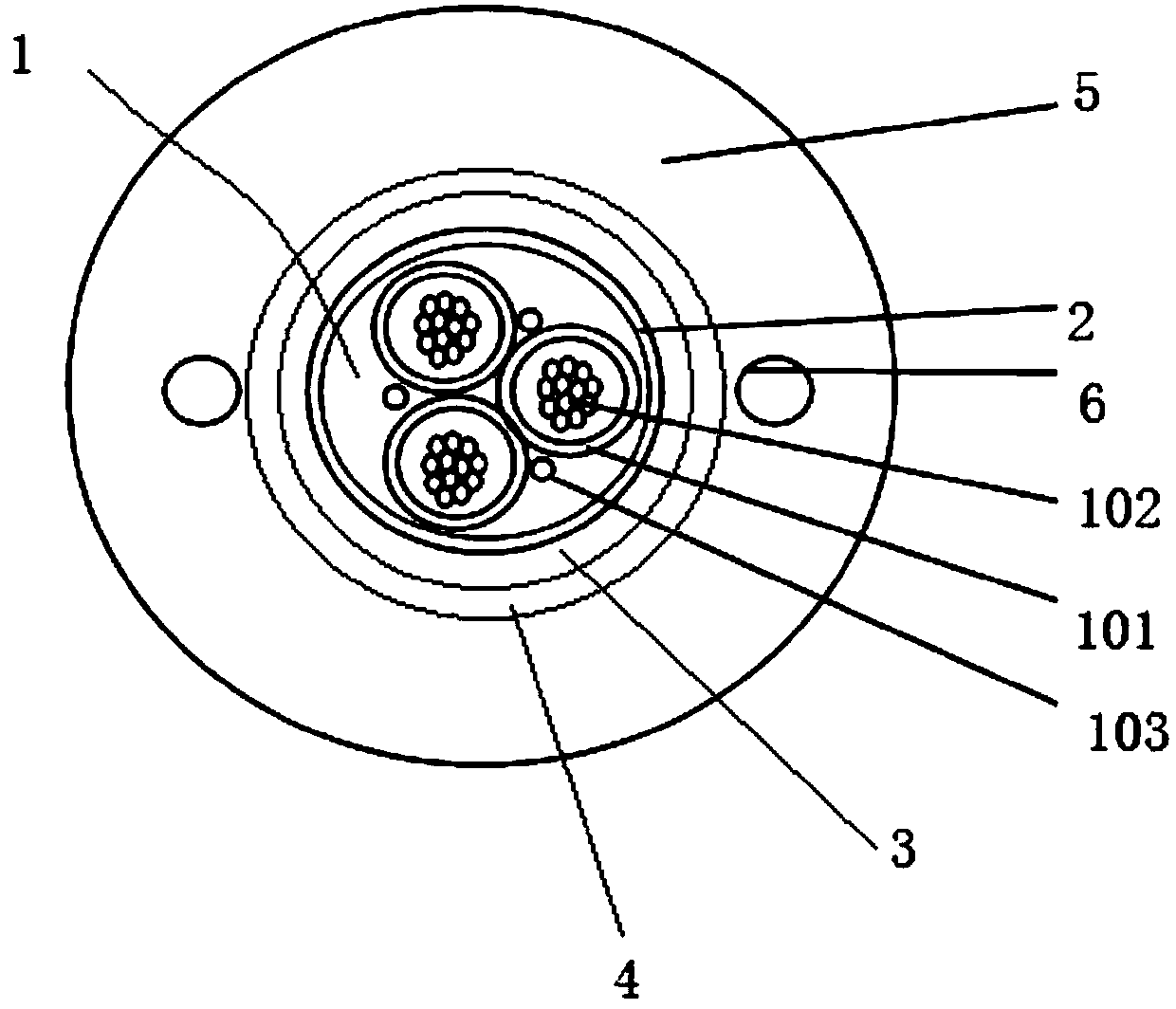

Breaking-force-limiting overhead leading-in optical cable

PendingCN107894640ASmall outer diameterSave reinforcement materialsFibre mechanical structuresClimate change adaptationCarbon nanotubePolyamide

The invention discloses a breaking-force-limiting overhead leading-in optical cable, and the optical cable comprises a light unit. The periphery of the light unit is covered with a water blocking tape, and the periphery of the water blocking tape is covered with a fire-resistant film. The periphery of the fire-resistant film is covered with a fireproof layer, and the periphery of the fireproof layer is covered with a PE outer sheath. The fire-resistant film comprises the following components by weight: 50-70 parts of epoxy resin, 30-50 parts of polyamide, 5-10 parts of nano-level magnesium hydroxide, 0.5-2 parts of polysiloxane grafted carbon nanotubes, and 3-5 parts of organic montmorillonite. The particle size of the nanometer magnesium hydroxide is 0.1-1 microns, and the length of silicone grafted carbon nanotubes is 2-20 microns. The mass fraction of smectite in organic montmorillonite is 96%-98%, the particle size is 300-500 meshes, and the ratio of diameter to thickness is 200-300. The optical cable has higher mechanical performances and environmental performances, and the overall size of the optical cable is small. The optical cable can also solve the problems that a conventional optical cable has a large outer diameter, is large in weight, and is not convenient for construction.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

An adjuvant for reducing the slow burnout response of solid engine

ActiveCN109184954BEasy to makeRaw materials are easy to getRocket engine plantsPhysical chemistryEthyl ester

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Early-stage and later-stage cultivation method for enokitake fruiting

InactiveCN108901585APromotes rapid germinationPromote germinationCultivating equipmentsMushroom cultivationAir changeRecovery stage

The invention relates to an early-stage and later-stage cultivation method for enokitake fruiting. The method comprises the following steps: fungus bottles which are in a stage after inoculation and before a heat emitting stage are cultivated in an early-stage cultivation room, and the indoor environment is set according to the conditions that the temperature is in a range of 18-20 DEG C, the humidity is larger than or equal to 64%, and the ratio of carbon dioxide concentration to air change frequency is lower than or equal to 2100 ppm; and the fungus bottles which are in a stage entering theheat emitting stage and before mycelium stimulation are cultivated in a later-stage cultivation room, and the indoor environment is set according to the conditions that the temperature is lower than or equal to 20 DEG C, the humidity is larger than or equal to 80%, and the ratio of the carbon dioxide concentration to the air change frequency is lower than or equal to 3100 ppm. According to the invention, the method of early-stage and later-stage separated cultivation is adopted, so that the purposes of shortening and stabilizing the fungus fruiting period and reducing the pollution rate and fungus killing rate are achieved through separately controlling the parameters of the cultivation steps in a hypha recovery stage after the inoculation and the hypha rapid growth stage in the heat emitting stage.

Owner:福建万辰生物科技股份有限公司

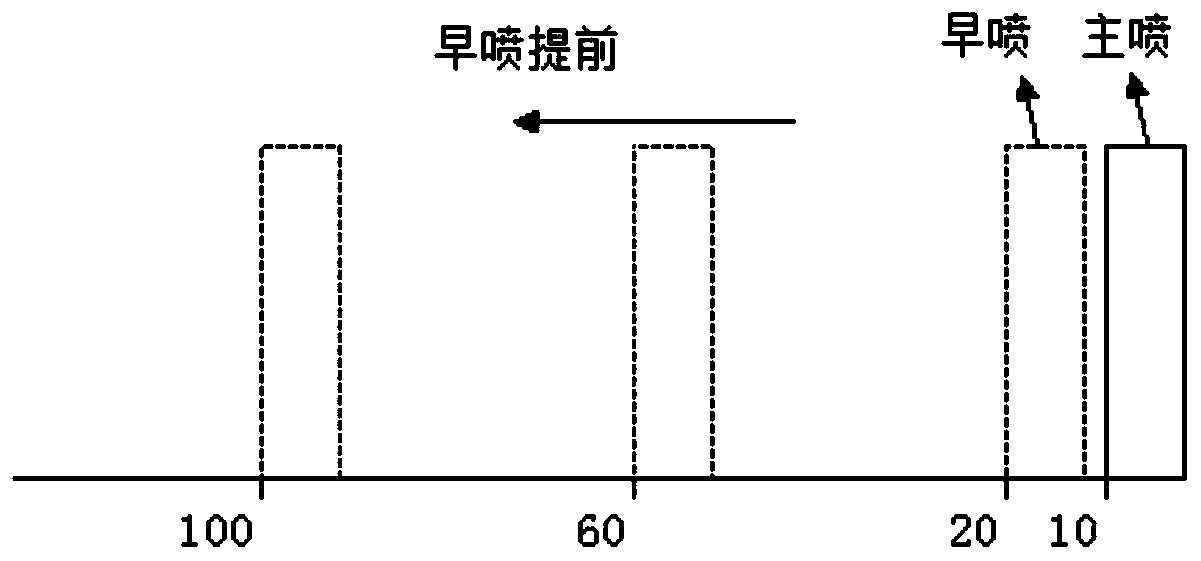

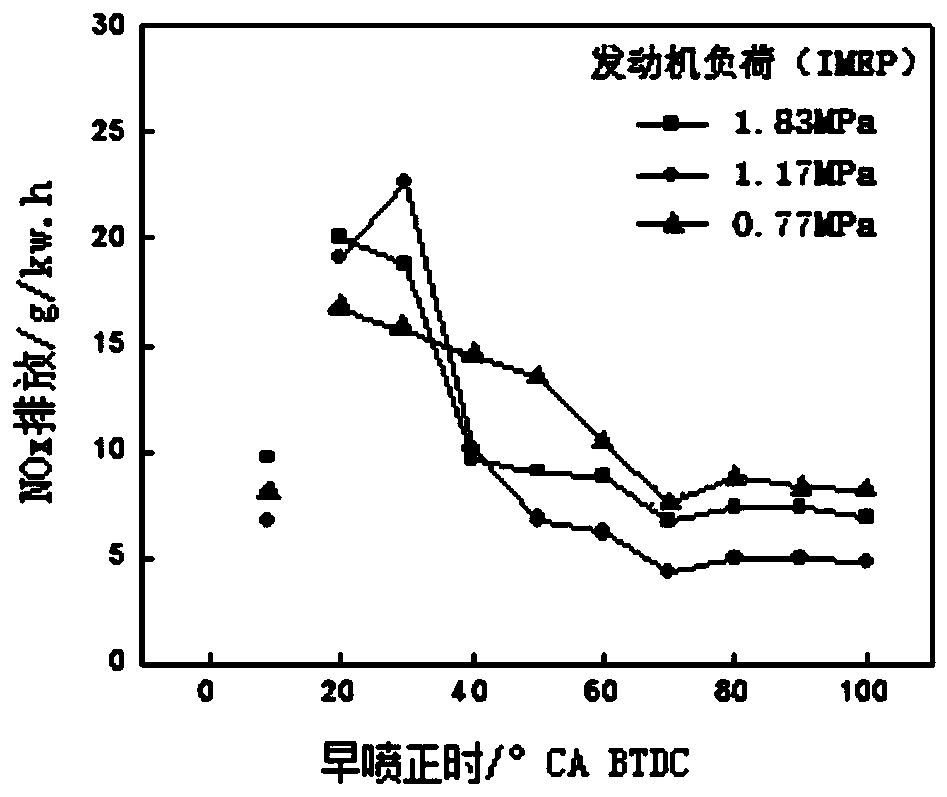

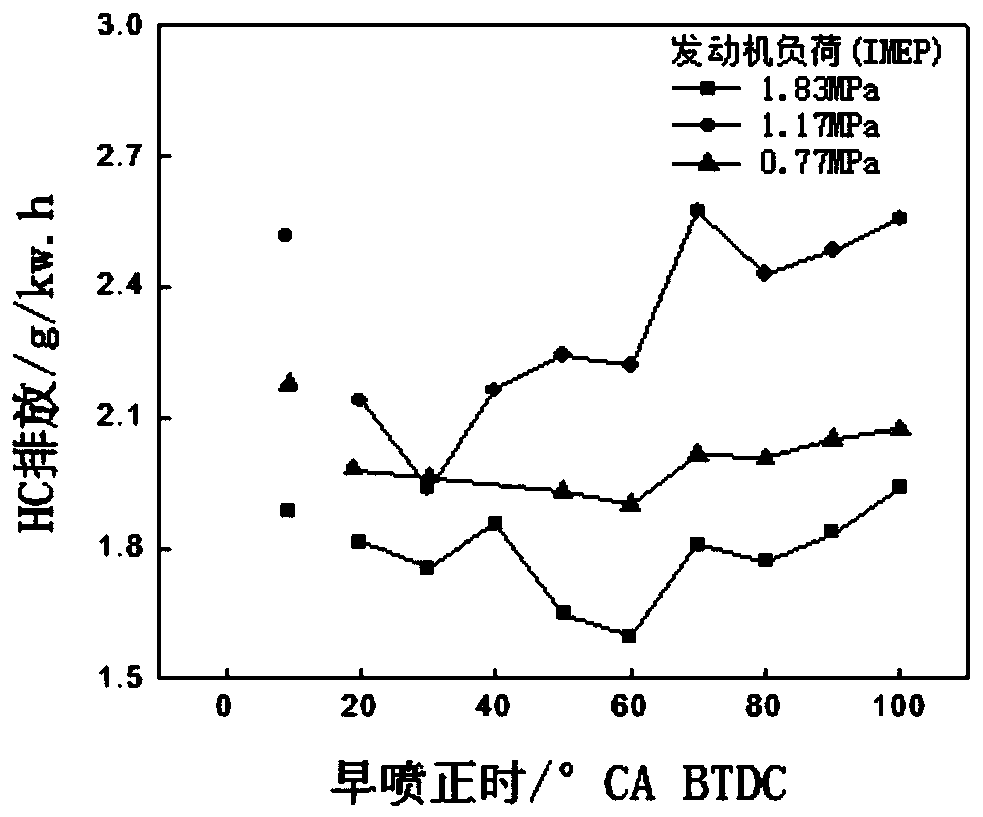

Multi-section jetting method for igniting natural gas engine through diesel micro jetting

InactiveCN110552794AReduce heat loadImprove reliabilityLiquid coolingElectrical controlWork cyclePiston

The invention discloses a multi-section jetting method for igniting a natural gas engine through diesel micro jetting. When natural gas is ignited through diesel micro jetting, diesel is jetted in twostages in one working cycle of a piston on the condition that the total diesel jetting amount is unchanged; the timing of the first stage of jetting is prior to that of the second stage of jetting; and besides, diesel jetting in the first stage is performed for N times, and N is greater than or equal to 1. By adopting the method, the thermal load of a diesel jetting nozzle is lowered; and reliability of a diesel jetting device is improved, and the service life of the diesel jetting device is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com