Multi-section jetting method for igniting natural gas engine through diesel micro jetting

A multi-stage injection and natural gas technology, which is applied in the direction of combustion engine, engine cooling, internal combustion piston engine, etc., can solve the problem of reducing the reliability and service life of the fuel injector, the poor cooling effect of micro-sprayed diesel oil on the fuel injector, and the fuel injector High thermal load and other problems, to achieve the effect of improving reliability and service life, reducing ignition intensity and reducing thermal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

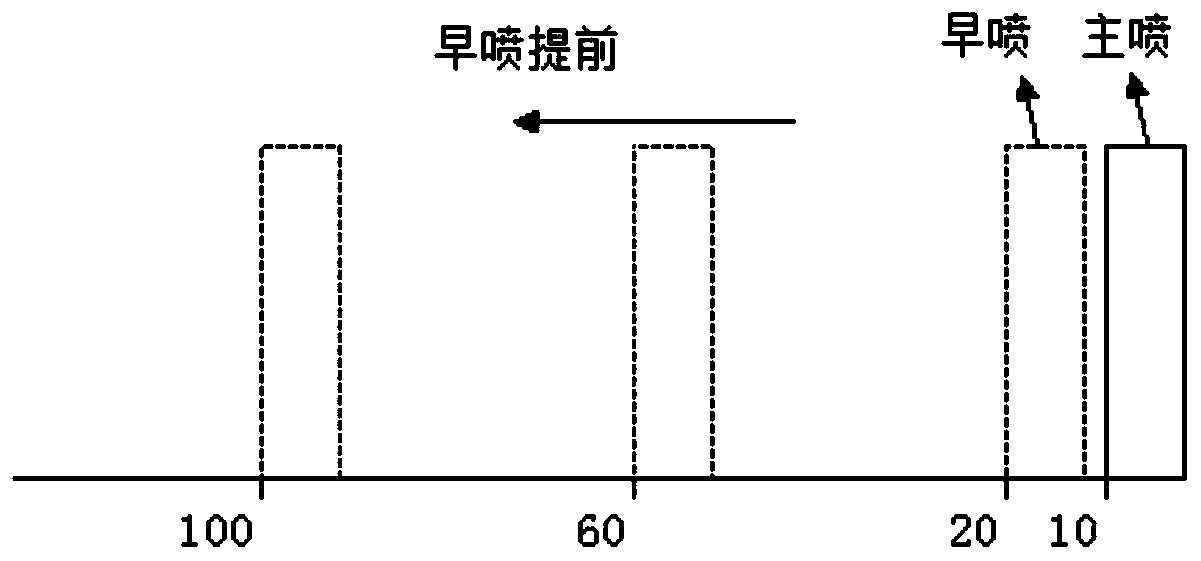

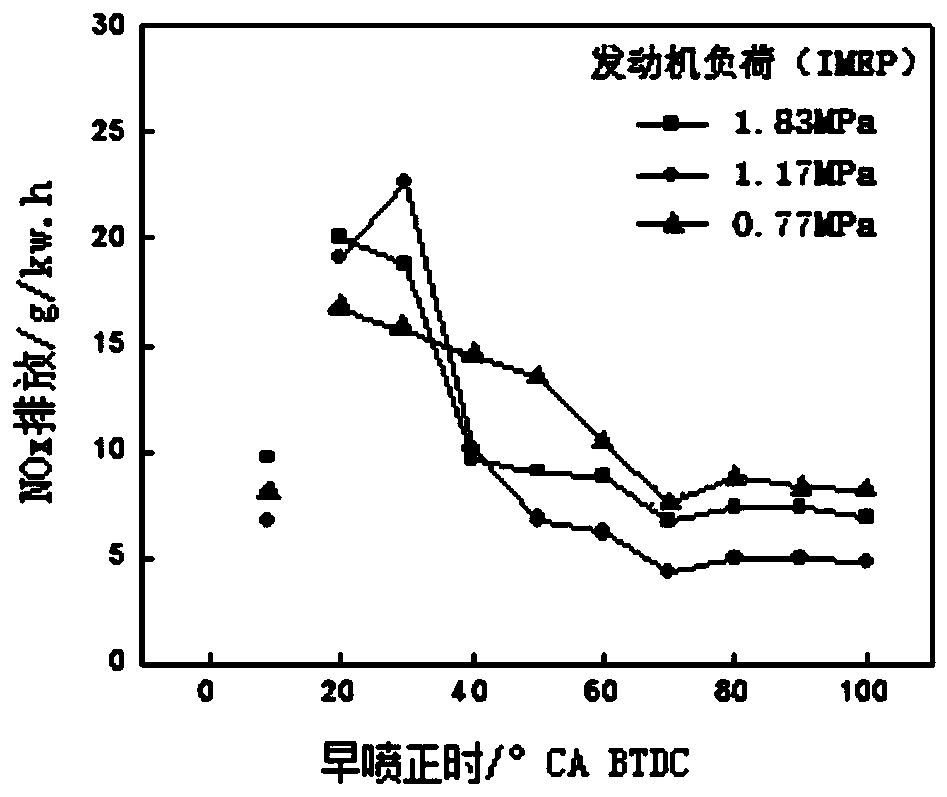

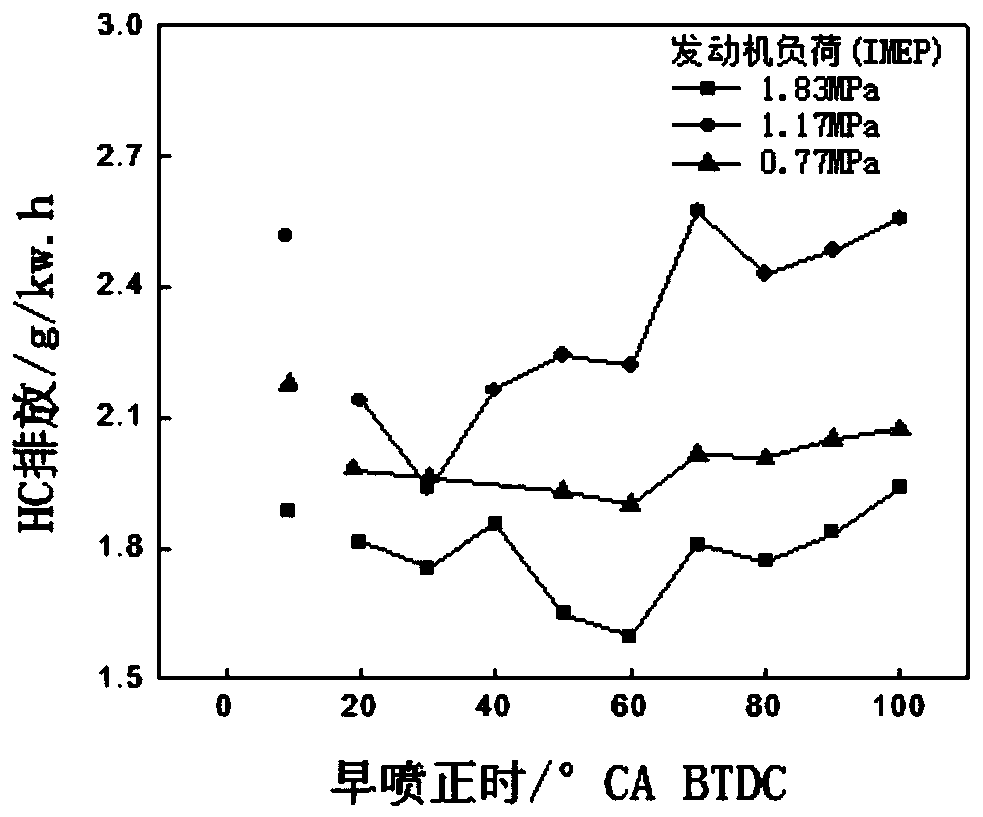

[0027] Embodiment 1: a kind of multi-stage injection method of micro-injection of diesel oil to ignite a natural gas engine, the multi-stage injection method is carried out according to the following steps: when carrying out micro-injection of diesel oil to ignite natural gas, under the condition that the total amount of injected diesel oil is constant, the same piston Diesel is injected in two stages in the working cycle, the timing of the first stage injection is earlier than the second stage injection, and the diesel injection in the first stage is divided into N times, wherein, N=1, the first stage injection The moment is 20°CA before the piston moves to the top dead center, and the moment of the second stage injection is 10°CA before the piston moves to the top dead center, and the amount of diesel injected in the first stage and the second stage is 5 mg, and The pressures of the diesel injection in the first stage and the second stage are both 110MPa, the pressure of the ...

Embodiment 2

[0029] Same as Example 1, the difference is:

[0030] The moment of diesel injection in the first stage is 30°CA before the piston moves to the top dead center.

Embodiment 3

[0032] Same as Example 1, the difference is:

[0033] The moment of diesel injection in the first stage is 40°CA before the piston moves to the top dead center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com