Engine exhaust temperature control method and engine

A control method and engine technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as low engine output power and affecting user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In order to ensure the normal driving of the vehicle, various operating parameters of the engine need to cooperate with each other to ensure the reliability and stability of the engine. One of the important parameters that characterize the working state of the engine is the engine exhaust temperature. As the name implies, the engine exhaust temperature is the exhaust temperature of the engine. Air temperature, in other words, refers to the temperature within the exhaust manifold of an engine. If the exhaust temperature of the engine is high, it will easily cause damage to structures such as the exhaust pipe and the supercharger. In the prior art, the torque limit is used to control the exhaust temperature of the engine, but the torque limit will directly reduce the output power of the engine and affect the user's use.

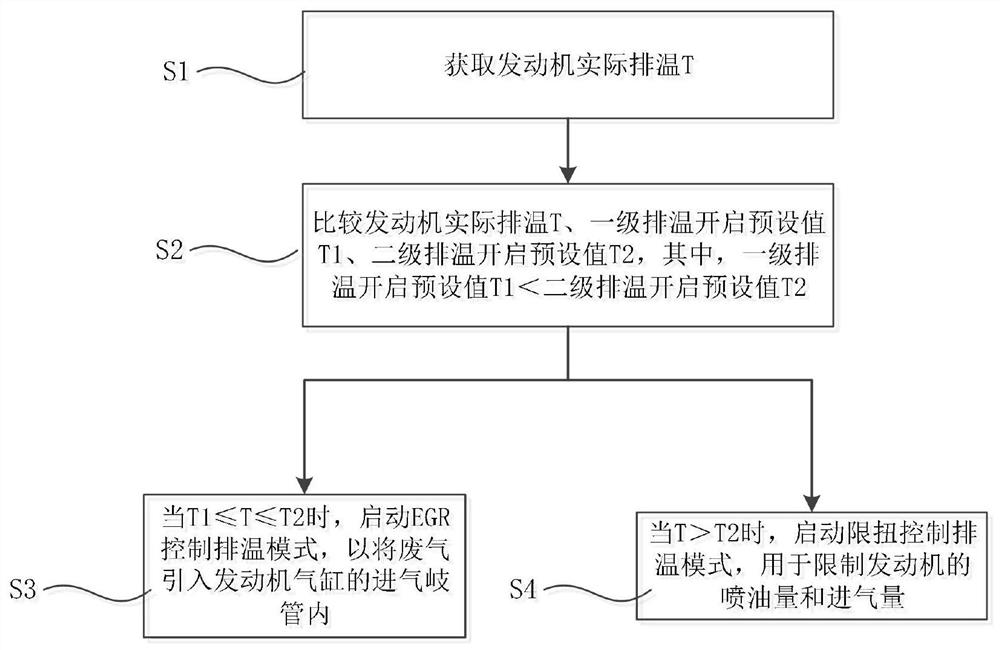

[0045] To solve this problem, such as figure 1 As shown, this embodiment provides an engine exhaust temperature control method, which includes the foll...

Embodiment 2

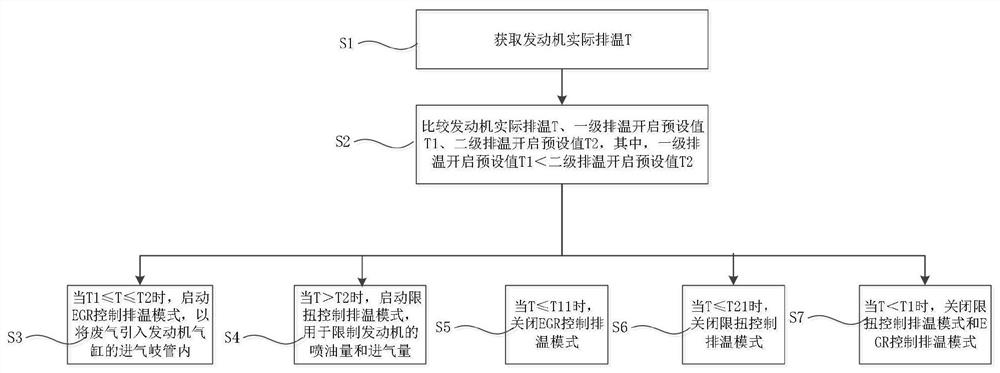

[0057] The steps in this embodiment are similar to those in Embodiment 1, and the difference lies in how to determine whether the EGR control exhaust temperature mode and the torque limit control exhaust temperature mode are turned off.

[0058] Among them, the first-stage exhaust temperature opening preset value T1 is the opening temperature for starting the EGR control exhaust temperature mode. With the operation of EGR, the actual exhaust temperature T of the engine gradually decreases. It can be understood that if the EGR control exhaust temperature mode is continued, the actual exhaust temperature T of the engine also tends to decrease gradually, so as to reach the safe range of the engine exhaust temperature.

[0059] To this end, the following steps are included after starting the EGR control exhaust temperature mode:

[0060] Compare the actual exhaust temperature T of the engine and the preset value T11 of the first exhaust temperature off, wherein the preset value of...

Embodiment 3

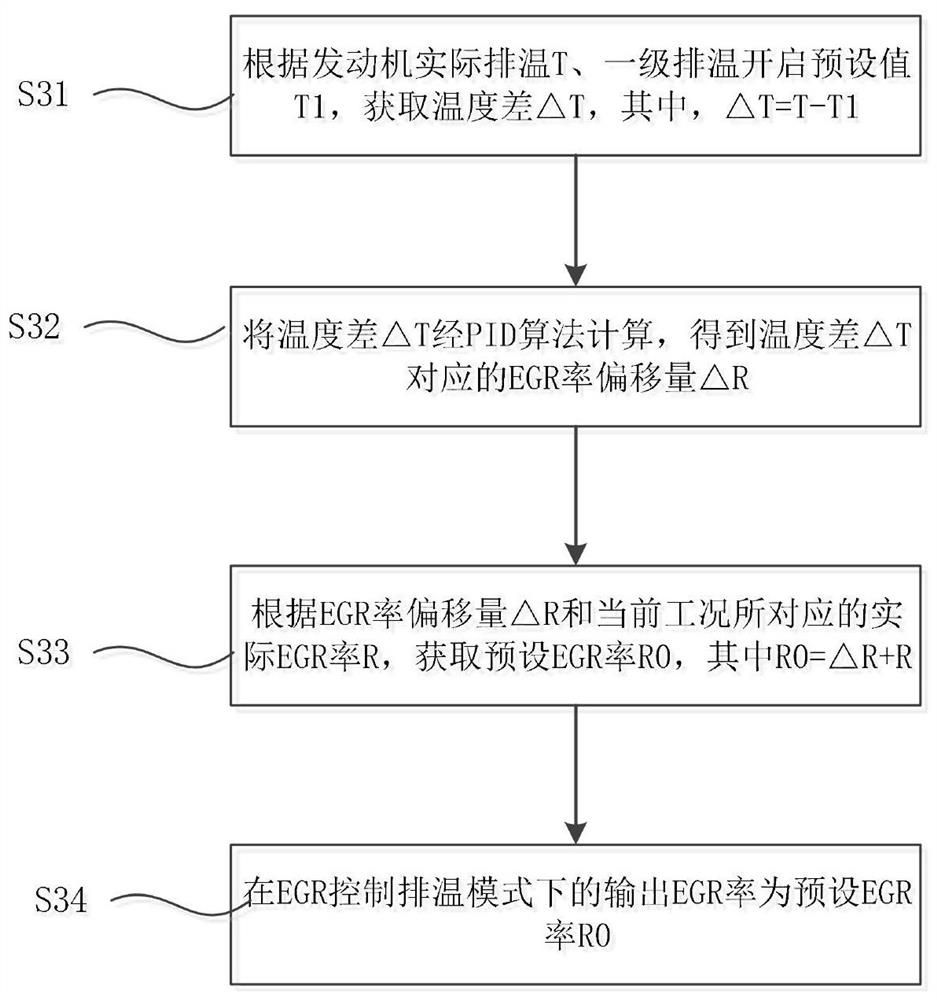

[0082] This embodiment is similar to the second embodiment, the only difference is that, on the basis of the second embodiment, this embodiment adds specific operation steps of the EGR control exhaust temperature mode.

[0083] As the main purification method in the engine, EGR has a great influence on the combustion temperature in the cylinder. With the increase of the EGR rate, the transient maximum temperature and average temperature in the cylinder decrease accordingly. Since high temperature environment is a necessary condition for NOx generation, the increase of EGR rate is beneficial to reduce NOx emission, which is one of the effective ways to reduce NOx emission.

[0084] Among them, the EGR rate is specifically the ratio of the amount of exhaust gas used for recirculating exhaust gas to the total amount of intake air sucked into the cylinder. The reasonable control of the EGR rate is extremely important for the purification effect of nitrogen oxides and the emission o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com