Organic compound

A technology of suboxide and niobium oxide, applied in the fields of inorganic chemistry, niobium compounds, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1 (comparison)

[0099] 53.98% by weight of precursor A4(Nb) and 46.02% by weight of precursor Al(Nb 2 o 5 ) were evenly mixed together and heated to 1400°C in a hydrogen atmosphere. The product properties are shown in Table 1.

Embodiment 2

[0101] Precursor A4 (Nb) was mixed with 1.5 times the stoichiometric ratio (relative to the oxygen content) of magnesium and 5.4 parts by weight of NH 4 Cl (per 100 parts of Nb) was mixed evenly and put into the reactor. The reactor was then purged with argon and heated to 700°C for 90 minutes. After cooling, air was slowly filled into the reactor for passivation. After washing and rinsing with sulfuric acid, a nitrogen-doped niobium metal containing 9600-10500 ppm (9871 ppm on average) nitrogen was obtained. The oxygen content is 6724ppm.

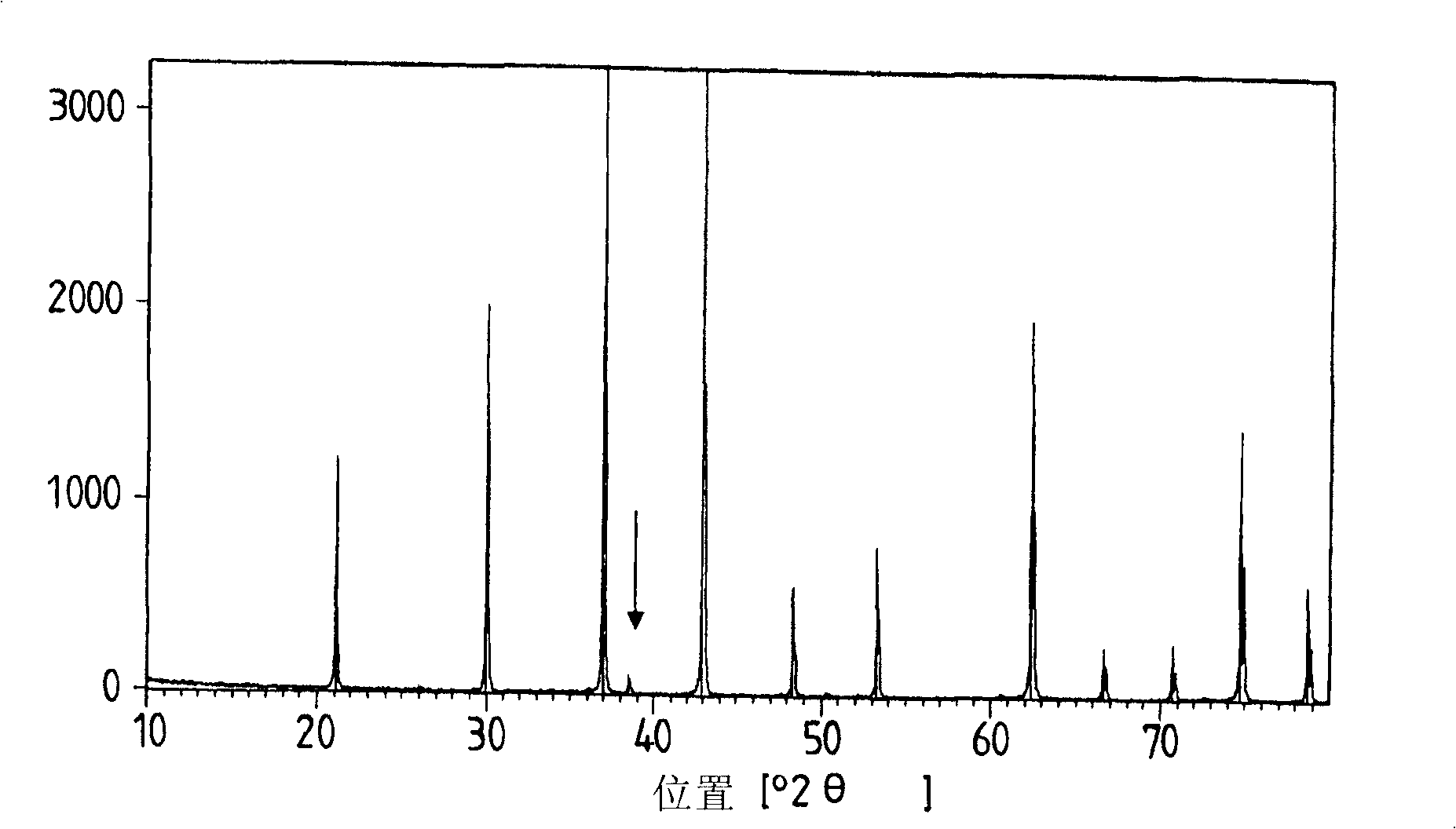

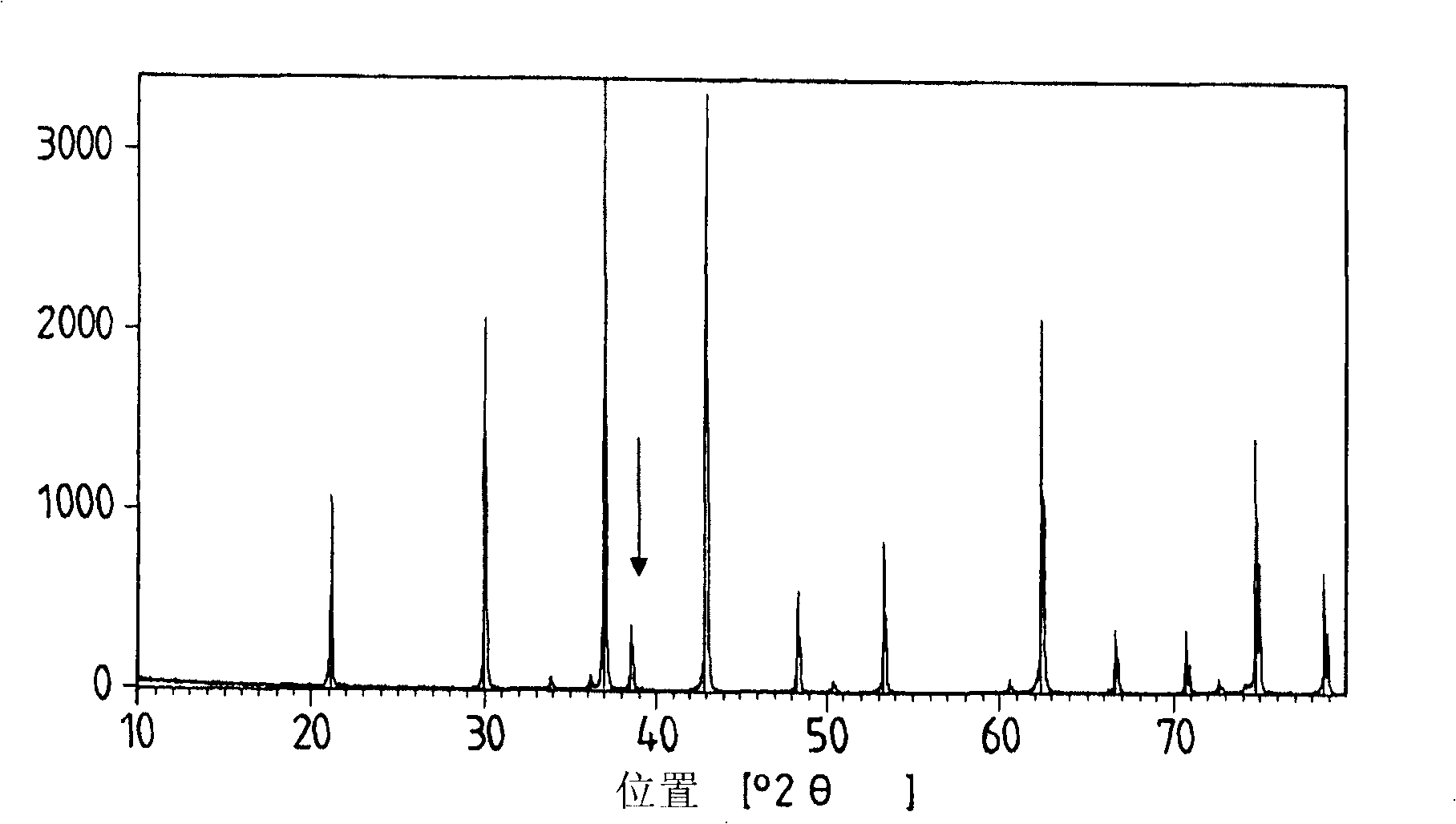

[0102] Nitrogen-doped niobium was converted to NbO as described in Example 1. The product properties are shown in Table 1. The x-ray diffraction pattern of the powder is shown in figure 1 middle. Obviously, the Nb at 2Θ=38.5° indicated by the arrow can be identified 2 N(101) peak. Therefore, at least a portion of the doped N to crystalline Nb 2 N-phase form exists.

Embodiment 3

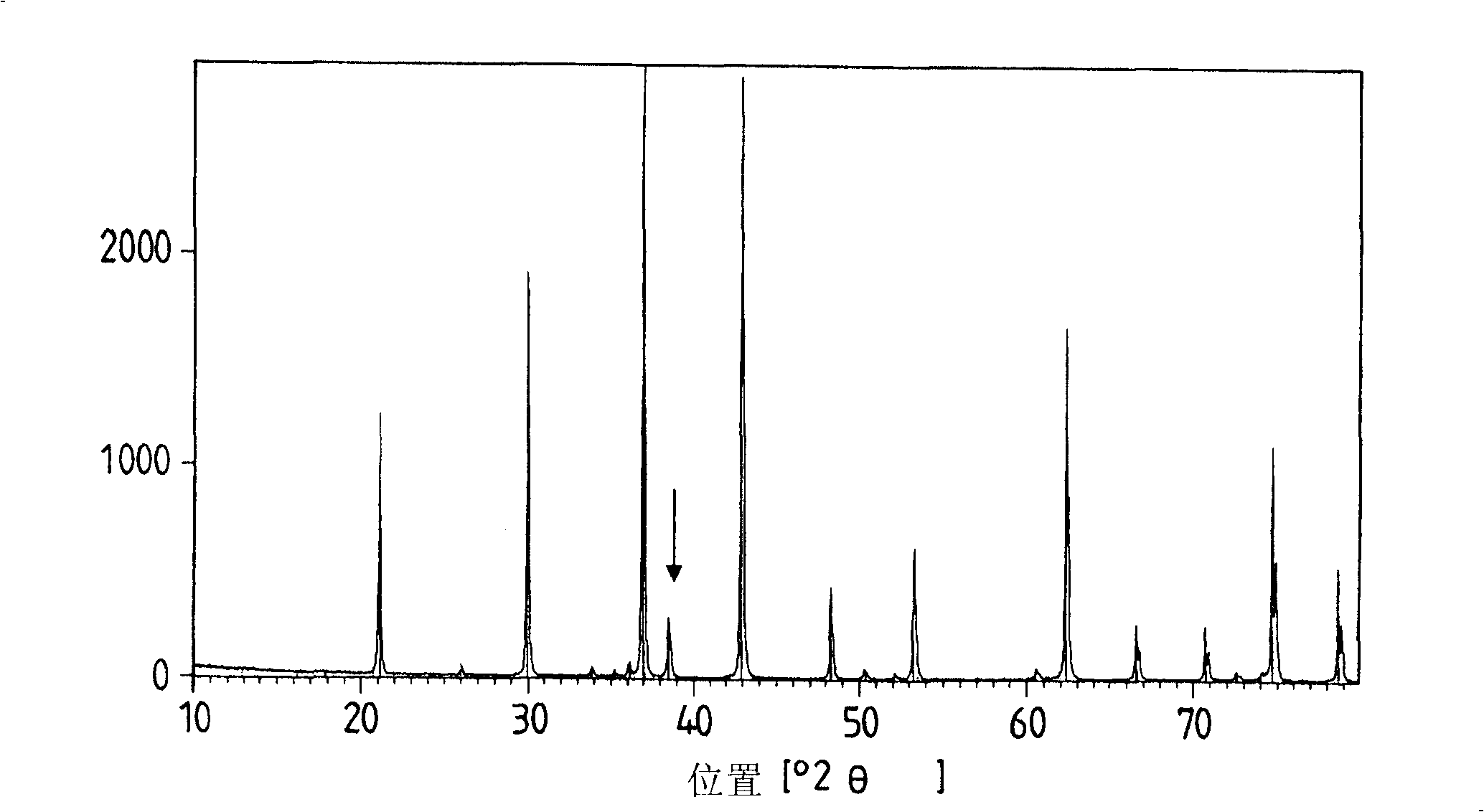

[0104] Repeat Example 2, except that the NH 4 The amount of Cl added was increased to 8.2 parts by weight. The average nitrogen content of niobium powder is 14730ppm. The oxygen content is 6538ppm. The product properties of this suboxide are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com