Flame-retardant glass fiber reinforced polypropylene material with low dielectric constant and high thermal conductivity and preparation method thereof

A polypropylene material, low dielectric technology, applied in the field of polymer material modification, can solve the problems of deterioration of flame retardant performance, fast burning speed, etc., achieve good mechanical properties, improve thermal conductivity, reduce burning rate and heat release energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

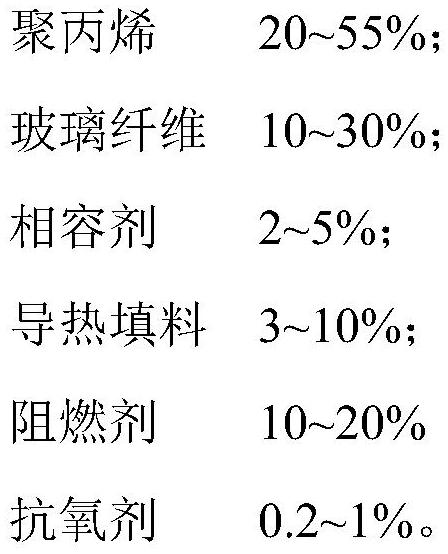

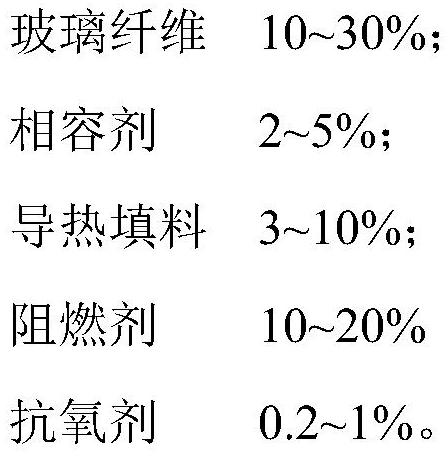

Method used

Image

Examples

Embodiment 1-4

[0040] Weigh PP resin, low-dielectric glass fiber, compatibilizer H501, thermal conductive filler silicon carbide, flame retardant and self-made 1010 / 1035 composite antioxidant according to the weight percent of Examples 1-4 described in Table 1.

[0041] Preparation:

[0042] Weigh PP, silicon carbide, compatibilizer, flame retardant and antioxidant according to the weight ratio, put them into a high-speed mixer, and stir at room temperature for 10 to 30 minutes.

[0043] (2) Add the mixed material in step (1) to the main feeding port of the twin-screw extruder, and add the low-dielectric glass fiber weighed according to the weight ratio to the side feeding port of the twin-screw extruder , fully plasticized and mixed at 200-230°C, extruded, cooled and granulated to obtain the low dielectric, high thermal conductivity, flame-retardant glass fiber reinforced polypropylene material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com