Intumescent flame-retardant heat-insulating fireproof coating and preparation method thereof

A kind of fire-proof coating and intumescent technology, which is applied in the direction of fire-proof coating, anti-corrosion coating, radiation-absorbing coating, etc. It can solve the problems of secondary damage, difficulty of rescue, limited protection time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

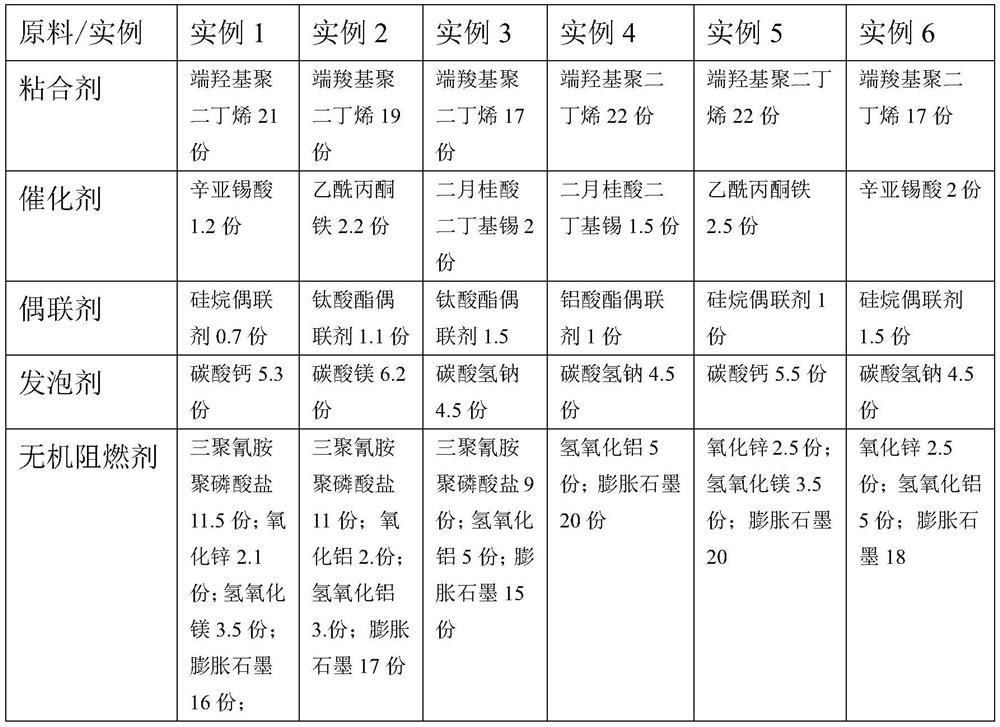

Embodiment 1

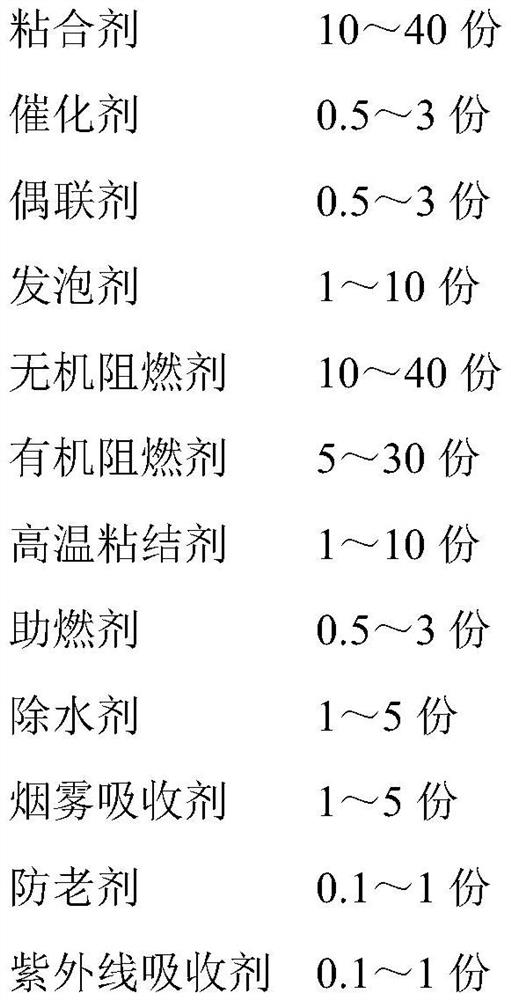

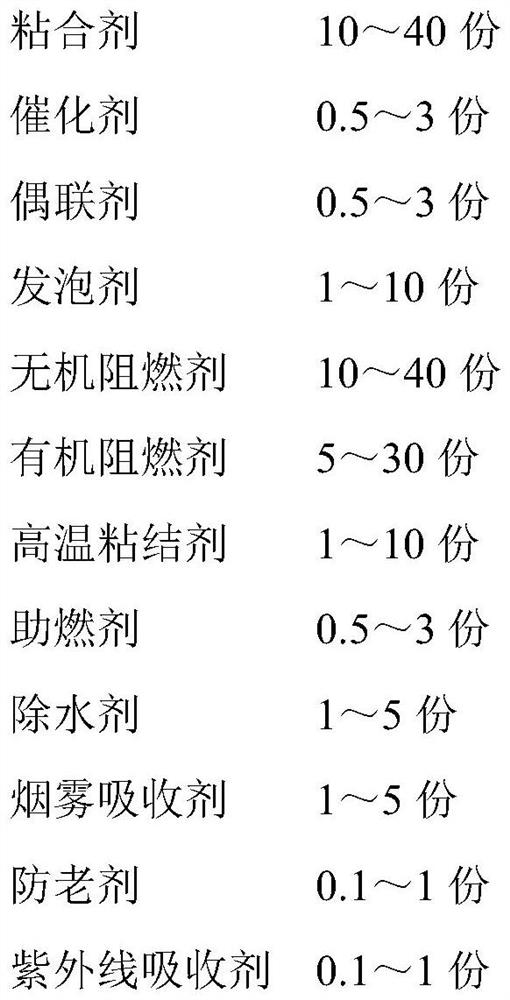

[0075]

[0076]

[0077] Among them, the diluent accounts for 1% to 5% of the total amount of components A and B by weight percentage, and the addition amount can be adjusted according to the viscosity requirements of the coating on the construction site.

[0078] A preparation method for an intumescent flame-retardant heat-insulating fireproof coating comprises the following steps:

[0079] 1) Put the foaming agent, inorganic flame retardant, high-temperature binder, water remover, smoke absorber, anti-aging agent, and ultraviolet absorber into the high-speed mixer according to the above ratio, and mix and stir, and the stirring time is controlled at 10 to 20 minutes. The speed is controlled at 500~1400 rpm;

[0080] 2) Put the adhesive, catalyst, coupling agent, and organic flame retardant into the water bath reactor, the stirring speed is 30-500 rpm, the temperature is 20-80 degrees Celsius, and the stirring time is 10-60 minutes to make a prepolymer;

[0081] 3) Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com