Patents

Literature

80 results about "Pyrolant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pyrolant (from Greek pyr, fire) is an energetic material that generates hot flames upon combustion. Pyrolants are metal-based pyrotechnic compositions containing virtually any oxidizer. The term was originally coined by Kuwahara in 1992, in a paper on magnesium/Teflon/Viton, to distinguish between compositions that serve as propellants and those yielding hot flames which are not necessarily suitable for propellant purposes.

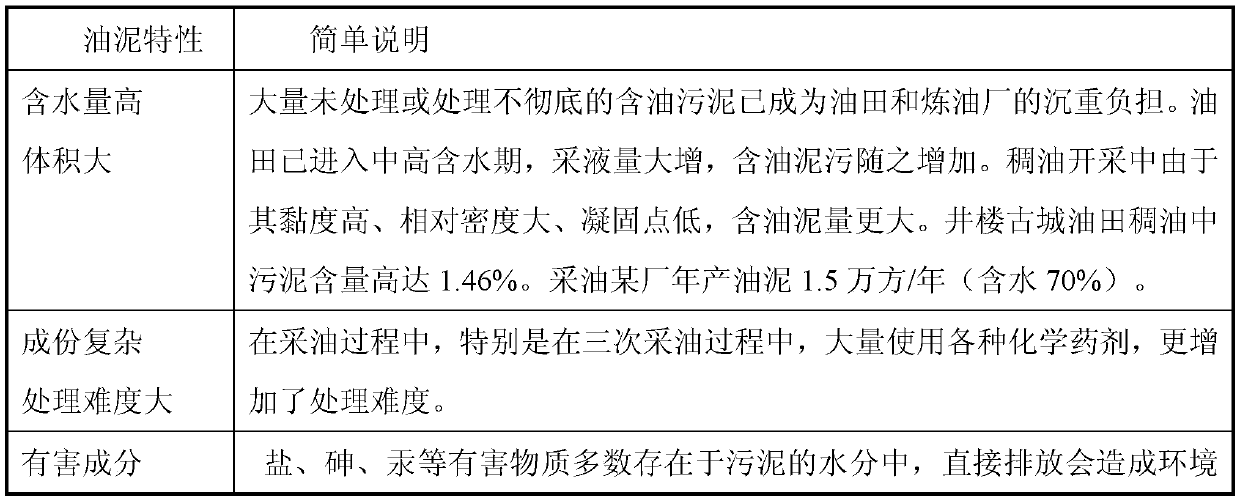

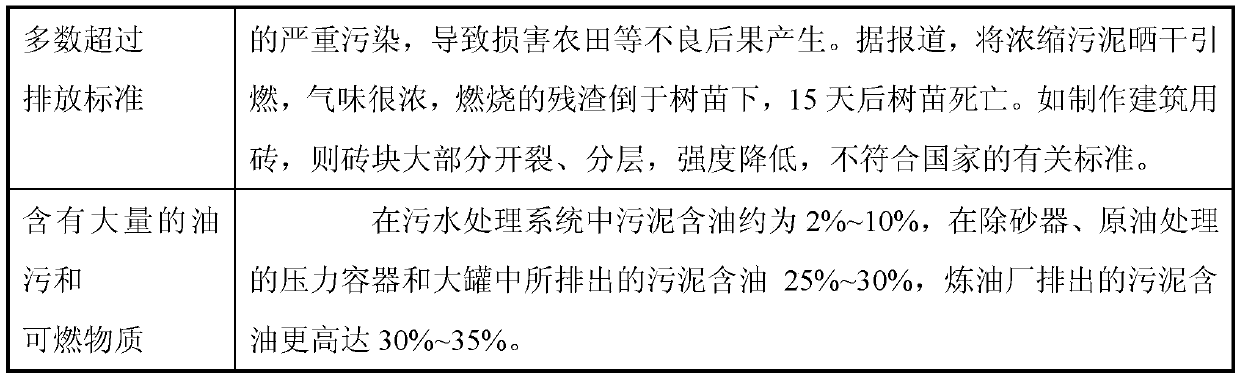

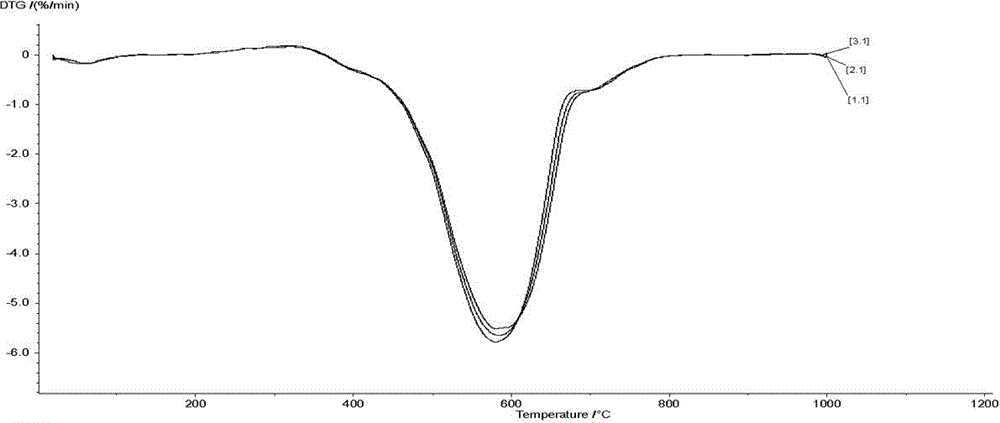

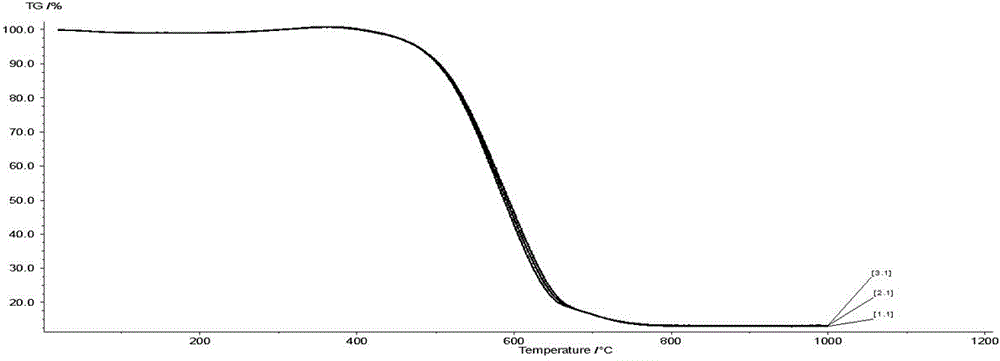

Composite fuel using oil-containing sludge and preparation method thereof

The invention provides composite fuel using oil-containing sludge and a preparation method thereof, relates to composite fuel and a preparation method thereof and belongs to the field of composite fuel preparation. The composite fuel and the preparation method aim at solving the technical problem that existing oil-containing sludge contaminates the environment. The composite fuel using oil-containing sludge is prepared from the oil-containing sludge, auxiliary fuel, an adhesive, a curing agent and a combustion improver. The preparation method includes the steps that the oil-containing sludge, the auxiliary fuel, the adhesive, the curing agent and the combustion improver are mixed, stirred, dehydrated, smashed, set and dried, and the composite fuel is obtained. The composite fuel using the oil-containing sludge and the preparation method belong to resource utilization of the oil-containing sludge. The problem about use of the oil-containing sludge is solved. Meanwhile, the heat value in the oil-containing sludge is utilized, the aim that harmful components in the oil-containing sludge are harmless is achieved, waste is turned into wealth, and products with additional value are produced. Investment is little, the composite fuel takes effect quickly, cost performance of the product is high, operation is easy, and the composite fuel has large competition advantages.

Owner:HARBIN INST OF TECH

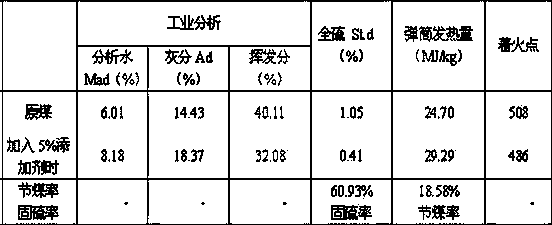

High efficiency coal additive

The high efficiency coal additive consists of desulfurizer, leavening agent, combustion adjuvant, smoke suppressor and corrosion inhibitor mixed together. The desulfurizer contains CaO, NH4HCO3, ZnO and SiO2; the leavening agent contains NaHCO3, KAl(SO4)2 .12H2O and acidified coal gangue; the combustion adjuvant contains Fe2O3, MgO, KCl, KMnO4 and NaNO3; the corrosion inhibitor is humic acid and NaNO3; and the smoke suppressor is also KMnO4. The high efficiency coal additive is mixed directly with coal for boiler, furnace, kiln, oven, etc. Detection shows that the high efficiency coal additive can result in desulfurizing rate of 85 %, save coal rate by14.77 %, raise heat efficiency by 9.19 %, lower carbon content of coal slag by 14.86 %,and reduce smoke, scale and corrosion by 90 %.

Owner:郴州市宇洁环保建材有限公司

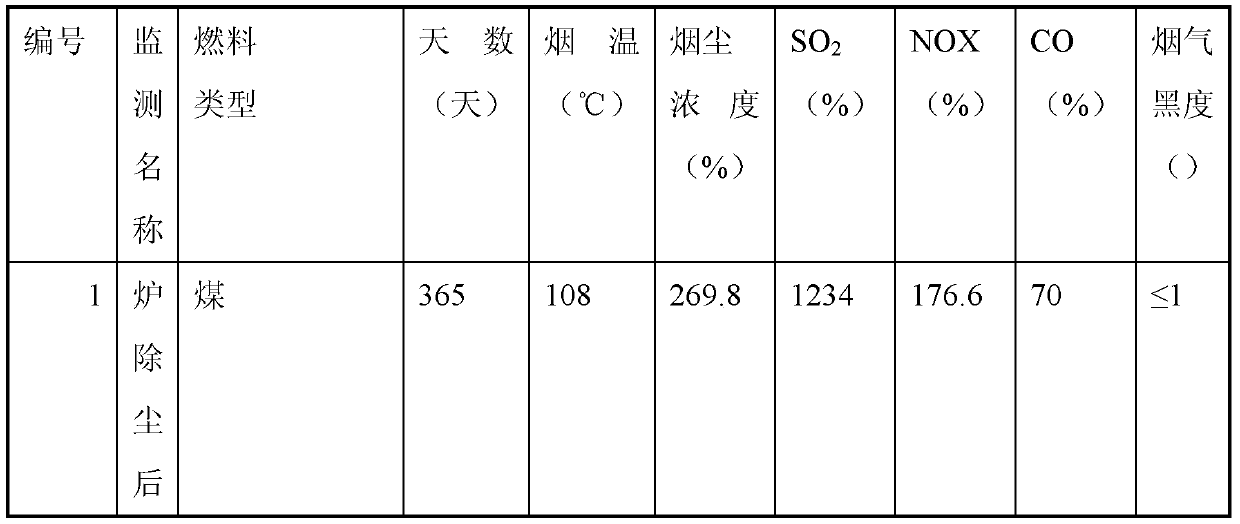

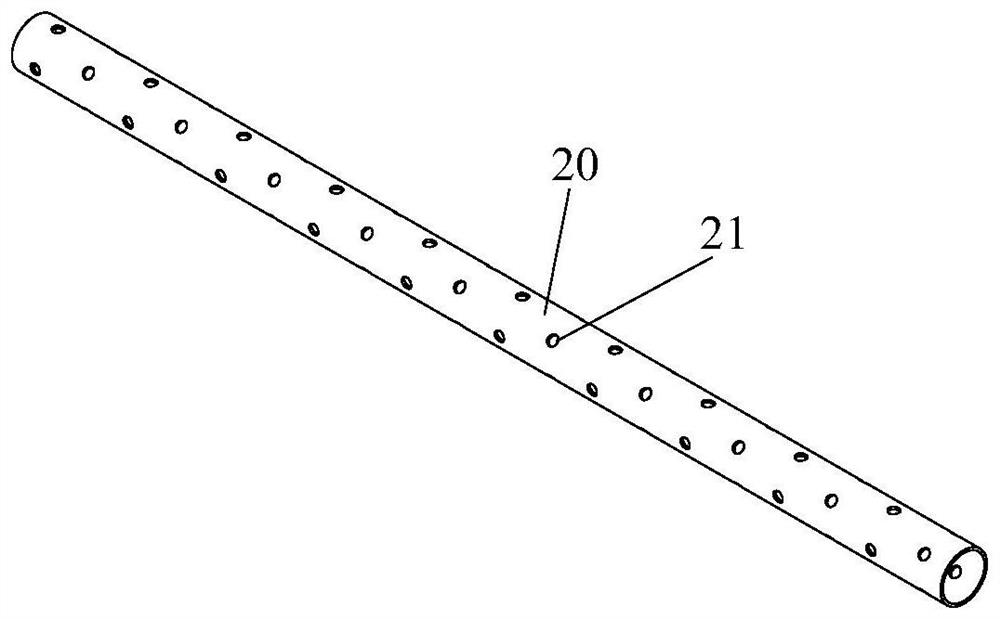

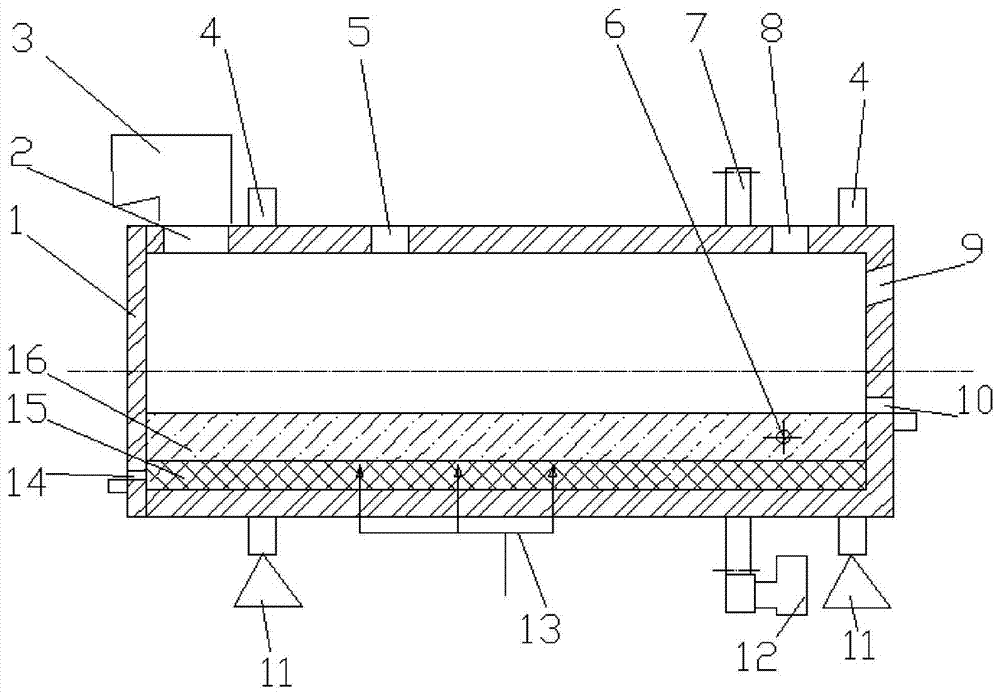

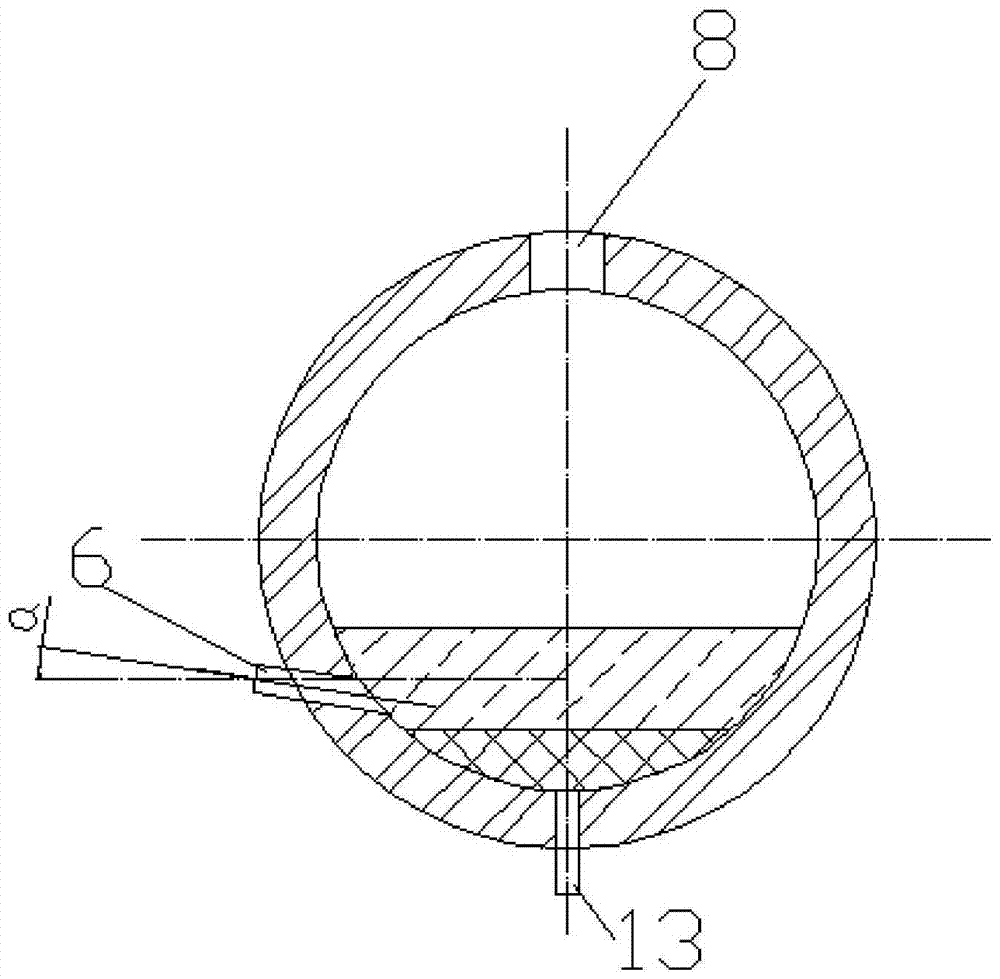

Burner, burning heating method and burning heating equipment

InactiveCN101576257AAvoiding Problems in Burning WaysIncrease flow rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The invention relates to a burner, a burning heating method and burning heating equipment. The burner comprises a distributor chamber and gas mixing pipes, wherein the distributor chamber is provided with a cavity, and a fuel gas inlet is arranged on the distributor chamber; the inlet ends of the gas mixing pipes are communicated with the cavity of the distributor chamber so as to obtain fuel gas; the side wall of each gas mixing pipe is provided with at least one gas inlet hole used for absorbing combustion improver to be mixed with the fuel gas; and the outlet ends of the gas mixing pipes are used for providing mixing gas of the fuel gas and the combustion improver for burning. The burning heating method comprises the steps of distributing and leading the fuel gas into more than one gas mixing pipe; leading the combustion improver into the gas mixing pipes and mixing the combustion improver and the fuel gas in the gas mixing pipes through a set process to form the mixing gas; and enabling the mixing gas to flow out of the gas mixing pipes for burning. The burning heating equipment adopts the burner of the invention. The technical scheme provided by the invention improves the mixing effect of the fuel gas and air in the mode of burning after mixing, thereby improving the thermal efficiency and reducing the energy consumption and the environmental pollution.

Owner:原所良

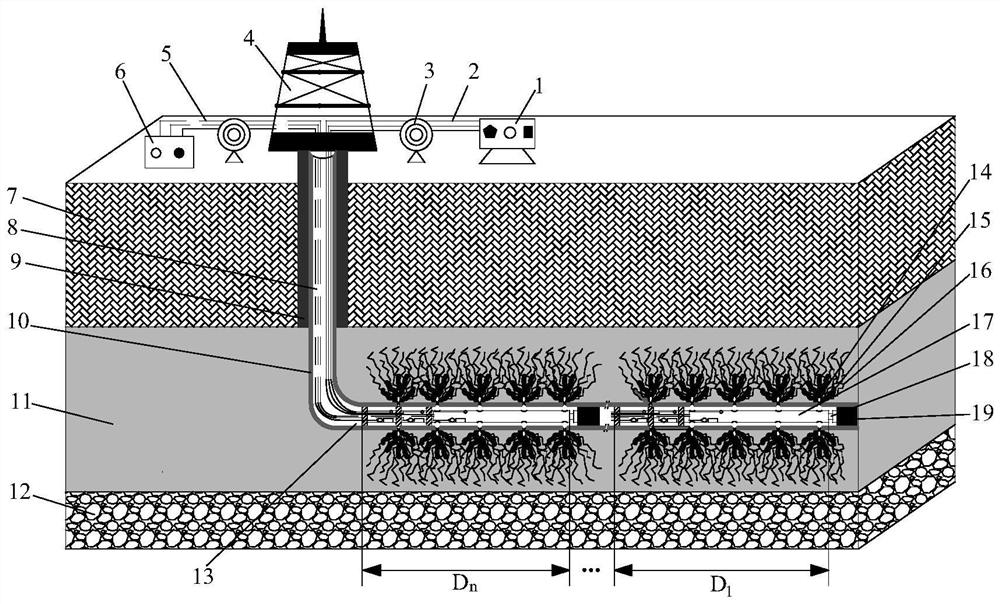

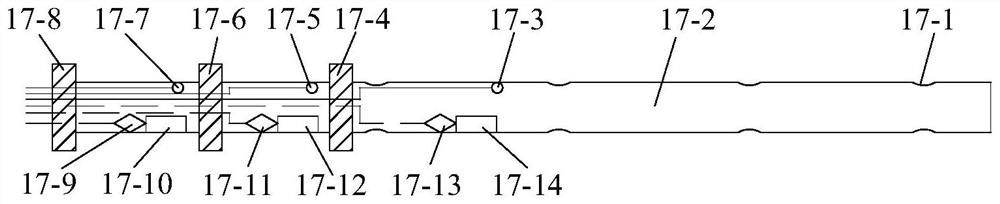

Shale reservoir methane in-situ multi-stage pulse energy-gathering blasting fracturing method

ActiveCN112878973AReduce pollutionRealize relay-type deep penetration and large-scale seam creationFluid removalDirectional drillingThermodynamicsHorizontal wells

The invention relates to a shale reservoir methane in-situ multi-stage pulse energy-gathering blasting fracturing method. The method is suitable for fracturing and permeability increasing of a deep shale reservoir to increase extraction of shale gas. A perforating gun is used for energy-gathered perforation to generate an energy-gathered slot in the well wall of a horizontal well, the position of an energy-gathered blasting pipe is adjusted to enable an energy-gathered hole to correspond to the energy-gathered slot, after in-situ desorption methane of a shale reservoir reaches the blasting concentration, ignition is carried out to release a combustion improver, first-stage blasting fracturing is carried out through high-temperature and high-pressure gas generated by synergistic blasting of the combustion improver and methane gas, and then methane continues to be desorbed to reach the blasting concentration, secondary ignition is carried out to release the combustion improver to carry out secondary blasting fracturing, multi-stage pulse energy gathering blasting fracturing is carried out on the shale reservoir in a circulating and reciprocating mode, the blasting-fracture mutual promotion fracture forming process is formed, and relay type deep-penetration large-range fracture forming is achieved. The method does not need to consume a large amount of water resources, desorbs methane in situ, does not have the processes of overground transportation, underground putting, mixing and the like, and has very obvious advantages of safety, economy and environmental protection.

Owner:CHINA UNIV OF MINING & TECH

Coal-based composite domestic fuel

InactiveCN103031163AEasy to ignitePromote atomizationLiquid carbonaceous fuelsFuel additivesPhosphoric acidEngineering

The invention relates to a clean fuel, in particular to a coal-based composite domestic fuel so as to solve the problem that existing domestic fuel oil has a lot of disadvantages. The composite domestic fuel is composed of light coal tar, methanol, a dispersing agent, a corrosion inhibitor, and a combustion-supporting agent. The light coal tar is the distillate distillated from coal tar during fractional distillation under a temperature below 280DEG C, and has a density of 0.91-0.99g / ml. The dispersing agent is any of polyisobutylene succinimide, phosphoric acid amide, alicyclic amine, and succinimide or a mixture of several of them in any proportion. The corrosion inhibitor is any of oleic acid glycol ester, N, N-bis(salicylidene)-propanediamine, benzotriazole, 2, 6-di-tert-butyl-p-cresol or a mixture of several of them in any proportion. The combustion-supporting agent is any of calcium naphthenate, magnesium naphthenate, iron naphthenate, and ferrocene or a mixture of several of them in any proportion. Being easy to ignite, the composite domestic fuel provided in the invention has good atomizing performance, more sufficient combustion, as well as higher thermal efficiency, the smoke blackness and other emission indexes all meet the requirements, and the economic effects are more significant.

Owner:山西佳新能源化工实业有限公司

Biomass fuel based on sepiolite powder combustion improver and preparation method thereof

InactiveCN105238484ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsSludgeCopper oxide

The invention discloses a biomass fuel based on a sepiolite powder combustion improver and a preparation method thereof. The biomass fuel based on the sepiolite powder combustion improver comprises the following components by dry weight: 50-65 parts of sawdust, 20-35 parts of straw, 25-35 parts of returned sludge, 5-15 parts of attapulgite clay, 1-10 parts of a fluxing agent, and 5-15 parts of the combustion improver. The combustion improver, comprises, by weight, 40-60 parts of sepiolite powder, 10-20 parts of activated carbon, 5-10 parts of magnesium oxide, 4-8 parts of lanthanum nitrate, 2-7 parts of potassium perborate, 8-15 parts of fluorite, 2-7 parts of sodium bichromate, 1-6 parts of acetone, 4-8 parts of copper oxide, 5-10 parts of magnesium oxide, and 5-10 parts of calcium permanganate. The biomass fuel provided by the has a combustion temperature up to 1410-1520DEG C, combustion efficiency increased by about 30% than ordinary biomass fuels, a calorific value up to 5100-5200 kcal / kg, combustion tail gas in line with the relevant provisions of the state, a sulfur removal rate up to 94.3%, and a nitrate removal rate up to 94.8%.

Owner:杨阳

Environmentally-friendly energy-saving combustion improver for coal

The invention relates to an environmentally-friendly energy-saving combustion improver for coal, comprising the following components in parts by weight: 1-50 parts of sodium chloride, 20-60 parts of sodium hydroxide, 20-60 parts of sodium carbonate, 20-50 parts of potassium carbonate, 20-40 parts of potassium nitrate, 15-60 parts of manganese dioxide, 25-75 parts of barium hydroxide, 30-80 parts of nickel oxide, 20-60 parts of magnesium sulphate, 50-100 parts of magnesium nitrate, 30-80 parts of strontium hydroxide and 30-50 parts of calcium carbonate. Multiple tests show that: combustion time of coal is prolonged, the coal can be completely combusted, and ignition temperature is reduced, thus the coal is difficult to coke, coked substances in a container are eliminated, and dust and smoke are eliminated and desulphurization is carried out, thus the coal is fully burned, the thermal efficiency is improved, non-metallic elements such as sulphur in the coal burning are effectively deposited into the coal, emission of harmful gas in acid gases such as nitric oxide and sulphur dioxide and the dust is reduced, and environmental pollution is reduced. Thus the aims of protecting the environment and saving energy sources are achieved. The environmentally-friendly energy-saving combustion improver is convenient, safe and reliable to use and has obvious economic benefit and social benefit.

Owner:张云佳 +1

Bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag

The invention discloses a bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag. The bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag comprises a furnace body and support bases arranged on the two ends of the furnace body. The outer wall of the furnace body is fixedly provided with rolling rings. The furnace body can be rotatably installed on the support bases through the rolling rings and is driven to rotate by a driving device. The top of the furnace body is provided with a smoke outlet opening, a first material-adding opening and a second material-adding opening from left to right in sequence. The lower part of a side plate of the right end of the furnace body is provided with a slag-discharging opening. A reducing spraying gun device is arranged at the bottom, under the first material-adding opening, of the furnace body. A heating spraying gun device is arranged below the second material-adding opening. The heating spraying gun device is located on the side wall of the furnace body and arranged close to the slag-discharging opening. According to the bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag, fuel and combustion improver are sprayed from a heating spaying gun into a slag layer of a molten pool, on the one hand, lead oxide of the slag layer is further subjected to reduction reaction, the lead content rate of the slag is decreased, and the direct recovery rate of lead is increased; and on the other hand, the temperature of the slag layer of the molten pool is improved, the slag is conveniently discharged, meanwhile, the distance of the spraying gun and the slag-discharging opening is shorted, the temperature of the molten poll is reduced, and the consumption of energy is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

Blast furnace coal injection combustion improver and use method thereof

ActiveCN104087692ALower ignition pointImprove combustion efficiencySolid fuelsBlast furnace detailsCokeAluminium powder

The invention belongs to the technical field of metallurgical industry and discloses a blast furnace coal injection combustion improver and a use method thereof. The blast furnace coal injection combustion improver comprises aluminum powder with activated aluminum being not less than 95wt%. According to the use method of the blast furnace coal injection combustion improver, the usage amount of a fire retardant accounts for 0.065%-0.10wt% of raw coal. According to the invention, the aluminum powder is adopted as the blast furnace coal injection combustion improver, the aluminum powder is mixed with the raw coal to prepare powder and then the powder is injected into a blast furnace for combustion to accelerate the oxygen diffusion velocity of coal powder and promote the macromolecule cracking of blast furnace coal injection coal powder, so that the purposes of lowering a coal powder ignition point and increasing the combustion efficiency of the coal powder positioned in front of a blast-furnace tuyere are reached, and the usage cost of the combustion improver disclosed by the invention is reduced to 3.23-2.07 yuan / ton of iron from about 5.13-6.17 yuan / ton of iron of the traditional rare earth combustion improver; the blast furnace coal injection combustion improver disclosed by the invention has the characteristics of no alkali metal, stable combustion-supporting effect and safe and reliable use and can effectively enhance the coal ratio of the blast furnace, reduce the coke ratio, increase the output and lower the addition cost, thus effectively increasing the integral economic benefit of blast furnace coal injection.

Owner:WUKUN STEEL

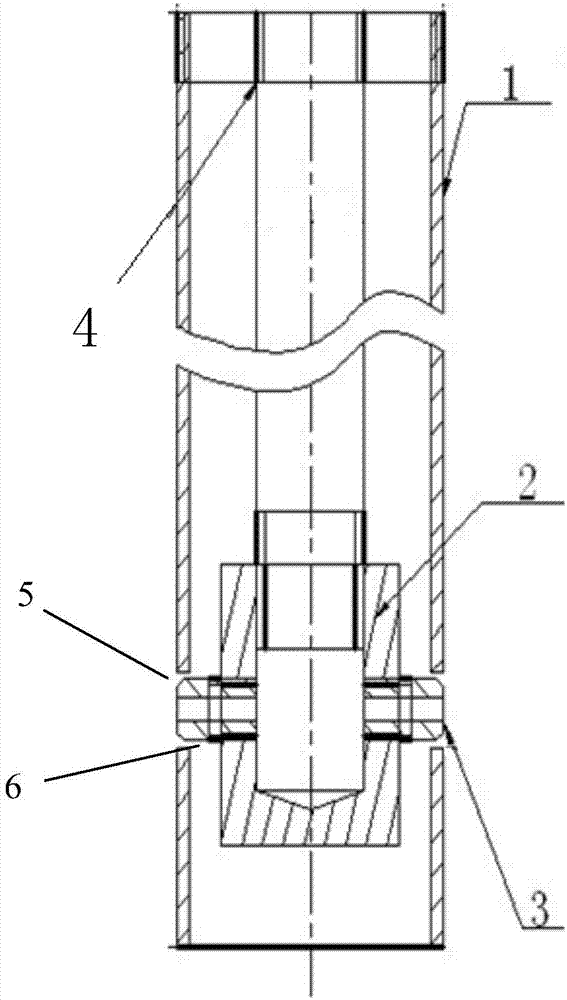

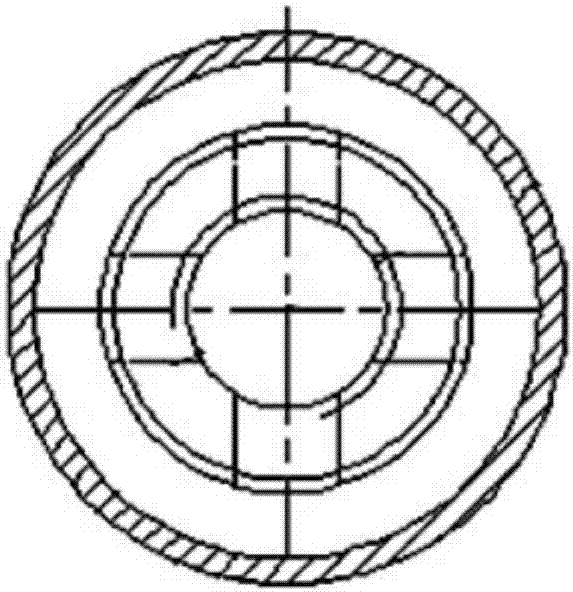

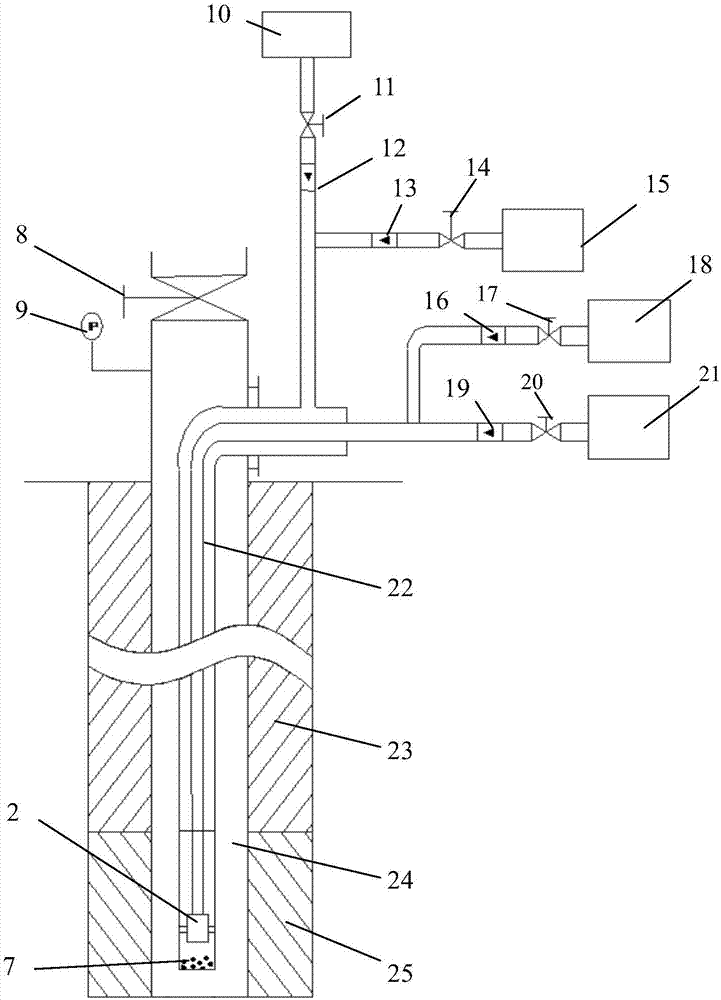

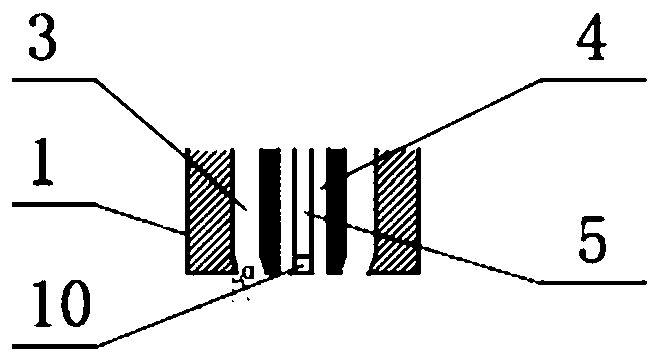

Underground coal gasification deep hole ignition system and method

ActiveCN107461189ARealize underground gasification deep hole ignitionAvoid the problem of easy drilling pluggingConstructionsCoal gasificationParaffin waxEngineering

The invention discloses an underground coal gasification deep hole ignition system and method. The system is characterized in that one end of a double-sleeve gas conveying pipe extends out of an ignition hole, the outer pipe of the end is connected with an oxygen supply device and / or an air supply device, and the inner pipe of the end is connected with a spontaneous-combustion-agent conveying device and a combustion-supporting-agent conveying device; an ignition device comprises an outer sleeve, an inner sleeve, a nozzle seat and at least three ignition nozzles, the outer sleeve and the inner sleeve are respectively connected with the outer pipe and the inner pipe of the double-sleeve gas conveying pipe, and the lower portion of the inner sleeve is fixedly connected with the nozzle seat; the circumferential direction of the inner sleeve is provided with threaded through holes which are arranged in an equal-distance manner and are adaptive to the ignition nozzles in number and position, and one end of each ignition nozzle is mounted at the corresponding threaded through hole; a corresponding hole is formed in a position, corresponding to the position of the other end of each ignition nozzle, of the outer sleeve, and a gap is formed between each hole and the end face of the corresponding ignition nozzle; the bottom of the outer sleeve is sealed, and metallic sodium wrapped by paraffin is placed at the bottom of the outer sleeve; the top of the ignition hole is selectively sealed by a pipeline, and the pipeline is provided with a pressure gauge and a valve.

Owner:天津市地质研究和海洋地质中心 +1

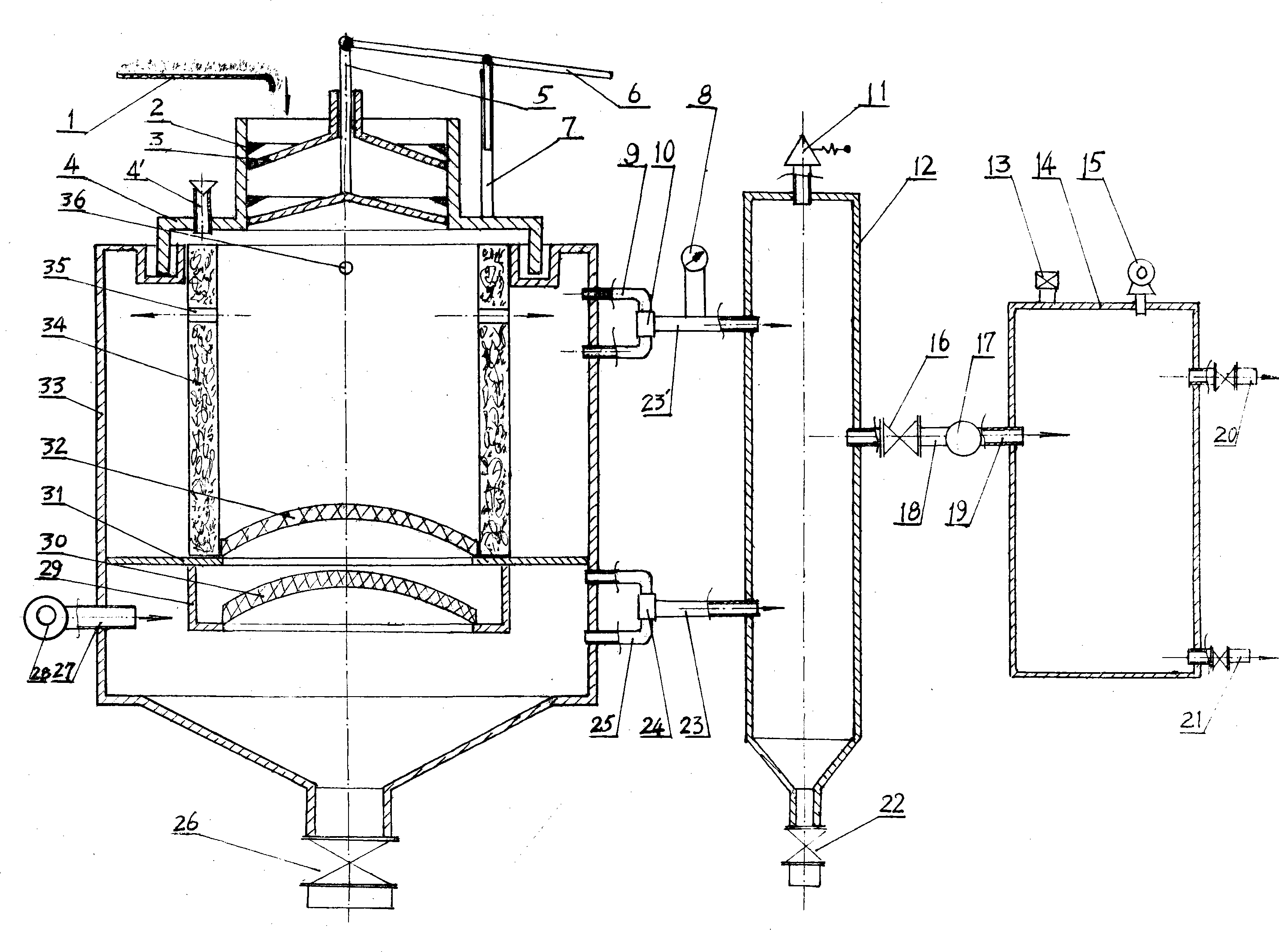

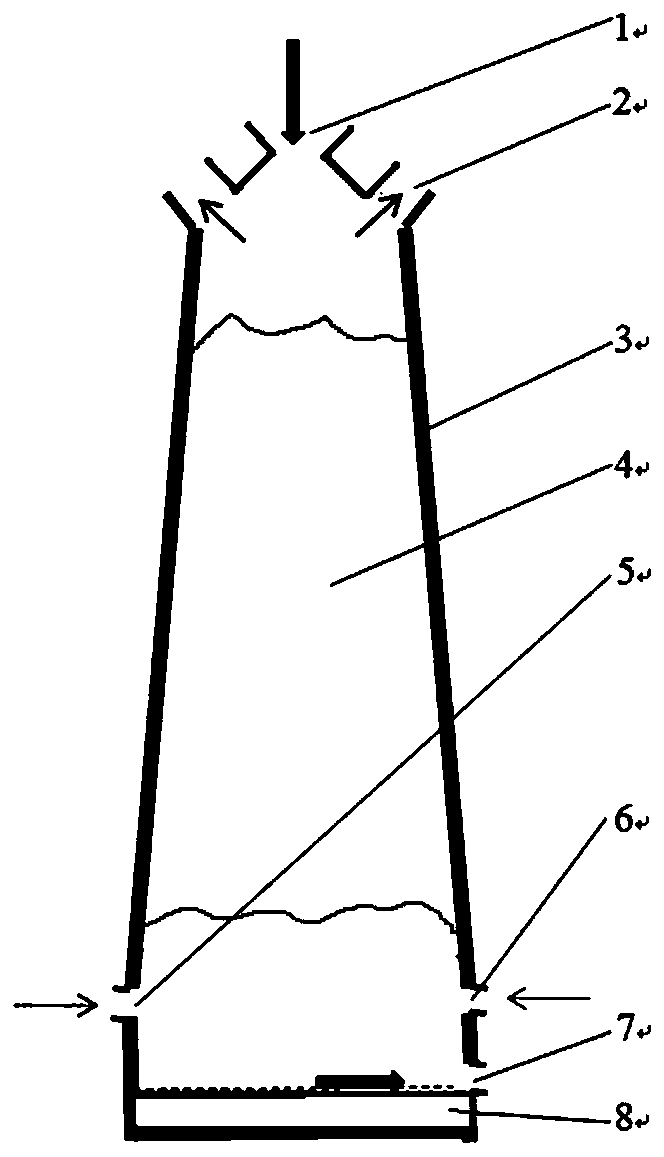

Mechanical stream-handing gasification furnace and used raw material

The invention discloses a mechanical continuous feeding gasification furnace which uses spherical or rod lump material products which are mixed and compacted by humic acid soil or mixed split coal or washing coal rock refuse which takes up 80 to 89 percent of the total weight, a combustion improver which takes up 1 to 5 percent of the total weight, a catalyst which takes up 4 to 9 percent of the total weight and water which takes up about 5 to 10 percent of the total weight as raw materials; separators and supported slabs of an inner cavity of a furnace body are provided with an arc flame bridge with rough holes and pores, a tube which can be flexibly replaced is put on the separator, a flume on the top of the furnace body is provided with an explosion proof cover which is provided with a double-layer bell in the middle, a filtering bucket beside the furnace body is connected with an air inlet pipe, and a valve and connecting pipe are used for connecting the filtering bucket and a pressurizing tank, a gas piping of which can send the produced flammable gas to users. The method uses humic acid soil or mixed split coal in coal mines or washing coal rocks which are left after steam coal or melting coal being washed by coal washers as raw materials to produce civil gas, which fully utilizes natural resources and has great economical and environment-protection benefit and popularization value.

Owner:戴太才

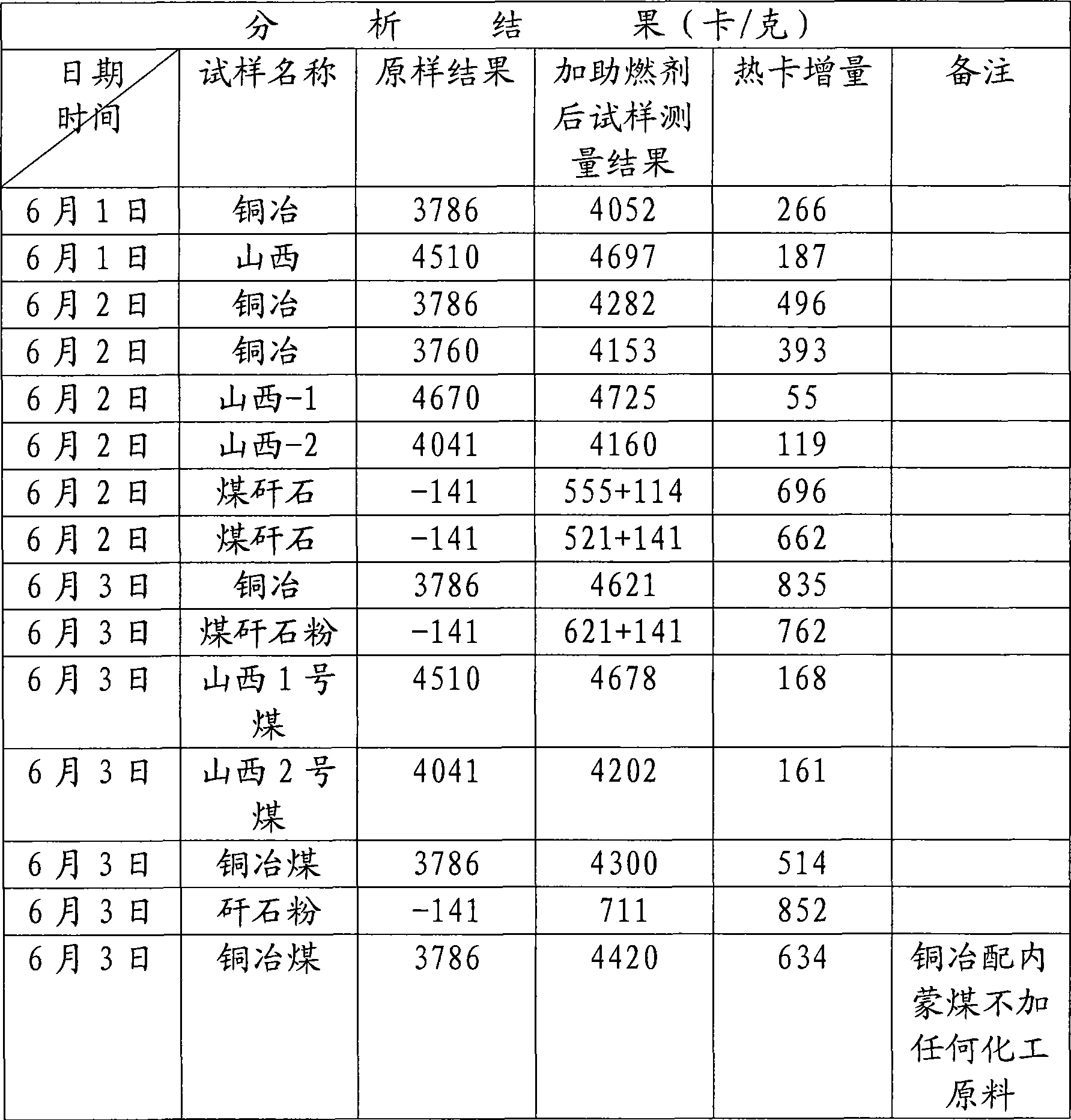

Environment-friendly fire coal combustion improver

InactiveCN104357124AAchieve recyclingRealize comprehensive utilizationSolid fuelsAdhesiveDust control

The invention relates to an environment-friendly fire coal combustion improver. According to the combustion improver, calcium carbide waste residues, iron mineral powder, coal ash, certain chemical plant waste liquids and the like are taken as efficient composition of the fire coal combustion improver, and the fire coal combustion improver is prepared by blending the efficient composition with a few quantity of strong oxidants, catalysts, adhesives, swelling agents, rare earth compounds and the like. The main technical formula of the fire coal combustion improver is characterized by comprising components in percentage by mass as follows: 20%-40% of calcium carbide waste residues, 20%-40% of iron mineral powder, 10%-20% of coal ash, 20%-30% of alkaline plant waste liquids, 0.5%-2% of potassium permanganate, 5%-10% of sodium chloride, 0.05%-0.2% of cerium oxide and 0.2%-0.4% of fatty alcohol-polyoxyethylene ether. 2%-10% of the environment-friendly fire coal combustion improver is added and matched with raw coal for use, the sulfur fixation rate is higher than 60%, and the theoretical coal-saving rate can be 10%-25%; the fire coal combustion improver can be matched with inferior coal such as coal gangue and the like, the problems of high combustion point and insufficient combustion are solved, and combustion and utilization of inferior coal resources are reinforced; and certain industrially discharged solid waste is used as a combustion-supporting, sulfur fixation, nitrogen fixation, smoke prevention and dust control component of the combustion improver, and the environment-friendly fire coal combustion improver has very important practical significance in the aspects of energy saving and environmental protection.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

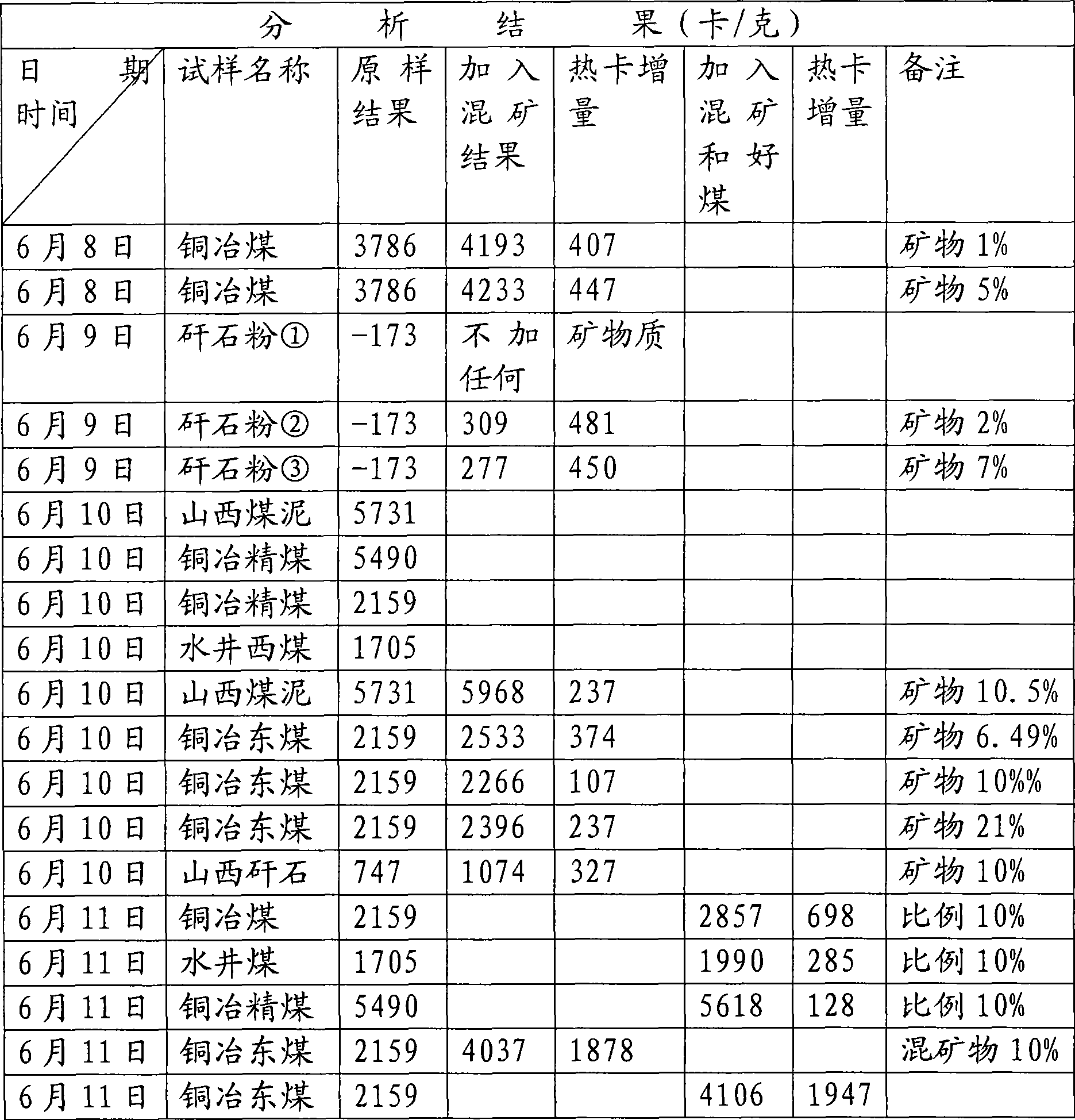

Nano ore coal combustion supporting additive, preparation and use as coal renewable energy source

The invention discloses a nanometer ore coal combustion-supporting additive, a preparation method thereof and application of the additive as renewable energy source of coal. The additive comprises the following raw material ores: 2 to 25 weight portions of saltpeter, 5 to 25 weight portions of marble, 5 to 25 weight portions of talcum, 5 to 20 weight portions of feldspar, 5 to 25 weight portions of picrite, and 1 to 10 weight portions of pyrolusite. The ores are subject to ultrafine grinding and are prepared into a coal combustion-supporting agent according to certain mixture ratio, and then the combustion-supporting agent is prepared into complex coal with coal gangue and coal according to the mixture ratio. The additive can ensure that 30 to 50 percent of standard coal is saved in the power generation industry and the cement industry, can reduce the discharge amount of sulfur dioxide and smoke dust, also reduce the environmental pollution of the coal gangue caused by land occupation spontaneous combustion at the same time, has good social benefit and economical benefit, meets the requirements of energy conservation, environmental protection and emission reduction, and is worthy to be promoted.

Owner:蒋凤亮 +2

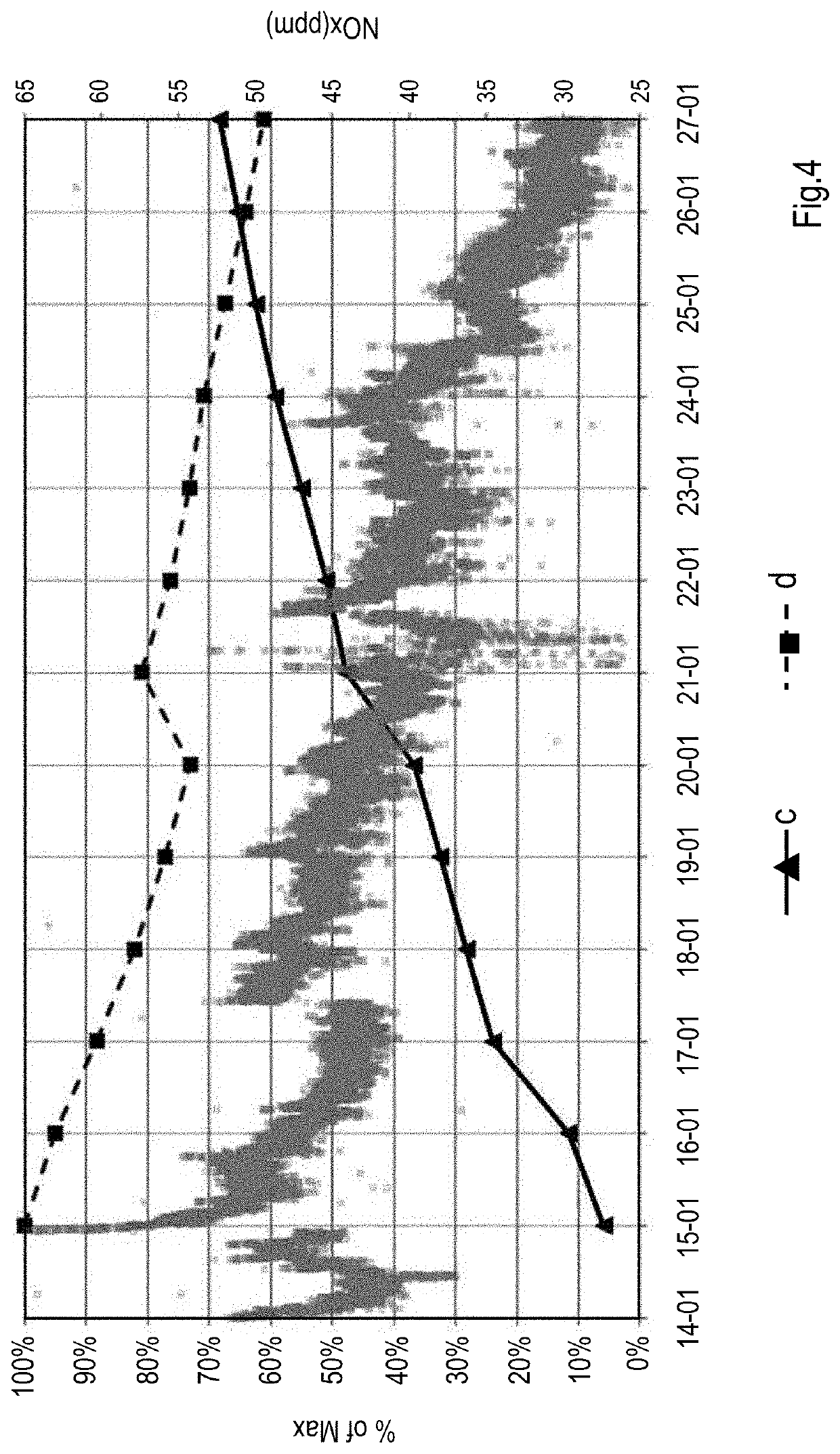

Method for regulating nitrous oxide recovery based on NO denitrification process

PendingCN111172197AReduce energy consumptionNo secondary pollutionNitrous oxide captureProductsN2O - Nitrous oxideNitration

The invention relates to a method for regulating nitrous oxide recovery based on a NO denitrification process. The gaseous pollutant NO is immobilized into a solution to form Fe (II) EDTA-NO in a complex state as a denitrification substrate, the yield of N2O in the reaction process is controlled by adjusting the addition amount of a carbon source, enrichment is achieved, and energy recovery in thedenitrification process is facilitated. Compared with the prior art, the method is simple in process, low in energy consumption and free of by-products, the conversion rate of Fe (II) EDTA-NO to N2Ois high and can reach about 0.45, and the obtained N2O gas can be used as an oxidizing agent, a combustion improver and the like.

Owner:TONGJI UNIV

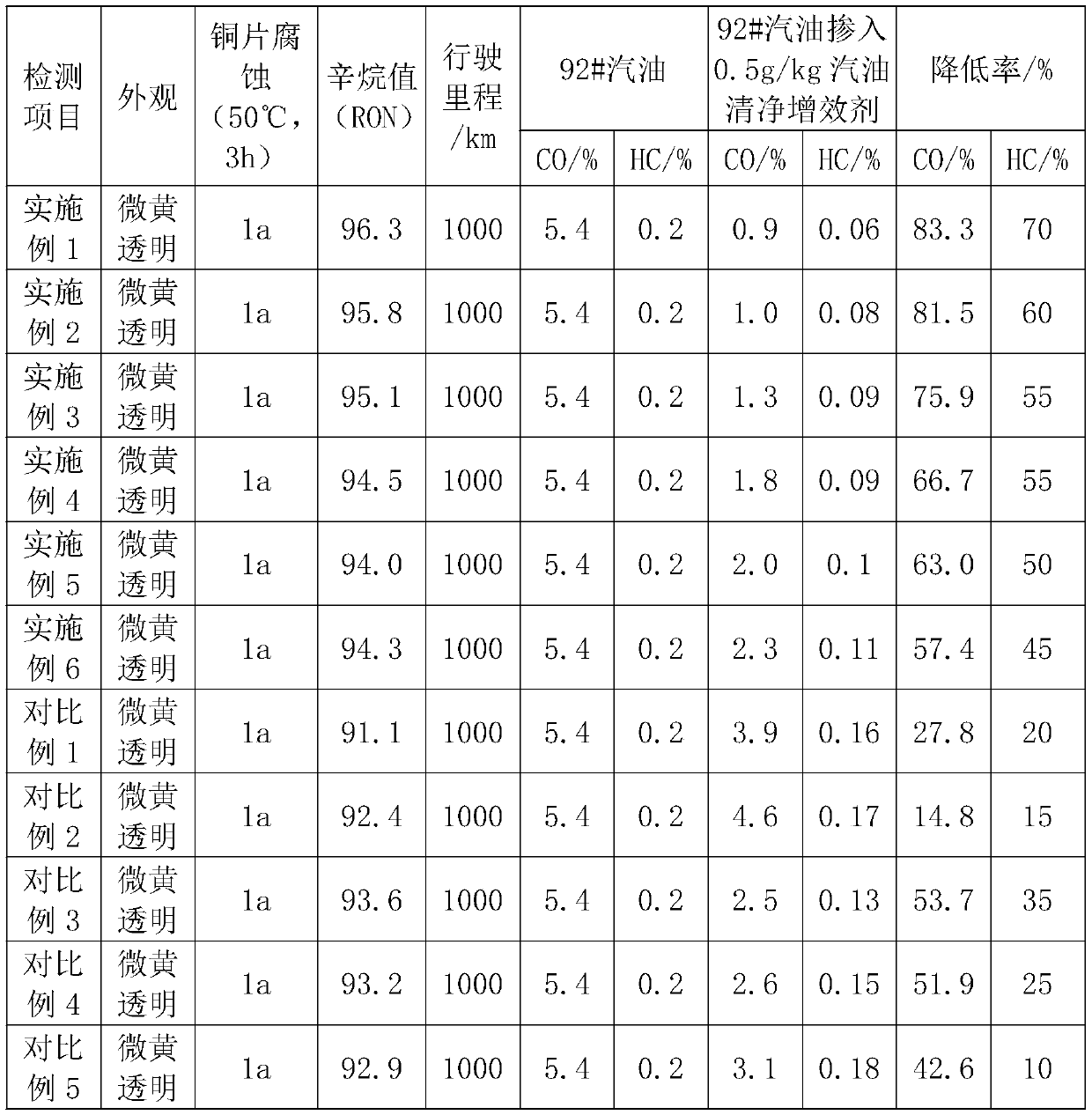

Gasoline cleaning synergist

InactiveCN110591778AGood dispersionStir wellLiquid carbonaceous fuelsFuel additivesMachine partsOil sludge

The invention relates to the technical field of gasoline synergist, in particular to a gasoline cleaning synergist. The gasoline cleaning synergist is prepared from the following raw materials in parts by weight: 10-25 parts of solvent oil, 10-25 parts of a plasticizer, 2-4 parts of a friction modifier, 35-45 parts of an oxidant, 4-6 parts of a lubricant, 8-12 parts of an improved cleaning dispersant and 0.1-0.4 part of a combustion improver. The gasoline cleaning synergist provided by the invention has a reasonable proportion. The gasoline cleaning synergist can adsorb generated small solid particles such as carbon deposits, paint films and the like to covert the generated small solid particles into a colloidal solution state to be dispersed in oil, so that the generated small solid particles are prevented from being further condensed into large particles to be adhered on machine parts and deposited into oil sludge; the gasoline cleaning synergist can wash down the paint films and carbon deposits adsorbed on surfaces of components and disperse the paint films and carbon deposits in the oil, so that engines and metal surfaces can be kept clean; combustion can be further promoted, emission of harmful gas can be reduced, and in particular emission of nitrogen oxides is reduced.

Owner:连云港爱华能源科技发展有限公司

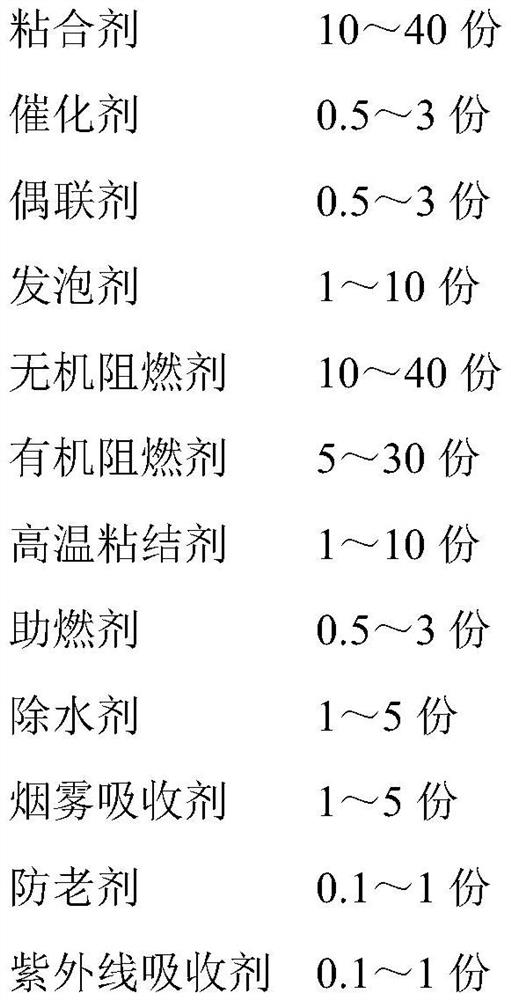

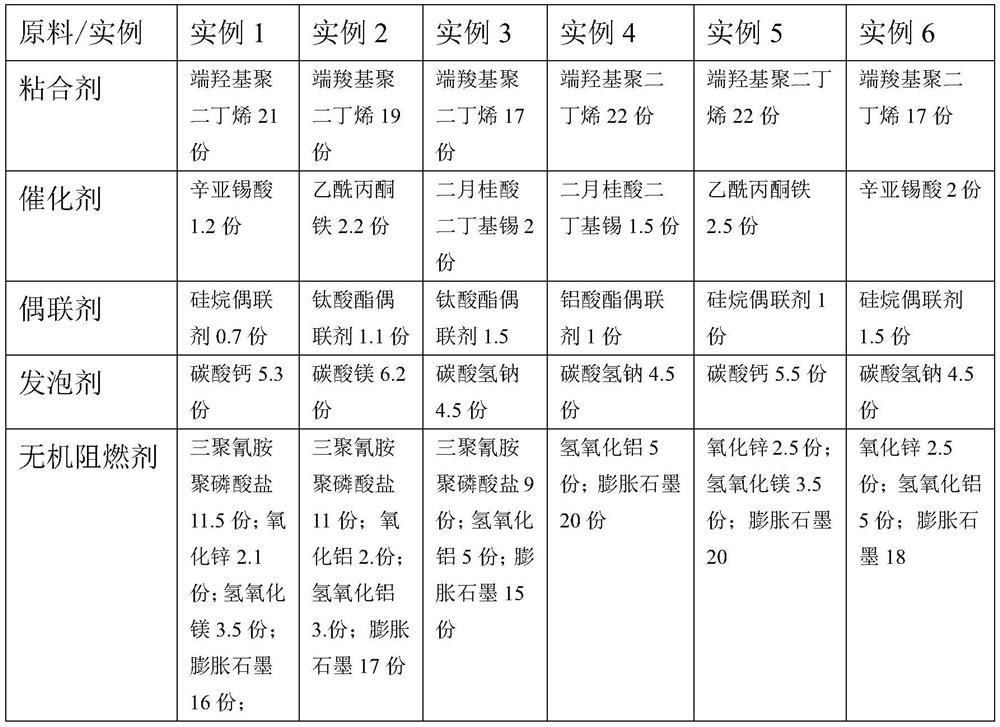

Intumescent flame-retardant heat-insulating fireproof coating and preparation method thereof

ActiveCN113122124ADelayed ignitionQuick releaseFireproof paintsAnti-corrosive paintsPtru catalystAdhesive

The invention relates to an intumescent flame-retardant heat-insulating fireproof coating and a preparation method thereof, the intumescent flame-retardant heat-insulating fireproof coating is formed by mixing a component A, a component B and an auxiliary agent, the component A comprises an adhesive, a catalyst, a coupling agent, a foaming agent, an inorganic flame retardant, an organic flame retardant, a high-temperature adhesive, a combustion improver, a water removal agent, a smoke absorbent, an anti-aging agent and an ultraviolet absorbent; the component B comprises a curing agent, a plasticizer and a chain extender; and the auxiliary agent is a diluent. The intumescent flame-retardant heat-insulating fireproof coating has the advantages that the intumescent flame-retardant heat-insulating fireproof coating is suitable for protection of various indoor and outdoor materials, particularly suitable for occasions with high fireproof performance requirements, such as electric power, information and petrochemical industries, can delay object ignition or reduce the combustion speed of a protected base material, can quickly release heat after the surface temperature of the intumescent flame-retardant heat-insulating fireproof coating exceeds 290 DEG C, a carbon flocculent isolation layer is formed through expansion, and conduction of the heat effect is isolated.

Owner:宋成镇

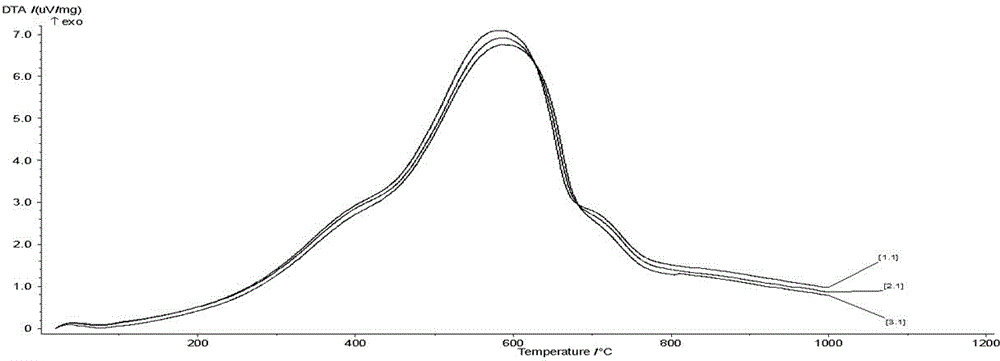

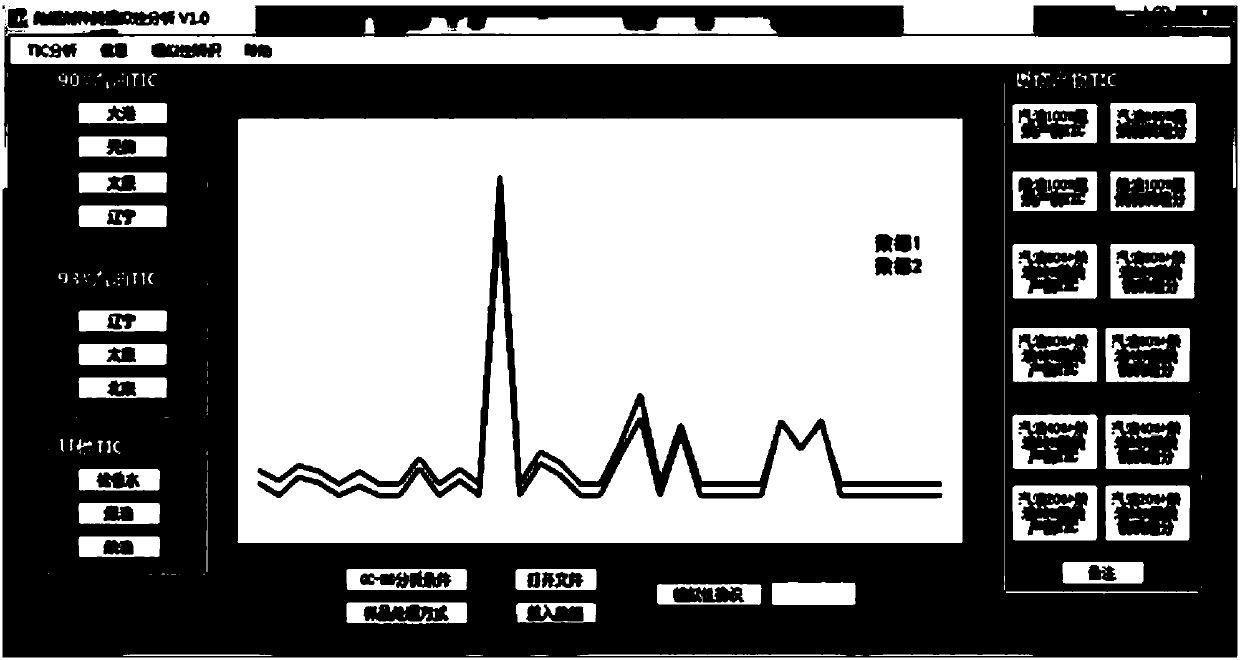

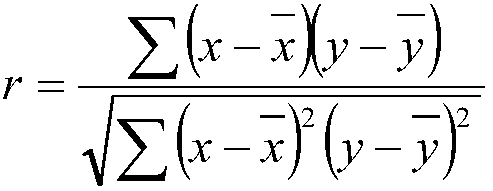

Method used for perform combustion improver kind similarity judgment using Pearson product-moment correlation coefficient (PPMC)

InactiveCN107677741AImprove accuracyComponent separationGas chromatography–mass spectrometryDecomposition

The invention discloses a method used for perform combustion improver kind similarity judgment using Pearson product-moment correlation coefficient (PPMC). The method is used for avoiding influences of the uncertainty and the randomness of artificial identification of chromatograms, and influences of combustible matters, and combustion or decomposition products of combustion improvers on spectrums, and providing reliable technical support for material evidence identification process of complex fire fields. According to the method, practical fire field environment is taken into consideration asfar as possible, gas chromatography-mass spectrometry (GC-MS) technology is adopted for detection of samples and samples containing combustion improvers; influences of combustible matters and combustion improver pyrolysis products on identification is taken into consideration; a combustion improver similarity analysis software is adopted for rapid identification. The method is rapid, is accurate,and is high in efficiency, is a simplified qualitative-and-quantitative method of similarity analysis of combustion improvers, and scientific reference execution standards and basis are provided forfire hazard investigation personnel.

Owner:UNIV OF SCI & TECH OF CHINA

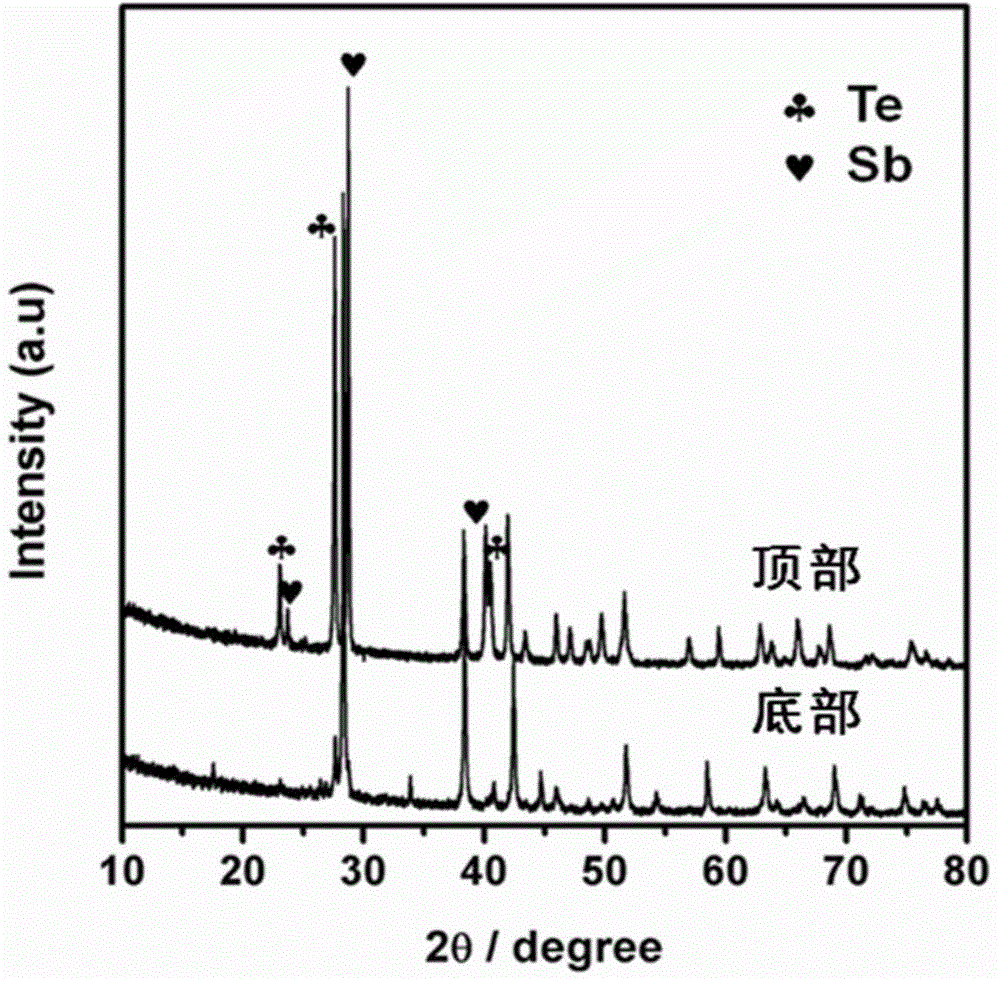

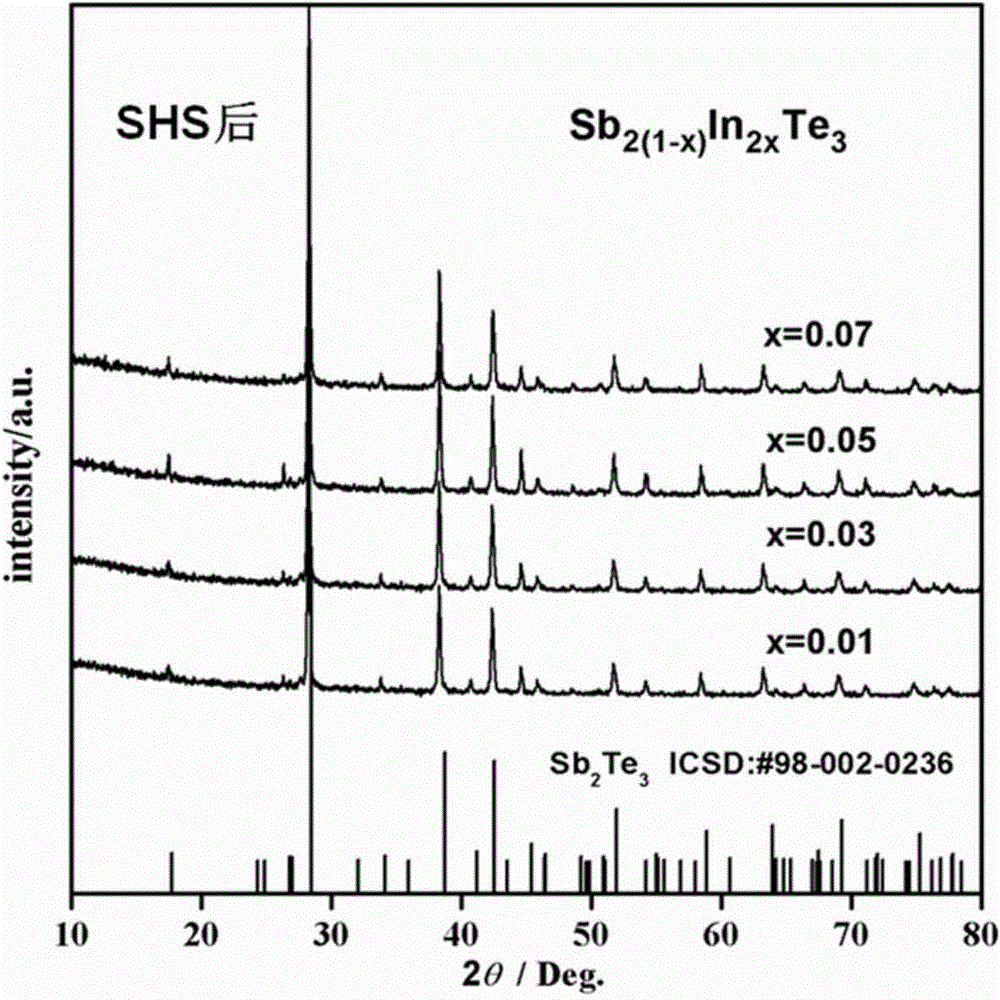

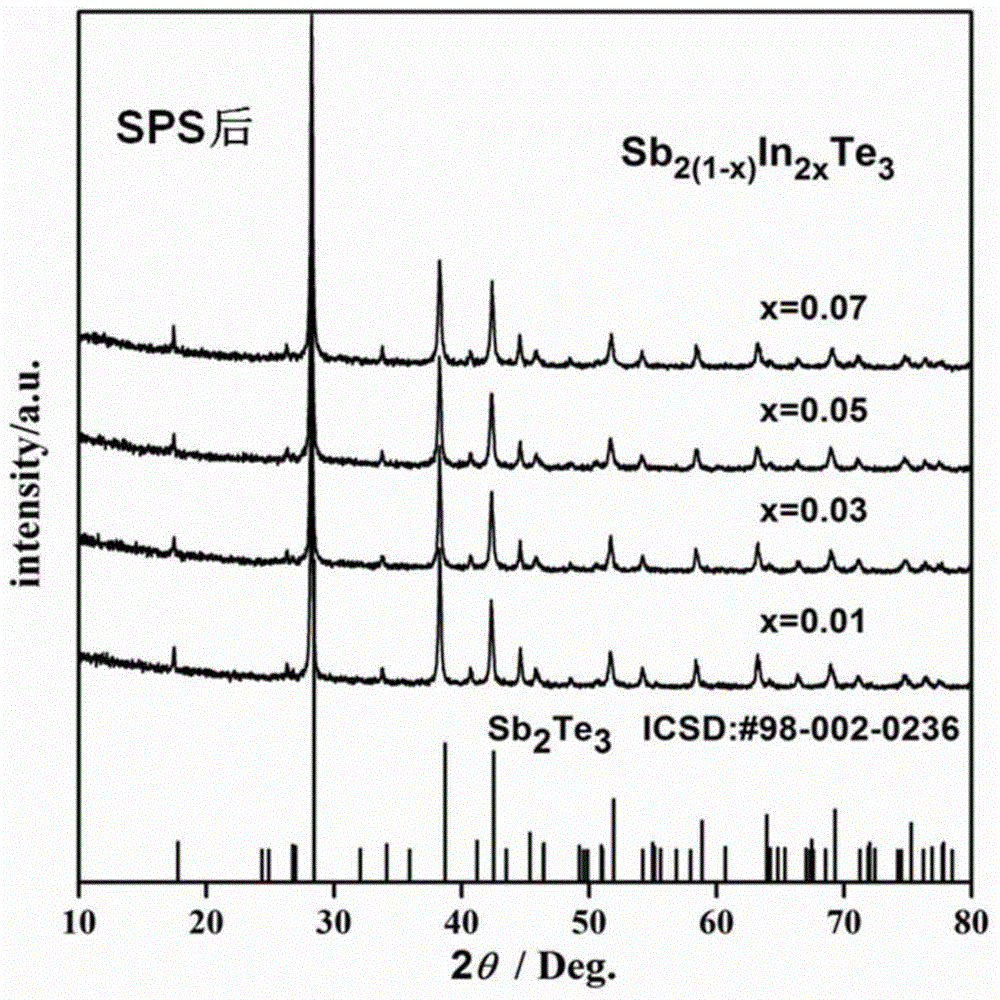

Self-propagating combustion synthesis method of Sb2Te3-base thermoelectric material and combustion improver thereof

ActiveCN104671222AImprove thermoelectric performanceShort preparation timeBinary selenium/tellurium compoundsThermoelectric materialsMetallurgy

The invention discloses a self-propagating combustion synthesis method of a Sb2Te3-base thermoelectric material and a combustion improver thereof. The synthesis method comprises the following step: by using Sb and Te simple substances as raw materials, carrying out self-propagating combustion synthesis reaction under the accelerating action of a combustion improver In simple substance to obtain the Sb2Te3-base thermoelectric material. The invention discloses a combustion improver In simple substance for synthesizing the Sb2Te3-base thermoelectric material by self-propagating combustion for the first time, which can accelerate the self-propagating combustion synthesis reaction of the raw material Sb and Te simple substances to generate the Sb2Te3-base thermoelectric material; and in combination with the discharge plasma sintering, a compact Sb2Te3-base block thermoelectric material can be prepared. The method enhances the pyroelectricity, has the advantages of ultrashort preparation time, simple technique, low facility request, energy saving, environment friendliness and the like, is suitable for large-scale production, and lays favorable foundation for scale-up preparation and large-scale application of the Sb2Te3-base thermoelectric material.

Owner:WUHAN UNIV OF TECH

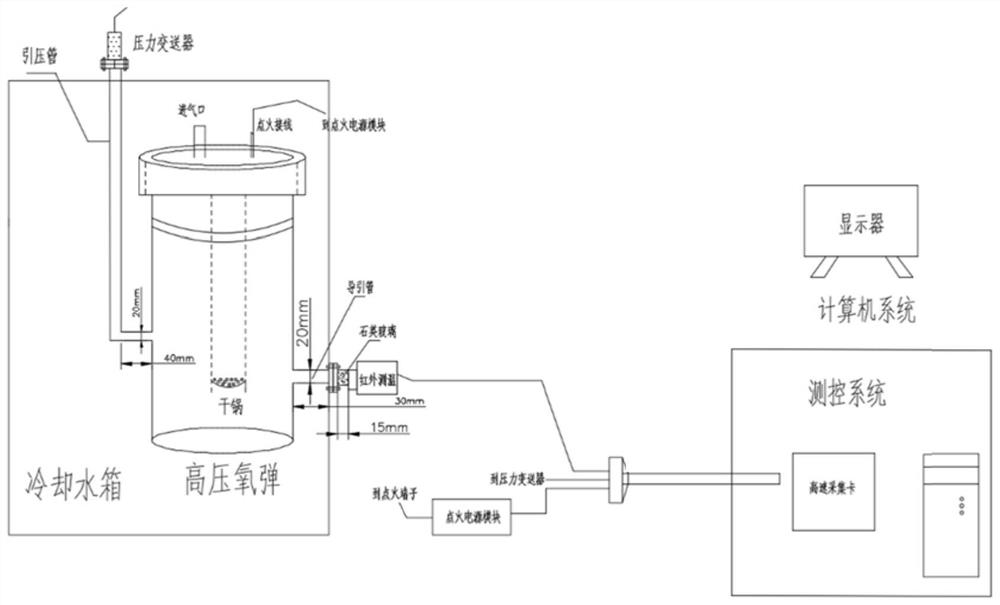

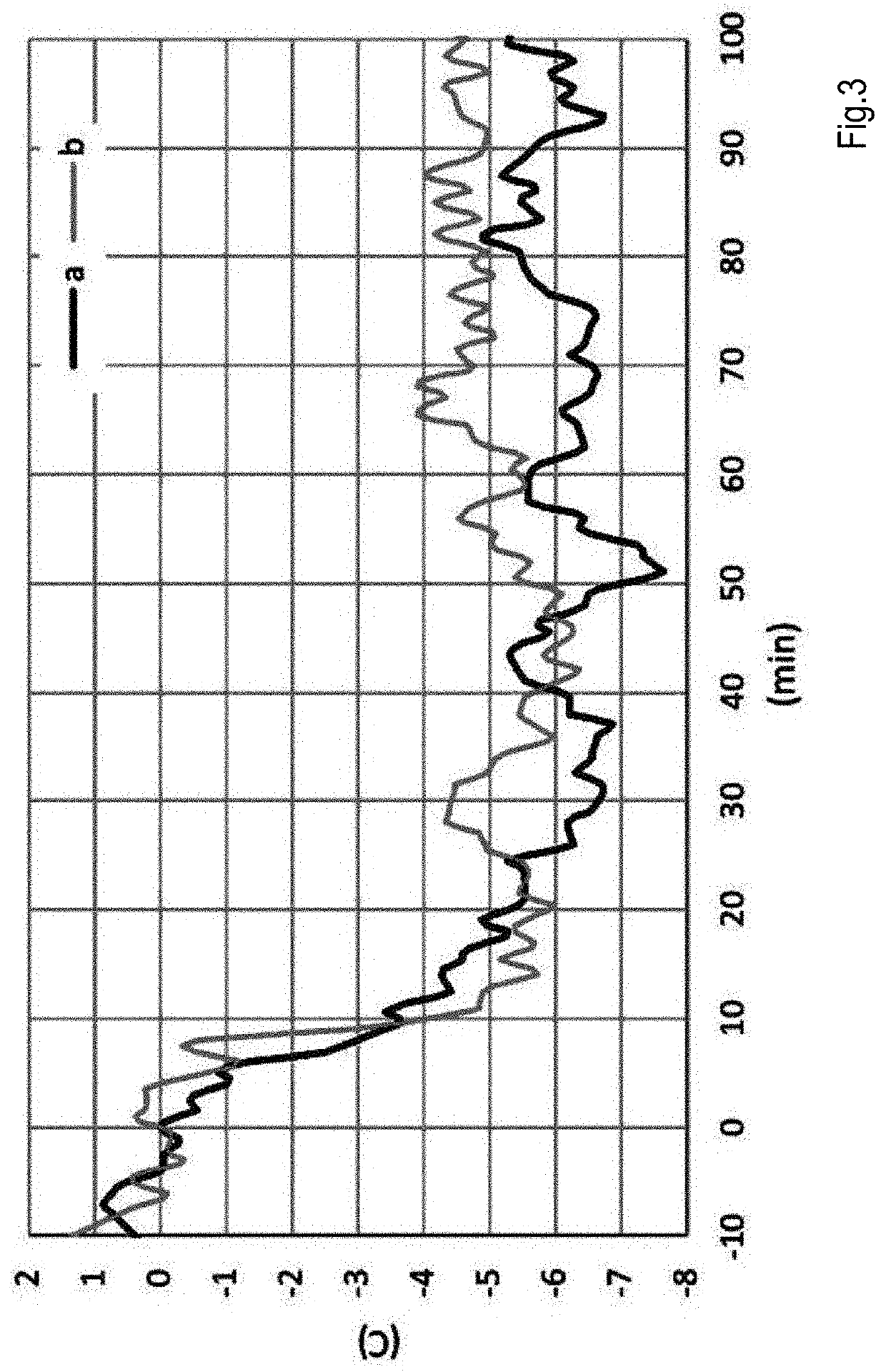

High-temperature and high-pressure testing system and method used in combustion process

PendingCN114252158AAccurate temperatureEasy to sampleThermometer detailsThermometers using electric/magnetic elementsEngineeringPressure data

The invention discloses a high-temperature and high-pressure testing system and method used in a combustion process, a high-pressure oxygen bomb is immersed in a cooling water tank, after a sample in the high-pressure oxygen bomb is combusted by an ignition device, a temperature measuring device and a pressure measuring device are respectively used for acquiring the temperature and the pressure of the sample in the combustion process; the temperature and pressure data are output to the measurement and control system; the measurement and control system is used for receiving and processing temperature and pressure data. When the temperature measuring device is an infrared thermometer, the infrared thermometer obtains the temperature of the flame center in the sample combustion process by detecting the temperature of the stand column in the crucible. The device is used for monitoring the real-time temperature and pressure in the sample combustion process to obtain the temperature-pressure change relation so as to determine the holding time of the sample at high temperature, can also be used for judging the accuracy of a combustion heat test, and is particularly suitable for combustion test when the sample is boron powder or a solid propellant. And a basic basis is provided for selecting proper combustion improver types, dosage, adding modes and the like to ensure complete combustion.

Owner:SHANGHAI AEROSPACE CHEM ENG INST

High-combustion-value biomass particle

InactiveCN106675694AFully contactedRelief of hypoxic conditionsBiofuelsSolid fuelsFurnace temperatureChloride

The invention relates to a high-combustion-value biomass particle, which is characterized by being prepared from the following components by weight percent: 30 to 50 percent of bark, 25 to 40 percent of straw, 20 to 45 percent of wood chips, and 2 to 5 percent of combustion-supporting agent. The heated potassium chlorate or potassium permanganate is subsequently decomposed by manganese dioxide to release oxygen, so that oxygen can be supplemented in the entire combustion process of the biomass fuel. The condition of partial hypoxia can be alleviated and the biomass fuel can be completely combusted. Magnesium chloride has the effect of bulking the biomass fuel and preventing coking, thus contributing to the full contact of oxygen with the biomass fuel and the complete combustion of the biomass. After the combustion-supporting agent is used, both the furnace temperature and thermal efficiency can be improved.

Owner:安徽润发生物能源科技有限公司

Anaerobic type household waste paralysis furnace

PendingCN110779020AWith removalUniform long-distance transportIncinerator apparatusCombustion chamberThermodynamics

The invention discloses an anaerobic type household waste paralysis furnace comprising a furnace body, a feeding device, a combustion supporting device, a combustion supporting agent spraying device and an exhaust device. The furnace body is composed of three layers of furnace bodies which are the heat preservation furnace body, the gas gathering furnace body and the paralysis body from outside toinside. An interlayer cavity is arranged between the heat preservation furnace body and the gas gathering furnace body. The interlayer cavity is divided by an upper heat insulation plate and a lowerheat guiding plate into an upper heat insulation chamber, a middle heat preservation chamber and a lower combustion chamber. A gas flow channel interlayer cavity is arranged between the gas gatheringfurnace body and the paralysis furnace body. The feeding device is fixed to an upper end opening of the paralysis furnace body. The combustion supporting device is fixed into the combustion chamber. The combustion supporting agent spraying device is fixed into the combustion chamber. The exhaust device communicates with the combustion chamber. Combustible gas and carbon generated by the paralysisbody releases heat in the combustion device by means of the combustion supporting device and the combustion supporting agent spraying device, and the heat is used for paralysis of the household waste.The exhaust device is used for conveying waste gas. The household waste undergoes paralysis by means of heat generated by the combustible gas and carbon, generated by the paralysis furnace body, in the combustion chamber, and therefore the utilization rate of the household waste is improved; and pollutants are combusted and decomposed, and therefore the secondary pollution problem can be avoided.

Owner:湖北中道环保科技股份有限公司

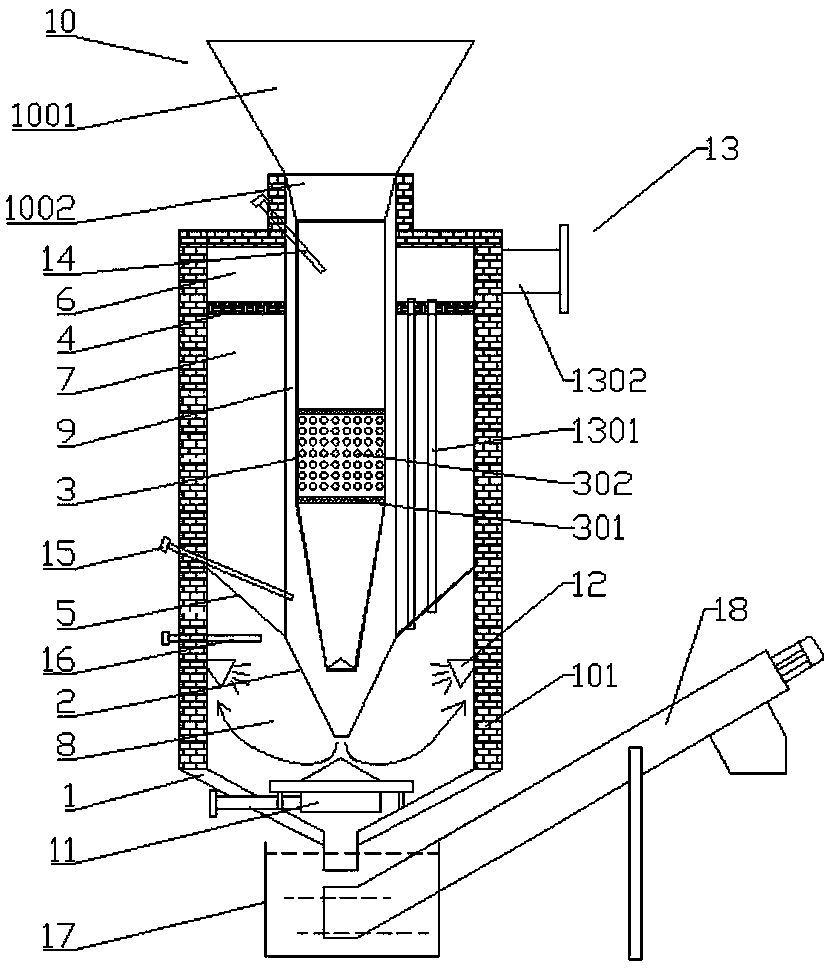

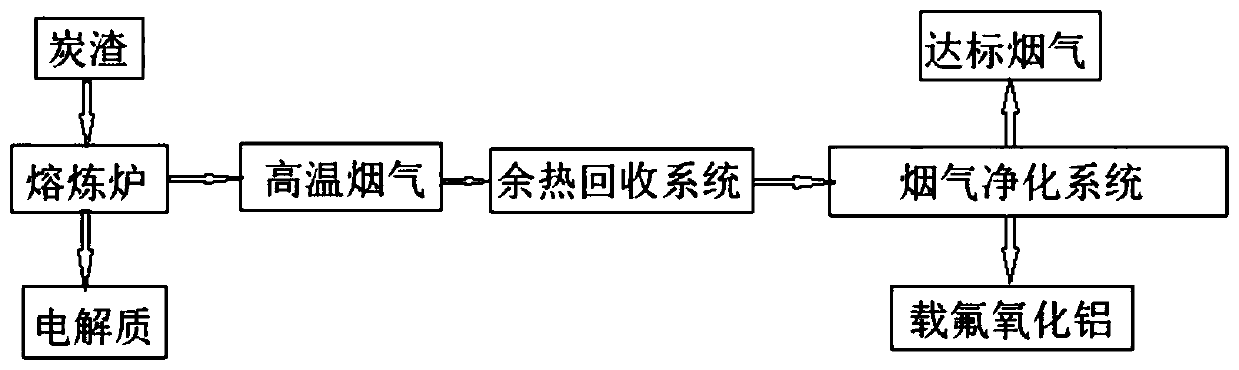

Smelting furnace and smelting method for recovering electrolyte from aluminum electrolysis carbon residues

InactiveCN111551027AGuaranteed service lifeReduce erosionCharge treatment typeCrucible furnacesAluminium electrolysisThermal insulation

The invention discloses a smelting furnace for recovering electrolyte from aluminum electrolysis carbon residues. The smelting furnace is a vertical smelting furnace and comprises a feed port, a fluegas outlet, a furnace body, a combustion improver adding port, a fuel adding port, an electrolyte overflow port and an electrolyte collecting tank at the bottom, wherein the feed port and the flue gasoutlet are located at the top position, the furnace body is located at the middle position, and the combustion improver adding port, the fuel adding port and the electrolyte overflow port are locatednear the bottom; and the furnace body comprises a cryolite layer, a corrosion-resistant layer, a refractory material layer, a thermal insulation material layer and a steel plate from inside to outside. According to the smelting furnace for recovering the electrolyte from the aluminum electrolysis carbon residues, the carbon residues and hot gas flow make reverse contact in the smelting furnace, so that the reaction area is increased, and the processing efficiency is improved; the electrolyte contained in the carbon residues is melted by utilizing the calorific value of the carbon residues, and meanwhile, process parameters can be adjusted according to different components of the carbon residues, so that process control is convenient; and the high-melting-point cryolite protective layer isformed on the inner wall of the smelting furnace in the operation process, so that corrosion of reaction materials to a furnace body lining is reduced, and the service life of the smelting furnace isguaranteed.

Owner:中铝郑州有色金属研究院有限公司

Method for reproducing compound leadless gasolin using emulsified compound leadless gasolin

InactiveCN1955265AAvoid wastingImprove evaporation effectLiquid carbonaceous fuelsHydrocarbon oils refiningIsobutanolOxidation resistant

This invention discloses a reproduction method of compound lead-free gasoline from emulsifying compound lead-free gasoline. This new compound lead-free gasoline is produced by blending isobutanol, ethylene glycol monobutyl ether, emulsifying stratified compound lead-free gasoline, additives, aviation kerosene, gasoline produc, light oil, methanol, modified alcohol and benzene according to a certain proportion and order. The additive is prepared with zinc oxide, oxidation-resistant, metal deactivator, colorant, smoke-reducing and fuel combustion improver according to a proportion. This invention avoids wasting emulsifying compound lead-free gasoline and changes it into a new gasoline which also has the merits of lead-free, environmental protective, good evaporating and antidetonate property, good stability and anticorrosion property and low cost.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Efficient pyrolysis garbage incinerator

ActiveCN112856437AShorten the timeFix slow responseBlast-producing apparatusAir/fuel supply for combustionAir volumeDrive shaft

The invention discloses an efficient pyrolysis garbage incinerator. The efficient pyrolysis garbage incinerator comprises an incinerator body, an air blower is welded to the right side of the incinerator body, a combustion-supporting pipe is welded to the front face of the incinerator body, the incinerator body comprises a reciprocating mechanism, and the bottom of the reciprocating mechanism is movably connected with a driving mechanism. According to the efficient pyrolysis garbage incinerator, a downward-pressing rotating disc is installed inside the incinerator body, when a driving shaft rotates, the air blower blows out mixed gas of a combustion improver sprayed out of the combustion-supporting pipe and air from an air pipe through a gas guide pipe, under the reversing effect of a reversing pipe, the mixed gas is sprayed downwards, mixed gas at the bottom is sprayed upwards, the driving shaft and the rotating disc form an eccentric mechanism due to the fact that an extrusion spring pushes out a limiting pin, the volumes of air entering the air pipe in unit time are different, a rotating speed difference exists between the downward-pressing rotating disc and a driving rotating disc all the time, the mixed gas and to-be-incinerated objects are fully mixed in combination with a stirring mechanism, and therefore the incineration efficiency is improved, and the problem that incinerated objects close to the middle of a traditional incinerator are not easy to incinerate is solved.

Owner:北京碧海能源装备有限公司

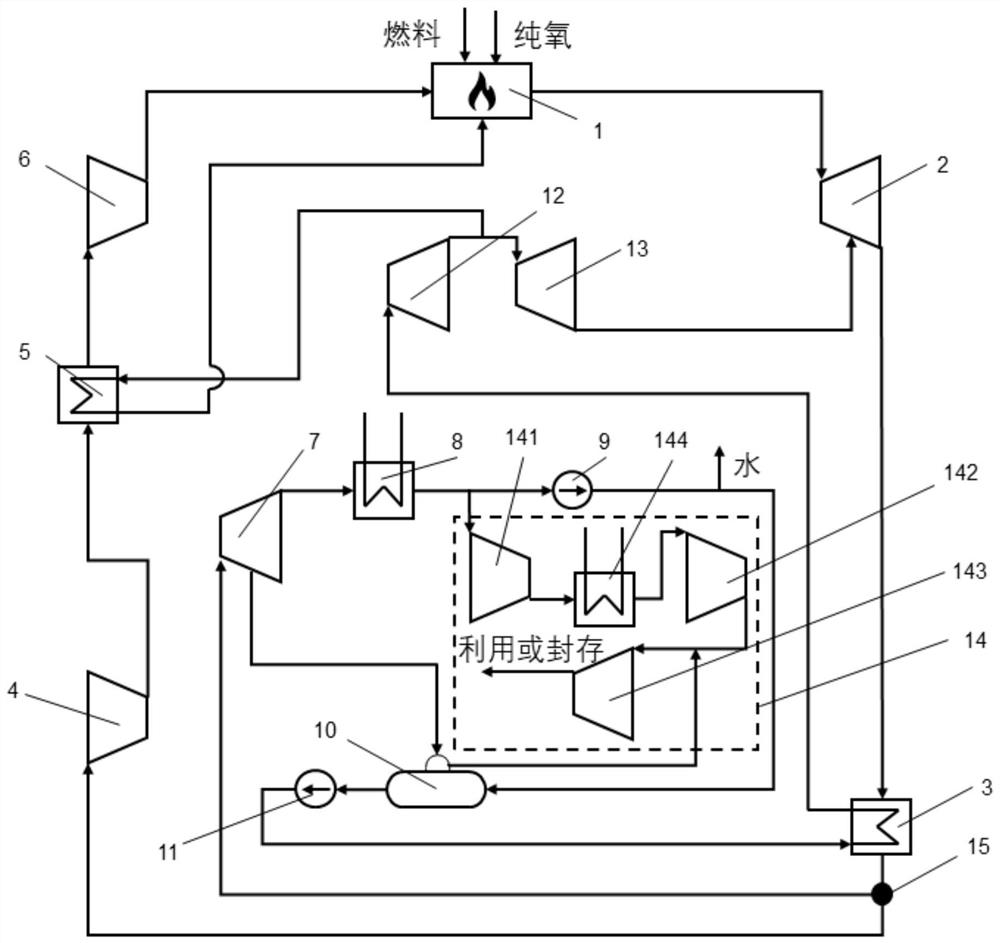

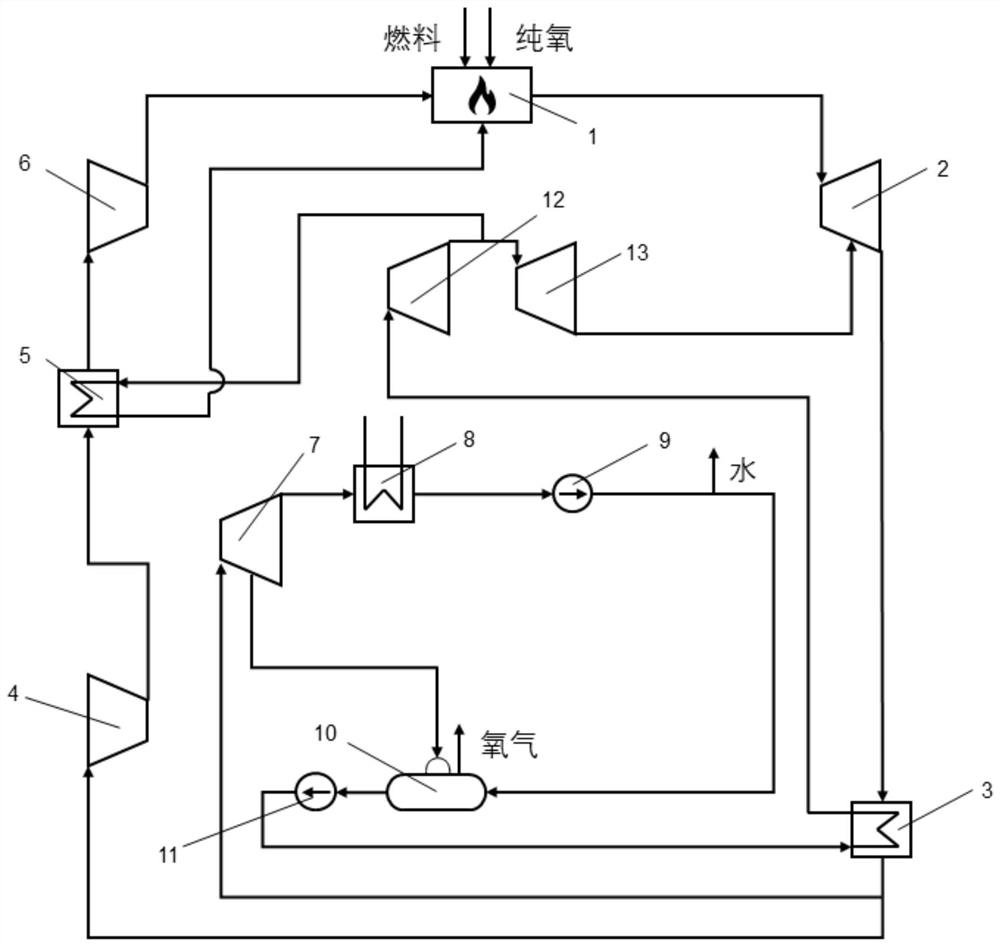

Split-flow recompression pure oxygen combustion circulation system

ActiveCN114382562AImprove utilization efficiencyReduce heat lossInternal combustion piston enginesSteam engine plantsCombustion chamberIntercooler

According to the split-flow recompression pure oxygen combustion circulation system with pure oxygen as the combustion improver, a combustion chamber, a gas turbine, a waste heat boiler, a first low-pressure compressor, a first intercooler and a first high-pressure compressor are sequentially connected in series, and a low-pressure steam turbine, a condenser, a condensate pump, a deaerator and a water feeding pump are sequentially connected in series. The hot end outlet side of the waste heat boiler is connected with the high-temperature inlet side of the low-pressure steam turbine and the inlet side of the first low-pressure compressor, so that working media flowing out of the hot end outlet side of the waste heat boiler are divided, and the liquid outlet side of the water feeding pump is connected with the cold end inlet side of the waste heat boiler. A high-pressure steam turbine is arranged between the cold end outlet side of the waste heat boiler and the inlet side of the combustion chamber, the low-temperature outlet side of the high-pressure steam turbine is connected with the cold end inlet side of a first intercooler and a gas turbine, and the cold end outlet side of the first intercooler is connected with the inlet side of the combustion chamber. The hot end inlet side is connected with the outlet side of the first low-pressure compressor, and the hot end outlet side is connected with the inlet side of the first high-pressure compressor.

Owner:TSINGHUA UNIV

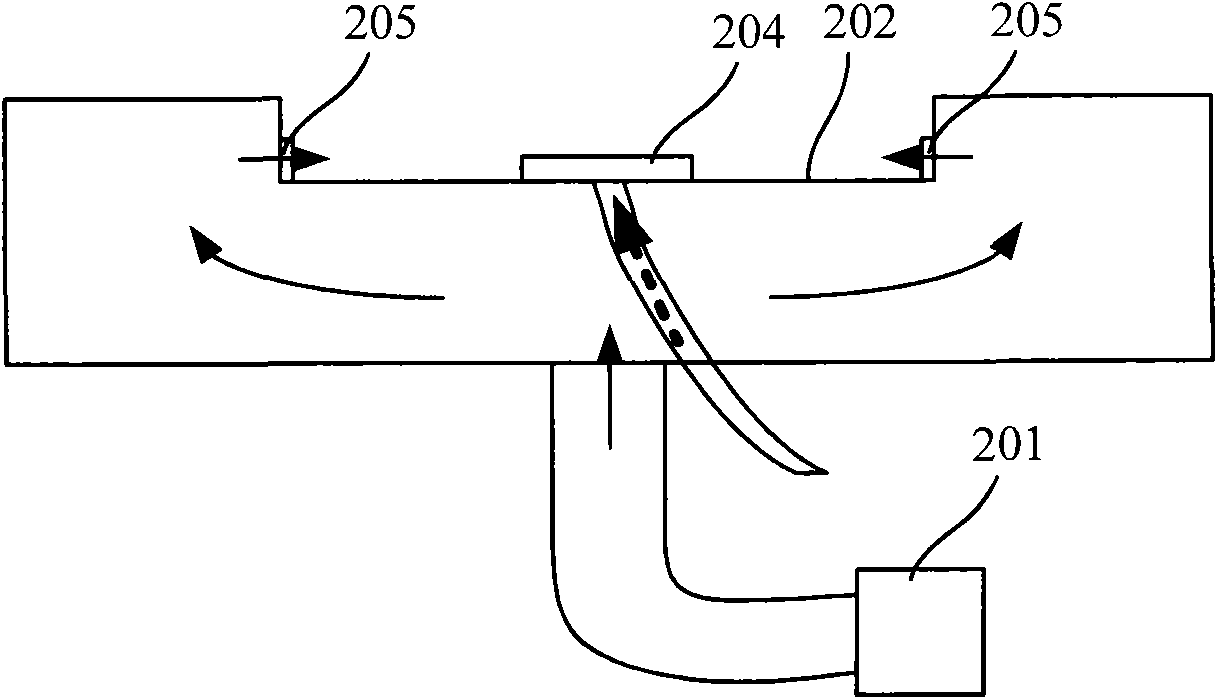

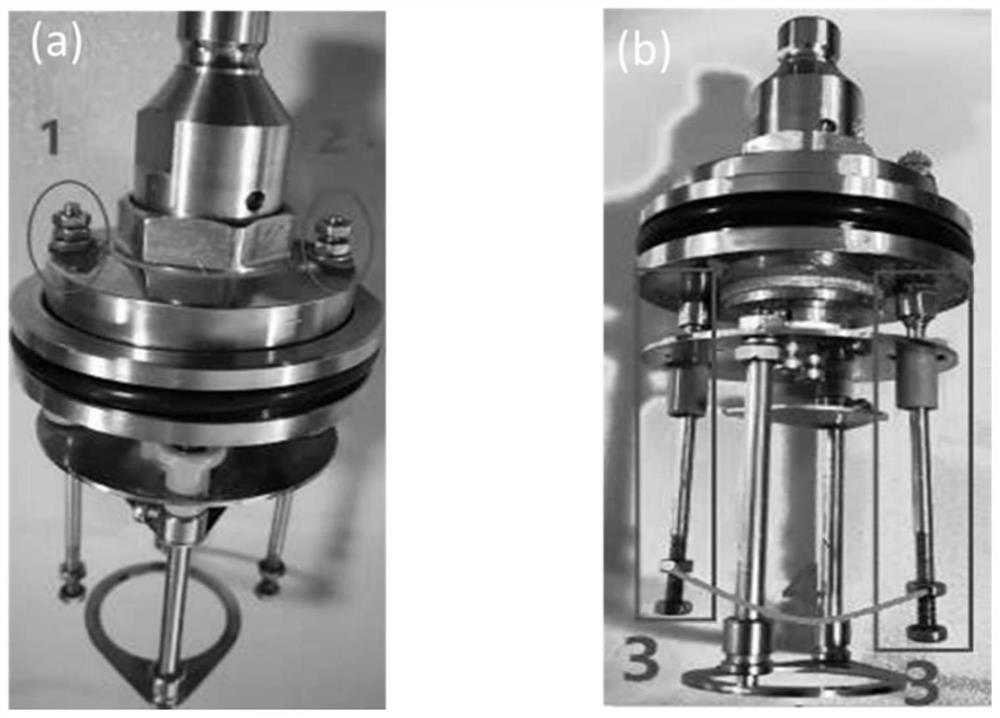

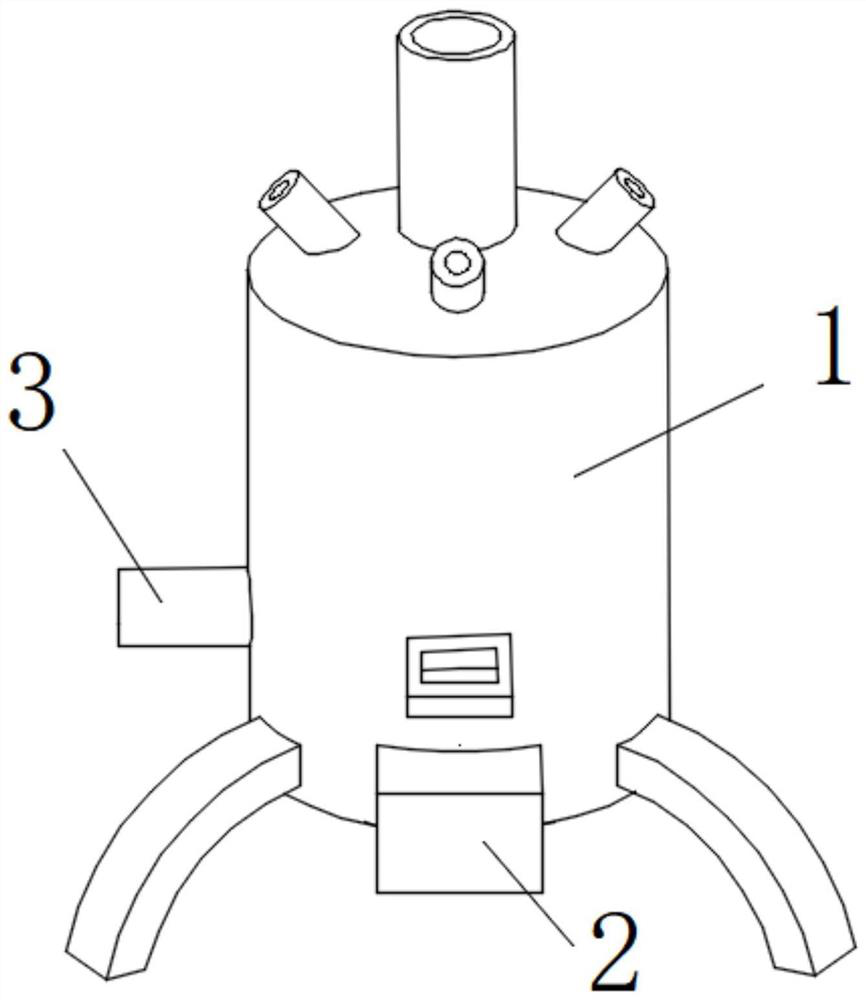

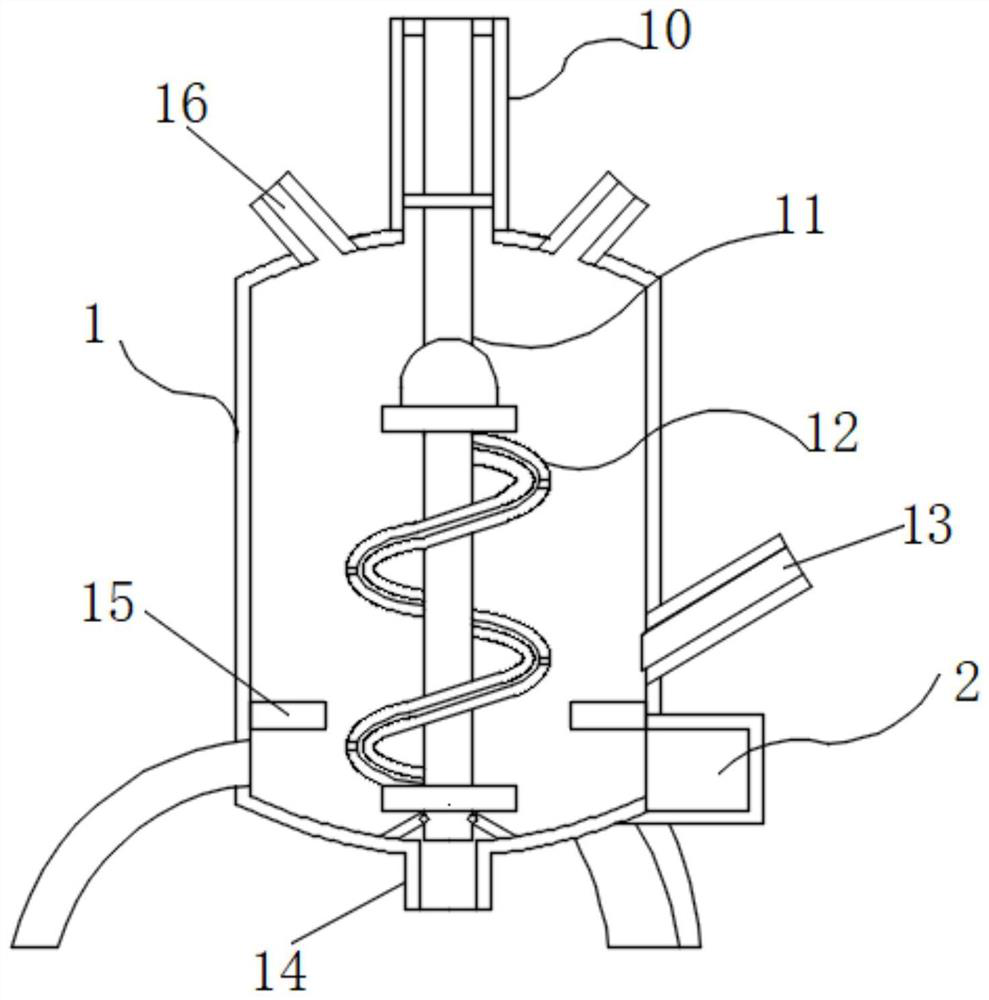

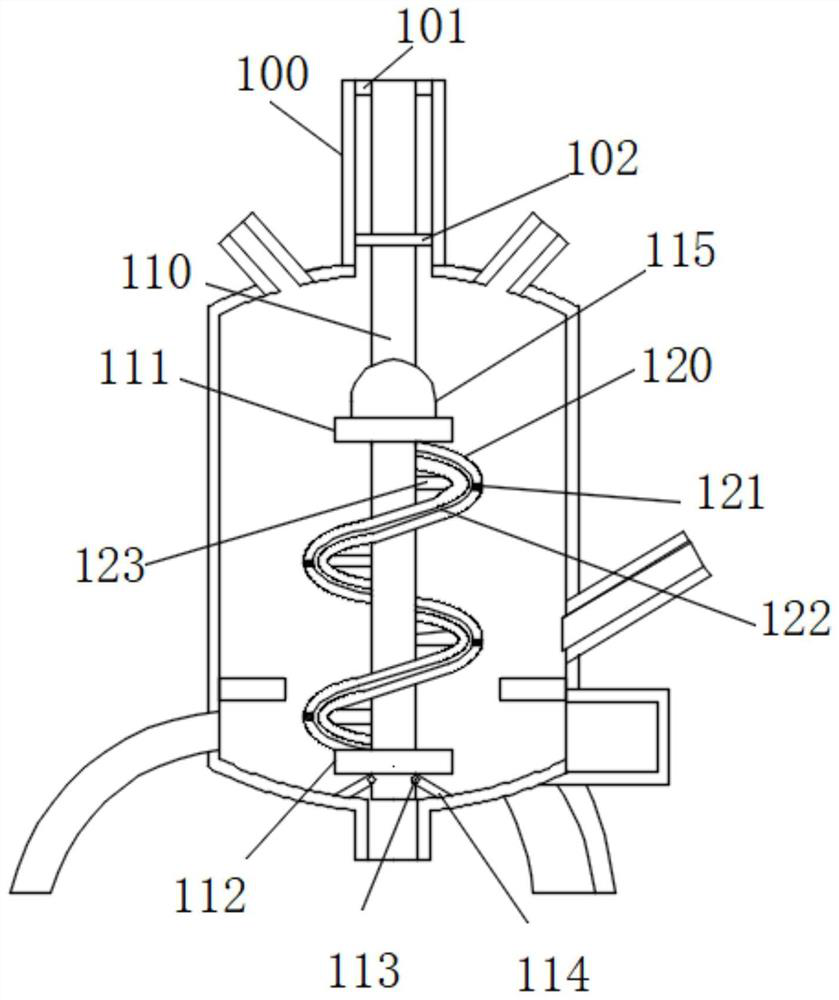

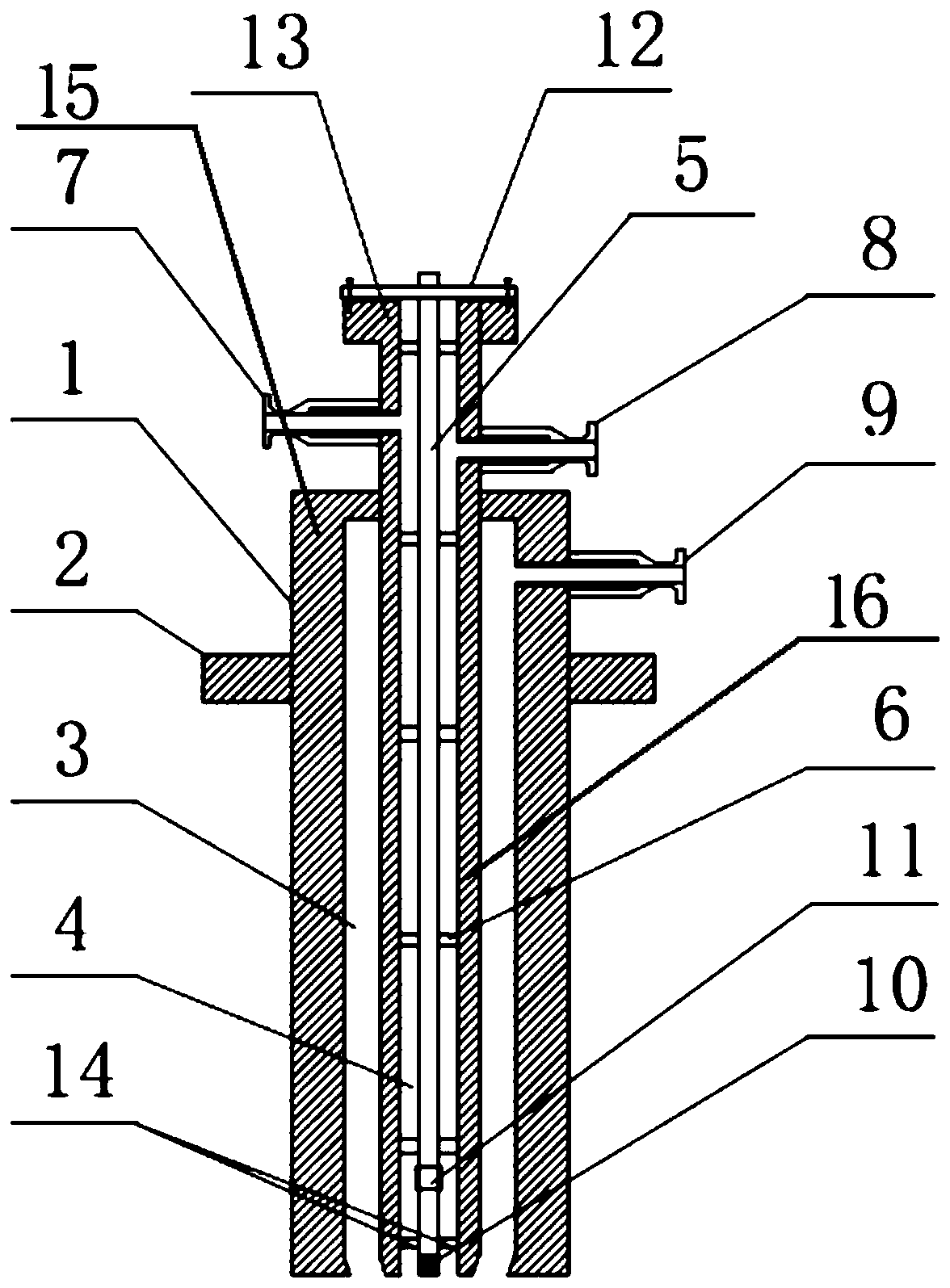

Multifunctional integrated start-up burner

PendingCN110669555AAct as cooling protectionPrevent backfireGasification processes detailsGasification apparatus detailsThermodynamicsWastewater

The invention discloses a multifunctional integrated start-up burner which comprises a central shell, an outer shell and an ignition rod, wherein the central shell and the outer shell are integrated;the lower end of the ignition rod is inserted into the central shell through the top of the central shell; the lower end of the ignition rod is provided with a high-energy igniter; the side surface ofthe central shell is provided with a start-up fuel inlet and a waste water inlet, wherein the start-up fuel inlet and the waste water inlet are positioned outside the outer shell; and the side surface of the outer shell is provided with an accelerant inlet. A combustion improver channel is formed between the outer part of the central shell and the inner wall of the outer shell, a start-up fuel-waste water channel is formed between the ignition rod and the inner wall of the central shell, and an atomizer is arranged between the ignition rod and the central shell, wherein the atomizer is positioned at the working medium outlet at the lower end of the start-up fuel-waste water channel, and the burner can realize the functions of starting ignition and putting waste water into the burner afterstarting ignition, and can also realize cooling and sealing of the start-up burner.

Owner:HUANENG CLEAN ENERGY RES INST

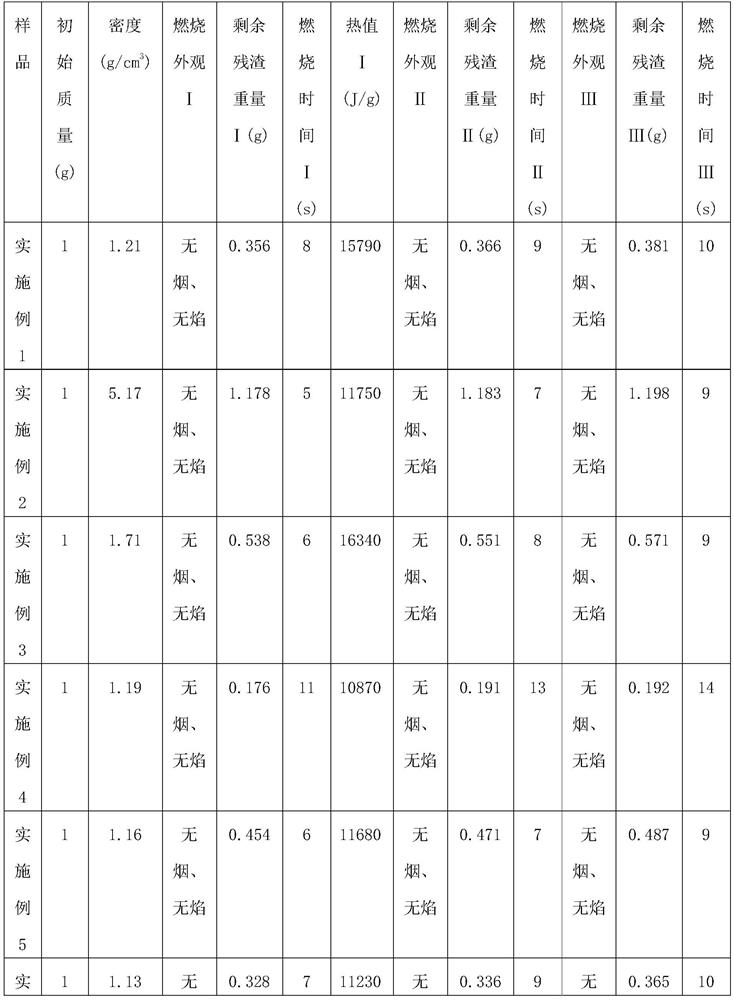

Flameless solid fuel, and preparation method and application thereof

InactiveCN113583729ANothing producedIncrease the calorific value of combustionBiofuelsSolid fuelsThermodynamicsSolid fuel

The invention discloses a flameless solid fuel, and a preparation method and application thereof. The flameless solid fuel is prepared from, by mass, 30-60% of a main combustion agent, 20-35% of a combustion improver, 1-5% of a flame inhibitor and 10-35% of a bonding curing agent. The fuel can be continuously and stably combusted in an oxygen-free environment, has the characteristics of high combustion heat value, low combustion speed, no black smoke, no peculiar smell, no obvious flame, no harmful residue, environmental friendliness and the like, and is simple in preparation process, low in cost and long in safe storage period.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

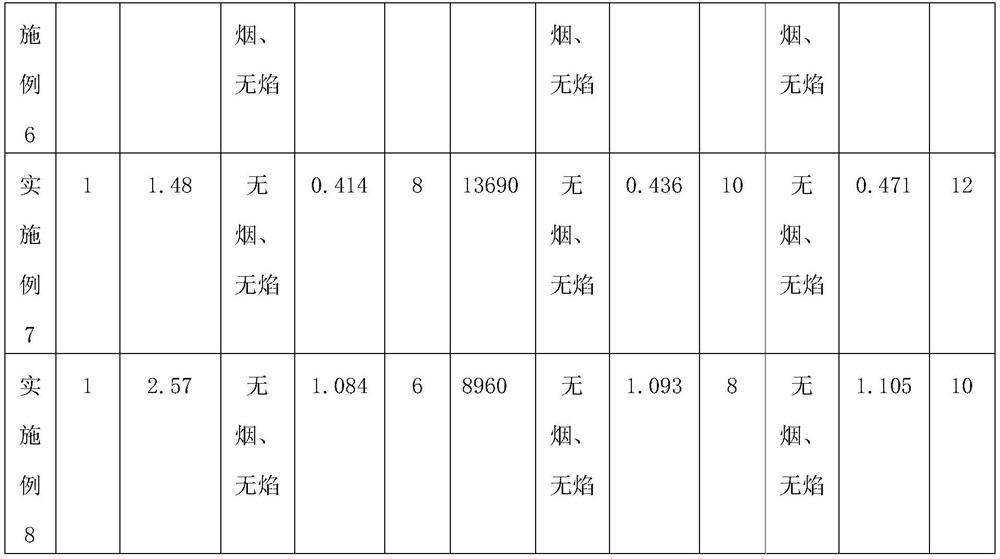

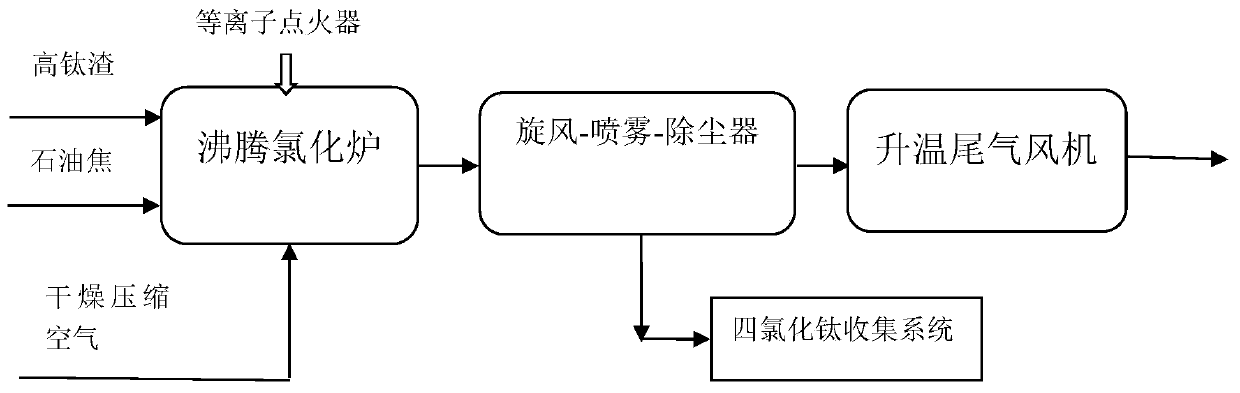

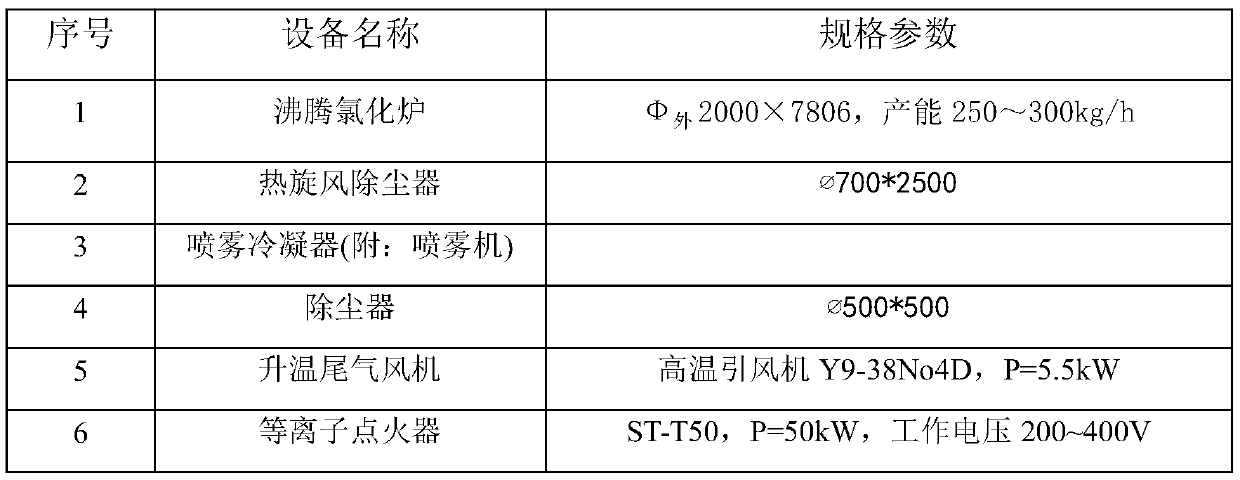

A method for igniting and starting a boiling chlorination furnace with a plasma gun

ActiveCN107804868BPromote environmental protectionPlay the beneficial effect of environmental protection and energy savingIncandescent ignitionChemical industryCombustionControl system

The invention discloses a plasma gun ignition blow-on method of a boiling chlorination furnace. High energy plasma generated by a plasma gun is taken as start energy for ignition and heating; compressed air is taken as the combustion improver; a boiling chlorination reaction raw material bed is gradually heated and ignited in a sectional type; after ignition and heating, the control system of a chlorination reactor is started, and the ignition-heating and device starting-running are seamlessly jointed. The technology is characterized in that (1) high energy plasma generated by a plasma gun istaken as the start energy for the ignition and heating of a boiling chlorination furnace, and the plasma is simple and is easy to control; (2) the raw materials are used to build a bed; other fuels such as coal, oil, gas, and the like, are not needed; the burning does not generated any smoke, and the technology is clean and environmentally friendly; (3) petroleum coke of the raw materials for building the bed is burned by the plasma flame, fine petroleum coke is burned at first, then coarse petroleum coke is burned, the burning is fast, the temperature is easy to control, energy is saved, andthe efficiency is high; and (4) ignition-heating and device starting-running are seamlessly jointed, and the production efficiency is high.

Owner:SICHUAN HONGDA

Co to co2 combustion promoter

ActiveUS20210162377A1Less NOx formationAvoid excessive diffusionCatalytic crackingCarbon compoundsEggshellMicrosphere

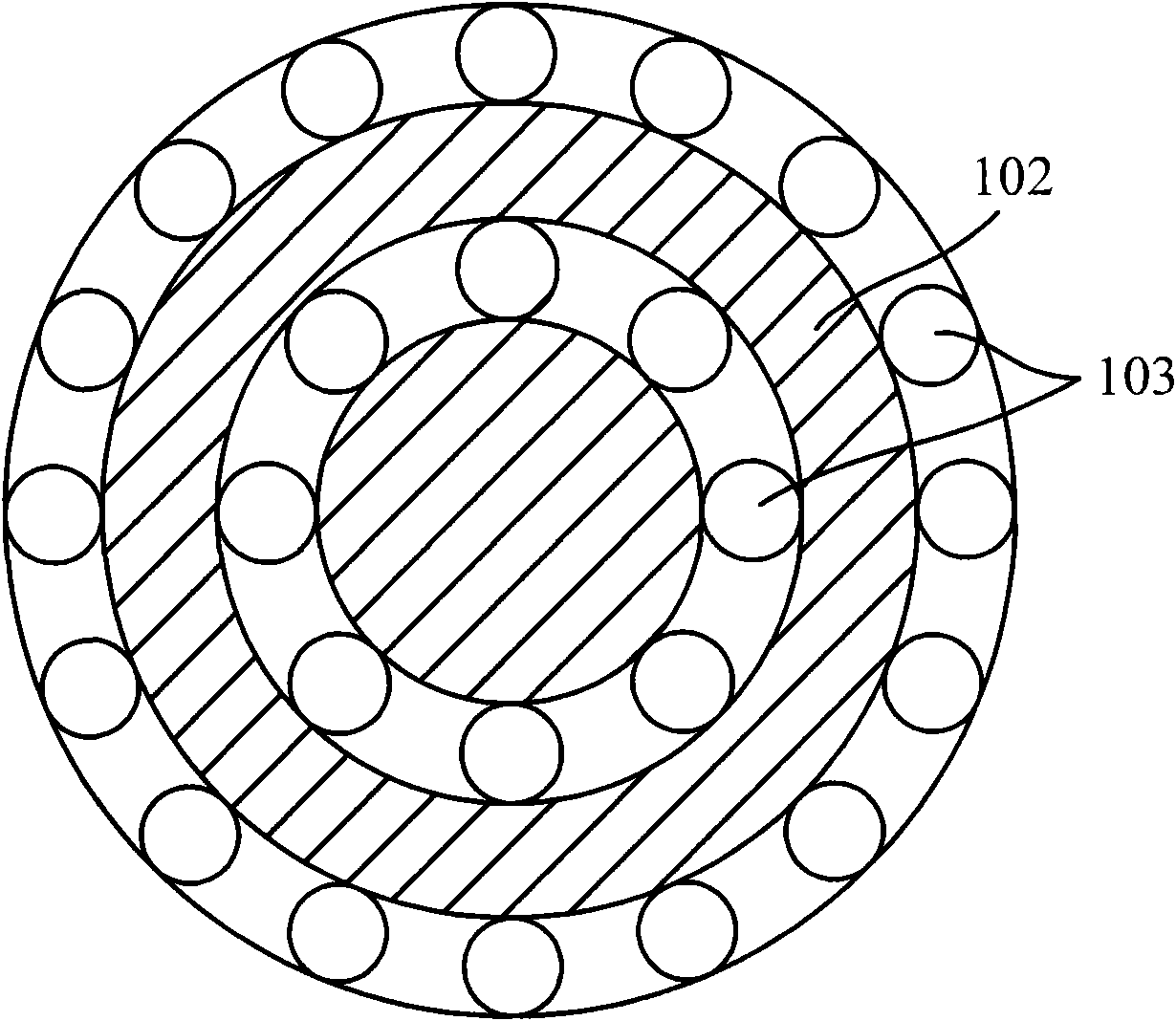

The invention is directed to a CO to CO2 combustion promoter comprising microsphere sized porous silica and / or alumina comprising particles further comprising on or more Group VIII noble metals wherein the noble metal is distributed in the particle as an eggshell such that a higher content of noble metal is present in the outer region of the particle as compared to the content of noble metal in the center of the particle.

Owner:COCHISE TECH LLC

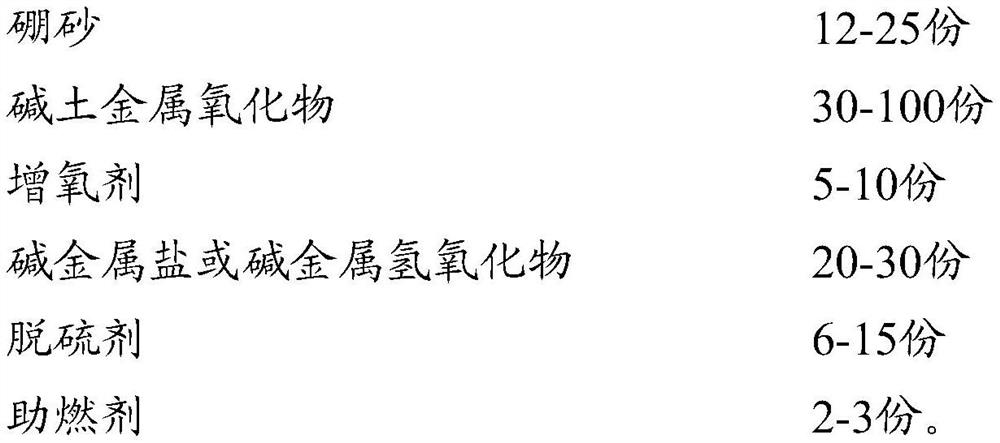

Carbon monoxide emission reduction sintering synergist and use method thereof

PendingCN114854471ALower activation energyEmission reductionSolid fuelsIndirect carbon-dioxide mitigationAlkaline earth oxidesMaterials science

The invention discloses a carbon monoxide emission reduction sintering synergist and a use method thereof, and relates to the technical field of fuel combustion supporting. The carbon monoxide emission reduction sintering synergist is prepared from the borax, the alkaline earth metal oxide, the oxygen producer, the alkali metal salt or the alkali metal hydroxide, the desulfurizing agent and the combustion improver as raw materials, and the prepared sintering synergist can provide sufficient oxygen for fuel in the combustion process by adjusting the composition and the proportion of the raw materials; the combustion speed of fuel is increased, emission of carbon monoxide is reduced, and sufficient combustion of the fuel is achieved.

Owner:河北辰朗化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com