Multifunctional integrated start-up burner

A start-up burner, multi-functional technology, applied in the gasification process, petroleum industry, details of gasification devices, etc., can solve the problems of complex process, high equipment price, many control points, etc., to achieve simple operation, low cost and effective. high component effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

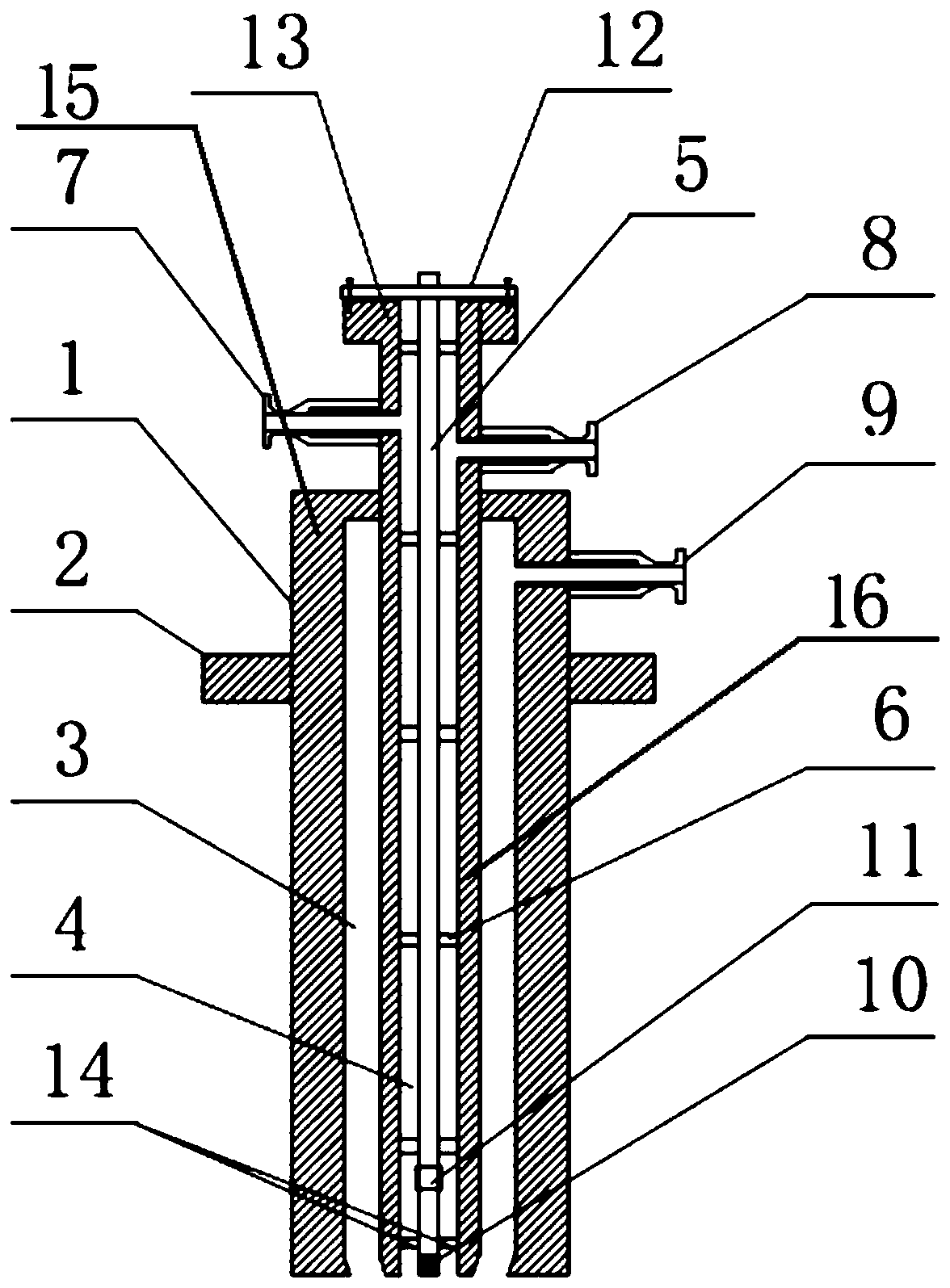

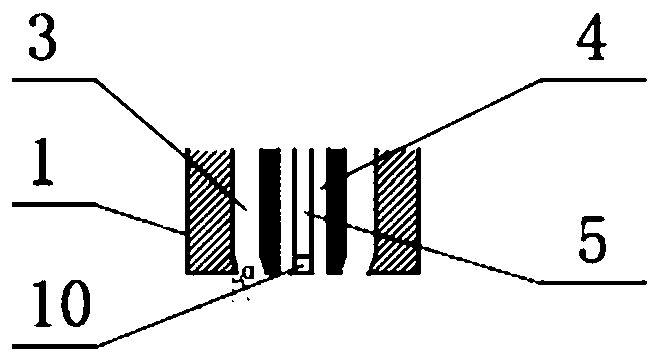

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 , the multifunctional integrated start-up burner of the present invention includes an ignition rod 5 and a start-up burner body 1, and the start-up burner body 1 includes a central shell 16 and an outer shell 15; the central shell 16 and the outer shell 15 is a whole, the lower end of the ignition rod 5 is inserted into the center housing 16 through the top of the center housing 16, the lower end of the ignition rod 5 is provided with a high-energy igniter 10, and the side of the center housing 16 is provided with a start-up fuel inlet 7 And waste water inlet 8, wherein, start-up fuel inlet 7 and waste water inlet 8 are located outside outer shell 15, and the side of outer shell 15 is provided with combustion aid inlet 9, between the outside of central shell 16 and the inner wall of outer shell 15 A combustion aid passage 3 is formed, and a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com