Preparation equipment for forming silicon dioxide film on surface of silicon substrate

A silicon dioxide and silicon substrate technology, applied in gaseous chemical plating, metal material coating process, semiconductor/solid-state device manufacturing, etc., can solve the problems of uneven film, poor deposition effect, etc., and achieve uniform coating , Accurate temperature control, stable and tight coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

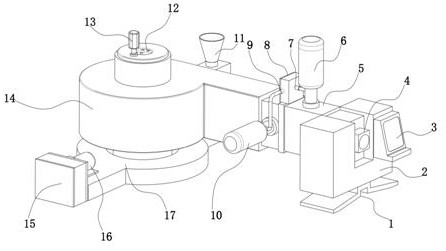

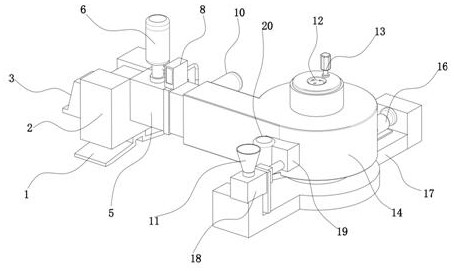

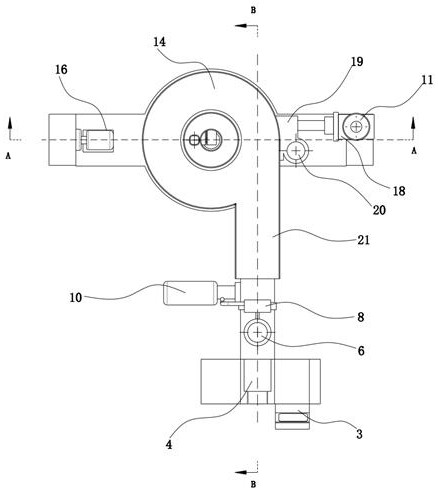

[0035] refer to Figure 1-7 : A preparation device for forming a silicon dioxide film on the surface of a silicon substrate, including a support 1, which is used to support one end of the device; wherein the other support passes through a temperature circle 17, and the middle part of the bottom inner wall of the temperature circle 17 is provided with a heating coil 26, and the heating coil 26 is arranged on the periphery of the heat exchange chamber 25, one end of the temperature circle 17 is provided with a precursor input assembly, the precursor input assembly is the main silicon source input end, and the other end of the temperature circle 17 is provided with Vacuum degree adjustment component, the vacuum degree adjustment component is to maintain the vacuum effect in the inner cavity of the preparation equipment;

[0036] Wherein the silicon source input end, the precursor input assembly includes a precursor input hopper 11, an extrusion pump 18 and a sprayer 19, the botto...

Embodiment 2

[0042] refer to Figure 8 : A preparation device for forming a silicon dioxide film on the surface of a silicon substrate. Compared with Example 1 in this embodiment, the main difference is that in this embodiment, a screw cap 30 is also included, and the screw cap 30 is used to prepare the chamber 14. The top is rotated to open and close, while the slit-type laser generator 4 is located directly above the top of the screw cap 30, and the inside of the preparation chamber 14 is provided with a connecting rod structure. Vertically hitting the substrate, combined with atomized silicon dioxide, can deposit better, and at the same time shrink the overall equipment volume;

[0043] In the present invention, a fan 31 is also provided at the end of the air passage 21, and the power of the fan 31 is adjustable to ensure that the flow rate and temperature of the gas source that can be sent into the gas source are all adjustable, and the atomized silicon dioxide in the deposition proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com